Protecting the base from moisture penetration helps protect building materials and structures from premature destruction.

Properly selected and laid according to technology, waterproofing material allows you to use basement floors and attics as rooms for domestic and residential purposes.

Types of films for waterproofing

Film insulation is most popular in private homes, apartments, offices and commercial properties.

Polyethylene film for waterproofing is available in various thicknesses and textures. We consider the types and their characteristics in the table:

| Type of film | Characteristic | Flaws |

| Polyethylene | Most often used in individual construction as additional protection against moisture penetration through the pores of the building structure. | It has insufficient strength, is destroyed under direct influence of ultraviolet radiation, and condensation collects on the surface |

| Modern polyethylene film | Available with one side smooth and the other fleecy. Condensation accumulates on a rough surface, this protects the thermal insulation material from absorbing condensate. | Not breathing |

| Polypropylene | Resistant to abrasion and high temperatures, chemically resistant. At t 140 degrees it begins to soften, at t 175 degrees it melts. | Has the lowest density of 0.91 g/cc |

| Based on synthetic rubber | Resistant to ultraviolet radiation and sub-zero temperatures. Able to restore their size after stretching. They have a long service life. | Difficult installation in corners, as the material is denser than polyethylene |

| Foamed polyethylene | Not only protects the surface from moisture penetration, but also retains heat well. Due to the porous structure, it dampens sound and impact noise. It is laid end-to-end. | Increasing the thickness of waterproofing |

| Reinforced | It has a multilayer structure, the middle layer is made of non-woven fabric or polypropylene mesh. Has increased strength. | Does not allow water vapor to pass through |

| Diffuse membrane | They are a material consisting of several layers, capable of transmitting water vapor and not allowing moisture to pass through. Available in single-sided and double-sided versions, it is important to lay the membrane on the desired side during installation. | High price |

The material is selected depending on the functional purpose of the room and the availability of funds.

Features of caring for dry floor screed

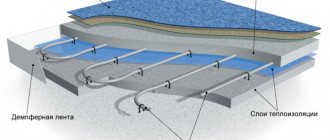

A dry floor screed is installed without the use of liquid, therefore the care of such a coating is radically different from the options described above. The material used to level the floor surface using a dry method is as follows:

- expanded clay or fine slag;

- vapor barrier coating;

- damper tape;

- solid board material - OSB, GVL or plywood.

Deep penetration impregnations

In order for the top layer of coating to serve for a long time, the seams between the slabs are puttied with gypsum compound, and the surface itself is covered with two layers of primer.

Eliminate moisture

The first thing the owner of a room where a dry floor has been screeded needs to know is to prevent large amounts of water from getting on the floor covering. Otherwise, the material will swell and warp the finishing layer.

Do not install heavy structures

The peculiarity of a dry screed is that if you install heavy objects or partitions with a large specific gravity on the floor surface, it can bend. In order for a coating constructed using the “dry” method to serve for a long time and preserve the horizon, it is better to exclude the installation of bulky and heavy objects.

Waterproofing functions

Properly installed waterproofing:

- will protect the premises from leaks of mortar to neighbors on the lower floor;

- will act as a barrier against the penetration of moisture from the soil to the finishing floor covering.

In rooms with high levels of humidity: bathrooms, baths, saunas, and basements, it is necessary to waterproof the floor.

Recommendations for use

All types of work using the technology must be carried out at minimum ambient temperatures of at least five degrees. The same applies to the initial stage of maturation of the finished solution on the floor surface. In order to perform semi-dry screeds at the proper level, you should adhere to certain operating recommendations:

- Any walking loads with a maximum weight of up to 100 kg are permissible only 12-18 hours after pouring and grouting the mortar.

- If there is a need for heavier loads, over 100 kg, then you will have to wait at least five days.

In these cases, you can experiment and leave ahead of schedule. But no one is immune from the negative consequences that can lead to redoing the “rough” floor.

There are several tips that should be followed during the operation of a semi-dry screed. No heavy objects should fall onto the surface, especially if they are sharp. When installing a heated floor under a screed, it should not be in working condition for 30 days after pouring out the solution. Finishing work indoors can be carried out, but for at least ten days no one advises placing scaffolding or stepladders on the base of the “sub-floor”.

Each of these points can only harm the freshly laid screed and damage it.

Advantages of polyethylene film

Polyethylene can be easily laid independently without the use of complex tools.

Most often, waterproofing is performed with polyethylene film due to the optimal price-quality ratio.

Advantages:

- low cost;

- high elasticity, due to this it is easy to fit;

- long service life;

- not subject to rotting.

Technical characteristics of the waterproofing film for the floor are shown in the table:

| № | Thickness | 0.4 mm or more |

| 1 | Texture | Smooth, double-sided or single-sided embossed |

| 2 | Operating over a temperature range | From - 40 to +80 degrees |

| 3 | Maximum stretch | 150 H at 50 mm |

| 4 | Width | 250, 365, 400, 500, 600 mm |

| 5 | Roll length | 50 m |

To increase resistance to mechanical damage, stabilized high-strength polyethylene is used.

Technical characteristics of polyethylene film

Polyethylene film is produced from low-density polyethylene, and many different additives are added to the composition itself, which affect the properties of the finished material. The film can also be made from high-density polyethylene. Polyethylene film, which is used in construction, varies in thickness up to 0.5 mm. It is very easy to find by the “T” marking. The material is presented in the form of a sheet or sleeve, and the film can be of different lengths and widths. The film retains its properties at temperatures from -50 to +60 degrees Celsius.

In addition to regular polyethylene film, reinforced film is also used. Its main difference is the presence of a mesh frame, which is sealed between layers of material. In this case, the strength is affected not by the thickness of the film, but by its density. Very often, a geomembrane is considered a type of polyethylene film. It has good elasticity, is resistant to mechanical stress and is completely safe to use.

Installation of waterproofing under the screed

Waterproofing material must be laid under the screed when the concrete slab serves as the first floor floor and foundation. In this case, it is necessary to protect the base from seepage of groundwater and leakage from inside the building (if pipes break), the film is laid between the layers of the subfloor and the finished floor. For more information about waterproofing under screed, watch this video:

Geotextile will serve as a backing for polyethylene.

It is necessary to lay waterproofing under the screed, extending onto the walls when installing heated floors - this will prevent moisture from penetrating from the walls to the floor. Installation sequence:

- We spread geotextiles on a flat surface free of dust and debris, and lay waterproofing on it in strips. If we use a simple polyethylene film, we overlap it by 15-20 cm; if we use foamed polyethylene, then we do it end-to-end.

- We fix the waterproofing joints with tape.

- We fold the material at the corners and secure it with a construction stapler.

After installing the waterproofing, we begin installing the screed. We carry out the work carefully so as not to tear the film.

Is it possible to lay film under the screed?

Can. But it depends on the need.

The film spreads to create a waterproofing barrier. If you have a multi-storey building and neighbors live below you, then waterproofing before installing the screed is guaranteed to be necessary. It is most often made either by coating (the best, but more expensive option) or by film. Both of them are reliable.

When installing film waterproofing, two layers of film with a thickness of 150 to 200 microns are laid, with an overlap of 120-200 mm, plus the same overlap on the walls. The joint is carefully sealed with ordinary silicone transparent sealant.

Of course, before these procedures, it is important to remove all debris from the surface of the slab, sweep and seal all technological holes with a thick solution.

While screeding the floor, make sure that you do not inadvertently break through the waterproofing layer.

Before covering, it is very advisable to check the film for defects and holes. Seal all holes and punctures with tape.

Of course, the film must be laid on a more or less flat, hard surface so as not to break through it during installation. If reinforcement and a lot of sharp edges of crushed stone stick out from the bottom covering, then it is better to make a coating waterproofing, for example, I use Ceresit CR-65...

To summarize, the film can be laid under the screed. But, of course, the purpose of this action is important, as well as what will be on top (heat and sound insulation).

www.remotvet.ru

Installation of waterproofing on screed

When the screed is completely dry, you need to prime it in two layers. Each subsequent layer is applied after the previous one has dried. For more information about different types of waterproofing, watch this video:

Damper tape

Then heat-insulating material is laid, damper tape is glued around the perimeter of the walls, and polyethylene film is covered in the manner described above.

When performing waterproofing, it is better not to skimp on quality, since the cost will pay off during operation. The durability of load-bearing structures and building materials in the house depends on the quality of the material.

Why did the tie with plastic film crack?

Quite often on forums there are stories that a short time after laying the screed, it cracks, even though a layer of plastic film was laid under the screed. Why is this happening? In fact, the reason lies not in the plastic film itself, but in the way the master performed the work itself. Often the cause of screed defects is not removed beacons. If the screed is not very thick, and wooden beacons were used, then this could easily lead to the screed simply starting to crack.

Some experts note that it is best to use polyethylene film under the screed when it is planned to fill it with a large thickness. The screed itself must be at least 3 centimeters thick. In this case, it will be possible to avoid any deformation of the floor, and it will be much easier for it to withstand strong mechanical loads.

If such a problem arises, it can only be solved by refilling the screed. If you do not pay attention to the cracks that appear, then it is quite possible that after some time the screed will simply collapse. Of course, you can constantly repair the screed, but after just a couple of similar procedures, their cost will be higher than pouring a new screed. Repeatedly carrying out the necessary procedure, it is worth making the screed thicker, and be sure to use plastic film, which will greatly increase the quality and strength characteristics of the screed.

Film insulation and features of its installation

Waterproofing with film is widely used in apartments and houses. It provides a good waterproof coating. The screed will protect the home from steam and excess moisture, and the floors from water leakage.

The film must be laid on the surface carefully so as not to damage it. Waterproofing the floor of an apartment using perforated film is the best and cheapest option. The material itself can be brown, black or gray in color. It should contain many cells. Based on the type of type, waterproofing film is divided into: flat and perforated. Perforated material is more suitable for installation on vertical surfaces.

Film waterproofing should be overlapped

To make the waterproofing layer strong and reliable, fold the film in two layers. It is best to glue the plastic film with construction tape. Before starting work, thoroughly vacuum the room so that there are no sharp objects under the film that could damage it.

If you want to get a surface without seams, paper is placed on the joint of the film and the top is processed with a hot iron. Don't forget to overlap for a better result. After laying the film, a cement-sand mixture is applied to the surface. Don't forget to check the floor level. Once the screed is completely dry, trim off the excess film.

Selecting material for screed

What do manufacturers offer today? It is necessary to indicate that all heat insulators are divided into several groups depending on their structural composition:

- roll and slab,

- bulk,

- sprayed

The first include mineral wool in rolls and mats, glass wool, polystyrene foam boards, foil penofol (foamed polyethylene). The second group includes expanded clay, perlite, and polystyrene chips. The third is polyurethane foam.

The rest are often used for thermal insulation of concrete floors, so let's look at them.

Foamed polyethylene

It is also called penofol. This is a thin layer of polyethylene foam, which is covered on one or both sides with aluminum foil. The latter performs two functions:

- waterproofing,

- reflector of thermal energy.

Thermal conductivity – 0.037-0.051 W/m K depending on the thickness.

Polyethylene foam itself does not absorb moisture very much. But after its penetration it sharply loses its qualities. Therefore, it must be protected on both sides.

Penofol should be laid on the floor in strips, joint to joint. The connection boundaries are covered with self-adhesive foil tape.