Communication entry points are those places through which various engineering communications enter your building or private house from the outside. Communications inputs come in different diameters and for different engineering purposes:

- Sewerage

- Water supply

- Electricity

- Gas supply

- Heating

- Ventilation and air conditioning

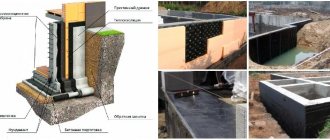

If the openings through which communications enter buildings are located underground (in the basement or basement) or on the roof, balcony or open terrace, then this may be a potential threat of leaks. Places where pipes, cables, etc. They enter your building from the street - these are weak points through which water and moisture can subsequently penetrate into the room. This is why special attention should be paid to their correct installation and waterproofing.

Injection of communication inputs – Injection waterproofing

As mentioned earlier, injection of bushings is one of the most effective ways to protect this area from water, since injection compounds are supplied under pressure and have the ability to fill absolutely all voids and spaces. The injection essentially gets into the space between the concrete and the sleeve, casing, cable, pipe and fills it and possible voids and microcracks around it. Thus, injection compounds or materials block water and prevent it from penetrating into the room. Injection waterproofing is mainly used when builders did not pay due attention to the issue of sealing the entrance points of utility networks during construction, which ultimately led to the formation of leaks in the building.

You can read more about the injection method of waterproofing in the article – “Injection waterproofing”

Installation of a sleeve for the passage of pipes through ceilings or walls is carried out in certain cases

Installing a sleeve for pipe passage through ceilings should be done in certain cases, for example, when the pipeline is subject to thermal expansion. And the need to install the sleeve must be taken into account at the highway planning stage. All nuances of use should be taken into account not only when laying a new pipeline, but also when replacing old communications.

The area where the pipeline is laid through the walls and ceiling becomes the main point of deformation stress. In such places, the pipe is exposed to the chemical environment and mechanical loads. Due to such circumstances, in the SNIP building codes, pipelines are equipped with additional structural parts, which are called sleeves. What they are and why they need to be installed will be discussed in detail below.

The device for passing the pipe through the wall is an important element, and it performs the following functions:

- mechanical;

- protective;

- waterproofing;

- fire protection;

- sanitary.

In addition, this element can increase the service life of the highway and facilitate the replacement of structures.

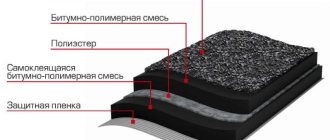

The sleeve is arranged as follows:

- a case for which a steel structure is used;

- packings made of soft, fire-resistant material.

The sleeve for the passage of the pipe is made in the form of tubular products. And the free space between the structures is filled with fire-resistant material. It must not be rigid in structure. This is necessary so that when the pipe heats up, it will begin to change its dimensions, and if there is hard material, it may become damaged.

The diagrams provided above show that the highway can pass through any building in two planes. Thus, the ceilings between floors are crossed by vertical networks (risers), and the walls are crossed by wiring running horizontally. The provided figure shows an example of the arrangement of a part, first in the ceiling, and then in the wall.

In both the first and second cases, the cover of the part must be firmly secured. The tubular product must move freely through it. The diameter of the cover in one and in the second case must be 10 mm larger than the diameter of the pipeline. And the cover itself is securely fastened in the passage hole.

Installation and caulking of the main line cartridge is carried out by calculating the height that the screed has. The length of the sleeve should be 20 mm greater than the thickness of the ceiling. If this point is not observed, then there is a risk of water entering the floors located below.

Is it necessary to install liners?

The need to install a sleeve for the passage of pipes passing through walls is dictated by the requirements of SNIP. They are due to the following reasons.

- The polymer pipeline changes its dimensions due to the influence of temperature. In addition to expansion, it can move. To prevent deformation and create the necessary free space, SNIP recommends using sleeves. These devices for passing pipes through walls and ceilings make it possible to maintain the integrity of the structure during installation activities and during significant temperature changes.

- SNIP also states that a device for passing pipes through walls and ceilings allows dismantling without destroying the structure.

- Installing protection for the passage of pipes through walls, ceilings or foundations becomes a barrier to the penetration of odors and insects from adjacent rooms.

In accordance with SNIP, sleeves are recommended to be installed only in certain cases. Their installation is not always considered advisable. Also, waterproof material for laying between pipe products is recommended in situations where the cartridge is laid through a passage unit through the ceiling.

Let's look at what types of sleeves there are

Sleeves for the passage of pipes in accordance with the requirements of SNIP differ in the material of manufacture. In addition, the size of the device for passing the pipeline through a wall or partition also differs.

Sealing of bushings prices and costs

Below are the average prices for work on sealing the entry points of various communications. Prices and cost of work vary depending on the diameter and list of work performed. The prices below do not take into account the cost of sealants or other materials used.

| Name of works | Inlet diameter | Unit | Price in rubles |

| Waterproofing of service entry points: – Installation of a technological fine – Surface preparation – Layer-by-layer compaction of expanding sealant | 50 | 1 PC | 2400 |

| 110 | 1 PC | 2500 | |

| 160 | 1 PC | 2600 | |

| Waterproofing of utility lines: – Installation of a process duct – Surface preparation – Installation of a bentonite profile – Layer-by-layer compaction of expanding sealant | 50 | 1 PC | 3400 |

| 110 | 1 PC | 3700 | |

| 160 | 1 PC | 3900 | |

| Waterproofing of communication inputs with the Stopaq system, including tying with an elastic profile and its sealing | 180 | 1 PC | 3900 |

| Sealing of communication inputs using the Injection method: – Joining the abutment seam / installing fines – Layer-by-layer compaction of repair composition – Marking injection centers, drilling holes (holes) – Installing packers (into holes) – Injection work using special equipment – Removing packers – Sealing injection centers with special composition | 50 | 1 PC | 6900 |

| 110 | 1 PC | 7400 | |

| 160 | 1 PC | 7900 |

Sealing of inputs price in estimate

The above prices do not take into account the complexity of the work and other factors that may affect the prices and the final cost of the work. If you want an accurate estimate with the final price per unit and the final cost taking into account the materials and work used, then you need to call a specialist or engineer from a company that specializes in waterproofing to inspect your facility. An experienced engineer, having familiarized himself with your facility and the specific situation with inlets and leaks, will be able to draw up a professional technical specification, which he will submit to the estimate department, which in turn will provide you with a detailed estimate, where you will see not only the final cost of the estimate, but also the prices for every position.

How to install internal sewerage

Before you begin installing internal sewerage, you should take into account that this process is labor-intensive and responsible. That is why it must be carried out taking into account SNiP. If the installation is carried out incorrectly, the holes in the places where the pipelines pass through are sealed poorly, then the entire system will not be able to operate reliably and for a long time. Installation should be done in stages:

- A sewer system plan is created. You can draw up a project yourself, but if there is not enough experience in this matter, then it is better to entrust this process to a professional. After all, if a seemingly insignificant mistake is made in the plan, this will lead to serious consequences. And eliminating them will require a significant amount of money.

- After the plan is received, you can begin laying the pipelines, and this operation must be done in such a way that the diameter of the resulting holes is as small as possible.

- To ensure that sealing these holes in the future does not take so much time, experts recommend starting to lay pipelines from plumbing fixtures to the place that leads the sewage system out of the facility.

- If pipelines are laid in a one-story building, then the system wiring must pass under the floor surface. When installing pipelines in a two-story building, the wiring must be done above the floor surface of the second floor.

Important! How to properly breed Rotband

Waterproofing and sealing of cable entries

It is best to install cables into the house through a sleeve specially installed for this purpose, as this will provide the opportunity to add new cables and repair old ones. Cable entries entering the building must be sealed using non-flammable waterproofing material. In addition to various sealants, there are also many devices on the market for sealing cable glands.

In the regulatory documents of the PUE Chapter 2.1. Clause 2.1.58 and SNiP 3.05.06-85 describe the requirements for cable passages

Sealing materials (sealants for cable glands)

In practice, there are quite a lot of options for sealing cable penetrations (pipes) through enclosing structures in order to carry out their installation with a full guarantee of dust and moisture protection and gas tightness. Modern design solutions are often implemented through the installation of embedded sleeves, openings or special communication input systems at the stage of capital construction. However, many technologies for sealing penetrations allow them to be used both for already laid lines and for laying through holes made in installed structures.

Sealing of bushings using injection

Mastic for sealing

The free space in embedded pipes (sleeves) after laying communication lines through them can be sealed using targeted plastic compounds - cable sealants (mastics, silicones, foams). To ensure reliable sealing of cable glands, the composition used, in addition to the above-described requirements of the PUE and SNiPs, must have excellent adhesion to the material of the sleeves and communication elements.

For example, the gap between a steel casing pipe, asbestos or fiber cement sleeve and a cable in a metal sheath when entering through the foundation or basement wall of a building can be closed with a polymer-polyurethane self-expanding aerosol (spray foam). However, difficulties will arise if the materials of the cable sheaths or embedded channels have poor adhesion to the sealing compound. The same polyurethane foam does not adhere well enough to the surfaces of polymer casing pipes or to polyethylene cable insulation. The solution to the problem is provided by the use of additional adhesive materials such as polymer-mastic tapes (type MG14-16). A rim of such tape is placed on the inner surface of the sleeve, as well as around the communication element. The remaining gap is filled with polyurethane foam.

The sealing of communication penetrations can also be carried out with one-component or two-component consistent adhesives based on modified silyl, polyurethane resins, bitumen, etc. What distinguishes them all is:

- excellent adhesion to most mineral and synthetic materials;

- non-shrinkage or self-expansion;

- ability to polymerize under humid and anaerobic conditions;

- maintaining plasticity throughout the entire operational period, which simplifies the removal of sealant during repairs of communications.

The two-component fast-hardening expanding composition FST-250 has proven itself well. It comes in convenient cartridges for a mounting gun, which allows you to work with it in the most difficult to reach places. The components squeezed out from the cartridge cylinder are mixed in a guide nozzle, through which they are introduced into the cavity being treated. After polymerization (within 10-15 minutes), the composition is able to withstand pressure from a column of water 5 m high.

Cable gland (seal)

Various cable seals (glands) - pressure glands, connectors, are widely used for penetrations into electrical panels, ASU cabinets, and distribution boxes. Model range of domestic type seals:

- PG and MG – made of polypropylene, polyamide,

- PMG and M – nickel-plated brass,

covers all known standard sizes of cables and wires, so you can always choose a gland suitable for solving electrical installation problems. The simplicity of the device, small dimensions and high insulation values make sealed glands a popular sealing element. Due to reliable mechanical compression of the elastomer gasket (rubber, neoprene) around the cable with a union clamp nut, it is possible to achieve a degree of protection of the sealing unit IP68. It should be added that for the domestic model range of cable glands, you can select imported analogues with the corresponding characteristics produced by Hummel, Weidmuller, AVC, Helukabel and others.

Rubber shock-absorbing seals GPD

It is convenient to seal passages when introducing cables through the building envelope or shell of structures using shock-absorbing rubber seals (hermetic bushings). The insulating effect of their use is achieved by compressing an elastic ring element made of elastomer between two flanges. The elastic coupling expands in a plane perpendicular to the axis of the seal, bridging the gaps and tightly squeezing the communication element. The force on the flanges is transmitted from tightening the nuts on the coupling screws from the accessible side of the product. Shock-absorbing inserts are designed for installation in polymer (steel, fiber cement, etc.) casing pipes, and also allow installation directly into drilled holes (with minor surface defects) in wall materials.

Silicone seals for communication inlets ASOKA SPD

Seal equipped with built-in compensator Asoka SPD/M

A typical representative of such products are rubber seals of the GPD series from the UGA company (Germany). They are widely used all over the world, and have also earned recognition from installers in the Russian Federation.

Cable seals are produced in the following versions:

- to protect penetrations under water pressure (up to 5 bar) and without direct hydraulic loads;

- collapsible and non-collapsible;

- with integrated support ring for corrugated communications;

- for one or more inputs, for which it is also possible to use replaceable elastic inserts with a given number and diameters of holes.

SALEX sealed bushings and sealed inserts

SALEX products are a close analogue of GPD systems. However, they are produced with shock-absorbing seals of two main types - sealed bushings and sealed inserts. The main difference between these elements for insulating cable or pipe penetrations is that sealed bushings are designed for installation in round holes, and sealed inserts in square or rectangular openings. Both can be produced:

- detachable or one-piece design. Detachable ones allow you to seal already installed communications;

- to enter one element or several;

- with symmetrical, asymmetrical placement of inlet holes of one or several different diameters.

The sealed bushings and sealed inserts offered by the enterprises are manufactured for installation on all standard pipe and cable products of domestic and European brands. In addition, at specialized enterprises you can order the production of sealing elements according to individual drawings.

Certificate of sealing of utility lines in a building sample

If you are performing work or are having work performed on sealing various engineering inputs into your structure or building, then you can hand over or accept this work based on the act of sealing the inputs (outputs). On our website you can download several samples of such acts.

- The act of sealing the inputs (outputs) of utility lines in the basement

You can draw up these acts yourself by downloading the necessary sample acts and filling them in with the details of the contractor and the customer.