Advantages and disadvantages

Due to its high technical performance, cement waterproofing has a number of advantages over traditional bitumen-based waterproofing.

- excellent waterproof performance;

- Possibility of application on a damp surface;

- technological ease of use;

- low cost;

- excellent grip on any type of substrate;

- good anti-corrosion properties;

- resistance to aggressive chemical compounds;

- high vapor permeability;

- frost resistance;

- environmental friendliness and safety of the material.

Among the few disadvantages of cement waterproofing are:

- low crack resistance;

- the need to apply several layers and additional reinforcement.

The use of cement-based waterproofing is not recommended for structures that have not yet matured and are at risk of ground or foundation movements.

You can learn how to strengthen the foundation in the article Strengthening the foundation of a brick house with your own hands.

One of the most successful ways to protect deformable structures from moisture is the use of polymer and polymer-cement concrete. These concretes have higher flexural tensile strength and brittleness.

For more information on waterproofing, see the article Waterproofing under a concrete floor.

Composition and main characteristics of the material ↑

The mixtures contain three components:

- Binder (astringent) is a high-quality cement that ensures the strength of the composition and largely repels water.

- The filler is fine quartz sand.

- Polymer additives. They provide increased adhesion of the composition to the base, penetrating deep into the surface of concrete and crystallizing in its structure, firmly connecting the base with the applied coating. Increases the hydrophobic properties of the cement composition. Gives elasticity to the waterproofing coating.

- The adhesion (adhesion strength to the surface) of cement (mineral) waterproofing is higher than that of bitumen and bitumen-polymer. The compositions adhere perfectly to concrete, brick (including sand-lime brick), metal and wooden surfaces.

- Mineral insulation has high mechanical strength and is resistant to abrasion.

- Cement-polymer waterproofing has a unique property: it is vapor permeable. That is, water will not penetrate inside the structure, for example, the base of a building, while the masonry, if it is moistened, will dry out. The occurrence of delamination is eliminated if moisture does not come from outside, but from inside the concrete; it will gradually be removed outside. In such cases, moisture tears off the bitumen waterproofing. If it is “leaky” in one place, the process of detachment from the surface continues further. This does not happen with cement mixtures.

- Due to its high vapor permeability, mineral insulation can be used not only for external, but also for internal waterproofing. This is the only possible solution when reconstructing buildings.

- Cement-based waterproofing can be applied to damp surfaces. There is no need to subject the foundation to prolonged drying and wait for weeks for dry weather. Special cement compositions (hydraulic seals) can be applied even in conditions of constant presence and leakage of water.

The main and, perhaps, the only drawback of cement-polymer based waterproofing is its rigidity. With high strength, it is inelastic (with some exceptions). Thus, if a crack occurs in a structure, for example, a pool bowl or foundation, the waterproofing layer will also be damaged. Pasted bitumen insulation can withstand much higher tensile loads. However, modern technologies offer a solution to this problem. Two-component cement-based mixtures with a high content of polymer components are produced. If necessary, the compositions are applied in several layers, reinforced with fiberglass mesh. Internal corners are treated with special elastic rubber-polymer tapes. The result is excellent; special cement compositions are ahead of bitumen ones. Unfortunately, not only in terms of characteristics, but also in price.

Materials

Cement-based waterproofing materials are dry mixtures of sand with a cement binder (Portland cement) and polymer additives. The materials have high water resistance and adhesive properties. The best option for all types of structures (concrete, brick, metal, wood). Thanks to the crystalline structure of the cement mixture, excess water vapor and condensate are easily evaporated from the surface of the base.

You can learn about the types and brands of cement and its characteristics in this article.

At the moment, this is the best option for waterproofing basements and basements, which are most susceptible to moisture and mold due to constant contact with groundwater.

Step-by-step instructions on how to waterproof a basement can be found here.

The environmental friendliness and non-toxicity of cement waterproofing meets the requirements for the protection of drinking water tanks. All this has made it possible to become a priority direction in this area, ahead of bituminous materials and conventional cement in many respects.

Waterproofing materials

Materials of various types and compositions are used for waterproofing structures.

It is not recommended to use materials such as:

- roofing felt (cardboard impregnated with bitumen),

- roofing felt (leather impregnated with bitumen),

- glassine (kraft paper impregnated with bitumen),

because they last up to 5 years, and they are only permissible in temporary structures.

A simple and inexpensive method of waterproofing is coating with bitumen or cement-sand screed 30 mm thick, with water-repellent additives or ironing of the surface. Liquid potassium glass is most often used as a water-repellent additive for cement-sand mortar, but it can also be modern special synthetic compositions.

Modern high-quality materials for waterproofing can be divided into 3 groups:

- Dry coating mixtures;

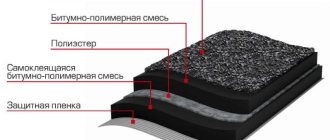

- Rolled bitumen-polymer;

- Polymer-based membranes.

Dry mixes include Penetron and Polybetonox. There are many rolled bitumen-polymer materials; there are materials based on fiberglass, fiberglass, PVC fabric, such as technoelast, uniflex, elon. Membranes have the longest service life and the highest price.

Kinds

According to their intended purpose, cement waterproofing mixtures are divided into:

- coating waterproofing;

- elastic coating insulation;

- plaster waterproofing;

- penetrating waterproofing;

- repair compounds;

- water plug.

Coating

A frequently used method for protecting foundations, plinths, floors, bathrooms, balconies, terraces, and water tanks (including drinking water) from moisture. Apply to concrete, brick, metal, wood, drywall, and other mineral surfaces. Hermetically seals microcracks and provides long-term waterproof protection of the base.

How to waterproof a foundation yourself, read the article Waterproofing a concrete foundation with your own hands.

Elastic coating

Two-component polymer cement mixture with active plasticizers.

The best option for complex surfaces prone to the formation of hairline cracks up to 0.5 mm (swimming pools, water tanks, terraces, wooden houses). They have high surface strength. Slightly more expensive than traditional mixtures.

Plastering

Cement-sand mixture for sealing non-deformable structures. It may include liquid glass as an additive. It is characterized by the possibility of application on uneven surfaces, ease of installation, good durability, and reasonable price. At the same time, the process is quite labor-intensive.

Due to their rapid setting, solutions containing liquid glass are good for oozing cracks.

Penetrating

Cement-sand mixture with the addition of chemical modifiers. Recommended for use on stable bases of basements, foundations, and basements.

Applicable only to concrete and reinforced concrete structures!

The main difference is the gradual penetrating effect of the active components, which are concentrated not on the surface, but in the thickness of the concrete layer (up to 10-12 cm). Insoluble crystals of penetrating waterproofing fill the capillary-porous structure of concrete and form an internal waterproof barrier. Over the years, the solidity of the structure only becomes stronger.

Cement waterproofing

Recently, cement-based materials have been increasingly used to create waterproofing coatings. This is due to the possibility of their application on damp (but not wet) substrates, a wide range of application conditions, the effectiveness of use for anti-pressure waterproofing, the ability to work both on the water pressure side (with positive water pressure) and on the opposite side (with negative pressure water).

Manufacturers usually offer a whole range of cementitious materials for waterproofing in the form of ready-to-use dry mixtures or additives to conventional compositions.

Cement waterproofing is a dry mixture based on a cement binder using filler (sand) and chemical additives that give the material the necessary properties (adhesion, waterproofness, strength, etc.).

Relatively low crack resistance is a common disadvantage of cement waterproofing. Therefore, waterproofing cement compositions are used for waterproofing rigid structures in which movement and the appearance of cracks are not expected.

Polymer-cement waterproofing is a cement-sand mixture that is sealed with an aqueous polymer dispersion, which increases the elasticity of the waterproofing.

The main advantage of flexible polymer-cement waterproofing is the ability to bridge possible cracks in the base.

Unfortunately, the use of these materials is limited by loss of elasticity over time. In addition, most of them do not have long-term resistance to constant exposure to water and do not withstand frost well. According to practice, they are acceptable for indoor use. On the street, when temperatures drop and cracks open more than 1 mm, failure of the reinforced coating occurs after 2-3 years.

Application

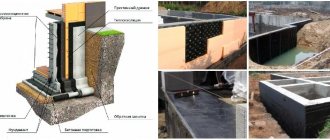

Cement-based waterproofing is a vapor-permeable material, due to which it is possible to use it under negative water pressure (pull-off), for example, for waterproofing a foundation from the inside.

It is necessary to clearly understand that the main directions for the use of cement and polymer-cement waterproofing materials are:

- waterproofing technical premises from the inside;

- waterproofing the bathroom;

- waterproofing of swimming pools (under ceramic tiles);

- waterproofing of tanks (without chemical load).

Waterproofness of concrete

Water resistance is the ability of concrete not to allow water to pass through under pressure that gradually increases to a certain value.

The following grades of concrete are distinguished by water resistance: W2, W4, W6, W8, W10, W12, W14, W16, W18, W20. Numbers 2-20 indicate the maximum pressure in atmospheres at which water infiltration through a 150 mm high cylinder sample has not yet been observed under standard test conditions (for example, for concrete grade W2, the water resistance of samples is 0.2 MPa = 2 atm).

As a rule, ordinary concrete has a water resistance grade lower than W2.

Cement waterproofing materials have a water resistance grade of W2-W16.

Advantages

- Increasing water resistance Cement waterproofing increases the water resistance of the insulated structure due to its own higher water resistance. One of the main quality indicators of the waterproofing mixture is the water resistance grade of the material. The higher this indicator, the more reliable the waterproofing.

- Application on concrete, brick and stone bases Cement-based waterproofing materials are applied to a damp (without free water) base.

The modern construction industry produces a complete set of materials for waterproofing, with each cementitious material performing a specific function:

- Coating waterproofing

- Plaster waterproofing

- Suture waterproofing

- Repair mixtures

- Water plug

- Penetrating waterproofing

- Additives to concrete

Coating waterproofing is used for waterproofing concrete, iron, foam, aerated concrete, and brick structures.

Waterproofing thickness is 2-6 mm.

Waterproofing compounds are produced in two versions: rigid cement waterproofing (dry mix) and flexible polymer-cement waterproofing (two-component composition: dry mix + aqueous polymer dispersion).

Polymer-cement waterproofing is used for waterproofing structures with increased cracking, subject to temperature and mechanical deformation, settlement and vibration.

Plaster waterproofing - dry mixtures for waterproofing concrete, reinforced concrete and brick structures when additional surface leveling is necessary.

Waterproofing thickness is 5-50 mm.

Suture waterproofing - dry mixtures for waterproofing joints, seams, interfaces, abutments, service entries in statically loaded prefabricated and monolithic concrete structures.

Cement waterproofing of joints is not used in expansion joints and under variable peak loads, the values of which exceed its technical parameters, and is also not used on weakened and fragile foundations.

Repair mixtures are cement compositions using reinforcing fibers, which are used for local restoration of surfaces (chips, potholes, cracks, erosion) of concrete, iron, foam, aerated concrete, brick and stone structures.

Water plug is a quick-setting (within a few minutes) cement compositions used for the rapid elimination of pressure leaks through cracks, joints and holes in concrete and reinforced concrete structures, brick and masonry.

Penetrating waterproofing - dry mixtures for waterproofing concrete and reinforced concrete structures (and nothing more!).

This type of cement waterproofing is not intended for waterproofing foam concrete and aerated concrete structures (due to the large pore size), brick walls (due to the absence of substances necessary for the reaction in the brick).

The main difference between penetrating waterproofing and all other cement waterproofing: the formation of a waterproof coating not on the surface of the concrete, but in its considerable thickness (the penetration depth of active chemical components can reach 10-12 cm).

Cement-polymer

Portland cement, fine sand and polymer additives are the main components of this type of waterproofing. The polymer-modified material acquires a number of important characteristics. The main one is the higher tensile strength of the material due to the elastification effect and, as a result, resistance to dynamic loads and the formation of cracks.

Polymer-cement mixtures can be one- or two-component.

In addition, waterproofing adhesive and repair polymer-cement waterproofing are distinguished. One-component (hard) mixtures are powder mixtures. Two-component (elastic) include acrylic emulsion as an elasticizer and a dry cement mixture with various additives, for example, microfiber.

One or another component composition of the mixture is selected based on possible deformation loads. For waterproofing brick, concrete, reinforced concrete structures that are not subject to deformation, one-component mixtures are used.

If the likelihood of cracks forming during the operation of the structure is high, and their size can reach 1 mm, elastic mixtures are used.

Cement coating

Coating cement waterproofing is one of the most affordable and easiest methods of reliable waterproofing. The foundation can be established brick, concrete, iron, foam, aerated concrete structures that are not subject to deformation loads.

The mixtures are produced in the form of a dry one-component composition or a two-component composition with the presence of polymer binders. Depending on the type of surface, the thickness of the layer can vary from a millimeter to several centimeters.

The period of curing of brickwork, concrete and reinforced concrete foundations before installation of coating waterproofing is at least 3 months. The curing period for screed and plastered surfaces is at least 28 days. The strength of the base is not lower than 15 MPa.

In the following video, the Bergauf Hydrostop material is offered as an example of coating cement waterproofing; relevant issues are discussed when performing installation work.

Cement based waterproofing. Step-by-step instruction

Before starting work, you should carefully study the manufacturer's recommendations. Basic instructions for applying cement waterproofing materials:

- Cleaning the surface from dirt, dust, and grease stains.

- Treating the surface with primer solutions using a roller and brush (in the joint area).

- Sealing seams and joints with protective sealing tapes. If necessary, fill seams and cracks with a repair mixture or seal.

- Carefully apply the waterproofing solution using a spatula and brush. Exposure, application of the second and subsequent layers.

When purchasing dry cement masses, you need to pay attention to the expiration date and the tightness of the packaging.