According to their main characteristics, supercapacitors differ significantly from simple conventional capacitors. They use modern technologies that make it possible to achieve an increase in service life and also reduce current losses during operation. The main task of manufacturers of these devices is to develop and create products that can replace batteries in many industries.

Application of electrical double layer

For a long time, electrolytic capacitors had high internal capacitance values. In various devices, various plates were made, in some they were made of metal, in others in the form of an electrolyte, where the insulation was the oxide of the metal used. Moreover, with ordinary capacitors the internal capacitance is much lower and equal to fractions of a farad, which in practice is not enough to power consumers instead of batteries.

To provide power to electrical consumers, devices based on the use of a double electric field have been developed. This phenomenon can occur at the boundaries of a material or substance under certain conditions in a liquid or solid state. As a result, two layers of oppositely polar ions of the same size are formed, a kind of capacitor with electrodes is obtained, between which a minimum distance equal to several atoms is formed.

Interesting to know! Devices obtained in this way are called ionistors, as well as supercapacitors or ultracapacitors.

Backup power supply with voltage above 5 V

The buffer power circuits presented in the figures are justified for low-power microcontrollers and other circuits capable of operating at a supply voltage of about 1.8 - 3.3 V. If you need to obtain a higher voltage (for example USB 5 V), you can choose one of four options :

- Using a supercapacitor with a higher operating voltage rating - While the most popular supercapacitors are designed to operate at voltages up to 5.5V, there are multi-cell models on the market with operating voltages ranging from 1.4V to 8.4V. range of total capacity up to 100 Farads.

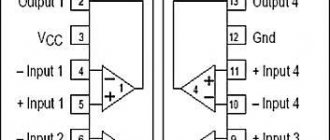

- Using series capacitors with the same rated capacitance - in this case, it is necessary to use a passive voltage divider or an active balancer that protects the capacitor of the smallest actual capacitance from breakdown.

- Using a DC/DC boost converter is the most cost-effective solution as it allows maximum recovery of the energy stored in the supercapacitor.

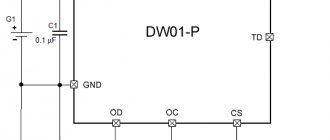

- Application of a built-in supercapacitor charge/discharge controller - Specialized controllers are available on the market that allow you to simply and efficiently control supercapacitor-based power circuits.

Technical implementation

An ionistor or supercapacitor is a device whose design contains two electrodes or plates made of activated carbon. The space between them is filled with a special electrolyte; there is also a membrane between the plates, thanks to which the electrode particles do not move, and the electrolyte freely penetrates into this space.

Moreover, it is worth noting that these devices do not independently determine the polarity of the charge of specific electrodes. This property is one of the main differences from electrolytic capacitors, in which failure to properly connect them led to premature failure. However, during production, ionistors are marked with polarity, as a result of the fact that during the production process these energy storage devices are already charged.

Types of supercapacitors

Currently, all ultracapacitors are divided into three main types:

- Double layer.

- Hybrid.

- Pseudocapacitors.

Double layer capacitors

These devices are a product in the design of which electrodes are used with the presence of pores coated with carbon of increased conductivity; a special separator is located between them. Due to the separation of charges on the electrodes, a significant potential value is formed, resulting in the accumulation of energy.

Interesting to know! The value of the capacitance is directly affected by the value of the double layer.

The double layer in this design acts as a surface capacitor. Thanks to the electrolyte, the two layers are combined into a series chain.

Hybrid supercapacitor

This type of energy storage is considered intermediate between batteries and capacitors. The design of such devices uses electrodes made of different materials, as a result of which the charge capacity is accumulated in different ways.

The process of charge restoration itself occurs due to a redox reaction. This design allows you to significantly increase the internal capacitance and increase the operating voltage. Electrodes consist of a compound of complex conductive polymers, which, when combined, represent a material with increased electrical characteristics.

Pseudocapacitors

These devices are products somewhat similar in their basic characteristics to batteries; they have two solid electrodes.

As a result, it became possible to use a capacitor instead of a battery. The operating principle consists of two main mechanisms:

- charge-discharge operating cycles;

- electrostatic reactions that are observed in double layer devices.

Interesting to know! The capacity of pseudocapacitors depends on the reactions of electrolytic charge transfer.

Why is a supercapacitor used so rarely in practice instead of a battery?

They have different goals

The battery stores much more energy, and this is its most important purpose - not to discharge as long as possible in household appliances, consumer electronics and cars.

The capacitor is self-discharging

It is also present in batteries, but to a much lesser extent. Supercapacitors charge quickly and release charge quickly - they are also not suitable for long-term energy storage due to leaks.

Different voltage

While the battery keeps your phone in working condition, the voltage remains virtually unchanged. The capacitor changes the voltage depending on the accumulated charge - the numbers change within significant limits, which is unacceptable for sensitive mobile electronics, for example.

→ In this article we consider the topic of supercapacitors in the most simplified version for the mass public.

The benefits of ionistors in recorders

If you are interested, for example, in the detailed possibility of installing capacitors instead of batteries in RAID controllers, then write about it in the comments or send a message to us on VKontakte @NeovoltRu.

Subscribe in the group to news from the world of gadgets, learn about improving their autonomy and progress in scientific research on batteries. Connect with us on Facebook and Twitter. We also maintain a busy blog on Zen and Medium - come check it out.

Main settings

The main characteristics of a supercapacitor include:

- charging time has a small value and is equal to from 1 s to 10 s;

- in comparison with acid batteries they have a significant number of operating cycles, almost more than 30,000 hours;

- rated operating voltage is up to 2.75 V;

- service life up to 15 years;

- operating temperature range from -45°С to +65°С;

- Specific energy intensity is up to 5 W*h/kg.

Energy density

The ability of ionistors to accumulate energy is lower than that of acid batteries. The energy value depends on the internal resistance of the device; the lower it is, the higher the energy density. Modern developments make it possible to use materials such as nitrogen and graphene, thanks to which it has been possible to achieve a significant increase in internal energy density.

Main differences

A capacitor is characterized by a short-term content of accumulated energy in finished form, which can be released instantly when a load is connected. In turn, the battery retains a supply of current for a long period in the form of a calculated chemical restructuring. The main differences between electronic devices and the features of their operation can be seen in the table:

| Battery | Capacitor |

| Charge stored in the form of a chemical process | The electric potential of the dielectric is used for accumulation |

| High storage density | Low density with little margin |

| DC only | Can be used with alternating current |

| Slow charge accumulation | Faster charging and discharging |

Attention!

In fact, there is no charge in the battery. When a load is connected, electricity is generated by the passage of ions from the anode to the cathode.

Regardless of the similarity in function, the battery and capacitor have significant differences in their design and application. The main difference is that the battery does not have a constant supply of energy - it is produced only when a load is connected. It is impossible for a capacitor to discharge for a long time - all the potential disappears in a short period.

Advantages and disadvantages

Like any electronic device, ionistors have some advantages and disadvantages during operation. The advantages of manufacturers include:

- They have a reduced specific cost when comparing the capacitance of a capacitor and a battery.

- Increased internal capacity, resulting in an increase in the number of charge-discharge cycles.

- More reliable and also have a longer service life, unlike acid and lithium batteries.

- They are environmentally friendly due to the materials used.

- Increased power ratings.

- Possibility of operation in a wide temperature range. Low temperatures are not a hindrance when starting up any type of equipment.

- Significantly increased time period during charge replenishment and during operating discharge.

- Unlike rechargeable batteries, they have the ability to be completely discharged to almost zero operating voltage.

Interesting to know! Supercapacitors are relatively small in size compared to other similar devices.

However, while there are many advantages during operation, there are also disadvantages. The disadvantages include:

- Low density of energy storage relative to similar devices.

- Reduced voltage value per unit of internal capacity of one element.

- Increased self-discharge reading.

- Not fully developed ionistor production technology.

Theory

Having gained the experience of my colleagues in the workshop, I decided to first conduct experiments on a virtual model of a hybrid battery. To do this, I took the wonderful Yenka program. I found on the net that the VAZ starter has a working current of approximately 150-200 amperes. But I didn’t find ionistors in Yenka. I used ordinary capacitors only with a large capacity. As a result of virtual experiments, 500 farad ionistors turned the starter for as much as 3.5 seconds until the voltage dropped below 8 V.

Voltage drop during virtual “cranking” of the starter from an assembly of 6 500F ionistors

An experiment in the program shows that it is possible to start from an assembly of six 500 farads. But in practice, my colleagues did not succeed. Possible reasons:

- I messed up the diagram in the program;

- the program is “lying”;

- in fact, the starter current is higher;

- in practice there were fake ionistors;

1 and 2, I believed the calculations “on the knee” and the result was similar to the program. 3 and 4 could not be verified.

Initially, I really didn’t like the terminals on 500 capacitor ionistors; they are smaller than on UPS batteries. And if you look at the car battery terminals and the thickness of the wire to the starter, then you can assume that due to the small cross-section of the ionistor terminals, there was a strong voltage drop across them and the current was not enough to crank the starter.

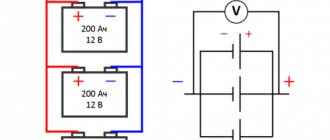

Capacitors, unlike batteries, do not have a stable voltage under load. That is, if we connect the starter to a battery of ionistors charged to 14 volts, then after 2 seconds of operation the voltage will drop to 11 volts, and after another 2 seconds to 7 volts. To raise the voltage again, you need to charge the capacitors. Therefore, the operating time of the starter strongly depends on the initial voltage. Since the maximum voltage of one ionistor is 2.7 volts, and the generator in the car can produce up to 14.5 volts, a minimum of 6 ionistors are needed, then the maximum voltage will be 16.2 volts. It would be wise to use the full potential of the ionistors and charge them up to 16 volts. I have not found reliable information about whether the starter will burn out at 16 volts. But in the characteristics of other electrical appliances in the car, Russians say in plain English: “up to 15 volts.” I decided to take a risk with the starter and assemble a hybrid battery, where there would be 6 banks of 16.2 V ionistors connected only to the starter, a balancing board, a regular 12 volt battery to power everything else and charged from the generator, and a step-up converter to increase the voltage from 12 to 16 volts.

Another significant drawback of ionistors, especially Chinese ones, is rapid self-discharge. Therefore, if you leave the converter constantly on, it will quickly drain the battery. Since charging the ionistors takes time, I decided to make the moment of turning on the converter as early as possible - when removing the car from the alarm system. Only negative comes from the signaling, so I let it go through a relay.

Features of application

Ionistors have gained wide popularity thanks to mankind’s desire to find new and more effective means of accumulating and storing energy for a long time. The main advantage that determined its spread was the ability of a supercapacitor to pulsely release significant energy from 0.1 s to 10 s in a short period of time.

Ionistors have found application in installations and equipment where fast and high-quality startup of electrical equipment is required in a short period of time, even at subzero temperatures. This reduces the maximum current load and leads to cost savings. It is also possible that it can be used to start an internal combustion engine.

By connecting capacitors into a battery, it is possible to achieve a maximum capacity comparable to a battery for powering electric vehicles. However, the weight of the power source will be significantly higher than that of conventional batteries. The developers have practically managed to solve the problem of excess weight; this requires graphene; however, this is only possible in laboratory conditions.

Currently, one of the most successful applications of ionistors is their use in public electric transport. The design of such equipment uses uninterruptible power supply devices that contain supercapacitors.

Emergency lighting that uses high-capacity capacitors instead of batteries has a significant advantage over systems with conventional batteries.

Interesting to know! Some foreign manufacturers integrate backup power supplies based on ionistors into LED lamps.

Application of supercapacitors

Emergency lighting systems are where using supercapacitors instead of batteries makes a real difference. In fact, it is precisely this application that is characterized by uneven discharge. In addition, it is desirable that the emergency lamp is charged quickly and that the backup power source used in it has greater reliability. A supercapacitor-based backup power supply can be integrated directly into the T8 LED lamp. Such lamps are already produced by a number of Chinese companies.

Ground LED lamp powered by solar panels, energy storage in which is carried out in a supercapacitor

As already noted, the development of supercapacitors is largely due to interest in alternative energy sources. But practical application is still limited to LED lamps that receive energy from the sun.

The use of supercapacitors to start electrical equipment is actively developing.

Supercapacitors are capable of delivering large amounts of energy in a short period of time. By powering electrical equipment at startup from a supercapacitor, peak loads on the electrical grid can be reduced and, ultimately, the inrush current margin can be reduced, achieving huge cost savings.

By combining several supercapacitors into a battery, we can achieve a capacity comparable to the batteries used in electric cars. But this battery will weigh several times more than the battery, which is unacceptable for vehicles. The problem can be solved by using graphene-based supercapacitors, but they currently only exist as prototypes. However, a promising version of the famous Yo-mobile, powered only by electricity, will use new generation supercapacitors, which are being developed by Russian scientists, as a power source.

Supercapacitors will also benefit the replacement of batteries in conventional gasoline or diesel vehicles—their use in such vehicles is already a reality.

In the meantime, the most successful of the implemented projects for the introduction of supercapacitors can be considered the new Russian-made trolleybuses that recently appeared on the streets of Moscow. When the supply of voltage to the contact network is interrupted or when the current collectors “fly off”, the trolleybus can travel at a low speed (about 15 km/h) for several hundred meters to a place where it will not interfere with traffic on the road. The source of energy for such maneuvers is a battery of supercapacitors.

In general, for now supercapacitors can displace batteries only in certain “niches”. But technology is rapidly developing, which allows us to expect that in the near future the scope of application of supercapacitors will expand significantly.

Development prospects

Modern technologies and developments suggest that ionistors will soon be used in almost all energy-intensive industries, the space industry, medicine and military equipment. The internal capacity of supercapacitors will gradually increase, making it possible to replace old lead-acid batteries.

It will also be possible to implement it in various electronic devices with regulation and control. Moreover, the production of environmentally friendly sources of energy saving, which significantly exceed their analogues in characteristics, will become available. Supercapacitors are also widely used in automobile transport, mobile and electronic devices.

Complete replacement of conventional batteries has not yet occurred since supercapacitors are used only in certain areas. However, science does not stand still and is constantly evolving, as a result of which we will soon be able to see these devices in automotive technology, mobile and electronic devices.

You may also be interested

.

Batteries 0

Supercapacitor instead of battery

Among the latest innovations in science and technology, it is necessary to note the appearance of a new type of capacitor - an ionistor, which is also called a supercapacitor. What kind of beast is this, and can it be used in a car DVR and other electronic devices as a backup power source?

Can an ionistor replace a battery?

From a school physics course we know that a capacitor can store energy by accumulating a charge of electricity. But the magnitude of this charge is very small, so it is only enough for a good spark in the event of a short circuit. Schoolchildren also use metal paper AC capacitors of 400...1000 Volts in order to shock each other with electric current, having previously charged it in a 220 V outlet. But capacitors are mainly used as radio components in electronic devices.

Form factor of ionistors, which are used as backup batteries

But at the end of the last century, a new type of capacitor was invented in secret laboratories, which uses an electrolyte and other tricky chemicals instead of a metal strip. Thanks to this design, a new type of capacitor with a small size has a huge capacity, which can already be used to accumulate a charge sufficient for short-term operation of electronic devices with low current consumption. It is called an ionistor because it functions by ion transfer in a chemical environment between the electrodes.

Such a powerful 3000 Farad ionistor can start a car

Nowadays, ionistors are used as a backup power source. For example, on Aliexpress for 5...10 bucks you can buy a 5-volt ionistor, which gets a full charge in just 10...100 seconds. However, it can power an average LED flashlight for 20...30 minutes.

Review of the Chinese ionistor

Now let's see if a supercapacitor can replace the battery in a car DVR? There are no components in the region that consume high current - servos, electric motors, powerful lighting lamps. Therefore, the current consumption is quite small - 50...100 mA. An average lousy ionistor will be able to ensure the operation of the DVR for 3...10 minutes. This is more than enough to finish the video and complete the work correctly.

This DVR uses a 7.5 Farad supercapacitor instead of a battery.

So, if you are hesitating whether to buy a DVR with a supercapacitor instead of a built-in battery, then all your doubts are in vain. This device will perform all the necessary functions in your car, even if the on-board network is disconnected in the event of an accident. However, this type of recorder cannot be used as a regular portable video camera outside the car - for street video recording, an external power source will be required.