The floor in the bathhouse is on screw piles

The method of arranging the subfloor and finished floor depends on the assembly method and material. If a bathhouse on stilts is built from ordinary timber or logs, then only a subfloor is installed in the room.

Laying of the finished floor begins only after completion of the shrinkage processes. If the frame and load-bearing elements of the bathhouse are assembled from glued profiled material, then rough padding, insulation, waterproofing and the finished floor can be laid within a couple of months after completion of construction.

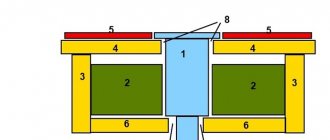

The level of packing of the lag beams of the subfloor is selected below the plane of the timber frame of the screw piles. The difference in height can be calculated by adding up the thickness of the padding boards, insulation and waterproofing membrane. After laying the sandwich on the floor, the plane of the foam insulation slabs should coincide with the piping line of the screw piles, as in the video

Bathhouse on screw piles: floor insulation

To assemble the subfloor of the bathhouse, an off-grade board is used; you can even use chain link or unedged lumber. The condition of the screw supports is not affected by the subfloor, the main thing is that the material is of the same thickness.

The boards are nailed onto the joist beams with ordinary nails, no screws, the fasteners are hit at the ends of the inch, moving 10-15 cm from the edge.

Sheet polystyrene foam is best suited for insulating the floor of a bathhouse on screw supports; you can take penoplex or technoplex. For middle latitudes, you can insulate the subfloor of a bathhouse with sheets 50 mm thick; if frosts in winter are more than 40 o C, then it is best to lay two layers of foam insulation.

Waterproofing the floor in a bathhouse on stilts

Before laying waterproofing on the subfloor in slab insulation, it is necessary to cut a hole for the outlet of the bellows cup of the water drainage system. The diameter of the hole in the polystyrene foam should be equal to or 1.5-2 mm larger than the cross-section of the corrugated or plastic pipe.

After installing the corrugation, film insulation can be laid. The best option for a bathhouse floor on screw piles is the EPDM rubber membrane. The material is rolled out as a single sheet over the surface of the insulation, and applied to the walls 25-30 mm per side.

To hold the waterproofing sheet around the perimeter of the washing or steam bath room, an aluminum threshold is stuffed, pressing the material against the insulation.

At the drain point, a hole with a diameter smaller than the internal diameter of the drain is cut, after which the upper flange of the drain device is installed and the structure is tightened with a mounting screw.

Shower floors in a bathhouse on stilts

The next stage of building a bathhouse is installing the finishing floor. Metal mounting “moths” are first attached to the walls, on which the finished floor joists are laid. The distance between the beams depends on the size of the steam room of the bathhouse; the screw foundation ensures high rigidity of the base, but experts recommend installing the floor in the bathhouse on stilts with a step of 50 cm between the beams.

Floor boards are laid on the logs, usually 25-35 mm thick floorboards are made removable on wooden pins. The boards themselves are sanded and chamfered to avoid splinters and chips.

Between the floorboards there are gaps of 1.5-2 mm, this scheme ensures reliable drainage of water even with a large number of washes, and the removable floor of the bathhouse on a pile-screw foundation allows you to periodically remove the boards and clean the lower level.

Floors in the bathhouse

Ordinary poured floors used in a traditional Russian bathhouse are not suitable in this case:

- Water flowing between the floor boards penetrates the soil and gradually destroys the metal of the piles and weakens the strength of their adhesion to the ground.

- It becomes difficult to maintain the temperature in the bathhouse due to the high altitude above the ground. Having an uninsulated space will require unnecessary fuel or electricity consumption.

The best option is to create an insulated floor with a reliable waterproofing coating. A layer of screed with pre-installed funnels for water drainage, which are connected to the sewer system, is poured onto the surface.

Ceramic floor tiles are laid on the screed, and for greater comfort it is recommended to lay wooden platforms with wide slats (8-10 cm) and gaps between them for free flow of water.

Floor insulation

Thermal insulation of floors in a house with a screw foundation is carried out in two stages: at the construction stage using the insulation method along the joists and during operation from the outside. Let's look at both options for floor insulation in more detail.

Internal insulation

Insulation of the floor from the inside in a house on screw piles is carried out using the method of insulation along logs. Conventional technology is used, which includes work in the following sequence:

- Cranial bars are packed along the lower edge of the joists.

- Then a rough base of boards is laid on these bars. They must be laid as tightly as possible, and the remaining cracks must be filled with foam.

- The next step is the installation of waterproofing material. For this purpose, roofing material or thick polyethylene film laid in several layers is used. Installation of waterproofing must be done with an overlap of at least 10 cm.

- Thermal insulation material is installed on the waterproofing layer. The materials used for insulation will be discussed below.

- The insulation is covered with a layer of vapor barrier material on top, after which the floor covering is installed.

The joists can be covered with floor tongue-and-groove boards or thick plywood. For additional insulation of floors, use linoleum on a thick base, carpet, or lay laminate flooring using a cork backing.

External insulation

During operation of a house on screw piles, additional insulation of the floor from the outside can be done. Let's study in detail the technology of how to properly insulate a floor using this method:

- Throughout the entire outer area of the house, a vapor barrier material is fixed to the bottom of the joists. It can be secured with glue or nailed with a construction stapler.

- After installing the vapor barrier material, a sheet heat insulator is installed, which is attached to the wooden base using self-tapping screws with disc-shaped caps.

Then the thermal insulation material must be covered with a wind membrane, which allows air and moisture vapor to pass in one direction: away from the thermal insulator, which allows it to breathe.

In some cases, the insulation of the floor on the outside of the house on screw piles is considered completed. But if desired, the heat insulator can additionally be covered with boards that are placed on the lower ends of the wooden beams of the base of the house.

Thermal insulation materials used

Modern technologies have helped to develop the latest highly efficient thermal insulation materials, which are used to insulate floors in houses on screw piles. Based on practical application experience, experts recommend using the following insulation materials:

- Extruded polystyrene foam. This modern insulation, perhaps, has the best performance characteristics of all the insulation used. Sheets of extruded polystyrene foam have excellent thermal insulation properties, are lightweight, easy to cut, and can withstand significant mechanical loads. In addition, expanded polystyrene practically does not absorb moisture, is not susceptible to rotting and mold, and has a long service life even in unfavorable conditions. The only disadvantage of this material is its fairly high price, which largely depends on the complexity of the technological process for manufacturing the insulation.

- Pressed basalt wool slabs have very low thermal conductivity and absorb various noises well. Light weight and installation also add to the popularity of this material. A significant disadvantage of mineral insulation is its hygroscopicity, which forces the use of multi-layer waterproofing during installation. That is why experts recommend using compressed types of wool for internal and external insulation of a house on screw piles. This heat insulator is more moisture resistant and durable, it is easier to install and secure.

- Polystyrene foam is low cost and light weight. Great for additional insulation. Due to its low cost, polystyrene foam is very popular. In addition, it has the following properties: low thermal conductivity, good moisture resistance, easy processing, durability.

- Foamed polyethylene on a foil base is used as a vapor barrier layer to protect the main insulation from external moisture. In addition, polyethylene foam enhances the thermal insulation characteristics due to the presence of a foil layer that reflects heat waves. Affordable price, easy installation and good performance properties make this material very popular.

Bathhouse: floor insulation

Why do you need to insulate floors? Seasonal bathhouses really don’t need this, but if you want to take a steam bath in the cold, you’ll need an insulated bathhouse. Insulation has already been mentioned twice above. But we will consider its options in order.

Insulation of the floor in a bathhouse on screw piles

The building, placed on stilts, does not have a concrete foundation, instead there is an empty space where the wind blows. Insulation of the floor in a bathhouse on screw piles should begin with the creation of a double floor: rough and white with a layer of insulation. To do this, a beam for tying is first placed on the pile heads, and boards soaked in antiseptic are nailed to it. A hydrobarrier film is laid over the entire base area, and then insulation is placed in the space between the boards - mineral wool, penoplex or extruded polystyrene foam. Then again the water barrier and the white floor.

If there is a concrete slab on piles, it is waterproofed by fusing roofing material or covering it with mastics. Insulation is placed on top, for example, extruded polystyrene foam. The next layer is a 5 cm concrete screed with a reinforcing mesh, and then - at the owner’s request: you can put a heating system and tiles, for example.

The floors in the bathhouse are poured, with a layer of insulation

Actually, we have already talked about a concrete field, but this is the same as a poured field. There are two cases of filling: on the ground and on the ceiling.

On the ground

There are many options offered on various resources. You can do this:

- A pit is dug inside a solid strip foundation to a depth of 40-50 cm.

- Gravel is poured and compacted so that its layer is 15 cm.

- A sand cushion is poured and compacted - 30-50 cm.

- Roofing felt is placed on top of it in two layers with sheets overlapping 10 cm and sealed with bitumen mastic. (2nd layer perpendicular to 1st.)

- A layer of insulation - expanded clay or mineral wool, or slag from a boiler room, or felt impregnated with tar. The layer thickness is 30-50 cm, extending onto the walls.

- Only for mineral wool - the second layer of hydrobarrier. This could be plastic film.

- A layer of reinforcing mesh with a rod diameter of 5 mm.

- Beacons and guides for creating the desired slope.

- Pouring concrete screed. Thickness is at least 3 cm.

As an option, two layers of concrete pouring are possible: the first layer immediately over the sand and gravel cushion, and the concrete is mixed with coarse gravel. A hydrobarrier is placed on the first screed, then insulation (for example, perlite with cement). Place a metal mesh and a new layer of concrete screed on the hardened mortar.

By overlap

This method was described above, where we talked about insulating a concrete floor in a bathhouse, in a concrete floor slab on stilts.

Insulating the floor in a bathhouse with expanded clay

Expanded clay is an excellent insulation material if its layer is 15 cm or more.

It can be poured between the joists on the subfloor with a hydrobarrier film. This is for dry wood floors. They also insulate concrete floors. It is placed on roofing felt or other waterproofing material placed on top of a sand and gravel cushion. A laser level will help level its layer. To create a slope, expanded clay is moistened with cement mortar.

IMPORTANT ! Experienced builders advise that when insulating the floor in a bathhouse with expanded clay, take it from different fractions - the large one is warmer, and the fine one will fill the space between the large particles. In addition, you need to monitor the moisture level of expanded clay - it is hygroscopic, and this has a bad effect on its heat-insulating properties.

With foam

Despite the fact that foam plastic is not a very suitable material for floor insulation, it is often used. Although its close relative - extruded polystyrene foam - is much more suitable for this purpose. The advantage of polystyrene foams is that they are not wetted by water. This eliminates the need to isolate their layer with a water barrier. Otherwise, the same methods of application in floor insulation as described above.

With perlite

Perlite is another great insulation material, but it has one big drawback: it is too light for outdoor use. As soon as the wind blows, part of the perlite will fly away with it. Therefore, they work with it indoors. For insulation, a mixture of perlite and concrete is often used, which increases the porosity of the latter and increases its thermal insulation properties. The proportions of the mixture are as follows:

- Mix 2 parts perlite with 1 part water.

- The mixed perlite is allowed to settle and 1/2 part of cement M300 and above is added.

- During the kneading process, add 1/2 of the water and another 0.5 liter on top.

The result is a dry, crumbly porridge, which is placed on the first concrete screed, and after 6 days it is filled with a second screed.

Insulation of the floor in the dressing room, in a wooden bath

The dressing room should retain the heat of the steam room and washing room, so it should also be insulated. The methods and materials are the same as in other rooms, there is only no need for slopes and drainage. The insulation is placed either between the joists on the subfloor, or on a film-insulated cushion of sand and gravel, or on the first concrete screed.

Thus, various materials are used to insulate the floor, and which one is better depends on the tasks at hand.

How to make the floor of a frame house on screw supports

The material for the frame structure is selected based on its technical parameters and the weight of the finished flooring. The base is point-based, a large load cannot be placed on it, and the house with decoration, furniture, and connecting grillage are also taken into account in the total pressure.

It is better to use light, dry boards; wet wood weighs much more. To make a warm floor, it is better to choose oak, aspen or coniferous species.

View of the floor covering from below

First, they build a foundation, then they erect a grillage, preferably made of wood. The next step is to assemble a frame with stiffening ribs from 10*10 cm timber. If the distance between the piles exceeds 3 m, additional intermediate supports will need to be installed.

The logs are installed every 55-60 cm, with a cross-section of 10*25 cm. The insulation is 25 cm thick.

If you need to cover several small spans, it is enough to take several smaller beams 5*25 cm.

Strapping elements are mounted under the beams for the installation of logs: the crossbars are inserted into pre-prepared cuts, fixed with self-tapping screws and nails.

Wooden elements must be treated with an antiseptic impregnation to avoid damage by insects or mold formation.

Floors on stilts

When the design documentation for a bathhouse provides for its installation on a screw or concrete foundation, which allows it to be raised above the soil level, the technology for laying the boards is somewhat different. Insulation of the floor in the bathhouse is carried out according to a different scheme. According to these requirements, the floor in the bathhouse is laid on stilts. To begin with, beam floors are laid in the upper part of a columnar or pile foundation, a frame is made of timber, onto which boards are laid. The void areas are filled with expanded clay or laid with mineral wool. A vapor barrier layer is laid on the insulation, then the logs are attached. All that remains is to fill the finished floor with boards, which is quite within the capabilities of every owner.

Floor structure

When choosing building materials for the floor of a frame-type structure, you need to take into account the strength parameters and weight of the structure. It is better to minimize the weight of the floor covering in order to relieve the supporting structures from unnecessary load. Option - wood. Popular: aspen, oak and conifers.

Structure

High-quality wood at the base of a building is a guarantee of a reliable structure. Poor material will not withstand significant load.

The construction of the floor of a frame house begins immediately after the construction of pile supports and the completion of the grillage. It is recommended to combine a wooden covering when tying, using coniferous beams with a diameter of 100*100 mm. If the interval between individual supporting structures is more than 3 m, it is better to additionally erect another pile.

The lags are installed on top of the securely fixed beams. The interval between individual elements is 0.5 m. The recommended log size is 100 * 250 mm. An exception can be made for the bathroom and corridor. Buy timber 50*150 mm.

To quickly install the logs, the timber is marked with markings for the step size. The strapping products are equipped with landing recesses to match the width of the joists.

Lags

The logs are additionally fixed with screws or other fasteners.

Improving the strength characteristics of the floor is achieved by laying additional lintels. They are stuffed on top of the logs, with an interval of 1.5 m. Often, this is a necessary measure when constructing a frame building with reinforced concrete ties and heating. Other situations require separate floor insulation.

Concrete floors

Many people study photos of floors in bathhouses on the Internet, and enter the search phrases “floor installation in a bathhouse on screw piles,” “sauna on stilts: how to make a floor.” There are plenty of options to explore.

Let us give an example of the arrangement of the most commonly used concrete floor, the arrangement of which is carried out in several stages:

- the soil base is carefully leveled and compacted;

- the first concrete layer is poured, the thickness of which is at least five centimeters;

- if the fill is frame, then expanded clay or felt material is used to insulate the floor;

- reinforcement is performed, over which the second concrete layer is poured (read: “Installing a concrete floor in a bathhouse with your own hands - stages of work”);

- the surface of the hardened concrete is leveled with a screed made of sand and cement;

- a final “fine” coating is arranged. For this purpose, finishing materials are used that are not susceptible to high levels of humidity.

When carrying out all construction work, it is necessary to maintain an inclined angle towards the drain, which should be approximately ten degrees. If you plan to install a furnace or boiler, the floor at this point must be especially strong, additional reinforcement should be provided, and cement of a higher grade should be used.

For the sewer network that discharges wastewater, it is necessary to make holes in the basement. Drain pipes made of plastic material will pass through them, designed to drain water into the drainage system.

What insulation is better for the floor of a frame house?

Floor insulation in a frame house can vary depending on the purpose of a particular room. According to GOST (state standard), the following can be used as insulation:

- expanded polystyrene;

- Styrofoam;

- mineral wool;

- ecowool;

- penofol;

- penoplex;

- expanded clay and other types of insulation.

The thickness of the insulation for the floor of a frame house in central Russia is chosen to be 200 mm. For more northern regions - 300 mm.

To insulate the floor of a frame house, you must choose only high-quality insulation. Otherwise, you may end up with insufficient insulation, which will lead to unnecessary costs for heating the premises.

Insulation with polystyrene foam or expanded polystyrene is the best and simplest solution. It is actively used in budget construction. The only condition is the use of good waterproofing so that the foam does not disintegrate into individual elements. When temperature changes, the foam can still form cracks. This is its main drawback.

To prevent such unpleasant moments, you need to lay the sheets “under tension” so that the sheets are tightly clamped between the joists. Such work should be performed by knowledgeable specialists.

Laying foam plastic between floor joists “in tension”.

Mineral wool can be used with great success for insulation. It has high thermal protection, is not flammable, but is also resistant to moisture. Waterproofing in this case must also be of high quality. It is better to use mineral wool in the form of mats than in the form of a roll, because the mats are denser. Be sure to cover the gaps between the mats.

If you choose an insulation thickness of 150 mm, then it is advisable to lay a layer 100 mm thick and cover the cracks with another layer 50 mm thick.

Ecowool is an analogue of glass wool, but is more environmentally friendly, although many experts question this fact. Ecowool is sprayed using special equipment and forms a layer of seamless insulation. Ecowool retains heat better than mineral wool, but is more expensive.

Insulating the floor with penoplex, which is a type of polystyrene, but is more reliable in strength and has a higher degree of thermal protection, will cost much more.

Insulating a frame house with expanded clay is quite possible. Expanded clay is cheap, it is fire resistant, and is also environmentally friendly. It is quite possible to insulate a floor with expanded clay yourself, without resorting to the help of a construction team. True, expanded clay is inferior in thermal conductivity to the materials listed above.

When insulating a floor with expanded clay, it is imperative to use waterproofing, because expanded clay absorbs moisture well. A layer of expanded clay is laid on the waterproofing, a leveling screed is made on top of it, then another layer of waterproofing is laid.

In principle, absolutely any insulating material can be used to insulate the floor. In the simplest cases it can be sawdust. As a rule, the better the quality of the material, the higher its price. Each owner chooses which heat insulator to choose.

Stages of floor insulation

Let's look at the main points of thermal insulation of different structures.

Wooden

Sequence of work:

- On top of the beams, rough covering elements are packed in steps equal to the width of the board.

- A moisture-proof film or other waterproofing material is fixed with a construction stapler.

- Depending on the design, insulation is laid across or along. To increase the effect, it is recommended to lay a foil vapor barrier film on top. Ondutis R Termo is popular. Plus, it protects the insulation from getting wet.

- The next layer is the sheathing. It consists of stuffed thin bars and slats. Responsible for floor ventilation.

The final step is laying the finished wood flooring.

Concrete

Work order:

- Ruberoid, insulating film are laid on top of the established concrete base, or the surface is simply coated with bitumen mastic.

- A layer of expanded clay, perlite is poured or polystyrene is laid (optional).

- A metal mesh is attached, which will serve as reinforcement.

- A self-leveling concrete screed is poured.

At the request of the owners, tiles are laid or removable wooden panels are used.

For self-construction, both concrete and wooden floors are suitable. In bathhouses made from fresh logs, the best addition will be a plank floor, in brick buildings - a monolithic concrete slab. In both options, it is necessary to decide at the project development stage whether the design will be torrential or not.

Thermal insulation of the first floor floor

If you decide to build a house on screw piles with your own hands, then special attention should be paid to insulating the floor of the first floor. The structural design of a wooden floor on the second floor does not require such careful thermal insulation

As a rule, the construction of houses on stilts is carried out using beams. To do this, we lay OSB boards or plywood along the slats attached to the bottom of the joists. The design in cross section will resemble the letter W.

Layout of a wooden floor on joists with insulation

Now you can begin installing hydro- and vapor barriers. To do this we do the following:

- We spread the waterproofing film over the joists so that it sag into the gaps between the joists. You can use membrane waterproofing or regular film.

- We place thermal insulation material in the spaces between the joists (on top of the film). Mineral wool is suitable for these purposes. If you want to properly insulate your house on stilts, then it is better to use basalt wool.

- The waterproofing film on the joists must be secured with a stapler.

- The structural design of the first floor floor in a house on stilts must include a vapor barrier. If you are building with your own hands, then do not forget that the vapor barrier material is laid with an overlap of 150 mm. The joints must be taped.

Using the method described above, the construction of the ground floor floor is carried out in any room, be it a bathroom, kitchen or living room. As for the structural pie of the second floor floor, it can be done without heat and waterproofing material. But in the bathroom and other places with wet processes, it is worth laying a waterproofing layer into the floor structure. In the video below you can learn in more detail about the construction of the floor of a house on stilts with your own hands.

Flooring installation

An example of laying tongue-and-groove finishing boards

The next layer of the structural pie is made with a board 3 cm thick. When laying the boards with your own hands, keep a step of 40-50 cm. This sheathing along the joists will allow you to get a ventilation gap. You can attach the boards to the joists with self-tapping screws.

We then proceed with the construction of the floor in the house in this order:

- We lay the subfloor on the sheathing of boards. It can be a tongue-and-groove board or a regular board. We fasten it to the sheathing with self-tapping screws.

- You can lay purchased flooring on the boards with your own hands.

Since the front layer of the floor in the bathroom and toilet will be tiles, it is better to lay plywood or OSB on the rough boards to level the surface. At the same time, the structural pie in such rooms must include additional waterproofing, which is laid over plywood.

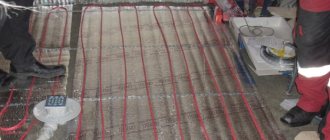

Warm floor of a frame house

You can make a warm floor in a house on stilts with your own hands. This is not shown in the video below, but the process is simple and takes place in the following sequence:

- A structural heated floor pie includes the same load-bearing wooden frame as for a non-heated floor, with the only difference being that the plywood sheets are not laid on backing boards, but on cranial blocks attached to the joists with self-tapping screws on the sides. You can use a cranial block with a cross-section of 30x30 mm and fasten it in increments of 15-20 cm.

- After laying the plywood on the beams and performing waterproofing, we lay expanded polystyrene in the gap between the joists. The top surface of the polystyrene foam boards should be flush with the top of the joists.

- Next, you need to lay a layer of vapor barrier film, placing it on the walls above the expected level of the finished floor.

- We lay a reinforcing mesh over the film and fill it with a thin layer of cement mortar.

- Then we lay the heating mats of the underfloor heating system on the reflective layer of foil insulation. We perform concrete screed.

- We install flooring. If the floor is in the bathroom or kitchen, then you can use tiles.

For more information on how to make a floor in a frame house, watch the video below:

https://youtube.com/watch?v=SYV5vkZOWZk

Features of thermal insulation of the floor of a bathhouse on stilts

When erecting a building on loose soil, preference is given to a foundation on screw piles. There is free space under the finished bathhouse, making it easier for cold to penetrate through the floor into the building.

Thermal insulation is performed in two ways:

- Laying insulation between the subfloor and the finished floor.

- Installation of a plinth made of thermal insulation boards and decorative panels.

The creation of a subfloor begins with a frame made of timber laid on the pile heads. The amount of space for insulation will be equal to the width of the lumber. Boards soaked in antiseptic are nailed to the timber. A layer of film waterproofing is laid on them and secured with a stapler. Mineral wool, penoplex or foam plastic are recommended as insulation. A second waterproofing sheet is laid on top of the material and the floor is laid.

Spray polyurethane foam is one of the methods of high-quality insulation. It forms a sealed layer that is resistant to moisture, frost and high temperature. Durable material with low thermal conductivity provides floor protection for up to 30 years.

Creating a base for a bathhouse on stilts allows you to close the space under the building. This improves its appearance and reduces heat loss. The outer part of the structure consists of decorative panels. Foam plastic or polystyrene foam is used as an insulating layer, glued from the inside of the finish. The joints between the panels are treated with polyurethane foam.

Insulated screed floor

It is made in the form of a continuous “pie” of covering from several layers, including insulation. Laying communications below its base can complicate the work and make it difficult to access them during operation. It is necessary to install in advance all elements that allow servicing utility networks, such as ladders, inspections, valves, etc.

The base level is set below the finished floor level to the height of the covering structure. The underlying layer of 0.15 meters is made of well-compacted medium-sized sand or gravel. A waterproofing membrane made of polypropylene film over 0.5 millimeters thick is laid on top of it. The panels are laid with an overlap of 10 centimeters, welded or fastened with adhesive. The edges of the film are placed on the walls of the grillage to a height equal to the thickness of the coating to prevent capillary filtration of moisture.

Ground floor with insulation.

A layer of solution 2-3 centimeters thick is applied to the membrane and insulation is laid. It is recommended to use special boards of extruded polystyrene foam or polyurethane foam. They have sufficient rigidity and low thermal conductivity; their edges have grooves and protrusions that allow the slabs to be joined without the formation of through gaps.

A leveling layer 5 centimeters thick is applied to the insulation, and a clean floor is installed on top of it. The screed is reinforced with a masonry mesh with a diameter of 3-4 millimeters with a cell pitch of 0.1 meters.

Instead of polymer thermal insulation, you can use expanded clay, as was usually practiced before. This solution is more complex and time-consuming, with dubious economic benefits. From 10 to 25 centimeters of expanded clay brand M-500, fraction 10-20, is poured on top of the waterproofing membrane. It needs to be compacted, leveled and poured with cement laitance, which will give structural rigidity to the backfill. After the binder has set, a reinforced cement-sand screed is laid over the insulation layer.

Pile foundation - optimal for baths on problem soils

It is most rational to build bathhouses in suburban areas with difficult terrain and type of soil on screw piles. This type of foundation has many advantages. Let's highlight the main ones:

- stability of the structure due to the strength of the supports;

- ease of doing the work yourself (by the way, they can be done in any weather conditions);

- effective ventilation of the space under the floor;

- high maintainability;

- increased reliability and durability.

In addition, the floors in a steam room on a pile foundation can be made in different ways. It is not difficult to choose the option that is suitable for us. Moreover, with proper arrangement, the floors will be well protected from melt and sediment water. This means we will get bases with a really long service life.

Most often, home craftsmen make the floor in a private bathhouse on screw piles from wood (so-called pouring structures) and concrete. The second option requires more serious financial costs. But concrete foundations are impervious to moisture. Due to this, they serve without accidents or deterioration in their operational technical properties for 25–30 years.

Wooden floors are easier to install and have a lower cost. They cannot be called durable. If we treat the wood used with special antiseptic compositions, the maximum service life of the floor base will be 9–10 years. No more. And without additional treatment, wooden floors in a bathhouse will have to be replaced after 3–5 years.

Next point. When arranging floors in a building on stilts, you need to carefully consider the issues of their high-quality insulation and drainage organization. Moisture from the steam room and washing room can be removed in several ways. The technology for insulating the floor base also depends on which one we choose.

How to choose material for insulation?

Different materials for construction can serve as a layer for heat insulation

In a log house, it is important to consider whether the selected type of insulator can be used in high humidity. According to experts, you should choose one of the following insulation materials:

Glass wool or mineral wool

Mineral wool has a significant list of advantages, which include:

- Non-flammability, i.e. fire safety.

- Low thermal conductivity.

- Not damaged by biological organisms (mice, rats, insects).

Based on the type of raw materials used in production, the following types of mineral wool are distinguished:

- glass wool;

- stone wool;

- slag.

Styrofoam

It is characterized by low cost combined with high heat-protective qualities. When laying the material, it is necessary to take into account the fact that the combination of high humidity levels and negative air temperatures can turn the slab material into scattered small balls.

Extruded polystyrene foam (EPS)

Many people are familiar with this insulation under the name “Penoplex”. In appearance, it is very similar to foam plastic, but it does not have its characteristic disadvantages. This material is practically unable to absorb moisture, and also has an increased level of strength. This means that low-temperature exposure is not dangerous for this material. In addition, the composition of polystyrene foam includes special additives that prevent it from burning.

Expanded clay

It is an inexpensive material that can be used for thermal insulation of floors in houses on pile foundations. Its thermal insulation qualities are lower than those of the materials discussed earlier, but its price is very affordable. The insulator is non-flammable, and its installation is extremely simple.

Floor insulation with expanded clay

The procedure for filling the thermal insulation layer will vary depending on the design of the floor of the bathhouse being equipped. There are few options:

the floor is laid over logs installed on compacted soil; the flooring is made on top of logs placed on brick supports;

the structure is represented by a concrete screed or reinforced concrete floor slab.

Choose your option, read the instructions specifically for it and get to work. The information is given in the table.

Table. Floor insulation with expanded clay

| Floor construction type | Insulation procedure |

| Floor on joists on the ground | It is assumed that the joists have already been installed and all that remains is to lay layers of insulation to create the final flooring. If you are insulating an already used wooden floor, you must first remove the flooring (damaged boards are replaced with new ones), replace rotten joists and thoroughly compact the soil. The subsequent steps are similar for both cases: - waterproofing is laid on top of the compacted soil. You can put either plastic film, roofing felt or glassine. Waterproofing is placed both in the space between the joists and on top of them. Lay the sheets with an overlap of 10-15 cm. Tape the joints with construction tape. You can attach the insulation to the joists using a construction stapler with staples or small nails; — a uniform layer of expanded clay is poured over the waterproofing. Further actions depend on whether expanded clay will be used as the only insulation, or whether a second thermal insulation layer, for example, mineral wool, is planned to be laid on top of it. If thermal insulation is performed exclusively with expanded clay, the order is as follows: - the selected vapor barrier material (preferably foil) is laid on top of a leveled layer of expanded clay with a thickness of 30 cm or more. The overlaps and fasteners are the same as when laying the material for waterproofing; — finishing of the floor is carried out at the discretion of the developer. If expanded clay is used together with other insulating material, the procedure is as follows: - a vapor barrier material is placed on top of a layer of expanded clay 10-15 cm thick (the specific value is selected taking into account the planned thickness of the upper thermal insulation layer). The recommendations are similar to the previous case; — expanded polystyrene or mineral wool is laid on the vapor barrier. The functions of the frame for placing the slabs will be performed by the logs - select the width of the thermal insulation elements according to the size of the spaces between the logs (or simply fill the frame with the required parameters from timber). If the height of the logs is not enough, nail a beam on top of them at the height of the top insulation; — the thermal insulation is covered with a layer of hydro-vapor barrier. The further procedure of work remains at the discretion of the owner. So, for example, if a concrete screed is to be poured, a reinforcing mesh is first laid on the insulation. If the floor is wooden, bars are nailed to the joists for laying the boards. |

| Floor on joists on brick supports | In this case, the procedure will differ little from the option discussed above. Minor differences are present only at the initial stages of insulation: - expanded clay is poured to the level of the logs laid on top of the brick supports; - cranial bars are nailed to the joists (the most commonly used option is 4x5 cm in size); - a rough flooring made of boards or wood boards is installed on top of the bars. Further actions are carried out similarly to the previous instructions. |

| Floor on concrete slab | The sequence of activities will differ little from the instructions you have already reviewed: - the base is covered with a water vapor barrier; — expanded clay is poured; — the backfill is covered with another layer of water vapor barrier. The further procedure is determined by the developer and depends on whether a concrete floor will be poured or a wooden structure will be installed. |

Expanded clay

Characteristics of expanded clay

Expanded clay - advantages and applications

What types of subfloors are there in wooden houses?

- According to the lags. Most often used as a base for finishing floor coverings with low load-bearing properties: laminate floors, linoleum, parquet boards or piece parquet. In these cases, subfloors absorb loads and distribute them evenly over the floor area. Sometimes such floors are called the base; this name is used by inexperienced builders, but has the right to life.

- Under the logs. At the bottom of the logs, cranial bars are fixed; they serve as the basis for fastening the subfloor, insulation, and vapor and waterproofing.

- Along load-bearing beams. In our opinion, this is the most successful option, but it needs to be thought through at the stage of designing a wooden house. Why do we think this?

The distance between the floor beams is ≈ 1–1.2 meters, specific values and thickness values are calculated depending on the load. Then logs are placed on the floor beams with a distance of 40–60 cm. Why do double work, it is much more expedient to install the floor beams a little more often, while reducing their size. These same beams will serve as joists. What will happen as a result? Significant savings in materials.

If you calculate the amount of timber for beams and joists in the traditional construction option, then the second option makes it possible to achieve savings of at least 40%. At modern prices for natural high-quality materials (and only the highest quality lumber is used for this work), the savings in monetary transfers amount to significant amounts. Another undoubted advantage is the increase in the height of the interior premises; with the height of the logs within ten centimeters, this is a noticeable increase.

Any low-quality materials can be used for the subfloor, except if it serves as the basis for installing finishing floor coverings. These can be either pieces of boards, OSB sheets, plywood or chipboard, or unedged boards. The thickness of the materials does not matter; boards or slabs with a thickness of one to three centimeters can be used on one floor. Thermal insulation materials will be laid on it; for them, minor differences in the height of the base are not critical. Of course, unedged boards must be sanded; wood pests breed under the bark.

Elements of subfloors

The second important point for all subfloors is protection from the negative effects of moisture. Currently, there are quite effective antiseptics available, which need to be used to soak the boards at least twice.

Fire protection of wood

No antiseptic - no problem. Just sand the boards, the effect will be exactly the same. Treat the ends of the subfloor boards with particular care. Inattention to the ends is one of the main mistakes of inexperienced builders. They first lay the cut boards on the supporting elements, and then use a brush to treat two surfaces, forgetting about the ends. The ends of the wood absorb the largest amount of moisture; in this place all the capillaries of the wood are open.

Drying oil

Treating wood with drying oil

And one last thing. Keep in mind that no antiseptics will help if the underground of a wooden house does not have effective natural ventilation. The subfloor will sooner or later lose its original properties. You will have to change not only it, but also the entire floor covering.

If you are afraid of rodents entering through the air, place metal grilles on them. If it seems to you that in winter the floors in the rooms on the first floor are very cold due to the vents (and this may be the case), then close them during the cold period. But be sure to open all the vents as it gets warmer. Ventilation, by the way, is a prerequisite for the durability of the lower crowns of a log house.

Installation of vents in the foundation

Correct placement of vents

Bathroom floor installation

The floors in a small bathhouse are usually arranged in such a way that excess water can seep between the floor boards and be absorbed by special membranes that ensure drainage of the liquid used for washing or washing.

At the same time, it is necessary to insulate the floors so that the bathhouse does not dry out quickly. It’s easy to insulate the floors in a bathhouse with your own hands, using the necessary high-quality insulation.

The ideal option for a bathhouse is to build a frame building made of natural wood, which can be easily heated in a short time. The floors in such a bathhouse are also made of wood, which is easy to do with your own hands.

High humidity and an abundance of steam in the bathhouse will lead to rapid deterioration of the wood, because the material is susceptible to biological damage in such conditions: pockets of rot appear, fungus and mold spread over the wooden surfaces of the floor and walls.

A reliable way to protect wood from excess moisture is to use vapor barrier materials, as well as special water-repellent films.

How to make a subfloor in a wooden house

Let's consider one of the most difficult options - installing subfloors on joists without floor beams. Such a floor is often found in small rooms of a private house or in cases of peculiarities of log house construction technology, when floor beams were not used.

Making a subfloor with your own hands

Step 1. Marking. Make a zero mark around the perimeter of the room using a water or laser level. This will be the finished floor level. From this mark you need to minus the thickness of the final coating and the lag. Make a second mark; the supports for the joists should be located at this level. They can be made from concrete, blocks or bricks. There must be concrete in the ground; only the above-ground part is allowed to be laid with bricks.

Marking the zero level using a laser level

Scheme for finding the level of the future floor

Step 2. Make supports in any way; the distance between them should take into account the linear parameters of the log and the total load on the floor.

Adjustable screw supports

Adjustable screw supports for logs - photo

Columns for logs

Step 3. Place all the logs under the rope, do not forget to insulate them with two layers of roofing felt.

Step 4. Secure the joists. To do this, you can use metal corners and fix them to the walls of the log house.

Attaching the log

The photo shows how to attach the logs to the wall.

Example of waterproofing lag

Do not forget to leave a gap of approximately 1–2 cm between the walls and the ends of the joists; take metal corners with oblong slots to ensure free longitudinal sliding. Tighten the screws in such a way that the logs can move in the slots. For reliability, it is recommended to attach the logs with dowels through at least one post; the side of the corner fixed to the log must also be movable.

Step 5. Prepare the material for the subfloor.

Oriented Strand Boards

We have already mentioned that in our case all the scraps are suitable, some can be covered with plywood or OSB, and some with pieces of boards or unedged materials. It is desirable that the sheets of plywood and OSB be moisture-resistant; if they are not, then soak them with drying oil or an antiseptic.

Plywood FSF

Step 6. Check the distance between the joists. If it is the same, then all the workpieces can be cut to a standard length.

Checking the distance between joists

Step 7. Place the boards on the prepared shelves. We have already mentioned that these can be either wide boards nailed at the bottom of the joist or skull blocks installed later on both sides. You should not try to make the subfloor continuous; small gaps do not affect anything. In order to save materials, it is recommended to specifically leave a distance of 5–8 centimeters between individual boards. But this can only be done in cases where pressed mineral wool or foam boards are used as insulation.

Sub flooring

Arrangement of the subfloor

Step 8. Vapor and waterproofing. If you have extra money and time, you can install hydro- and vapor barriers in any case.

Vapor barrier layer on subfloor

Vapor barrier laid on the floor

If you don’t want to act rashly, then figure out why such protection is needed. Mineral wool has excellent heat saving properties, does not rot, and does not promote the proliferation of microorganisms, including fungi. This is great, but it has two very significant drawbacks. First, with increasing relative humidity, thermal conductivity increases sharply. Water conducts heat well; there is no need to talk about any heat-protective functions. Secondly, it takes a very long time to dry. This means that all adjacent wooden elements will constantly be exposed to high humidity. There is no need to explain what the result of such conditions is.

Laying vapor barrier on the floor

If you insulate the ground floor with mineral wool, then a vapor barrier is required. It will prevent moisture from the ground from penetrating into the thermal insulation. If foam-based materials are used as thermal insulation, then such vapor barrier is unnecessary, these materials do not absorb water.

Vapor barrier on the floor - photo

Now about waterproofing. In any case, the subfloor below does not need to be covered with such materials; there are no “gushing” sources in the underground. But after thermal insulation is laid on the subfloor, it is necessary to protect it from moisture penetration from the finished floor. This applies to all types of materials, mineral wool and foam. Waterproofing protects not only them from water, but also the subfloor boards and joists.

Materials for floor insulation in a wooden house

Floor insulation with mineral wool

Insulating layer over mineral wool

Materials for thermal insulation of bath floors

Maximum protection of the base is possible only if the insulation is properly selected. There are the following types of thermal insulation materials for bath floors:

- Wool on fiberglass and basalt base. Lightweight thermal insulation material with high heat-saving characteristics. It quickly absorbs moisture, so it requires additional hydro- and vapor barrier.

- Expanded polystyrene. A moisture-resistant and practical insulating material, characterized by its low weight and affordable cost. Insulating the floor in a bathhouse with penoplex provides for the accessible installation of a heat-insulating floor pie, which you can do yourself. Used for insulation of wooden and concrete bases in combination with vapor barrier protection.

- Expanded clay. An environmentally friendly and durable material with a porous structure and high thermal insulation characteristics. It is produced on the basis of clay and slag screenings. Expanded clay is used in dry form as underground backfill mixed with a cement composition.

- Foam-based polymers – ecological wool and penoizol. Foam insulation ensures maximum filling of existing gaps and deformations in the flooring, therefore they are successfully used for thermal insulation of wooden bases on joists.

- Perlite. It is an expanded sand mixture, which, when mixed with cement and water, acquires additional porosity and strength. A lightweight insulating material used as a connecting layer when constructing a concrete screed.

Insulation materials and their properties

Basic insulation scheme Unlike vertical structures, not only rolled mats or slabs, but also bulk or loose materials can be used to insulate the floor (methods for insulating a frame house are described in detail in our article). You just need to remember that they must be light, since the structure does not have the ability to rest on the ground. Therefore, such a fairly weighty material as expanded clay cannot be used in this case.

We invite you to familiarize yourself with the Board for the ceiling in a wooden house

But what is possible? We hope that the next chapter will help in choosing the right insulation.

Variety of materials These materials include:

- Mineral wool (GOST 4640-2011), produced either from the melt of gabbro-basalt rocks, or from volcanic or metallurgical slag. The advantage of these wools is not only the thermal conductivity coefficient required for this design, but also its almost absolute non-flammability. According to the standard, the temperature limit for them ranges from -180 to 700 degrees (read the article about insulating a frame house with mineral wool).

Basalt slab

Cutting mat made of slag wool

Glass wool in roll

- Foam plastics (GOST 15588-2014). This term may hide slabs made of foamed plastics, two types of which are actively used in construction. One is polystyrene and the other is polyurethane. The latter is also molded into slabs, but due to the higher price in this form it is less popular among the people. If it is used, it is often in the form of foam, but expanded polystyrene is in great demand. PPS slabs come in three types: the cheapest type “P”, which is cut from one large block and has a pronounced grain structure, and “T”, formed by pneumatic, vacuum or combined methods. Both options may contain graphite, which is added to improve thermal insulation characteristics.

Eps with graphite

Extruded polystyrene, type "T"

Polystyrene type "P"

Note: Polystyrene boards may have a quarter molded edge. But here this is not required, since the slabs are not joined to each other, but are laid between the logs. Therefore, to insulate the floor inside the frame, you need to take the option with a regular rectangular edge. The sizes of these slabs are different, as are the variations in thickness.

- Ecowool (GOST 16381-77). This term is usually used to refer to cellulose insulation containing fire retardant and biocidal additives, but according to the standard, the type of ecowool raw material used may differ. That is, they can be made not only from inorganic substances, but also from organics or a combination of both. So you shouldn’t rely on the absolute environmental friendliness of this material, which is so promoted by its sellers. However, it is quite suitable for floor insulation, especially if it is not loose wool, which can lose volume, but slabs or mats.

We invite you to familiarize yourself with Sagus wood bleach instructions for use

Ecowool board

How to make a floor in a bathhouse on stilts: from the foundation to insulation – Russian Bath

Floors in a bathhouse must have several significant functions that justify their difference from the “residential” standard. In addition to the fact that they must guarantee safe movement in conditions of constant humidity, it is also necessary to provide methods for draining water from the surface. A properly constructed surface will not succumb to rotting and premature wear.

Before starting construction, it is advisable to familiarize yourself with the different technologies and their specifics. After this, you can safely choose the most acceptable option.

But for the majority of those who want to start arranging a bathhouse with their own hands, it will be enough to gain general knowledge about the principles of constructing floors on a columnar foundation.

Diagram of a concrete floor with ventilation in a bathhouse

https://www.youtube.com/watch?v=

When starting to build your own bathhouse, you must initially consider the type of water drainage and decide on the choice of material for the floor.

In most cases, the floor is concreted or a covering of boards is laid on joists. A concrete foundation requires significant labor costs, finances and a lot of time.

However, its service life can last up to half a century.

A simpler and cheaper option is to install lumber floors. It's not difficult to do. There is enough video and photo materials on this topic on our website.

Wooden structures, based on the type of water drainage and the associated complexity of the device, are divided into leaking and “non-leaking” types.

This type of flooring is relatively easy to install and quite cheap. This is a regular flooring where gaps are left between the boards to allow water to drain to the ground.

In this case, no additional sewer “delights” are provided, except for the drainage pit located under the floor.

Insulation is not provided, so this type of bathhouse is built on summer cottages in the southern regions.

An example of a wooden dry floor frame with a slope for water drainage

This system of floors resting on a foundation or standing on stilts has its own difficulties. Here you need to install two rows of boards. For the top flooring that goes over the logs, a tongue-and-groove pine or larch board is used, which is installed without gaps.

Below there must be subfloors. This is a so-called “dry” floor; it is advisable to install it in a steam room and here it is necessary to insulate the space between the boards. It is advisable to place the floorboards on the finishing floor with a slight slope towards the wastewater collection.

At the lowest point you need to make a hole to which a siphon is connected to drain the waste.

Floor on stilts

All elements of the wooden frame must be treated with impregnations or bitumen mastic

If, according to the design, the bathhouse stands on a screw or concrete foundation and is raised above the ground, then the technological process of laying the boards changes.

The floor also needs to be insulated according to a different scheme. The same requirements apply to structures on piles.

First, beams are laid on the upper part of the bathhouse's columnar or pile foundation, and then the “skull” beam, on which the subfloor boards are laid.

The gaps between the beams are filled with expanded clay, and if a continuous surface is provided, then with mineral wool. Then a vapor barrier (glassine) is laid, and then the logs. Insulation is placed in the gaps between the joists. You can do the finishing step with your own hands - lay the boards. The video information in this article will help anyone who builds with their own hands to understand all the intricacies.

- The construction of the foundation on piles increases the strength of the entire structure;

- The ability to build baths on “soft” soils that tend to move;

- Reducing construction costs;

- Noticeable reduction in time spent on construction;

- Increasing the bearing capacity of the foundation.

Concrete floors

An example of a concrete floor in a bathhouse with a drain

The installation of concrete floors is carried out in several stages. The design is a kind of cake consisting of many layers:

- Compacted base on the ground;

- The first layer of concrete, at least 5 cm thick;

- Expanded clay and felt as insulation when pouring frames;

- A layer of concrete reinforced with mesh;

- Leveling finishing layer;

- Final coating.

Compact the soil and lay a reinforcing layer of gravel and crushed stone on top, and pour each layer with a slope in the direction of the drain hole. As a result, a properly laid base should have a slope of at least 10º. But the main thing you need to pay attention to when arranging concrete floors is a more powerful base for the stove.

When constructing a floor in a steam room using a non-leakage type, the installation of the logs should be perpendicular to the water drainage

One of the main structural elements of a wooden floor is strong logs, which can rest on timber when using the columnar foundation method. But you need to remember that all contact points must be carefully insulated using roofing felt with an intermediate coating of preheated bitumen. If the floor is installed on stilts, then it is advisable to use an insulating material with more effective properties.

After attaching the logs, boards treated with special anti-rotting compounds are laid on them. If a leaky floor is to be installed, a gap of 3-4 mm is required between the boards for ventilation and water drainage. And along the perimeter of the area there is a technological gap of 2 centimeters.

We suggest you familiarize yourself with How to insulate a pipe in a bathhouse: how to wrap and secure a metal chimney pipe, insulation from the ceiling, how to do it in a sauna, what to wrap or cover with, photos and videos

The main enemy of a bath is high humidity, constant evaporation and dampness. And here you can’t do without waterproofing. But the materials will still need to be treated with appropriate antiseptic compounds. Otherwise, mold and mildew can destroy wood and even concrete foundations.

During construction, all elements are necessarily impregnated with antiseptics, which are sold in abundance in construction stores. And here the main thing is not to be lazy and carry out the processing several times. In addition, it will not be possible to insulate a bathhouse without using waterproofing. These measures will increase the service life of all elements and extend the life of the structure as a whole.

Schemes for installing different types of floors in a sauna

If, for some reason, these measures were not taken during construction, then it is necessary to perform a number of fairly simple procedures that will avoid the destruction of the wooden components of the floor and walls.

It is advisable to cover the boards with wax or varnish with water-repellent properties after finishing the work.

The described schemes introduce the developer only in general terms to the methods of arranging floors in a bathhouse. This is just a general recommendation. You can learn more about the construction process by watching videos and photos on our website.

Loading…

The choice in favor of a pile foundation when building baths is made on difficult terrain with soft soils. It also often happens that baths are built on the banks of various bodies of water.

Then it is necessary to organize the foundation structure in such a way as to be able to select the desired level for large differences in height.

The load-bearing beams installed on the piles are the basis for the construction of the frame. They also influence the design of the floors in the bathhouse.

If you have a bathhouse on a columnar foundation, you will learn how to make a floor below from this article.

Floors in bathhouses on screw piles are conventionally divided into two types, depending on the consistency of use:

- leaking type, used for non-permanent (seasonal) use;

- non-leakage type, designed for use of the premises all year round.

As a rule, to create a floor in a bathhouse, a project is developed with calculations of all elements and dimensions. A water drainage system is immediately thought out, a cesspool is constructed, and sewer pipes are laid to the place where the foundation is laid.

Floor construction

Installation varies depending on which type you belong to.

Spilling floors

If you decide to make a floor in a bathhouse on screw piles, it will not require a significant financial investment, it is easy to install and lightweight in design.

However, preparation for this type of coating begins when marking the perimeter of the future bathhouse and screwing in the foundation piles. A pouring floor in a bathhouse on stilts involves the flow of streams and drops of water falling down through the floor covering.

Previously, most bathhouses and shower cabins were built this way, where water flowed through the boards in the floor directly onto the ground, but the eternal problem was excessive floor moisture and a constantly damp floor.

To do this, a pit up to 700 mm deep is dug in the middle of the bathhouse area, to which slopes with a gradually increasing level approach from the edges.

Such a wastewater receiver is covered with a layer of fine crushed stone and filled with a layer of screed.

From the pit to the cesspool, or the place designated for drainage, a pipe runs that drains water. Sometimes, instead of this design, special plastic pallets are used that perform a similar function.

Floor boards are laid directly on the joists, with the most common option being to create floor boards with load-bearing boards running along the joists. The technical gap between the boards is 3 mm, between the floor boards and the perimeter of the bathhouse - 2 cm. This design allows you to periodically remove the floor covering and dry it.