No. 1. Types of electric heated floors

Electric heated floors can be used in any room, even on the balcony . With it, you definitely don’t have to worry about flooding your neighbors, and you don’t have to coordinate any documentation. Moreover, electric heated floors are more durable than water heated floors and are easier to install . Underfloor heating systems allow a more even and efficient distribution of heat in the room compared to conventional radiator heating. Moreover, you can turn on the heating even when the heating season has not yet begun, and the apartment is already quite cool. Typically, a heated floor is used as an additional source of heat , but in some cases it can take on the main role and become an independent heating method .

The choice of a specific underfloor heating system will depend on many factors. This is the type of flooring, type of room, heating requirements, budget, as well as the role assigned to the heated floor (main or additional source of heat). Luckily there is plenty to choose from.

According to the type of system, electric heated floors are divided into the following types:

- cable _ Its basis is a heating cable that converts electrical energy into heat. Such an electric heated floor can be either an additional or the main source of heat. It is laid under tiles, porcelain stoneware and stone floors. Heating cables from Rehau have become widespread;

- film _ Its basis is a film that carries out heating according to the infrared principle, i.e. The objects heat up first, and then the air. It is easier to install the film, it takes up a minimum of room height, and can be laid under laminate, carpet, linoleum, or parquet boards;

- core the floor works in the same way as film, according to the infrared principle, but has a more reliable structure. The basis here is more or less rigid emitter-rods, which are connected by two parallel conductors. I have not found widespread use yet.

According to the heating principle, electric heated floors are:

- convection _ These are cable floors (heating cable and heating mat). Heating of the room is carried out according to the principle of convection, i.e. the cable first heats the screed and floor covering, the latter warms the air in the room. Warm air rises, cools and returns down. The cycle repeats. The room warms up evenly, and the floor temperature will always be slightly higher than the air temperature;

- infrared. These are films and carbon rods that heat the floor covering, interior items and people. Then the air warms up from the heated objects. In this case, the heating rate is higher, and the loss of valuable energy is lower. Savings on electricity can reach 60% (when compared with convection systems).

According to the type of installation, electric heated floors are:

- installation in screed or tile adhesive . This is how cable and rod floors are installed. Installation is possible during a major overhaul;

- installation without screed , under the floor covering. This is how film IR floors are installed. Installation is possible during cosmetic repairs.

Differences between the two categories

- Firstly, these are two different systems in terms of structural content. Water pipes are pipes with hot water flowing inside them. Electrical – this is cabling.

- Secondly, energy carriers are different.

- Thirdly, various installation methods.

- Fourthly, water heated flooring is usually installed in private houses; it is not recommended to install it in city apartments. The electrical system can be installed anywhere.

As you can see, the differences are striking, so there is no need to choose between them. You just need to decide for yourself what is convenient and profitable. For example, if you are the owner of a private house where a water heating system is installed with the installation of a heating boiler and radiators, then you should consider installing water heated floors in some rooms. Otherwise, it is better to opt for electric heating elements.

What is the difference between water and electric heated floors?

That is, the question of which warm floor is better to choose can be classified as rhetorical. In this regard, another question can be formulated, which concerns the electrical system. The thing is that in this category there are several positions that differ from each other in technical characteristics, which the majority of consumers may not know about. Therefore, it makes sense to understand electric heated floors.

No. 2. Cable heated floor

Cable flooring is valued for its versatility and reliability. For its arrangement, single-core and two-core cables are used:

- single-core is cheaper, but more difficult to install, since both ends must be connected to the thermostat. Another disadvantage is the formation of a strong electromagnetic field. As a rule, such a cable is used in garages, warehouses and similar premises;

- A two-core cable is more expensive, but creates a minimal electromagnetic field (at the TV level), and it is easier to install. For apartments this is the cable they choose.

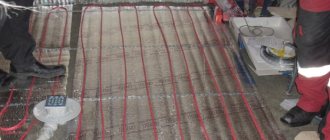

The cable thickness is 5-7 mm , it is sold in coils, usually laid a snake pattern . The final power of the system depends on the installation step. Installing a cable floor is not very easy, but the cable itself is inexpensive. The cable floor is laid on a layer of thermal insulation (extruded polystyrene foam or polyethylene foam) to prevent heat loss. The cable is not laid on the insulation itself - there must be an intermediate screed between them. Mount the cable in a screed 3-5 cm thick , which must be taken into account when calculating the height of the room after renovation. Thermal insulation must be selected so as to prevent overheating of the system.

The cable is connected to a thermostat , with which you can control the heating of the room and set comfortable conditions. There are systems with two sensors: the second is necessary to control the level of heating of the floor surface, this is important for wooden coverings. If heating is installed in several rooms, then each has its own thermostat, since heat losses are different everywhere, and household heat requirements may differ.

Recently, a cable with a thickness of 2-2.5 mm has appeared, which allows you to reduce the height of the tie. The height of progress is structures that accumulate heat. They work and accumulate heat during periods when electricity is cheaper, and then release the heat.

Main advantages:

- versatility. It is best to lay the cable under tiles, porcelain stoneware, stone and self-leveling flooring , but some experts allow installation under laminate, linoleum, parquet boards and carpet, however, in these cases the heat transfer will be lower due to the low thermal conductivity of the materials;

- resistance to deformation and damage;

- relatively low cost;

- Possibility of installation in rooms of complex configuration;

- can be used as the main source of heat;

- ability to accumulate heat.

Minuses:

- the screed “steals” useful space;

- complexity of installation. Screeding is a labor-intensive process, and laying a cable floor requires skill (calculating pitch, marking, fastening);

- inability to use heated floors for the first 30 days;

- After turning on the heating, you will have to wait about 3 hours for the room to warm up.

Features of “water heated floor”

One of the important components of this system are pipes made of polypropylene or metal-plastic. Heating of the room occurs due to heat transfer from hot water. The water is heated in the boiler and driven by a circulation pump through pipes (circuits). The boiler can be gas, electric or alternative.

Regulates the temperature in a circuit or multiple circuits of the manifold. If the temperature in the room has not reached the set temperature, the thermostatic valves open, allowing coolant to enter the system. If the floor temperature becomes high, the valves block the access of water, and the pump also turns off.

The installation of a “warm water floor” system is prohibited in apartment buildings due to a number of reasons:

Due to the danger of leakage. If water is supplied from central heating for a “warm water floor” system, then, after passing through it, it cools and returns back cooled. The neighbors' apartment becomes poorly heated. The heat balance between apartments is disrupted, the pressure in the pipes decreases;- The very installation of this system in houses with central heating is considered illegal. According to the housing code, it is prohibited to make changes to the central heating system;

A water heated floor requires a hot water supply. If it is not there, the system does not work. And in apartment buildings there are interruptions in hot water;- You cannot use the “water heated floor” system in cases where the heating season in an apartment building has not yet begun or has already ended. In this case, the system will also not function.

“Water heated floor” fits perfectly into the heating of a private house. This system is budget-friendly because water acts as a coolant. Its cost is low.

No. 3. Heating mat (thermomat)

In fact, this is the same cable as in the previous version, only the manufacturer has already attached it to the mesh for you, freeing you from one of the most complex installation processes. The thermomat is a thin electrical cable attached to a fiberglass mesh.

Installation of heating mats can be carried out on a ready-made screed . Thermal mats are sold in rolls about 50 cm wide and 20-24 m long. The cable is already laid at a certain pitch, the power is indicated by the manufacturer (usually 100-150 W/m2 , less common 200 W/m2 ), so there’s nothing to calculate you will have to, as well as mark the location of the cable on the floor. It is enough to roll out the mats on the floor (avoiding areas where massive furniture will stand), cut the mesh in some places (but do not cut the cable - it is simply unrolled, as in the figure below), fix the mesh and apply a minimal tie. You can do without a screed by using tile adhesive, onto which the tiles are ultimately laid. This way you don’t lose any height at all and secure the mesh.

pros:

- very simple installation;

- the small thickness of the mat (3-4 mm) and the ability to do without a screed will allow you to maintain the height of the room;

- heating speed, within 30-40 minutes after switching on the set temperature will be reached;

- possibility of installation during cosmetic repairs;

- installation can be carried out in any shaped premises;

- The service life of thermomats is up to 15-20 years.

Minuses:

- The thermomat is more expensive than the cable;

- heating mats are lower in power than cables, so they can only be used as additional heating;

- if the installation was carried out in tile adhesive, then it will not be possible to turn on the heated floor for 7-10 days, if in a screed - 21-30 days.

Thermal mats are chosen when there are no plans to carry out major repairs, and/or when it is necessary to maintain the height.

Types of warm electric floors by type of system, heating and installation

According to the type of system, they are distinguished:

- Cable floor. The cable is the main component that converts electricity into heat. The system is suitable as additional or main heating. Installed with tile floors, stone floors, porcelain tiles.

- Film floor. It is based on a film that heats the room according to the infrared principle: first - objects, then - air. A strong feature is the ease of installation and small size of the structure. This warm floor is suitable for laminate, parquet, linoleum, carpet.

- Rod floor. The system operates on the infrared principle, but has a more reliable structure than a film floor. The design uses rod emitters that are connected by parallel conductors. Not a very common solution.

Based on the type of heating, there are two types of systems:

- Convection. It consists of a heating cable and a mat, it works according to the convection type. Heating occurs in the sequence - screed, floor covering, air. Then the heated air rises, cools and returns down, and this happens in a circle. The room is heated evenly, and the floor temperature is higher than the air temperature.

- Infrared. The structure consists of films and carbon rods. The floor covering is heated first, then objects and people, and then the air. The advantage of the system is a slightly higher heating rate with little loss of valuable energy. Compared to convection floors, up to 60% energy savings are achieved.

Based on the type of installation, the following types of floors are distinguished:

- Screed, tiled floor. Suitable for cable, rod floors, created during major renovations.

- No screed. Installation is carried out under the floor covering during cosmetic repairs. The method is suitable for film and infrared floors.

Cable heated floor

Creation is carried out using single-core and double-core cables with a thickness of 5-7 mm. With their help, a snake is formed with a certain step. The pitch affects the power of the system.

To prevent heat loss, installation is carried out on a thermal insulation layer and an intermediate screed. The height of the tie depends on the thickness of the cable. To control the heating of the room, a thermostat is connected.

Heating mat

The system is a cable floor, which is placed on a grid, which makes installation easier. The heating mat has a certain pitch and power. In most cases it is 100-150 W/m2, sometimes 200 W/m2.

Installation of the floor is possible not only with a screed, but also without it - with tile adhesive, followed by laying tiles. Thermomats are a good solution if major renovations are not planned and you need to maintain the floor level in the room.

Film floor

IR film flooring operates by converting electrical energy into infrared radiation, that is, first the objects are heated, then the air from the objects is heated. The heating principle is considered the “healthiest”, as it functions like the sun’s rays. In some cases, the system is installed on walls.

IR film consists of polyester layers with copper conductors and carbon strips. The film thickness is only 0.4 mm, width – 50-100 cm, length – 50 cm. Cutting lines are provided to facilitate work.

The film is laid on a flat base under parquet, laminate, carpet, linoleum. Contact clips are used for connection. In some cases, a layer of plywood or fiberboard is additionally mounted on top of the film.

Rod floor

The operating principle is approximately the same as the film analogue, but the design consists of parallel flexible rods, which gives the system increased strength and reliability. Installation is possible in a screed, tiled floor. The power range of the rods is 130-160 W/m2.

No. 4. Film infrared heated floor

Film IR floor is a flat heating element that converts electricity into infrared radiation. It works on the principle of solar rays : it heats objects, but not the air. IR radiation travels in a straight line, heating objects in its path (furniture, people, flooring). The presence of an intermediary, air, is excluded, but it also warms up over time from heated objects. This type of heating is considered the most comfortable and healthy for humans.

IR film consists of two dense polyester layers, between which there are copper conductive bars and strips of carbon paste. The thickness of the film is only 0.4 mm, the width of the roll is from 50 to 100 cm, the length is up to 50 cm. The film is laid on a clean, level base directly under the floor covering. The roll has cutting lines, so it is easy to install the film in a room of any configuration. The segments are connected to each other using contact clips. When laying, 5-15 cm are removed from the walls, and 30 cm from radiators. The film is not placed under massive pieces of furniture.

Filling with screed or tile adhesive is not carried out - the film is easy to damage. The floor covering (laminate, parquet) is laid directly on top of the heated floor . When laying under linoleum and carpet, it is better to lay an additional layer of fiberboard or plywood. The film is sometimes mounted on walls.

The film can be continuous or segmented . The last option is more common. Segmented film can be striped, wavy, in the form of a honeycomb, and even with perforation (used for laying in screed, it has good adhesion to concrete and higher power). Continuous film appeared later; it can withstand more severe loads and is used for installation in gyms and shops. Moreover, continuous film can be covered with furniture - it can self-regulate, and rearrangement of furniture is not a problem for it. Some manufacturers produce special film for installation in infrared saunas.

pros:

- instant heating;

- high efficiency and economy, thermal energy losses are minimal;

- simplicity and speed of installation;

- a thin film will help maintain the height of the room;

- maintainability. If any part of the film is damaged, it can be removed and replaced. If one element is damaged, the others continue to work;

- The service life of film heated floors is up to 20 years;

- the air does not dry out;

- You can turn on the heating immediately after installation.

Minuses:

- thermostats and temperature sensors are often the first to fail, after 5-7 years of operation, so you will have to change them;

- installation of heavy furniture and household appliances can damage the IR film;

- for proper installation of the film and its long-term operation, the base must be perfectly flat;

- price.

Film infrared flooring is laid under laminate, parquet, carpet and linoleum . Many manufacturers do not recommend installing it under ceramic tiles. If this is not prohibited by the manufacturer, then get ready for complex installation using special waterproofing materials. In this case, it is more convenient to use a cable floor.

The power is 130-230 W/m2, so the room will warm up effectively. Such heated floors can be used as the main and additional source of heat. To be used as primary heating, the film must cover 70% of the floor area. If you cannot meet the conditions, then take a more powerful film (more than 220 W/m2) for rooms where it covers less than 60% of the floor.

Infrared flooring system: advantages and operating principle

Infrared heated floors are a modern and most effective way to heat houses and apartments, in addition to the main heating systems. Due to its parameters, economic benefits and installation method, it is becoming widely popular and pushing aside traditional analogues.

The functionality of the heaters is based on the radiation of infrared waves, invisible to the eye and completely safe for the health of people and pets. The wave spectrum occurs when equipment elements are gradually heated after being connected to the network. In contact with furniture and other surfaces, infrared rays first heat them, then distribute the resulting heat evenly into the atmosphere of the room. This operating principle allows you to feel a comfortable temperature much faster while the air inside the room warms up.

It is impossible to talk about the absolute advantages of IR floors in comparison with other underfloor heating systems, however, their advantages are impressive:

- Arbitrary placement of heating elements.

You can heat only the necessary areas: rest areas or the most ventilated rooms. This approach saves energy and makes it possible to rationally use the material. If necessary, the device can be disassembled and moved to another location.

- Possibility to carry out installation yourself under any type of surface.

To install the heat source in question, you do not need to create a concrete screed and be limited by the choice of the final floor surface.

- Economically profitable.

The complete set (thermostat, temperature sensor, wiring, IR film, substrate) costs significantly less than other floor heating systems.

- Frost-resistant and versatile.

The heating element will not fail if left unused for a long time during periods of cold and frost, so the floors in question are perfect for a wooden house or cottage.

- Uniform heating throughout the entire height of the room without dehumidification.

Thanks to the action of wave radiation, warmth is felt immediately after turning on the system.

Types of infrared heaters

The entire range of infrared floor heating is divided into two types: rod and film.

The rod type of equipment received its name due to the shape of the structure itself - the rod. IR rods contain materials made of silver, carbon and graphite and are used to connect insulated copper wires. Thanks to this composition, the heating system produces a self-regulating effect. The disadvantage of this type of floor is that the heating elements are connected in parallel: if at least one of them is damaged, the entire equipment will stop functioning. There must be a flat surface under the core floor. The main heating mats are placed from the walls at a distance of 15-20 cm. When laying out, do not allow the wires to intertwine or tangle.

Film types of IR floors are rolls consisting of carbon paste and tightly sealed polypropylene film. Along the edges of the roll, section by section, there are silver and copper strips (tires), through which electric current is conducted. When the current reaches the carbon, heat begins to form. The advantage of a film floor is the location of the heating elements in sections. Each department is completely independent in operation and can be easily removed. The latter makes it possible to position the equipment in any convenient direction for different finishing coatings.

Buying an IR system: tips for choosing

Having decided to acquire an additional heat source, study the information on what to look for when purchasing the appropriate equipment. The manufacturer and popularity of the models play a significant role in choosing a product, but other criteria also need to show interest:

- power;

This parameter directly determines which floor covering the system can be used with. Typically the power ranges from 130-450 W/m2. For light finishing surfaces (linoleum, carpet) 160 W/m2 is enough, for tiles or porcelain stoneware - up to 220 W/m2, higher power is for industrial conditions and infrared saunas.

- thickness of polymer or carbon layers;

The minimum thickness is 0.3 mm, often used is 0.338 mm. Anything thicker is more durable and resistant to external influences, but it takes away the height of the room.

- roll width;

The material is produced in rolls from 50 to 100 cm. They are installed so that they are as close to each other as possible. From this rule, as well as the parameters and features of the room, the appropriate width is selected. This minimizes costs and ensures quick installation during renovations.

- appearance of stripes;

Silver and copper strips or busbars must not have any damage, gaps or signs of oxidation. The width of strips made of copper alloys should be at least 13-15 mm; otherwise, the quality of the floors is worse. Silver tires can be 1.5-2 mm wider.

- the presence of an anti-spark grid;

In this case, it is enough to look at the location of the mesh of silver strips: it should be on the border of the carbon layer and the copper busbar. Adding silver to carbon over time leads to sparking and a decrease in heating power.

- laminated spaces;

When laminating, the space between the carbon strips should be cloudy in color. With adhesive production technology – transparent. After some time, the adhesive strips become brittle, which affects their service life.

- heating rate.

A high-quality infrared floor system heats up in 5-10 seconds.

No. 5. Rod infrared floor

This type of floor also works on the principle of emitting infrared rays, but instead of film, parallel rods are used. The rods are flexible, but they are much stronger than the fragile IR film, making the system more reliable. The rods are laid in screed or tile adhesive. The power of carbon rods reaches 130-160 W/m2. The roll width is 83 cm, the length is up to 20 m, and the pitch between the rods is 9-10 cm.

Advantages:

- economy, efficiency and high heating rate, like IR film;

- simple installation;

- you can place heavy furniture without fear;

- reliability;

- versatility. This warm floor is compatible with all known floor coverings;

- regulation of heat generated. When overheated, the rods simply stop producing IR rays, so there is no need to worry about rearrangements. True, for self-regulation to be realized, it is imperative to immerse the rods in a 3 cm thick screed.

Minuses:

- high price;

- complaints about the durability of carbon rods. Burning often occurs at the junction of the rod and conductor.

The best heated floors in the form of heating mats

Such equipment has a similar principle of operation to cable equipment, but here the heating element is already laid on a lattice base, which greatly simplifies installation.

The master just has to spread the mat in the right place and cover it with the floor covering allowed according to the instructions.

Devimat DTIR-150, 450 W, 3 m2 - for loggia

This is the best heated mat floor for a loggia, because its width allows you to cover a long area of up to 6 m with a width of 500 mm. The cable is laid on a foil base and attached to a mesh, which simplifies unfolding.

The power of 450 W is optimal for maintaining a comfortable temperature on the balcony. The kit includes a wire for connection, a coupling and corrugated protection. The thickness of 5 mm does not require a large layer of mounting adhesive.

Pros:

- cold end 4 m long for connection;

- Teflon internal insulation;

- aluminum foil for screening;

- heating to a temperature of 90 degrees;

- certified by all GOST, CE standards;

- installation in tile adhesive is simpler;

- There are two cores inside for greater efficiency;

- Suitable for tiles, porcelain stoneware, parquet boards, carpet.

Minuses:

- cost from 7000 rubles;

- It is more difficult to cut the mat for separate placement according to the area.

Equation 1260 W, 9 m2 - for the children's room

This is the best heated floor for arranging a children's room due to the power of 1260 W, which allows you to use the mat as the main heating and will prevent children from catching a cold from playing on the floor.

The cable is supplied in a green insulating sheath on a white mesh with a cold lead for connection and corrugated protection. It can heat up to 9 m2, which corresponds to most children's bedrooms.

Pros:

- two cores for increased heat transfer;

- weight 3 kg;

- power supply from a household network 220 V;

- laying without screed in tile adhesive;

- covers 9 m2 at once;

- suitable for interaction with programmable thermostats;

- can be laid under parquet boards, laminate, linoleum, porcelain stoneware.

Minuses:

- cost from 10,500 rubles;

- You need a good thermostat that clearly monitors the duration of switching on so that the increased heating power does not lead to a fire.

No. 6. Heated floor power

Regardless of what type of heated floor is chosen, it is necessary to determine the required heating power, which depends on a lot of factors :

- climate of the region, orientation of the room to the cardinal points;

- material of walls, roofing and ceilings;

- quality of thermal insulation. If the apartment is poorly insulated, then, in principle, there is no point in installing heated floors;

- type and purpose of the room, desired heating temperature;

- The function of underfloor heating is main or additional heating.

Specialists who provide comprehensive services for the installation of underfloor heating can accurately calculate the required power. This is a complex task that requires taking into account many factors. You can try to perform the calculation yourself using special programs and calculators, which are full on the Internet: you just need to enter the initial data, and everything will be calculated automatically. If you are too lazy to do this, or you want to roughly estimate the required power, then use the average parameters (for central Russia, in conditions of high-quality insulation and double-glazed windows):

- if the floor will be used for main heating – 150-200 W/m2;

- on loggias – 130-180 W/m2, maximum 200 W/m2;

- for wooden floors – 60-80 W/m2;

- apartments on the first floors or above an unheated room - 130-180 W/m2, maximum 200 W/m2;

- in bathrooms - 130-140 W/m2, maximum 200 W/m2;

- in kitchens, living rooms - 100-150 W/m2, maximum 170 W/m2.

Warm electric floor

You can create a floor heating system in any room as additional or main heating.

When choosing a design, it is worth considering the following points:

- features of the flooring;

- features of the premises;

- heating level requirements;

- purpose (main, additional heat source);

- estimated budget.

Modern electric floor heating is a durable and relatively easy-to-install system. No special permits are required for its installation. Unlike radiator-type heating, heat distribution is uniform.

No. 7. Thermal insulation of heated floors

If you do not use a layer of thermal insulation, then the heat risks going not only to the apartment, but also to heating the powerful interfloor ceilings and walls of the house. Not only will it be colder in the apartment, but you will pay for heating the floors out of your own pocket.

Thermal insulation is strictly necessary:

- IR film requires reflective insulation;

- Mineral slabs or extruded foam are placed under the cable floor.

The thickness of the thermal insulation layer depends on the characteristics of the room. If there is a heated room below, then a layer of up to 20 mm is enough; if below there is a basement, or the insulation takes place on the balcony, then it is better to use a layer of 35-40 mm.

Water floor rating

Water heated floors are in great demand. This system is mounted under the tile and operates from a boiler with a pump. Let's consider the rating of the best materials that are used for laying water floors:

Pipe, corrugated 15A, annealed, allows you to install a heated floor over a long period. At the same time, the guarantee for these pipes is quite long; they can be safely poured under concrete and not worry that there will be a leak.

Such a pipe can be bought in coils, one containing 100 or 200 meters, it all depends on the size of the room. This material can withstand heavy loads. It has high thermal conductivity and is absolutely safe in all respects.

The cost of corrugated pipe is affordable. The only drawback is installation; it may require a large number of couplings for connection.

Neptun IWS PE-Ha pipe is the most economical material suitable for heated floors in an apartment. The cost of one bay of 100 meters is not high.

The pipe is of high quality due to the fact that it is sewn from polyethylene and equipped with an additional special layer that acts as a barrier against the flow of oxygen. Due to good flexibility, there are no problems with installation; the bending radius is 80 mm.

In this case, pressing will be necessary, in addition, a layer of concrete must be at least 30 mm on top of the pipe in order to completely level the surface and make the heated floor even.

No. 8. So which electric heated floor is better to choose?

No one will give a definite answer to this question. It all depends on these basic factors:

- type of flooring. If you are going to lay ceramic tiles, porcelain tiles, stone, self-leveling floors, then feel free to choose cable heated floors. If you are ready to spend money for the sake of convenience, use a cable floor on ready-made mats. It is better to install IR film under laminate, parquet boards, linoleum and carpet;

- room height . If the room is high, and the fact that it is reduced by 8-10 cm will not upset you, then you can install a cable floor (layer of insulation + cable + screed + finishing material = 8-10 cm). If such a solution causes inconvenience or makes a low room even lower, then opt for thermomats (loss in height up to 5 cm) or IR film (up to 2 cm);

- humidity . For the bathroom and toilet (and other wet rooms) where tiles will be laid, it is better to choose cable flooring or thermomats. Of course, modern waterproofing materials are almost perfect and allow you to use any heated floor in wet rooms, but why unnecessary waste and risk;

- question price . The cheapest is considered to be a regular cable (by the way, it still remains the most popular), but to the final cost it is worth adding the price of materials for the screed, as well as payment to specialists, since the process is quite labor-intensive and complex. The thermomat costs 25-30% more than a regular cable, but you can save on installation. The film is the most expensive, but it is easy to install and consumes a minimum of energy, quickly paying for itself. The rod floor is still the most expensive and unprofitable;

- power consumption . IR film will be the most economical, followed by a regular cable, and thermomats are considered the most expensive to operate. They consume 30% more electricity than cable. A concrete screed heated by a cable still generates heat for some time after the heating is turned off; IR technology does not have this;

- ease of installation . You can install thermomats and IR film yourself. A cable floor requires making a screed, calculating the cable turns and laying them correctly;

- maintainability . To repair a cable heated floor, you will have to break the screed! Mats and film benefit greatly in this case.

Please note that it is not recommended to install a heated floor system under thermal insulating coatings. This includes cork flooring and materials with a high wool content. The loss is small - such coatings are already comfortable to move and have a warm surface.

Types of electrical transformer substations

In specialized online stores and regular construction supermarkets you can buy 4 types of electric heaters for underfloor heating:

- resistive and self-regulating cables;

- cable mats;

- thin polymer film;

- carbon rods.

Reference. The products are sold as a ready-made set of fixed-power ETP. For automatic temperature control, a sensor with a corrugated tube and a room thermostat are purchased. You will also need a power cable with copper conductors to connect the heating circuit to the mains.

Each type of heater is used in certain conditions and differs in characteristics and installation method. Therefore, we will consider all options separately.

Features of heating cables

The flexible ETP conductor is made of the following materials (the device is shown in the diagram below):

- heating core (maybe 1 or 2);

- internal insulation made of heat-resistant plastic such as FEP, TXLP or PVC;

- shielding layer of aluminum foil or copper braid;

- outer shell made of PVC polyvinyl chloride;

- additional grounding conductor.

Note. The shield serves as a barrier to electromagnetic radiation emitted by any live electrical conductor.

A single-core cable (otherwise known as a heating section) ends with two connecting couplings - cold ends. The two-wire type is connected on one side, which greatly simplifies installation work.

The diagram does not conventionally show an additional grounding conductor - it is present in any cable product

A conventional resistive section is heated by its own resistance, selected based on a specific heat transfer of 100...150 W/m² of floor area. A self-regulating cable functions differently: a semiconductor matrix is embedded between 2 current-carrying cores, changing the resistance depending on the heating. The price of such products is appropriate - from 10 USD. e. per linear meter.

Features of cable heating sections:

- The conductor is afraid of overheating and requires heat removal over the entire surface; the critical temperature threshold is 90 °C. An exception is a self-regulating cable that can reduce heat transfer as the temperature rises.

- The finished circuit cannot be shortened and the end couplings must not be rearranged - the resistance of the section will drop and the temperature of the cores will increase. How long the internal insulation will last under extreme conditions is unknown.

- Heat transfer from 1 m² can be adjusted by decreasing or increasing the pitch of the conductors. But you need to understand that the heated area will also change, the optimal power is 100 W/m².

- Most cables are designed for “wet” installation - pouring cement-sand mortar 3 cm high above the outer sheath (minimum).

- The heating section cannot be laid on top of thermal insulation, like pipes for water heat exchangers. The material will begin to reflect the heat flow, and the cable will begin to overheat. Therefore, the base is made of concrete.

Note. There is an exception to every rule. Some brands, for example, Devi, make cable sections for “dry” installation - under laminate or parquet on wooden floors.

A single-core section must be connected with two cold ends, and a two-core section with only one.

Circuits made of heating cables work without problems in wet rooms - bathrooms, showers, kitchens. You just need to select a regulator with a high degree of protection, plus install an RCD in the apartment (operation current 30 mA), if there was no such device before.

Here is a list of proven brands that produce high-quality floor electric heaters:

- Devi (made Denmark - Poland);

- Nexans (France);

- Shtoller (Germany);

- Teplolux (Russia);

- Profitherm (Poland).

You can learn more about electric underfloor heating systems on the Heating-Systems website.

Cable mats

Heaters of this type are the same cable attached to a durable nylon mesh 0.5 m wide. There are a number of design differences:

- smaller diameter compared to resistive sections – 3…3.5 mm;

- fixed distance between loops;

- reinforced external insulation.

Laying mats with your own hands is easier than laying a classic cable. The heating elements are integrated directly under the tile; there is no need to pour screed on top. On the contrary, a thick monolithic layer will worsen the heat transfer from the heaters.

When you need to change the direction of the layout, the mat mesh is simply cut with scissors

Important point. The mesh between the loops of the wire can be cut to fan out the electrical cable or make a 180° turn and roll out the roll in a different direction.

Disadvantages of cable mats:

- the cost of electric heaters is higher compared to classic sections;

- you cannot customize the layout step to suit your needs;

- With the help of mats it will not be possible to organize full heating - there will not be enough specific power per 1 m².

Film heated floors

This type of TP is made on a base of ultra-thin (0.4 mm) polymer film. Heating carbon tracks are applied to the surface and then covered with a protective layer on top. Characteristics of film ETP:

- heat transfer from 1 square meter – 130...230 W depending on the type of product;

- Thermal film width – 50, 80, 100 cm;

- melting temperature of the base - 110...130 degrees;

- installation method - “dry” installation directly under the floor covering - linoleum, laminate, carpet, parquet board.

The design of a heating carbon film

Manufacturers call the film infrared because the carbon tracks emit radiant heat. Another question is how infrared radiation penetrates into the room through the carpet - this is physically impossible. But our task is not to destroy myths, but to objectively indicate the pros and cons of heaters.

Advantages of carbon film:

- The material is thin and very compact.

- The TP is installed easier than cables; you can install and connect the film yourself.

- Strips are allowed to be cut crosswise; the permissible pitch is indicated by the manufacturer.

- Acceptable price.

Among the disadvantages, it is worth noting the fear of overheating and a limited scope of application - you cannot lay infrared film under tile adhesive or screed. The reasons are poor adhesion to a smooth surface and interaction with cement mortar (consequences unknown).

Clarification. New types of self-regulating ETPs have appeared on sale, automatically reducing the heating intensity in the event of an increase in operating temperature. An example is CALEO PLATINUM film.

Schemes of the “pie” of warm film floors

And lastly: due to the fixed size, it is inconvenient to lay out the material in narrow rooms. Example: the width of the corridor is 1300 mm, and the width of the heater is 500, 800 and 1 m. You will have to cut the film into pieces and lead separate power wires to each.

Rod heaters

The design of the elements is as follows: carbon heating rods are attached to two parallel power lines. As a result, we get mats laid under screed or tiles, only with the function of self-regulation. Thanks to it, the ETP does not overheat.

The effectiveness of core floors compared to other options has not yet been confirmed. The manufacturer himself indicates conflicting technical parameters, which we present in the table:

Note. Please note: the heat output of 1 linear meter is declared at 116/138 W, and energy consumption is only 24 W per linear meter. Although it is well known that electric heaters produce 0.98 kW of heat, consuming 1 kW of energy.

According to user reviews, rod TPs are not very reliable. Individual elements burn out, the circuit continues to work, but areas of the floor become cold. Homeowners also report insufficient surface heating. The products are clearly unfinished.

Recommendations for selection

In the vast majority of cases, ETPs are purchased to heat bathrooms or bathrooms in apartments. It is not profitable to organize complete electric heating - unlike water systems, cable circuits cannot be connected to a gas boiler. Hence the advice: combine heaters with traditional radiator heating.

Which electric heated floor is better to choose depending on operating conditions:

- For comfortable heating of tiles in the bathroom, a resistive cable or mats are suitable. The second option is preferable; the costs are approximately the same.

- Cable sections should be placed under the screed - self-regulating or inexpensive resistive ones. If the ETP is responsible for heating the house, then the installation interval is selected based on 120-150 W/m².

- Lay the film under the covering in living rooms and corridors. Keep in mind that dry installation is cheaper to do yourself. If the heat generated is not enough, the rolled material can be mounted in ceilings and even walls, as the craftsmen in the photo do.

- Purchasing rod mats for pouring is a risky undertaking. If you really like these heaters, then choose products from serious manufacturers, for example, CALEO.

Together with the ETP, a thermostat is purchased that maintains the surface temperature and protects the circuit from burnout. To regulate a small area, any device is suitable - mechanical or electronic. It is more convenient to control the heating of 3-5 rooms using touch or programmable thermostats.

The origin of the thermostat does not matter; combining different manufacturers is quite acceptable.

No. 9. What else to consider when choosing a heated floor system?

To guarantee a good and durable heated electric floor, pay attention to the following nuances:

- thermostat can control temperature by air and floor. If the heated floor is the main source of heat, it is better to install air regulation in the room. In a children's room or bathroom, the floor temperature is important. There are dual regulators. It makes sense to use them for wooden floors;

- Along with the purchase of the heated floor, it is better to immediately purchase all the components ;

- heated floors must have certification and a guarantee . Also, the system must be accompanied by instructions indicating operating conditions and installation nuances;

- before purchasing, check the condition of the cables/film/rods, assess the integrity and compliance with the declared package;

- give preference to products from trusted manufacturers. Among the most reliable we note Rehau, Devi, Energy, Ensto, Eltherm, Caleo, Teplolux.

Rating of electrical cables

Electrolux ETC 2-17-1200 - the system is presented precisely by Scandinavian masters, where the need for heat is much higher than in European countries. This company combines safety and comfort at a high level. If you buy a kit, it is designed for 10 square meters.

Cable systems can last a long time, sometimes they can be installed on a permanent basis, especially since they are poured into concrete. If we talk about cost, then it can be considered the most expensive of all heated floors, but it completely pays for itself in a short period of time.

The manufacturer's warranty is 20 years, which is quite a lot.

Floor DEVIflex 18T (DTIP-18) - this company has long established itself as the best manufacturer of electric heating devices. Heat cables have been manufactured for quite a long time, so the company has established itself as one of the best.

This company was included in the rating of heated floors under tiles, which are of high quality and have a number of advantages, due to their efficiency. Despite the fact that the cable is expensive, it has high heat dissipation.

Warmstad WSS-1115 - heat cable presented by a domestic manufacturer. Many users fell in love with the fact that it is low cost and at the same time will not differ in quality from its Scandinavian counterpart.

The only drawback is that it is considered a fake, in which case the cable may burn out and break over time.

To avoid such problems, the heated floor should not be hidden under a thick layer of floor covering, so that if something happens it can be dismantled.

Thermo SVK-20 - the cable is best used for installation in a small room, as independent heating. In this case, we can talk about complete safety, since the cable is sealed and enclosed in a special sheath that is not subject to fire.

We recommend: How to calculate the power of a heated floor?

As for energy consumption, 1 kilowatt per hour is enough for this brand. The best part is that you can get a lifetime warranty from the manufacturers.

Which floor is best?

Many people choose thermal cables as a heated floor. Such a floor is laid under the fill and additionally they try to make gutters for the cable to prevent freezing. An alternative to cables are warm mats, which help make installation quickly and efficiently.

We recommend: How to install PERT pipes for heated floors?

But the cost of this material can be quite high and even in some cases unaffordable for large rooms. Among other things, we must remember that mats can sag over time, resulting in uneven floors.

Infrared film can cope with heating small rooms. It is easy to install and has low power.

Many people prefer water heated floors. Despite the fact that in addition to pipes it is necessary to use additional material, such as:

- pump;

- collector;

- heating devices.

This type of underfloor heating remains the most reliable option.