Hidden electrical wiring is the standard of safety and aesthetics. But there are times when you have to lay open wiring. The most striking example is wooden houses. Or if the renovation has already been completed, the walls have been finished, and it turns out that the wiring system does not meet the requirements. The best way to hide the electrical cable, protect it from external influences and preserve the aesthetics of the room is to use special cable channels. If previously these were only gray or white nondescript structures, today they can look like an ordinary baseboard and imitate the texture of wood. We figure out how to choose a cable channel for electrical wiring, determine the size, types and materials.

No. 1. Basic selection options

A cable channel is a special hollow structure with space for electrical wires. The product consists of a tray, which is installed on the surface of a wall, floor or ceiling, and a lid. There are boxes with a slightly different design, but this is the most common. Cable channels can also be used to lay telephone, Internet and television lines; they are often used to disguise air conditioner wires. In large offices, where it is necessary to provide each workplace with electricity, the Internet and a telephone line, cable channels are completely irreplaceable.

When it is not possible to hide wiring in the wall, a cable channel is a real salvation. The main advantages of such a solution are:

- protection of wiring from ultraviolet radiation and mechanical influences;

- increasing the fire safety of the premises, although many are ready to dispute this point, because the cable channel is a closed space, and the wires certainly heat up, i.e. the heat remains inside the structure, which means the risk of ignition is much higher than when laying the wire without protection. But it is also worth considering the fact that the cable channel is a sealed structure, there is almost no oxygen supply, so the fire will not be able to spread, and the ignition will go out. In addition, there are perforated channels, which, due to the influx of fresh air, cool heated cables;

- the ability to instantly replace the wire or lay a new branch. If the cable is in the wall, then any manipulation will lead to serious damage;

- the ability to lay several wires in one channel, incl. different types, such as wiring and telephone lines. For these purposes, there are special designs with internal partitions;

- quick installation of electrical wiring.

as a disadvantage , since a plastic channel running along the wall is unlikely to decorate the room, but everything is learned by comparison. A neat cable channel is clearly much better than a hanging bundle of wires. If we take into account the presence of numerous modifications of the channels, the wiring can be made almost invisible. There are products that are indistinguishable from ceiling or floor plinths, there are models painted to look like wood - there are a lot of options, however, such solutions with increased aesthetics are more expensive than the simplest products made of white plastic.

The disadvantages include the fact that the cable takes up a little space. Yes, often such a loss does not bring any inconvenience, but there are times when every centimeter counts. In addition, high-quality wiring using cable channels is only possible when using a large number of auxiliary elements, i.e. In addition to the channel itself, tees, corners, etc. will be needed. Please also take into account the fact that a protruding element on a wall or floor can easily get caught and damaged.

When choosing a cable channel for electrical wiring, consider the following factors:

- material of execution , which affects the level of durability, strength and fire resistance;

- design features . The cable channel can have a rectangular, angular or semicircular cross-section, it can be flexible or lattice - there are a lot of variations, each will be indispensable in a given situation, and we will consider each type further;

- features of the room where the wiring is being laid. For example, a channel for a wooden house must meet increased fire safety requirements, but for moving structures it is unacceptable to use stationary cable channels;

- appearance . Aesthetics are important for residential premises, so the color and shape of the cable play an important role;

- size . The more wires you need to hide, and the larger their cross-section, the larger the cable channel will be needed, but we will return to this later.

Criteria for selecting and purchasing cable channels.

Before choosing materials for future work, it is necessary to draw up a schematic plan that will give an idea of where and how the main box with outlet points to sockets and switches will go. According to this plan, we will have an idea of the cross-sectional size, the length of the large main box and the dimensions of the smaller cable channels for outlets. At the same time, it is necessary to take into account that during installation it will be necessary to lay additional wires immediately or later, and the cross-sectional dimensions of the boxes must be selected with some margin.

Considering that plastic boxes of a standard length of two meters are produced and sold (without cutting), then you need to buy with a margin of 15-20%; Some of the material may be damaged during the work. Moreover, knowing the frequency of changes in the assortment of goods in our stores, it may not be possible to purchase additional boxes with exactly the same parameters.

The color and texture, the appearance of the cable channel can be chosen at your own discretion, but it is worth remembering that white boxes have a wider choice than boxes with a wood texture. Companies such as Elekor and Legrand, which produce plastic boxes, also supply accessories for them - these are various kinds of corner transitions, plugs, tees, external and internal corners, joints. It is also advisable to select them to match the texture and color of the main product. This component of the purchase significantly affects the ease of installation and the appearance of the assembled structure.

When choosing a cable channel, you must especially take into account the quality of the product. What is of great importance here is not the rough execution of the ends, but the quality and tightness of the closure of the fastening locks.

Relatively inexpensive designs of plastic boxes (for example, the Elekor company) suffer from a similar drawback. The flanges of the lid are unable to lock into the grooves of the box and bounce off, and if you try to adjust it with a mallet, the box can burst from a light tap.

A high-quality cable channel design must close and open tightly by hand without the use of additional tools. The most annoying thing in this situation is that such shortcomings appear at the moment when it is necessary to close an already mounted box with wires loaded inside.

When choosing materials, you must also remember about special junction boxes used for external wiring of electrical networks. Their number should correspond to the number of wiring nodes, the color should correspond to the appearance of the box, and the number and size of holes should correspond to the number and size of wiring wires.

No. 2. Cable channel material

The most popular channels are plastic ones; metal ones are less commonly used. There are also ceramic cable ducts , but they are expensive and not very practical, so they are used quite rarely.

Plastic cable channel for electrical wiring

Due to their low cost and ease of installation, plastic channels have gained the greatest popularity. The products are made from PVC with the addition of special substances that increase the material's resistance to sunlight, fire and aggressive chemicals. As a rule, the channels have a U-shaped cross-section, but they can be triangular, in the form of a hemisphere, and also W-shaped, when there are partitions inside for several types of cables. Used for laying low-current and power lines in residential premises, offices and enterprises.

Advantages:

- low price;

- minimum weight;

- operation is possible in a wide temperature range, from -320C to +900C;

- fairly simple installation due to a simple fastening system and low weight;

- corrosion resistance;

- enough variety. Channels are available in various shapes and colors; you can choose a product that will be as similar as possible to a regular floor plinth and made to look like wood;

- the structure will require minimal maintenance;

- the material is easy to cut.

The plastic cable channel cover is installed as simply as possible - no additional tools are needed. The standard length of one section of a plastic channel is 2 m, width and height range from 10 to 60 cm, but other options may occur.

The plastic cable channel can be attached to the surface using self-tapping screws, metal staples or dowel nails. Permanent fastening involves gluing the channel to the wall, but it is also important to take into account the weight of the product. To make it possible to hide wiring of any complexity, in addition to straight channels, additional elements are produced, such as tees, corners and plugs. There are even separate elements for sockets and switches.

Despite their fairly high fire resistance and self-extinguishing ability, plastic cable ducts are not recommended for use in areas with increased fire hazard.

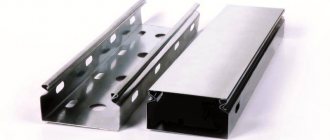

Metal cable channel for electrical wiring

Metal products can withstand increased loads, which is why they are used primarily in enterprises and not in residential premises. They are used for internal and external cable routing. The products are great when you need to hide an impressive bundle of wires.

Metal cable channels are made from:

- galvanized steel;

- anodized aluminum.

galvanized steel box has high mechanical and corrosion resistance and becomes protection against electromagnetic rays, therefore it is often used for laying cables for video surveillance and warning systems.

An anodized aluminum box also becomes a good barrier to electromagnetic rays; it is resistant to fire, mechanical stress, durable, and is not afraid of sunlight.

The metal cable, as a rule, is U-shaped and can be solid or perforated. If the base is flammable, then a solid channel must be used. Separately, it is worth highlighting the staircase channels - they are used only in production conditions. The channels are secured to the base with dowels, anchors or bolts.

The main advantages of metal cable channels :

- fire resistance;

- high strength, allowing to withstand the weight of a whole bundle of power cables;

- durability and resistance to mechanical damage;

- protection against electromagnetic radiation, which is important for communication cables.

Among the disadvantages , we note that installation is more complex compared to a plastic channel: since the weight of the metal is greater, the installation process also becomes more complicated, but this work still cannot be called particularly difficult.

Thanks to the presence of a lid with a latch, assembly is carried out in a fairly short time. Complex systems are assembled using T- and X-shaped parts, as well as angles of different configurations.

Installation instructions

The profile of the new cable channels comes with special holes.

You save a lot of time because you don't need to drill the bottom of the profile. In addition, ready-made holes allow you to level the fixtures. There are 2 options for attaching the profile to the wall:

- Classical.

- Using dowels and special tools.

The installation result is excellent. The dividing partition helps to carefully align the profile at the joint. When all the profiles are joined, the joint cover adapts to the depth of the profile and is simply glued.

To install cable channels, follow the instructions provided:

- Unpack the product.

- Remove the top covers.

- Create the necessary markings along the walls.

- Cut the box to the required length (you can use a saw or knife for this).

- Remove the upper part from the channel.

- Place the box in the required location.

- Place a level on the product.

- Align the channel.

- Make holes (for installation using dowel nails).

- Secure the product (for this you can use glue, dowels, etc.).

- Lay the necessary wires (install sockets if necessary).

- Close the product.

- Clean up the construction site.

There are 2 types of partitions:

- load-bearing;

- dividing;

Load-bearing partitions allow you to mount covers on multi-section cable channels. The flat corner is mounted as simply as possible. Its design guarantees perfect separation of sections of insulated wires.

The internal angles are variable, they consist of 2 parts:

- top;

- bottom;

They adapt perfectly to wall corners and are easily installed on the cable channel profile. The external corners are also variable and can be easily snapped onto the profile. By design, corners are one-piece accessories, completely ready for installation.

For multi-section cable channels there are corner separators. They are supplied with corners and provide a real separation of low and high currents when wires pass through corners. The angles vary smoothly in the range of 60–120 degrees, which allows installation on any wall configuration.

Cable holders hold all the wires inside the profile and provide you with even more ease of installation. The plug adapts to different sections thanks to its streamlined parts, and the front part of the plug will not get lost during operation.

Flexible covers can be easily and simply installed along the entire length of the cable channel and at corners, and the appearance of the installation is simply delightful. An overlay at the junction of the lids with a non-losable decorative lid allows for easy joining with the next lid. The new dedicated box gives you a complete solution for even the most complex installations.

The corresponding cover is mounted on the load-bearing partition. This load-bearing partition can also serve as a separator to separate 2 sections with the same lid.

No. 3. Types of cable channels by design

There are a huge variety of different cable channels, and in many selection guides all types are listed en masse. To make it more convenient, we suggest first dividing all product options by type of design, and then by installation features.

Based on the type of design, the existing range of cable channels can be divided into the following types:

- smooth, with a solid body without holes, is a fairly popular option. Material of manufacture: plastic or metal. Ideal for mounting on walls and ceilings. Since the structure is sealed, there must be enough free space inside so that the wires do not heat themselves and cause a fire;

- perforated cable channels They weigh less and are cheaper, but these are not their main advantages. The holes provide effective ventilation so that the risk of cable overheating is minimized. Additional convenience - the teeth in some places can be broken off and a sufficient hole can be obtained to lead the wire to a socket or switch, which is very convenient. The downside is its low aesthetics: such a channel does not completely hide the wiring, so it is rarely used in residential premises. If the wall material burns easily, it is better to use a smooth channel;

- flexible cable channels - an alternative to more familiar rigid products. The latter are well suited if the surface has the correct geometry. If there are many non-standard architectural elements in the room, or there are rounded surfaces, then it is better to use flexible cable channels. They are several types: tubular, rubber and flexible chains (so-called tracks). Another option is smooth tubes made of soft plastic. Rubber and plastic channels protect the cable well from any damage, so they can be used even in rooms with high humidity, with the exception of baths and saunas. Tubular channels are made of metal twisted into a spiral. Such products can bend in different directions. Flexible chains typically bend in one plane and can be made of metal or plastic. Often, tracks are used in industrial settings to connect equipment. Cable tracks can be closed or open. The former are used when the cable needs protection from moisture, dust and other negative environmental influences. If there is no source of dangerous influence on the wire at the installation site, then you can use an open-type flexible track - it is cheaper and lighter. Separately, we note the flexible channel with the function of three-dimensional circular rotation; individual elements, if necessary, can be removed from it or, conversely, added. These are quite expensive products that have so far found application in the creation of robotic mechanisms. However, even the most common flexible channels are more expensive than similar rigid options, so they are used only in places with complex surface topography;

- wire channels allow wires to be effectively ventilated and provide the easiest possible access to cables. These are the cheapest cable channels; they are widely used in industrial and warehouse premises;

- staircase channels receive a reinforced structure, are used when laying heavy cables, and are made only of metal. Not used in private construction;

- transparent channels – this is more of a design decision than a constructive one. This is a channel with a triangular cross-section, designed for installation at the junction of floors and walls, ceilings and walls, walls and wall cabinets. The longest side in such channels (the hypotenuse) is made of transparent or translucent plastic. These products are intended either only for installing LED strip lighting, or for simultaneous cable laying and lighting.

Types and purpose

Cable channels (in everyday life they are often called simply boxes) consist of a main part and a cover. Wires are laid inside the base (the box itself), they can be separated by a partition. Then they are closed with a lid, which snaps tightly using a special double lock. It can be removed later to remove, add or replace wires. You can lay both electrical power cables and low-current wiring, telephone and Internet cables in plastic channels.

What types of cable channels are there? Among plastic products, the following main categories can be distinguished:

- Mini-channels (section from 10 × 10 to 60 × 80 mm). Compact, universal, suitable for installation on walls, ceilings, partitions. Often used for laying individual or paired computer, telephone, and television wires.

- Parapet guides. These are larger profiles (from 10 × 20 to 100 × 60 mm), designed for a larger number of wires, installation of sockets and switches. They are often installed in offices, as well as in residential premises, where it is necessary to lay a whole bundle of various wiring at once. Inside such guides, you can use special separators to group power and low-current wires separately. Parapet channels are also universal; for example, they are equipped with fittings that make it easy to form any angles in the range from 7 to 90°.

- Floor-standing. These are boxes with an oval surface that do not interfere with walking around the room.

- Angular. Such cable channels with a cross-section in the shape of a quarter circle are designed for fastening at a 90° angle. They are usually installed at the junction of the ceiling and the wall, less often at the junction of two walls.

- Electrical skirting boards. The cable channel, made in the form of a plinth, is mounted at the junction of the floor and the wall. It performs a decorative function, as it covers this joint. At the same time, you can hide all the wiring in it without installing additional profiles on the walls.

In addition, there are specialized cable channels:

- Transparent - for installing LED backlighting (LED strips). Depending on the shape and size (width ranges from 5 to 20 mm), they can be used under the ceiling, along the walls near the floor, on the wall or ceiling in any convenient place.

- Perforated profiles are lighter, cheaper, and easier to install.

- Halogen-free – made from halogen-free plastic. This is important when laying in closed spaces.

- Flexible (with a round or rectangular cross-section) - for laying on uneven surfaces.

- Ladder – with a reinforced structure, for laying heavy cables.

- Wire guides are simple, cheap guides that do not have high aesthetics, which is why they are used in technical rooms.

No. 4. Types of cable channels according to installation features

Wiring, telephone and internet lines can run along walls, ceilings, floors and corners. Each case has its own type of cable channel:

- wall products have a square or rectangular cross-section, sizes vary in a wide range, which allows you to equip systems of any complexity;

- mini cable channels - a variation of wall boxes. The main feature is its minimal dimensions, which allows the product to fit very neatly into the interior. The channel remains almost invisible, especially if you match it to the color of the wall. This product is designed for laying single wires or several thin cables, often used when installing television, telephone and Internet lines. To create various configurations, corners, plugs and tees are used, but these elements are not cheap, and they are rarely found on sale, so craftsmen simply file the channels at the desired angle to create a right angle, which works out well. Attach mini cable channels to self-tapping screws, dowels or adhesive tape. The latter option is especially convenient when laying wires along furniture (for example, under a table);

- floor cable channel differs in cross-section in the shape of a hemisphere. Thanks to this solution, the risk of tripping over the box and getting injured is eliminated. In apartments, this type of channel is not used very often. The products are much more popular in large office spaces such as open space, when it is necessary to provide appropriate conditions for many workplaces in one area. In this case, electricity, Internet, and a telephone line are supplied to the tables in floor ducts. The requirements in terms of strength for such products are increased. It's better to take an aluminum box. Plastic will also work, but not ordinary, but reinforced, with additional partitions that can also be used as a separator between wires for different purposes;

- corner have a cross-section in the form of a right triangle, designed for installation under the ceiling, at the junction of the surface of the wall and the ceiling. In appearance, such a box can easily be confused with the simplest ceiling plinth, so the product cannot harm the aesthetics of the room. Like other cable channels, it consists of a tray and a cover, and the latter can be transparent or opaque. Products with a transparent cover are used for installing LED strips;

- plinth with cable channel – this is the best example of combining business with pleasure. In appearance, the product is no different from a regular floor plinth; it can be of almost any color and shape. The internal cavity is intended for the location of wiring cables, the Internet, cable television, and thanks to the external and internal corners, turns and splitters, a very complex configuration can be created. There are even sockets and socket groups that can be successfully fitted into the floor plinth. If you need to stretch a whole bundle of wires, then this option is unlikely to work, since there must be enough space inside. The main disadvantage of such channels is their high cost, but they allow you to avoid the dirty and complex process of wall slitting;

- parapet cable channels They resemble baseboards, but are installed at a small height from the floor (80-100 cm), they have a symmetrical cross-section and sufficient width. The products have gained wide popularity when laying wiring in offices and various institutions; such channels are not suitable for home interiors, as they will be very noticeable, with the exception of loft-style interiors.

How to make a socket in a cable channel

Nowadays great importance is attached to the quality of repairs, so they prefer to hide all protruding wires, cables, and crudely made parts.

In offices, houses, apartments, and industrial enterprises, for aesthetics and convenience, a cable channel for sockets and switches is installed. An interfering cable is placed in it, and such a device can pass along the wall or floor.

No. 5. Cable channel size for electrical wiring

The length of straight sections of the cable channel is, as a rule, 2 m; products of other sizes are less common. Width and height are more variable parameters. The choice depends only on how many wires will be hidden inside and what their cross-section is. It is recommended to leave enough free space inside the cable channel so that the wires do not overheat. Paragraph 2.1.61 of the PUE states that in boxes with openable lids, wires should fill no more than 40% of the internal space ; for boxes with blind lids this figure is lower - 35%. It turns out that in order to choose the right cable channel for electrical wiring, you need to calculate the sum of the cross-sections of all the wires, and then start from this when choosing the dimensions of the box itself.

In practice, things are a little easier than they seem. Many manufacturers indicate how many and what kind of wires can be placed in a particular cable channel. Cable channels of the following sizes in mm are considered popular: 12*12, 10*20, 10*30, 16*16, 16*20, 16*25, 16*40, 16*60, 25*25, 40*40, 60*60, 60*80, 100*150 are less common. Mini cable channels have dimensions of 10*10 and 10*15 mm. Products in other sizes are also available for sale. When choosing, it is important to pay attention to the fittings of the appropriate size, which will allow you to build a neat system.

Cable channels: types, sizes, secrets of selection and installation

Cable channels: types, sizes, secrets of selection and installation

It is not always possible to lay wires in a hidden way, and it requires a lot of effort. In such cases, the problem can be easily solved with the help of cable channels - they are mounted even on finished finishing, look beautiful, and allow you to create networks of different configurations. In addition, their installation is a relatively clean job that does not require wall chiselling. And most importantly, the cable laid in the box is easy to inspect and replace if necessary, even several years after installation. Let's take a closer look at what cable channels are, how to select them, calculate them and install them on surfaces made of different materials.

No. 6. Cable channel color and design

The main task of the cable channel is to protect the wires, but no one has canceled aesthetics. It is desirable that the product dissolves against the background of the surface to which it is attached, fits into the interior as much as possible and does not attract too much attention. Fortunately, in terms of design, there are enough cable channel options:

- White channels have become the most popular , they are cheaper than others, and there are a lot of different accessories for them. Ideal for apartments with white ceilings and walls, as well as for non-residential premises;

- cable channels in gray and black shades used in production and offices. Certain types of channels (for example, floor and parapet) are available only in three basic shades: white, black and gray;

- Skirting and wall cable channels are often made to look like wood of different species. Such products look impressive - the main thing is to find suitable fittings;

- Colored boxes come in a variety of shades; some manufacturers even agree to paint them in a specific color. If you choose a box to match the walls, it will be almost invisible;

- boxes in the form of brass or bronze tubes are an ideal option for decorating a room in a retro style, however, it will be more difficult to insert all the necessary wires into such a channel;

- box traditional metal shape – a good option for rooms in a modern style.

If you are an adherent of the loft style, then you won’t need to hide the wiring particularly - this direction requires demonstration of communications.

Preparing the premises and installing cable ducts.

Preparing the room consists of checking and, if necessary, leveling the ceiling and walls of the room. The gaps between the wall-ceiling and the boxes do not look aesthetically pleasing, they create curvature of the box itself and, as a result, loose closure of the cable duct covers. A smooth surface of the ceiling and walls is the main guarantee of high-quality installation of the electrical network.

Experienced specialists install the electrical wiring system in most cases before the final finishing of the room. If the walls are finally ready for delivery and after that the wires are installed, then all the shortcomings will be visible to the naked eye, and this requires especially careful work.

Preparing the tools for installing the electrical network is also of great importance. Trimming and fitting plastic boxes is best done with an angle grinder - an angle grinder. All other files, side cutters, knives, and so on can crack and break plastic.

At the same time, working with an angle grinder requires special protection of the eyes and respiratory tract from dust particles, so you must additionally have glasses and a respirator.

To mark the base (walls - ceiling) and plastic boxes, a simple pencil is usually used, and the type of this base depends on the fastening material and tools for fastening. If the walls are painted, covered with gypsum fiber, plasterboard, glass magnesite sheets or wallpaper, the plastic base of the boxes can simply be glued using construction adhesive (liquid nails). In this case, you must count on the fact that you cannot install the wiring right away; you must wait for the glue to dry completely.

If the base is wooden, then the cable ducts can be fastened using self-tapping screws or simple screws. Then you will need a screwdriver (preferably battery-powered), if not, then a small drill with a slightly oblong bit and a set of drills with a diameter of 3 mm. Fastening is done with self-tapping screws through a drilled hole at the bottom of the box to a wooden wall.

A concrete or brick wall requires fastening a plastic box with screws and dowels. The procedure is usual in such cases: we drill holes at the bottom of the box, attach it to the base, make marks with a pencil and punch holes for the dowels with a drill; we lay dowels and fasten the cable channel with screws. This installation method is labor-intensive, but reliable.

Drilling holes in the wall through the attached plastic box is also an option, but this can lead to breakage of the plastic and high consumption of material. Also, during work, the box may shift, which will lead to additional work. When working with a concrete base, you can use a hammer drill.

The length of the cable channel is determined using a tape measure or, if possible, by attaching it to the base. It is advisable to carefully inspect the factory cut of the channel and cut it if there are any bruises.

Using a building level, when attaching the box, it is necessary to control its horizontal position; to control the vertical, a simple plumb line is sufficient. When marking bends, we also use a construction angle.

The lids are tried on the mounted boxes, cut separately, numbered and placed in the designated place.

Particular attention is required to ensure joints during the transition from horizontal to vertical. Closed box lids should not leave noticeable flaws in the form of cracks and holes. For better quality work, specialists use several techniques: they cut the joining boxes to 45 or cut the inner sides to the width of the counter box and attach them to each other. The best option in this case is to use fittings.

An ideal option for the transition from a horizontal level to a vertical level, when boxes of the same cross-section are used. The “T-shaped” connection of channels can be worked out in boxes with different cross-sectional sizes. There is enough hole in the side of the large box for the cable to be routed out.

Here the saying: “Measure twice, cut once” sounds most relevant.

No. 7. How to evaluate quality when purchasing?

When purchasing, carefully inspect the selected sample. A small examination will allow you to understand how high-quality the product is:

- The plastic must be rigid enough to hold its shape properly. Cracks, dents and other deformations are not allowed;

- ideal geometry, smoothness and evenness of the ends - evidence of high quality

- The cover should be easy to install and remove. It's better to try closing and opening the lock a couple of times. If all this happens very easily, and no cracks appear on the plastic, then you have a quality product;

- evidence that the manufacturer took a responsible approach to the issue of channel production is the presence of separators, clips and ties for convenient installation of several different cables. Yes, not every high-quality channel has such bells and whistles, but their presence means that this is a really good product.

How to check the quality of a cable channel

When choosing a cable channel, pay attention to the quality of casting and plastic. The walls should not be very thin, the tray should be rigid and hold its shape well.

Please note that there are trays with dividers. These types of cable channels are convenient if you need to lay low-current (Internet, telephone, antenna, TV) and power (wiring) cables. Some large-section trays have clips or ties molded in them for more convenient fastening of wires and cables. All these bells and whistles are a sign that the manufacturer is serious about production.

The second thing you need to pay attention to is the lock and how well it closes. These locks come in different designs. The simplest ones are single ones. They are easy to install and remove, but with a lot of cables there is not always a way to keep them in place.

One of the important criteria is the type of castle

A double lock is more reliable, but is harder to close/open. In warm weather it can be easier to handle - the plastic is more elastic. In a cold room this can be problematic. However, they try to use double locks, as they are more reliable.

You can check the quality of the cable channel by opening/closing the cover a couple of times. If there are no cracks/damages, the product is normal.

No. 8. Manufacturers of cable channels

As you know, the name of the manufacturer is a kind of guarantee of quality. If substantial funds have been invested in advertising and promotion, then who would want to spoil it all with dubious products. Among the leaders in terms of cable channel production it is worth noting:

- Hager is a German company that mainly produces channels for office spaces, but their attractive appearance allows the products to be used in residential areas;

- Schneider Electric is a large European corporation with factories around the world, incl. and in Russia. The range of cable channels is one of the widest among all competitors. There are plastic and metal products, models for installation on the floor and walls, boxes of different sizes are available, incl. and mini versions;

- DKS are domestically produced channels, there are wall and floor options, as well as mini cable channels. The range of colors is not very large, but in most cases it is quite possible to find a suitable product;

- Legrand is a group of companies with offices around the world that produces a wide range of products under different brands. Cable channels are presented in plastic and aluminum versions, floor and wall models, sizes vary widely;

- IEK - a domestic manufacturer, offers parapet and wall cable channels of different sizes, color - white and imitation wood.

Types of cable channels

First you need to decide on the type of cable channel. We talked in detail about what types of cable channels there are in a separate article, now we will briefly repeat it again. They are distinguished according to 4 criteria:

- According to the method of installation and location in space.

- According to the material from which it is made.

- By design.

- By appearance.

To choose a cable channel for electrical wiring, you need to take into account all the differences, let's look at what they are.

According to the installation method, they are distinguished:

- Wall-mounted. In cross-section they have a rectangular or square shape, depending on the dimensions and the number of wires being laid. There is a separate option here - mini cable channels, they are needed for laying single or just thin wires and cables, such as television and Internet cables.

Based on the material from which it is made, it is divided into many types:

- PVC.

- Metal (galvanized steel or aluminum). Suitable for use outdoors, in rooms with increased fire hazard and difficult environmental conditions.

- Halogen-free (does not contain bromine, fluorine, iodine, chlorine, astatine), recommended for use in closed, unventilated areas.

The following cable channels are distinguished by design:

- Smooth. Solid smooth body.

- Perforated. Lighter and cheaper than usual.

- Flexible. They can be corrugated or consist of links, like a chain. They are chosen for installing and laying cable lines in geometrically complex areas, for example, along a semicircular protrusion on a wall or column.

- Transparent. More likely not a constructive, but a design decision. Suitable for lighting the ceiling with LED strip. They can be wall-mounted, ceiling-mounted or in the form of a plinth.

In appearance, cable channels vary in color, can be made with wood texture, etc. In fact, among all this variety, simple smooth white PVC cable ducts for external installation of wiring are most often chosen for home and office.

There are many manufacturers on the market, their products differ in quality, appearance and design, but the essence remains the same. Popular manufacturers are Legrand and IEK.

No. 9. Features of installation of cable channels

Installing cable channels is a simple procedure, and if you dare to do the electrical wiring yourself, then installing the boxes will not be a particular problem. In general terms, this process goes like this (for more details, see the video):

- cable channels are placed only vertically or horizontally, which is not surprising, given the requirements for the installation of electrical wiring. Sloping areas are allowed on stairs and attic floors;

- The cable channel is fixed with fasteners or adhesive tape/glue. The method with self-tapping screws is more universal, just keep in mind that for drywall and foam blocks you will need special fasteners. It is better to choose screws with large heads, otherwise the plastic box may become deformed. Self-tapping screws are installed in increments of 30-50 cm; for fairly curved walls, the increment can be reduced to 20 cm, and for perfectly smooth walls, the increment can be increased to 60-70 cm. First, holes must be made in the channel tray, then applied to the wall, marked on its surface fastening points, drill holes in the wall, install plugs and only then proceed to installing dowel nails;

- If you don’t want to drill into the wall, you can glue the channel with glue or double-sided tape. In this case, increased demands are placed on the base: it must be smooth, even and dust-free;

- It is better to trim separately on the tray and the lid, but you need to mark the cutting line when the lid is installed on the tray. For cutting, you can use a plastic saw or a sharp knife; the edges are treated with sandpaper. The metal box is cut with a hacksaw;

- After the channel tray is installed, they begin laying the wires, and then close the box cover.

Finally, we note that the wires can be hidden in corrugated and reinforced pipes made of PVC and metal, but they are often used to protect wires in grooves.

They are also applicable for external wiring, when the aesthetic result of the work done is not of great importance. Tags:Electricity

Installation rules

The installation procedure depends on whether shaped products - corners, branches and plugs - will be used or not. If they exist, the manufacturer gives clear recommendations about what distance should be left for proper installation. They should be followed to the nearest millimeter. Then everything looks neat. We will talk about the basic rules for installing cable channels of the usual type below in more detail.

How to choose a size

If you decide to route wires into cable channels, first you need to decide what size they are needed. Dimensions are selected based on the number and size of conductors that will need to be laid and some reserve added for the future - so that if necessary, one or two more wires can be laid.

When choosing a size, you need to take into account the number of cables that will need to be laid

The number of conductors in a cable channel is not standardized. The main thing is to be able to close the lid without problems. A limitation may be the need for separate placement of power and low-current cables. In this case, select the cross-section so that there is at least a small distance between the groups of cables.

Installation procedure and features

According to the rules, wiring is laid horizontally and vertically; inclined installation is permissible only on stairs. In other cases, the rules are not deviated from when wiring is open. To obtain an even cut when installing plastic cable channels with thin stacks, use metal scissors or others, but the cutting edge must be sharp. Aluminum and metal trays are cut with a hacksaw. Thick plastic can also be cut with the same tool - there will be a smooth edge and the profile will not wrinkle.

If you need a piece of a certain length - for a outlet, for example, you need to cut it in this order: snap the lid, align the edge, apply marks on the lid and body at the same time. Then you can cut it separately. With this order, the length of both products will be the same.

Please note that when passing the corner, the lid is not cut into two parts, but only the side walls are cut so that it can be bent. Do not forget that when going around the outer corner, the cover should be longer than the tray; in this case, it is better to mark the places of cuts on it after the cable channel body is secured.

Rules for installing plastic cable trays

The cable channel is attached to a non-wooden surface using nails with a wide head (screws can be used), or to plaster or plasterboard walls using self-tapping screws. For installation on brick or concrete walls, installation with dowels is required. The fastening step of the fasteners is about 60-70 cm; at the ends of the profile and at the joints, the fasteners are installed at a distance of 3-5 cm from the edge.

If two pieces of cable channels are joined, the cover must be positioned so that the joints of the housing and the cover do not coincide. Otherwise, the joint will be too noticeable and an unevenness may form, which will further emphasize the joint.

Order of laying wires

We lay conductors in the mounted housings. To prevent the walls of the cable channels from sagging, we install supporting jumpers with some steps, and then snap the covers. At this point, the installation of wiring in the cable channels can be considered complete.

Methods of using cable channels for laying open electrical wiring

A wide range of components for electrical wiring allows you to implement the most complex projects. Installation of the wall box is carried out taking into account the height of the sockets, junction boxes and switches. For open spaces, designs of wall and floor cable ducts made of metal are used. This provides protection from the effects of electromagnetic vibrations. Such options are relevant when installing information wiring.

Before proceeding with installation, it is worth understanding the basic elements of the electrical circuit.

Installation of a floor skirting box

Installation of wiring in the channels is carried out after completion of finishing work. Markings for the cable mesh are marked on the walls. Laying is done from the distribution panel. First of all, main lines are installed, and then branches from them. If the channels do not have holes, you can make them yourself.

Installation of a wall channel with wires. The channel section is fixed to the wall. In this case, the line should be positioned in the center of the holes. After this, fastening with dowels is carried out. After installing the connecting parts, the box is cut to the required length.

Wall Channel Installation

- floor plinth with separate sections for low-current wires;

- ceiling material;

- designs of cable ducts on the floor with protection from mechanical impact;

- corrugated pipes and trays used in utility rooms or for external facades.

Outdoor cable channels are used for the local area. Flexible structures can be used for the street.

Installation of wall boxes is carried out using self-tapping screws. They should be installed at certain intervals. The load is determined by the number of wires inside. To fix it on a wooden surface or on drywall, it is necessary to screw it in every 40-50 cm. If the walls are uneven, then the distance may be less to hide flaws.

To work with a brick or concrete wall, installation is carried out using dowels. To work, you will need a hammer drill with a nozzle with a diameter of 6 mm. The simplest fastening option is liquid nails, which are construction adhesive.

Floor channels will allow you to disguise any wiring so as not to spoil the interior. In this case, the structure is combined with the baseboard. Before installation, markings should be made on the walls and floor. Interestingly, plastic cable channels are mounted not to the floor, but to the wall. Installation is carried out using screws, liquid nails and dowels.

Angled cable channel

Used for mounting LED strip lighting. Most often, such products are made of aluminum, and the lid is made of heat-resistant plastic. The corner cable channel is used to fill the junction of the main line in the corners.

For the home, a flexible cable channel for wires is often used. Lightweight metal models are also used. There must be enough space inside the case for a certain number of cables. It is important to check the availability of the necessary accessories for the cable products.

Flexible designs allow you to disguise a large number of wires. When choosing products, you need to count all the locks, mounting fasteners and plugs on the spot. You can organize electrical wiring according to an open circuit using the following types of electrical boxes.

Installation of boxes

Before installation, it is necessary to prepare and level the surfaces of walls and ceilings.

Direct installation of boxes can be done before or after finishing finishing work in the room. Marking of products is most often done using a simple pencil. The boxes are fastened in different ways - by gluing or fastening with screws or self-tapping screws. The cable should be laid only after the glue has completely dried. The main method of fastening is self-tapping screws. After 50 cm, holes are drilled in the box. Next, the box with holes is applied to the wall and points are marked along them for installing dowels. Using these marks, holes are drilled in concrete or brick for dowels, to which the box will be screwed with self-tapping screws.

Thus, it is quite easy to install cable channels. If you have the necessary tools and follow the established rules, even a novice specialist can cope with this task.

Laying wires in the cable channel and installing sockets and switches

Cable channels for laying open electrical wiring

Laying the cable in the cable channel: installation instructions with photos

Laying cable channels

Plastic boxes for electrical wiring

The best plastic boxes for electrical wiring: how to choose the size and type of box for wiring installation

Dimensions

Modern technologies make it possible to produce specialized boxes of various sizes and designs:

- polygonal;

- triangular;

- and others;

The length of the product in the package is:

- 15 m;

- 16 m;

- 20 m;

- 42 m.

- 70 m.

- 100 m.

Section:

- 12×12;

- 16×16;

- 20×10;

- 40×16;

- 60×40;

- 80×40;

- 100×60 and others;

Of course, the construction market offers standard devices that have average characteristics.

The most popular are square-shaped plastic covers, which are used to protect various cables.

These devices have different sizes and characteristics. Installation of products is carried out in 2 ways. Thanks to special latches, installation of the box is carried out in the shortest possible time. In order to choose a model, you need to take into account the number of wires. Since the size of the device will depend on this.

The most common sizes of specialized boxes:

- 80×60;

- 60×40;

- 40×16;

- 25×16;

- 12×12;

- 100×60;

- 80×40;

- 40×25;

- 25×25;

- 16×16;

The most common cables are 100*60 and 12*12. Various couplings are used to connect boxes. As a rule, models are sold in the form of planks (2 meters). All plastic models are attached in a standard way.

Using a screwdriver, the device is screwed to the surface. All additional components and accessories must be purchased separately.

Taking into account the cable width

The box must be free enough to lay the wire. The small cross-section will not allow the lid to close tightly. A tightly laid wire will overheat.

Dimensions of electrical installation cable channels in cross section

Mini-channels are produced by industry with the following typical cross-sectional dimensions:

- 10x10mm;

- 10x12mm;

- 12x12mm;

- 12x16mm;

- 16x16mm;

- 16x20mm;

- 20x20mm;

- 20x25mm;

- 25x25mm;

- 25x40mm;

- 40x40mm;

- 40x60mm;

- 60x80mm.

Trays of this type are designed to accommodate one or two wires.

Floor boxes are produced with the following cross-section:

- 160x65mm;

- 50x12mm;

- 92x20mm;

- 75x17mm.

Trunk plastic boxes for electrical wiring have the following typical cross-sectional dimensions:

- 20x10mm;

- 30x10mm;

- 40x25mm;

- 25x25mm;

- 40x40mm;

- 40x16mm;

- 80x60mm;

- 100x60mm.

For the plinth type, the size is determined by the width of the cover (diagonal wall) and is usually made 50 or 70 mm. You can also find the sizes of skirting boards with cable channels, which are given according to the height and width of the base. In this case, the most popular are 50x50 mm skirting boards. They allow you to place several wires in one product. Trays measuring 100x100 are designed to accommodate three-wire wires.

Dimensions for corner structures depend on the dimensions of the internal part of the product. The most popular size is 40x40 mm.

Depending on the purpose, flexible corrugated models are available in the following diameters: 16mm; 20mm; 25mm and 50mm.

- 16mm pipes are used for laying lighting and telephone cables;

- to create outlets for sockets or switches, use 20mm corrugated channels;

- Corrugated cable ducts with a pipe diameter of 25 mm are used between electrical panels or distribution boxes.

The industry also produces cable channels designed to accommodate LED strips; they are produced in widths from 5 to 20 mm. In addition, LED channels can be located in plinth boxes.

Skirting electrical installation tray with LED channel

Wall thickness of plastic cable channels

Depending on the size of the trays, products with different wall thicknesses are produced. The strength and flexibility of the box depends on its value.

Small mini-channels are made with a wall thickness of 0.7 mm. Medium-sized boxes (from 20 to 40 mm wide) have a thickness of about 1.3 mm. Wide main profiles (from 60 to 100mm) are manufactured with a thickness of 2.4mm.

In addition to boxes of standard sizes, many companies produce custom-made products made to customer sizes.