Installation of a distribution box in an apartment is an important stage of electrical wiring; thanks to it, the electric current is evenly distributed to points that consume electricity (lamps, sockets, switches). A properly installed box ensures 100% uninterrupted use of electrical wiring. In appearance, the junction box is a metal or plastic structure with holes on the sides. Wires extend from the box, which provide current to all important electrical devices.

What is a junction box for?

To distribute electricity evenly, the wiring is divided into separate groups of consumers. In rooms, distribution boxes are installed at the wiring connections.

Distribution boxes perform several important functions in residential premises:

- ensuring fire safety;

- creating an aesthetic appearance in the apartment.

The wires are located inside the box; thanks to the housing, they are not subject to mechanical stress, which ensures their safety.

According to the installation principle, the boxes are built-in and external. Built-in ones are installed in specially prepared recesses in the wall, and overhead ones are fixed on the wall surface.

Overview of types and characteristics of electrical distribution box

Laying electrical wiring requires a person to be careful, attentive, and most importantly, to know exactly how to distribute the wires throughout all rooms of the apartment. To simplify the process as much as possible, a junction box is used. You can find out about the motion sensor for turning on the light and tips on how to choose here.

Different types of distribution boxes in the photo

Types and characteristics

Today on the domestic market you can find the following options for distribution boxes:

- distribution box 80x80x40mm for outdoor installation ip55 - a compact device, installation requires certain skills.

- distribution box 100x100x50mm for external installation ip55 - used for distributing electrical wires throughout the apartment. Installation is carried out outside.

- Tyco 100x100x50 ip54 – has high technical characteristics.

The photo shows a distribution box 80x80x40mm for outdoor installation ip55

Distribution box 100x100x50mm for outdoor installation ip55 in the photo

- UK 2p - the device meets high European quality standards.

Tyco distribution box 100x100x50 ip54 in the picture

UK 2p distribution box in the photo

- explosion-proof distribution box – has improved technical characteristics and is distinguished by a high level of safety. Read an overview of the types and characteristics of a 220V voltage stabilizer for the home on this page.

- KRA 4 distribution box is a multifunctional device, easy to install.

KRA 4 distribution box in the picture

- electric with terminals - this option is traditional and has been used by domestic consumers for a long period of time.

- for open wiring - installation is carried out on the wall surface; sometimes additional protection may be required.

- with a terminal block - allows you to distribute the maximum number of wires throughout the apartment.

The photo shows a distribution box for open wiring

- metal distribution boxes with IP65 lid – made of metal, has a long service life.

Distribution box with terminal block in the photo

- metal u996 with lid - the device is easy to use and maintain.

- optical - it is one of the latest developments and has an increased level of protection. See the guide on how to properly solder with a soldering iron here: https://howelektrik.ru/elektrooborudovanie/instrumenty/payalniki/rukovodstvo-kak-pravilno-payat-payalnikom.html.

The picture shows an optical distribution box

Installation

The installation of the distribution box is carried out either under the ceiling or at the entrance to the room. In this case, all that needs to be done is to secure it to the surface using dowel nails.

Installation of the distribution box in the picture

How to connect the wires?

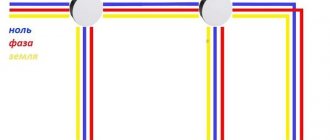

In accordance with the standards and rules, all wires are connected to each other in accordance with the pole characteristics.

Connecting the wires in the junction box in the photo

It must be remembered that they can be attached to each other in various ways, however, the standard wiring diagram is used:

- Twisting - this option is the simplest and does not require any special skills from the apartment owner;

- Soldering - in this case it will be necessary to use a soldering iron to connect the wires;

- Welding – a welding machine is used. The connections are highly reliable. Read how to choose a voltage stabilizer for a refrigerator.

- The use of automatic machines - this method is the best, because careful fixation is performed and the wires are protected from external influences and premature wear.

Methods of connecting wires in the photo

Wire connection diagram in a junction box

Wiring a junction box requires special skills, because only a person with enough experience can create the entire system correctly.

The photo shows the junction box after connecting the wires.

The video below shows how to connect the wires in the junction box:

Soldering and welding

In order for the wires to last as long as possible, it will be necessary to “fix” them in the junction box. The simplest and most convenient option is to use automatic clamping machines, which carefully fix the wires and easily allow them to be dismantled.

Traditional connection methods are also used:

- Pike:

- The wires are exposed;

- Prepare the soldering iron and nickel;

- The metal is degreased;

- Begin soldering. The soldering iron is heated well.

- After everything is done, the connection must cool down.

The photo shows the process of soldering wires

- Welding:

- Welding is used in cases where it is necessary to connect large diameter wires.

- It is necessary to prepare the electrodes and the welding installation itself.

- You should remember safety: glasses + gloves, turn off the power.

- Afterwards, solder everything and carefully tap out the excess.

How to wire a socket?

The figure shows a diagram of connecting the socket to the distribution box.

To lay the connecting lines from the socket to the distribution box, you will need to:

- Determine how exactly the electrical cable lines will be installed: in the wall or on top of it.

- If the installation is carried out in the wall, then it will be necessary to make a groove into which the cable will subsequently be laid. Then, after installing the system, the surface is carefully puttied and leveled.

- If installation is carried out on top of a wall surface, then it is worth stocking up on plastic cable ducts and dowel nails.

- The wires to the socket are attached to two docking terminals. You need to connect “+” to “+” and “-” to “-”. When connecting, the wires can be twisted or soldered. The second option is the most reliable and increases the service life of the equipment several times.

- Then the cable suitable for the junction box is secured into automatic clamping mechanisms.

Attention! Before laying the cable and connecting it to the outlet, you must completely de-energize the room. You should also remember that the system will be safer if the outlet has a ground connection.

How to find it in the apartment?

The photo shows an example of the location of the distribution box in the apartment.

In order to determine the location of the distribution box in the apartment, you will need to perform the following steps:

- It is necessary to use the cable laying diagram in the apartment and its wiring.

- If there is no diagram, then you should tap the surface, where it is dull, there is a box.

- You can use a special device. Which will determine the location of the box within a few seconds.

Cost of distribution box for electrical wiring?

At the moment, you can purchase equipment of this type in any online store that will specialize in the sale of electrical equipment and components for creating various devices. You can also make a purchase in a regular department or store. The average price for a distribution box varies from to rubles.

Read how to choose a plastic cable channel.

Where to buy a distribution box for electrical wiring?

Where to order in Moscow:

- JSC “SPETSTEKHMONTAZH” Moscow, Novokhokhlovskaya st., 91, building 10, territory, Contact telephone number; +7 (495) 728-76-58.

- Company “Prestige-Electromaterials>”, Moscow, Dmitrovskoe shosse, 58, metro station Petrovsko-Razumovskaya, A167, A677, A763 Contact telephone (multi-channel);

- Energy Systems company Moscow, Profsoyuznaya str., 93A Contact phone number.

Where to order in St. Petersburg:

- Online store Xcom.spb St. Petersburg, Stachek Ave., 92, building 3, Contact phone: 8 (812) 740 1110;

- , St. Petersburg, Yakornaya street, building 11, Contact phone: 8 (812) 318 35 35;

- LLC “Elektrostroy SPb Corporation 1” St. Petersburg, Morskaya embankment, building No. 9, room 18-N, Contact phone: +7 (812) 914-92-65.

Video

Watch the video on how to install a junction box:

The presence of a distribution box allows you to distribute electrical wiring throughout your apartment or house. For this reason, it is very important to use only high-quality materials that will have a long service life.

Dec 9, 2015HowElektrik

Main function of distribution box

The distribution box allows you to reduce wiring costs. If it didn’t exist, each electricity consuming device would be connected with a separate cable. The absence of a box provides for an increase in the channels for laying wires, and visually this looks unaesthetic.

The advantage of using junction boxes is undeniable, and proper connection of wires will ensure the safety of the premises. This device isolates contact points from the effects of flammable wall materials.

The ease of use of the junction box ensures ease of repair. The main function of the box is that it ensures uniform distribution of electricity to the locations of the main consumers. In addition, such designs of switching boxes involve adding new branches of electrical networks to the existing wire if necessary.

Types of distribution boxes

Distribution boxes according to the type of fastening are divided into:

- overheads, which are installed outside on the wall;

- internal, installed in the prepared wall recess.

The main purpose of the junction box is to provide easy access to the electrician in the event of a system malfunction. For convenience and to preserve the integrity of the wires, the box is closed with a lid. To carry out any manipulations with the electrical wiring, specialists just need to remove the cover and get acquainted with the causes of the problems.

Distribution boxes are made from the following materials:

- Plastic.

- Metal.

Metal cases are made of tinned steel sheets or aluminum alloys. The main requirement for materials is that they are not subject to corrosive changes.

If a distribution box is needed for strategically important facilities, then it must be selected with the following characteristics:

- screw cap;

- waterproofing gaskets.

The metal case has universal properties and perfectly protects the wiring during a fire, that is, during a fire, the metal structure is able to preserve the contents of the box for some time, during which it is possible to de-energize the network.

The plastic case also has positive properties: resistance to oxidative processes and the ability to isolate electric current.

Distribution boxes vary in geometric shape and are:

- round;

- square;

- rectangular.

If a small number of wires are supplied to the box, then a round box configuration can be used. In cases of a large number of wires, it is better to use a rectangular distribution structure.

Important! If the walls are concrete, then it is easier and more convenient to install round box structures.

The dimensions of distribution boxes depend on the number of wires and their cross-section.

Kinds

Distribution boxes (also known as junction boxes, switch boxes and branch boxes) differ in design, appearance, material of manufacture and degree of protection, as well as the presence or absence of terminals inside. For each case, you should select your own option, otherwise this element of electrical wiring will be of little use.

Types of boxes and wiring options

By installation method

According to the installation method, the boxes differ in:

- open;

- hidden.

The former look more presentable and are used when laying electrical wires openly. The second ones are installed inside building structures and then covered with decor. For example, it is recommended to do electrical wiring in a wooden house with your own hands using open installation. But when laying cables in steel pipes under the finishing, hidden wiring is also possible using appropriate electrical installation products.

Step-by-step instructions for terminal wiring

By type of material

Boxes for arranging branching points for wires are made from non-flammable plastic or metal. They are usually selected in accordance with the braiding (insulation) material of the electrical wiring. If the cable is armored or laid in a metal pipe, then the junction box must also be made of metal. For other cases, it is better to choose a plastic analogue.

Other boxes

The degree of protection of junction boxes is IP from “20” to “68”. For dry, heated rooms, IP “20” or “30” is sufficient. But usually for domestic conditions, in a cottage or garage, they choose the option with IP “55”. But for bathrooms and outdoor installation, you should purchase an electrical installation product with IP from “65” to “67”. The number of inputs can be from two to sixteen.

If the degree of protection is increased, then the cable openings are equipped with glands. But usually they are simply made in width to match the thickness of the inserted wire. The inputs can be located both in the sides of the product and on its bottom (the inner side in contact with the wall).

Distribution of wires in the box

Internal structure of distribution box

The design of the junction box consists of a housing and a cover, as well as side inlet holes.

The internal cavity of the box is equipped with terminals and clamps for fastening wires. Typically, the input cable is secured using terminals, and separate wires are secured using clamps. If the box is not equipped with terminals, the wires are secured together by twisting.

The disadvantage of a terminal connection is that after use the bolts can become loose and disrupt the wiring contact. Loose contact causes heating and subsequently burning of the wires. Twisting is considered a more reliable method.

It should be taken into account that the connection of aluminum and copper wires in the junction box leads to destruction of the connection and the occurrence of an electrochemical process.

Important! Brass terminals provide high-quality connection of aluminum and copper wires.

Installation

During electrical installation work in houses of concrete or brick construction, electrical devices are placed in the wall cavity in specially prepared holes in the wall. Such recesses are made with a hammer drill; in cases of a round design of the distribution panel, the holes are made with a special crown. In the seat, the box is attached to the wall using alabaster mortar, which guarantees a strong connection between the housing and the wall.

After determining the installation location of the box, you need to prepare the wire network and make the connection. In order to bring them to the switching box, you need to prepare grooves into which the wires will be laid. If the walls allow the possibility of wiring in a horizontal position, then the gaps between the walls and the ceiling are quite useful for this.

After preparing the channels and socket boxes, the wiring of the switching box wiring system is carried out.

Important! To ensure the correct connection of the wires in the junction box for the purpose of quickly carrying out subsequent repair work, the wires are marked.

The input cable from the electrical panel is designated as “input”; the wire from the sockets should also be marked, because labeled wires will not allow mistakes during maintenance and repair. In order for the wires to be used correctly, the cross-section must be strictly observed; for example, to supply electricity from the panel, a two or three-core cable with a cross-section of 4 square millimeters is used.

Such a cable guarantees full use of any high-power consumer. For the lighting system, a cross-section of 2.5 square millimeters is used, and for sockets - 1.5 square mm.

After familiarizing yourself with all the nuances, they begin to install the junction box. The basic principle of installing the switching structure is indicated by precise adherence to the sequence of wiring connections. The wiring diagram in the distribution box includes the following parameters: phase is connected to phase, zero is connected to zero, and grounding is connected to grounding.

Laying of wires occurs subject to compliance with all parameters and requirements of the drawn up connection diagram. The wires are laid inside the box, preferably with an allowance of about 10 centimeters. When connecting wires, it is necessary to strip the ends of insulation and secure them in the terminals.

If there are no fasteners, you can simply fix the connections by twisting. This method involves twisting the wires at the points of contact; this method is often used and is considered reliable. After this, the joints are fixed with insulating material (insulating tape or plastic caps).

Important! The wires are mounted in pipes made of metal or plastic, which provide insulation from external negative factors.

Various modifications of switching devices are widely presented in specialized electrical stores. The included instructions indicate the main characteristics and current voltage ratings.

Installation

The junction box is installed on the wall with a lowering of 10–30 cm from the ceiling. Moreover, this is done in such a way that there is open access to its lid. Checking the condition of the wires should be carried out on a regular basis.

Step-by-step instruction

Installation of the junction box is carried out in four simple steps:

- Fastening the box to the wall according to the wiring diagram.

- Planting wires inside and then connecting them to each other.

- Checking the assembled electrical network.

- Closing the electrical installation product with a cover.

The junction box is secured using self-tapping screws or plaster (if it is recessed into the wall).

Arrangement of input cables in the box

Wire connection methods

According to the PUE, the electrical wires inside can be connected:

- twisted;

- soldering;

- welding;

- terminals;

- crimping.

How to properly connect wires in a junction box

Twist

Twisting is the fastest and at the same time the most unreliable way to connect indoor electrical wiring. To cover the exposed wires, special plastic caps or electrical tape are used.

Twist connection method

Soldering

Soldering is done with tin on top of the pre-twisted wire. This connection is much more reliable and durable. However, such installation takes a lot of time.

Welding wires

For welding you need an inverter welding machine. This method is even more reliable and more complex, but as a result, the two connected cores actually turn into a single solid one. It is recommended to choose it only in special cases. For example, when grounding is done in a private house under a powerful load or additional pumps and uninterruptible power supplies are connected for a gas boiler.

Terminal connection

If the wires are made of different materials, then it is best to use terminals with screw or spring clamps. The terminal connection is extremely simple to make; you only need a screwdriver. The most important thing here is not to overtighten the clamp bolts.

Terminal connection of wires

Crimping

When crimping, press pliers and sleeves are used, made of the same metal as the cores, and sized to match the thickness of the wires being connected. Some craftsmen use pliers for this, but such connections are rarely reliable. It's better not to experiment.

Crimping connection method

Wiring diagrams

To avoid any confusion when connecting electrical wires, it is worth preparing in advance the wiring diagrams for all installed junction boxes. This drawing should indicate “from where and where” each core goes. In general, it is advisable to use different colored wires to avoid confusion.

Wiring diagram

Connection principles

For quick connection and to avoid confusion, the wires are marked with colors of different shades. The following color combination is considered popular: white indicates phase, blue indicates zero, and light green symbolizes grounding. When connecting, strict compliance and consistency must be observed.

Like any other work, electrical wiring in a junction box also begins with a design. To draw up a competent electrical wiring diagram, you need to determine the exact location of electrical installation points - lamps, sockets, switches. In accordance with the diagram, distribution boxes are placed in convenient places. Providing access is necessary for carrying out repair and maintenance work in case of interruptions in the electricity supply.

The rules for electrical installations stipulate that wires must be connected by soldering, welding or using clamps. However, the “old-fashioned” method of twisting wires has proven itself among the people; this method ensures the manufacturability and reliability of the system.

Sometimes twisting the wires is not enough; to ensure reliability, the contact area is treated with soldering. After connecting, the wires are insulated and placed in the box body so that they do not come into contact with each other.

After carrying out the entire complex of work, diagnostics are carried out; for this, the most powerful electrical appliance in the apartment is connected to the network and the wires are checked for the presence of heating. If you find any wire heating up, this means that it does not have enough contact area, and in such cases the junction box should be repaired, possibly replacing the wire with a larger cross-section wire.