Basic terms

For a better understanding, let’s understand the basic terms, because this is important for the correct selection and installation of the grounding conductor.

Let's look at the basic definitions:

- Grounding is the connection of metal parts of an electrical installation or equipment to a grounding device. In other words, this is a set of measures aimed at increasing human safety when using electrical appliances.

- A grounding device is a group of elements that ensure the removal of voltage (potential) into the ground to protect a person from the negative effects of electric current. It consists of a grounding conductor and a wire or busbar connecting to a non-current-carrying part.

- Ground electrode is a structure consisting of several welded metal bars immersed in the ground to a certain depth to ensure rapid removal of potential. The main characteristic of the ground electrode is its resistance, which should not exceed 4 ohms.

- Grounding wire is a product that connects a metal non-current-carrying part of equipment to a ground electrode. Fixed by welding or bolting. The degree of safety directly depends on the correct choice of this part of the design.

- A grounding bus is an element of distribution boards designed to connect PE conductors, a neutral working wire and a ground electrode. The main difference from the wire is the design features that allow other grounding wires to be attached to the bus.

Today, the term “ground loop” is often used. This is the name of the ground electrode used in everyday life. This also means a structure consisting of several electrodes or metal corners located in the ground and mounted in the shape of a triangle. It is to this structure that the grounding busbar is connected.

General concepts.

Grounding

– intentional electrical connection of any point in the network, electrical installation or equipment with a grounding device.

Grounding is designed to drain leakage currents

arising on the body of electrical equipment during emergency operation of this equipment, and

providing conditions

for immediate disconnection of voltage from the damaged section of the network by triggering protective and automatic shutdown devices.

For example: an insulation breakdown occurred between the phase and the housing of the electrical equipment - some phase potential appeared on the housing. If the equipment is grounded, then this voltage will flow through the protective grounding, which has low resistance, and even if the protective shutdown device does not work, then when a person touches the housing, the current that remains on the housing will not be dangerous to the person. If the equipment is not grounded, all the current will flow through the person.

Grounding consists of a ground electrode

and

a grounding conductor

connecting

the grounding device

to

the grounded part

.

Ground electrode

is a metal rod, most often steel, or another metal object that has contact with the ground directly or through an intermediate conducting medium.

Grounding conductor

– this is a wire connecting the grounded part (equipment housing) to the ground electrode.

Grounding device

– this is a set of grounding conductors and grounding conductors.

Types and features of grounding

When purchasing a wire to connect to a grounding device, it is important to know the types of grounding and its purpose.

There are two types in total:

- Working. Purpose - to ensure normal operation of the electrical installation. Without this condition, the functioning of the network would be impossible for various reasons. In other words, this is the normal operating mode of the equipment. An example is grounding the neutral of power transformers in order to increase the short-circuit current and increase the sensitivity of relay protection.

- Protective. The task is to guarantee the safety of people from being exposed to electric current at home or when servicing equipment on overhead lines, substations or other electrical installations. Depending on the situation, it may be provided for protection against lightning, surge voltage and potential that may appear on the body of household or other equipment.

In apartments and private cottages, protective grounding is used, which we will discuss in more detail.

The principle of construction and purpose of protective grounding

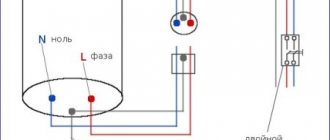

In simple terms, protective grounding is formed as follows. The ground wire is connected to a non-current-carrying metal part.

At the next stage, the “ground” connected to the equipment is combined, and then goes through a separate wire or busbar to the grounding device.

In the event of a voltage breakdown on a metal body and a person touches it, the potential goes through the ground and not through the body. Due to the low resistance, protection and RCDs operate faster.

In comparison, the R of a ground loop is only 4 ohms or less, and that of a human is more than 1000 ohms. According to Ohm's law, we know that current always follows the path of least resistance.

Thus, protective grounding is designed to solve the following problems:

- reducing the potential difference between the grounded device and other objects and protecting human life;

- draining current into the ground and increasing its values to trigger protective devices (RCDs, automatic devices).

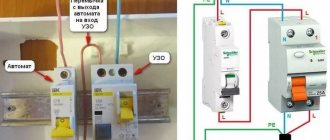

Therefore, when laying a conductor for grounding, it is important to ensure the presence of protective devices. The latter must quickly respond to leakage or high currents by cutting off the damaged area. The sooner this happens, the better.

Types of grounding

Before you go to the store to buy a grounding wire, you should familiarize yourself with the main types of grounding. Among them:

Working. Designed to ensure the normal functioning of any equipment. If this is not done, then using the electrical network will be almost impossible.

Protective. Designed to prevent injury to a person as a result of exposure to electric current. It has found application both in everyday life and in production. Protective grounding can be used to prevent lightning strikes or to reduce the likelihood of electric shock generated on the frame of any equipment.

The last option is considered the most common, as it is used not only in production, but also at home.

Purpose and principle of grounding organization

The grounding wire must be connected to metal, which under no circumstances can be exposed to electric current. If an electric charge occurs on the body of the equipment or machinery, it will move through the wire to this metal and literally go into the ground, bypassing the human body. The specificity of the process is that low resistance allows the protection and RCD to operate faster.

A striking example of the explanation is that the ground loop has a maximum resistance value of only 4 ohms, while the human body has 1,000 ohms. In physics, this process is explained by Ohm's law. Electric current always moves along the path with the least resistance.

Accordingly, protective grounding is designed to solve several main problems at once. Namely:

protect human life by reducing potential differences;

draining electric current into the ground and provoking the activation of protective equipment - RCDs or automatic machines.

Therefore, when arranging grounding, protective equipment is often installed in the system. These devices must respond as quickly as possible to any changes in the state of the electric current and block its flow to the problem area. The faster the organization of this process, the better for equipment and people.

Section requirements

Almost all industrial premises and most home apartments are faced with the need for a master to independently arrange grounding. In the first case, this is caused by the need to connect new machines and technical devices. The second is that until 1998, even tires were not created in apartment buildings.

Taking into account the PUE, four different schemes can be organized. Namely:

TN-S. In this case, one neutral and one conductor are allocated. This option is suitable for AC voltage networks.

TN-C. In this case, zero and ground are the same wire. Often used in old apartments where the neutral passes separately.

TT. Direct land allocation for any equipment.

Grounding cross-section requirements

Many owners of houses and apartments are faced with the need to do grounding themselves. This is explained by the fact that in old buildings before 1998, there were no grounding connections and, accordingly, no busbars for connection at all.

Even if the house already has a grounding system, when choosing a wire, you need to find out the type of system.

Taking into account the PUE, four grounding schemes are distinguished:

- TN-S - use of neutral and separate conductor. The circuit is relevant for alternating voltage.

- TN-C - combining “0” and ground with a common wire. In this scheme, the neutral goes separately, which is typical for old buildings.

- TT - direct ground to electrical equipment.

- IT - connection to the housing using resistance or insulation of current-carrying conductors.

More about grounding systems, their advantages and disadvantages.

To choose the correct cross-section, it is important to consider one more point - the type of grounding.

It could be:

- stationary (done without the need to move, on an ongoing basis);

- portable (can be removed if necessary and moved to another object).

For domestic purposes, as a rule, the first option is used. It is this that we will focus on when choosing the section (S).

To avoid mistakes, follow these simple rules:

- For phase S up to 16 sq. mm grounding conductor is selected of a similar size.

- At S the phase has from 16 to 35 sq. mm cross-section of the “ground” conductor is selected to be 16 sq. mm.

- If S of the phase wire is over 35 sq. mm, the ground electrode must have a thickness of at least half this value.

Most often, copper wires with S equal to 4 square meters are tried on in a house or apartment. mm. Under such circumstances, S of the grounding wire is selected with the same parameter.

If, for example, the thickness of the phase suitable for the cabinet is 25 sq. mm, the optimal parameter S is 16 sq. mm. Everything is simple here, so there should be no confusion.

It is important to remember a number of more rules:

- For TN-C and TN-CS, the lower cross-section threshold is 10 square meters. mm for copper and 16 sq. mm for aluminum conductor.

- In an apartment or house, a wire with one core is sufficient.

- Color requirements: yellow-green.

Sometimes when calculating the grounding cross-section, a special formula is used. It takes into account the short-circuit current, protection response time, type of insulation, type of gasket and other features. In practice, this method is rarely used.

Brand and requirements for conductors

The core of a grounding wire or cable can be single-core or multi-core - it depends only on where it will be used. For example, to ground a door in an electrical panel, you need to ensure its mobility. The rigid core will break due to constant opening of the door and its bending. Therefore, the core must have an appropriate flexibility class that does not interfere with opening, for example 3 and higher.

At the same time, to connect, for example, the casing of an electric motor of a pumping station to a gas pump, there is no need to ensure mobility, since this type of electrical equipment is permanently mounted. Therefore, rigid conductors can be used.

The grounding conductor can be:

- isolated;

- non-insulated;

- is part of the cable;

- be a separate single-core wire;

- aluminum;

- copper.

This begs the question: which wire should I use to connect the ground?

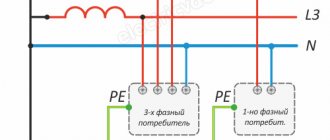

Stores sell cable products with different numbers of cores: 2, 3, 4, 5. This is necessary for assembling certain circuits for connecting devices and connecting electrical equipment to networks with different numbers of phases.

To connect grounding in sockets and other electrical equipment of a single-phase network, it is convenient to use three-core cables, for example VVG 3x2.5. And for connecting three-phase equipment to the network and grounding, four-core cables are intended, for example AVVG 4x32. Moreover, in thick cables the grounding conductor usually has a cross-section smaller than that of the phase conductors. Let's give examples.

- VVG – suitable for internal use. To install it outdoors, it must be placed in corrugated pipes or pipes. It is produced with different numbers of cores; there is a more detailed review of this cable on the website. For use in hot rooms it is better to use VVGng-ls. This cable is rigid and better suited for permanent installation.

- NYM is a foreign brand with characteristics similar to VVG. Hard.

- VBBShv - suitable for outdoor use and burial in a trench, often used to connect a private house to the network. Hard.

- PVA is well suited for connecting power tools and extension cords, because it consists of multi-wire flexible conductors. Produced in two and three-wire versions.

- ShvVP - similar to the previous one, only it is not round, but flat.

- ESUY is a single-core soft copper wire.

Ground wire color and connection features

To avoid confusion, it is important to understand what designations need to be provided for such wires.

Today the following types of markings are used:

- PE - 0 protective wires and bars, colored in the form of intertwined yellow-green shades.

- N - 0th wires, indicated in blue (neutral).

- PEN - combination of zero and ground. The main part is blue, at the edges there is a combination of yellow and green colors.

In our case, a designation with the corresponding color design (yellow and green) is used. It is designated in the same way in a three-core wire.

If you don’t have a wire with the required color on hand, you can use regular yellow and green electrical tape. All that is required is to make marks on the ends of the wire.

Grounding (PE) is brought out and connected to the grounding bus, body or metal panel door. The neutral wire (N) is connected to the neutral busbar.

Read more about grounding and zeroing, what is the difference between them.

Wire marking

Grounding wires have another characteristic feature - markings.

Ground color

Grounding, according to the rules of the PUE, must be painted yellow-green. However, it is rare to see light green or all yellow wires. The cable can also be equipped with a blue braid at the fixation points, which indicates grounding along with zero.

In the distribution panel it is connected to the busbar, housing and panel door made of metal. In the box, the connection tends to the ground wires. The grounding conductor must not be connected to the residual current device.

Symbols on electrical diagrams: for direct current, standard grounding, to the electrical equipment housing, clean and protective.

Neutral color

An example of the appearance of a neutral wire.

The neutral conductor is strictly blue in color. In the distribution panel it must be connected to the neutral bus, which is designated by the letter N. All remaining blue conductors are connected to it. Through an electric meter or directly without installing a machine, the bus is connected to the input. In the distribution box, all wires, with the exception of blue, should not be used for switching. Neutral conductors in sockets are connected to the contact designated N - located on its back side.

Phase color

Compared to ground and neutral, phase has a wider range of colors. Any colors except blue, yellow and green can be used to designate a wire. The most common are black, red and brown.

In the distribution box, the phase that leaves the consumer is connected to the contact of the automatic switch located at the very bottom, or the residual current equipment. The switches carry out phase switching.

Independent wire designation

From time to time there are conductors with unusual colors. Such solutions do not comply with the standards set out in the PUE. To make the task easier, it is recommended to label the wires yourself with the necessary colors. Colored electrical tape and heat-shrinkable tubing are used for this.

Another task of the master is to write down the meanings of the colors separately on a piece of paper.

Marking

For a better understanding, let us raise the issue of marking the insulation of the conductors used.

The following symbols can be used in the wire name:

- A - aluminum core (in the absence of a letter - copper);

- AC - presence of lead braid;

- AA - stranded wire with an aluminum core and a braid of the same material;

- B - corrosion protection, made of double-layer steel;

- G - without shell;

- Bn - protection from moisture and resistance to fire;

- NP - non-flammable material;

- R - rubber shell;

- B - polyvinyl chloride shell;

- K - control cable, etc.

You must pay attention to the above markings when choosing a wire for grounding in relation to its cross-section (this was mentioned above).

Brands and requirements

When purchasing a grounding cable, you need to thoroughly examine it for the possibility of using it in a house, apartment or special room (for example, a bathroom, sauna, etc.).

The grounding conductor can be single-core or multi-core. Here you need to focus on the installation location and ease of use.

Here are some examples:

- When connecting the case to the cabinet door, it is necessary to maintain mobility, so it is better to use a multi-core product. If you install a single-core conductor, it will quickly become damaged due to frequent bending.

- To connect the body of an electric motor, where mobility is not needed, rigid conductors are useful. There are no special requirements for flexibility here.

- When arranging grounding in an apartment or house, you can use any type of wire, taking into account the risk of damage and ease of installation.

Depending on the type, the grounding conductor can be made of aluminum and copper, come as a separate product or as part of a cable coil, be with or without insulation.

Today there are several main brands of wires.

NYM

A product with a copper core and an intermediate shell of green-yellow color. It is easy to install and is used for voltages up to 660 V. Operating frequency 50 Hz.

The number of conductors can be from one to five with a cross-section from 1.5 to 6 square meters. mm. The rated current is determined by the working cross-section of the conductor.

Operating temperature range from -50 to +50 degrees Celsius. The bending radius is no more than four cable diameters.

Pros: resistance to moisture and fire, flexibility and a wide range of design options.

Cons: high price and fear of direct sunlight.

VVG

Cable with polyvinyl chloride insulation, outer PVC sheath and without a special protective layer (armor). It can be single or multi-core.

In 3, 4 and 5-core cables, grounding and neutral can be provided.

Allowed to be used as a grounding conductor at voltages up to 600 V.

Some types of cable are designed to operate at 1000-2500 V. Operating temperature ranges from -50 to +50 degrees Celsius.

PV3

Copper wire with polyvinyl chloride insulation. It is highly flexible, which allows it to be used for grounding various devices and mechanisms (including in everyday life).

The product is resistant to moisture and can operate in temperatures from +60 to -70 degrees Celsius. Therefore, it can be used even in extreme conditions - baths, bathrooms and outdoors.

PV3 is not afraid of mold and is not susceptible to fire. When exposed to high temperatures, normal melting of the shell occurs.

PV6

A reliable product used for laying live parts and grounding. During use, it is important to avoid direct sunlight and high temperatures.

The cores of the product consist of copper and can be single-wire or multi-wire. Operating voltage up to 1000 V.

Thanks to the use of transparent plastic, it is more convenient to monitor the health of the device.

Colors may vary, so color marking must be done independently. To do this, you can use the approach mentioned above - marking with yellow and green electrical tape.

ESUY

Highly flexible copper ground cable. The core is made of thin wires. There is a high strength braid on top. Organosilicon rubber is not used in production.

The product has high frost resistance, a transparent shell and an operating temperature range from -40 to +70 degrees Celsius.

The most popular brands of wires/cables for grounding are discussed above, but other options can also be used. The main thing is that the conductor meets the requirements of flexibility and cross-section.

Requirements

Grounding conductors shall comply with the requirements of 543.1.1 or 543.1.2[2].

Their cross-sectional area must be at least 6 mm2 for copper or 50 mm2 for steel. If a non-insulated grounding conductor is laid in the ground, its dimensions and characteristics must correspond to those specified in Table 54.1 [2]. For example, for a round vertical grounding electrode made in the form of a hot-dip galvanized steel rod, the minimum diameter will be 16 mm. And for a horizontal grounding electrode and a grounding conductor made in the form of a round wire made of the same steel, the minimum diameter will be 10 mm. I will give this table below: Table 54.1. Minimum dimensions of commonly used ground electrodes, embedded in soil or concrete, used to prevent corrosion and provide mechanical resistance

| Electrode material and surface | Profile | Diameter, mm | Cross-sectional area, mm2 | Thickness, mm | Coating weight, Gy/m2 | Coating/shell thickness, microns |

| Steel embedded in concrete (bare, hot-dip galvanized or stainless steel) | Round wire | 10 | — | — | — | — |

| Ribbon or strip | — | 75 | 3 | — | — | |

| Hot-dip galvanized steelc | Stripb or profiled strip/plate. — solid plate, — perforated plate | — | 90 | 3 | 500 | 63 |

| The round rod is installed vertically | 16 | — | — | 350 | 45 | |

| Round wire - installed horizontally | 10 | — | — | 350 | 45 | |

| Pipe | 25 | — | 2 | 350 | 45 | |

| Twisted (embedded in concrete) | — | 70 | — | — | — | |

| The cross profile is installed vertically | — | (290) | 3 | — | — | |

| Copper-clad steel | The round rod is installed vertically | (15) | — | — | — | 2000 |

| Copper plated steel | The round rod is installed vertically | 14 | — | — | — | 250e |

| Round wire - installed horizontally | (8) | — | — | — | 70 | |

| Strip installed horizontally | — | 90 | 3 | — | 70 | |

| Stainless steel | Stripb or profiled strip/plate | — | 90 | 3 | — | — |

| The round rod is installed vertically | 16 | — | — | — | — | |

| Round wire - installed horizontally | 10 | — | — | — | — | |

| Pipe | 25 | — | 2 | — | — | |

| Copper | Band | — | 50 | 2 | — | — |

| Round wire - installed horizontally | — | (25)d 50 | — | — | — | |

| A solid round rod is installed vertically | (12) 15 | — | — | — | — | |

| Stranded wire | 1.7 individual twist | (25)d 50 | — | — | — | |

| Pipe | 20 | — | 2 | — | — | |

| Solid plate | — | — | (1,5) 2 | — | — | |

| Perforated plate | — | — | 2 | — | — | |

| aChrome 16%, Nickel 5%, Molybdenum 2%, Carbon 0.08%. | ||||||

| b Both rolled and cut strip with rounded edges. | ||||||

| c The coating must be smooth, continuous and free from sagging. | ||||||

| d Thickness provides protection against mechanical damage to the copper coating during the installation process. It can be reduced, but not less than 100 microns, if special precautions are taken to avoid mechanical damage to the copper during the installation process (for example, drilled holes or special protective tips) - taken according to the manufacturer's instructions. | ||||||

| e If experience shows that the risk of corrosion and mechanical damage is extremely low, a section of 16 mm2 may be used. | ||||||

| Note : Dimensions in parentheses are applicable for protection against electric shock only, while values not in parentheses are applicable for protection against lightning and electric shock. | ||||||

When minor ground fault current is expected to flow to the grounding electrode (for example, in TN or IT systems), grounding conductors may be selected in accordance with the guidelines of 544.1 [2].

Attention! Aluminum conductors should not be used as grounding conductors.

Note

. If the lightning protection system is connected to an earthing conductor, the cross-sectional area of the earthing conductor must be at least 16 mm2 for copper (Cu) or 50 mm2 for iron (Fe) (see IEC 62305 series).

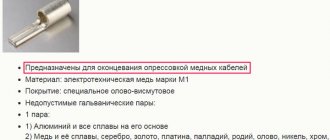

The connection of the grounding conductor to the ground electrode must be reliable and with appropriate electrical characteristics. The connection can be made by welding, crimping, connecting clamp or other mechanical connector. The mechanical connection must be installed in accordance with the manufacturer's instructions. Installation of the connection clamp must not result in damage to the electrode or grounding conductor.

Connecting conductors to grounding electrodes by soldering is only possible if proper mechanical strength is ensured in the soldered electrical contacts.

Note

. If vertical electrodes are used, it must be possible to control the connection and replace the vertical rod.

To carry out measurements of the resistance of the grounding device, it must be possible to disconnect the grounding conductor in a convenient place. In electrical installations of residential buildings, such a place, as a rule, is the main grounding bus. Disconnection of the grounding conductor must be possible only with the help of a tool.

An identification sign must be provided at the points where grounding conductors enter houses:

Wires for grounding 380 Volts

When choosing a 380 V ground wire, it is important to adhere to the same requirements as discussed above. Pay attention to the type of insulation, cross-section, flexibility, operating temperature and other parameters. There are no special differences in requirements between grounding at 220 or 380 V.

If we talk about the type of wires used, it is recommended to use the brands already discussed above.

To these you can add a PVS 5x6 wire in double round insulation with five cores. Suitable for powering and grounding equipment up to 660 V.

Ground wire size

Since the effectiveness of the protective device and ensuring human safety directly depends on such a parameter as ohmic resistance, the grounding wire must have an appropriate cross-section that meets the operating parameters of the laid line or electrical installation. Due to the fact that, unlike the phase and neutral busbars, protective grounding does not have to withstand the load for a long time, its cross-section can be made with excellent parameters.

Figure 3: example of a cable with a smaller PEN core cross-section

So the cross-section of the PE conductor is determined in accordance with clause 1.7.126 of the PUE; the simplest option is to calculate the value based on the area of the phase conductors:

- For phase wires up to 16mm 2, the grounding cross-section should be the same;

- For models from 16 to 35mm 2, grounding can be at least 16mm 2.

- For lines with a phase wire cross-section of 35 mm 2 or more, the grounding wire must be selected with an area of at least half the phase wire.

This option is the simplest, but it is not always advisable to install a large cross-section conductor on the grounding, as this affects the total cost of cable and wire products. In such cases, it is possible to determine the cross section by calculation:

- S – area of the grounding wire;

- I – short circuit current value;

- t – response time of protective devices;

- k is a coefficient determined by the materials of current-carrying and insulating elements and temperature.

What is better to buy for a private home and bathroom

Now let's look at how to choose a grounding wire for a specific installation location.

For home

When installing a grounding structure in a private house, take into account the cross-section of the wiring and the presence of a grounding loop. If the ground electrode is buried in the ground and the bus bar is removed, all that remains is to select the correct cable.

Please note the following points:

- Section. Must be selected taking into account operating conditions. In most cases, a wire of 4 sq.m. or more can be used for the home. mm and thicker.

- If a wire with a cross section of 6 square meters is used. mm without insulation, preference must be given to a stranded conductor.

- It is recommended to use steel reinforcement with a diameter of 16 square meters or more as grounding conductors. mm. It is allowed to use a steel angle of 50 mm or more.

- After completing the work, it is important to measure the resistance, which should not exceed 4 ohms.

When choosing a cable, you can use any of the ones suggested above - VVG, PV-6, NYM, ESUY, PPV and others.

Read - how to make grounding in a private house.

For bathroom

When it comes to the bathroom, it is important to ground all metal elements. This category includes the body of a metal bathtub, hot and cold water supply pipelines and other metal elements.

The cross-section of the ground wire must be at least 2.5 square meters. mm, but when using a thicker phase wire, it is necessary to use a “ground” of 4 square meters. mm.

Wires that are connected to metal elements can be brought out to a common busbar, and from there the wire can be directed to the panel or to the machines (there must be a grounding wire for a bolted connection).

The conductor used can be flexible or solid, depending on the installation characteristics. Here the decision is made on the spot.

An important point is the requirement for cable resistance to temperature and moisture. The above brands of wires fully comply with the required characteristics.