Preparatory stage

Preparation for installing the machine involves laying electrical communications. Before you begin laying electrical wiring, purchase the following components:

- Wires. Based on the average power of the washing machine, choose a copper wire with three cores with a cross-section of 2-3 mm and high-quality insulation.

- Emergency shutdown devices (or residual current circuit breakers). They will protect the device from voltage surges.

- Circuit breaker. The machine will protect the machine from short circuits and unacceptable voltage drops. Complete with an emergency shutdown device, the switch will protect your equipment from all risks associated with electricity.

- Additional components - terminals, cable ducts, clamps, etc.

Before buying everything you need, you should read the instructions for the device and the rules for connecting the washing machine to the electrical network.

How to properly connect the machine to the electrical network - instructions

Do you think that draining and filling the machine with water are the most important steps?

It is equally important to ensure that the washing machine is properly connected to electricity. It's not just about the risk of breakdown, but also about your safety. Therefore, today we will talk about how to properly connect a washing machine to electricity.

Electrical connection: preparatory work

If you decide to organize a renovation of the room in which your washing machine is installed (or will only be installed there), immediately include the wiring in your plan. It must take into account the connection of the MCA.

Drilling walls, chipping tiles, and then putting everything back in place is a waste of time and money, so it’s better to do everything according to the rules the first time.

What you need for proper connection:

- Wires. Don't even try to save money on them. Taking into account the average connection power of the washing machine, use a 6mm three-core copper wire with good insulation. From the table below you will learn more about the characteristics of various wires.

- The residual current switch is more popularly known as an emergency shutdown device. It is needed to ensure that your washing machine does not burn out during a power surge. This means that the machine not only will not break down, but also that there will be no short circuit or fire.

- Circuit breaker. This part will protect the machine from short circuits and voltage drops below the permissible level. Together with the previous component, the machine will completely protect you and your machine from any risks.

- Accessories. Terminals, cable boxes, good clamps and so on.

Having purchased everything you need to connect the washing machine to the electrical network, start studying the connection rules. Spend a little time, it will pay off - in the future there will be no problems with the operation of the SM.

Important! Experts do not advise taking on the task yourself and recommend contacting an electrician if you do not have experience in this industry.

Rules for connecting the machine to the electrical network

So, let's look at the basic requirements for installing the machine:

- Correct connection diagram. Do not use dubious diagrams “on a piece of paper” downloaded from the Internet; the diagram should be developed by a specialist.

- Copper and aluminum wires should not be twisted.

- To make the correct wiring, use copper wires of the required cross-section.

- There is no need to ground wires using batteries and pipes.

- When choosing a socket, choose a product based on high-quality ceramics.

- Do not use an extension cord unless there is an outlet nearby. The same can be said about adapters from a Euro plug to a regular one. It is better to install an outlet near the washing machine than to take risks.

- Do not twist the “Zero” and “Ground” wires under any circumstances.

- Before laying the wiring, carry out strict calculations of the number and power of devices that, in addition to the washing machine, will be connected to it.

Communications wiring diagram

Of course, you need a reliable CM connection diagram. To play it safe, you need to run a cable of the required cross-section directly from the distribution panel, also including three important components in this circuit:

- machine;

- emergency shutdown device;

- grounding

If it is not entirely convenient for you to pull the wire from the panel itself, because it is located in the corridor, or even in the entrance, then there is a simpler solution. You can connect it to another outlet - from the stove will also work. From the socket it is necessary to separate the wire into 3 wires.

Important! If the wires are made of different metals, for example, copper and aluminum, then they must be connected only using terminals; they cannot be twisted!

As a result, all the wires converge in a good ceramic Euro-type socket. It is important that such an outlet has the ability to connect a grounding wire.

Next, put the wires in the box, and hide the disconnect device and the circuit breaker with special covers made of aluminum or plastic. This design will look good in the interior and will prevent the harmful effects of moisture on the wires.

Connection standards

Rules for connecting a washing machine to the network include the following:

- use of proven electrical connection diagrams developed by specialists;

- elimination of twisting of copper and aluminum wires;

- use of wires of suitable cross-section;

- exclusion of grounding using water pipes, radiators and the like;

- use of suitable sockets with a ceramic base;

- exclusion of extension cords and adapters from the electrical circuit.

Before laying the wiring, it is important to take into account all the electrical appliances that will be connected to it (except for the washing machine) and calculate the rated power of the devices.

Electricity consumption calculation

Manufacturers produce washing machines of different capacities. Information on the amount of kW consumed is indicated in the documentation for the device. Power is also determined by the energy consumption class to which the equipment belongs.

The energy consumption of a washing machine depends on the wash cycle, the amount of laundry and the type of material. The average power is 4 kW. At the same time, class A+++ machines consume only 0.15 kW/h per 1 kg of laundry.

Attention . The most economical devices are those that belong to class A+++. They consume a minimal amount of electricity (about 0.15 kW/h).

There are four main energy consumers in a washing machine:

- Motor - it is responsible for rotating the drum.

- Heating element - responsible for heating water and automated drying.

- Pump – pumps out water.

- The control panel consists of various lights, sensors, and indicators that are responsible for the operation of the device.

The total power of the washing machine is the sum of the power of each of these four components. The more powerful each of them, the more energy the device as a whole consumes.

Communications wiring diagram

Proper communication will protect the car from most risks. First of all, a separate cable with the appropriate cross-section is carried to the installation site directly from the electrical distribution panel, including a circuit breaker, an emergency shutdown device and grounding in the circuit.

If this is not possible, then the wire is led from the electric stove socket. The slab liner, as a rule, is made with a reserve and is able to withstand additional load.

Important . Wires of different metals are connected using terminals. These wires cannot be twisted.

Next, connect the circuit breaker, the emergency shutdown device according to the diagram, and ground it. As a result, the three wire strands converge in a Euro socket with a ceramic base and the ability to connect a ground wire.

Carrying out electrical communications for washing machines

Let's consider existing high-quality solutions for this problem. The first thing to do is to run a separate cable with the appropriate cross-section directly from the distribution board. The circuit also includes a circuit breaker and grounding, an emergency shutdown device.

The option when they are connected to an outlet for an electric stove is quite acceptable. Its indicators should be sufficient to cope with the current loads. The three-core wire is removed from the outlet.

If wires made of different metals are used, they are connected with special terminals. Twisting is not permitted.

As the standard connection diagram says, then work proceeds with the following components:

- Machine.

- Emergency shutdown device.

- Ground wire.

The three cores of this wire should then converge inside one Euro socket. It would be good if it had a ceramic base. The main thing is that you can connect the ground wire yourself.

Wires should be hidden as much as possible inside special channels. The automatic switch and emergency shutdown device are placed in plastic and aluminum boxes.

Such solutions have their advantages:

- Attractive appearance.

- Less chance of wires coming into contact with moisture.

If you use the machine correctly, equipped with an emergency shutdown system, then the classic circuit can be simplified. But there are not very many really high-quality machines being produced on our market yet.

Particular attention is paid to the outlet to which the washing machine is directly connected. The main thing is to choose high-quality products that provide maximum protection. At the next stage there is a connection to the water supply and sewerage system.

Requirements for sockets

To connect washing machines to the network, sockets with a grounding contact are used (they are also called Euro sockets). It is better to use a socket with ceramic fittings.

Important. The use of extension cords, tees and adapters in the electrical circuit is undesirable, as it can lead to a short circuit in case of poor contact, overload or water ingress.

If the socket is installed in the bathroom, then choose a special device with a higher protection class, designed for use in conditions of high humidity.

Connecting the washing machine to the water supply

The process of supplying water to the washing machine is simple. We will tell you how to install and connect the washing machine. Connection diagrams may be different, but the general requirements must always be met:

- The pipeline branch supplying water to the washing machine must be equipped with shut-off valves. It is recommended to use ball valves. Then, if a leak occurs, you can quickly shut off the water supply to the machine.

- The pressure in the pipes should not be less than one atmosphere. If the pressure is insufficient, you will have to install a special pump.

- Clogged water can quickly damage the washing machine mechanism. As a rule, most of their models are equipped with standard mechanical cleaning filters. If water of increased hardness enters the apartment, it is recommended to additionally install a polyphosphate filter. It is a flask filled with an active substance that prevents the appearance of scale. The filter media can be easily changed as you use it.

To connect the washing machine, flexible hoses with a diameter of ¾ inches are usually used. The hot water supply is used very rarely, so one hose for supplying cold water is sufficient.

- If the apartment has metal pipes, then the easiest way is to make the connection yourself using a crimp coupling. Its two halves are bolted to the pipe, securely fixing the sealing gasket. After this, a hole in a pipe with a diameter of 10 mm is drilled directly through the threaded outlet for the tap. A ball valve is installed, and a flexible hose leading to the machine is connected to it. The joints are sealed with rubber cuffs.

- A tee is installed on metal-plastic pipes. After the tap is made in the right place and the fitting is installed, the tap and flexible hose are installed. You can connect the washing machine to the water supply.

- Sometimes a method is used to supply water to the machine through a tee on the outlet of the water supply for the mixer or flush tank. But before each wash, you will have to unscrew the flexible hose leading to the mixer. Therefore, this method can only be considered as a temporary option.

Power and cable cross-section

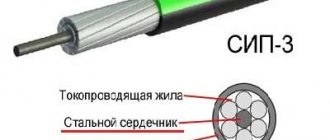

The power of most modern washing machines varies from 2 to 2.5 kW. These data are included in the documentation for the device. Knowing the power, determine the required cross-section of the supply wires.

Attention . To power the washing machine, a three-core copper cable is laid (phase, neutral, ground).

Most often in apartments, a wire cross-section of 2.5 square meters is used for an automatic washing machine. m. This cross-section will allow, in addition to the washing machine, to connect a hair dryer, electric razor and other small equipment to the same outlet. Accordingly, to protect this outlet line, a circuit breaker with a rated current of 16 (A), characteristic C and an RCD of 25 (A), 30 (mA) are used.

Cabling

Before laying the cable, determine the location of the outlet. In this case, the height of its placement and distance from the distribution board are taken into account.

Having decided on the route for laying the cable, mark it on the wall with a marker, as well as the place for the socket box. A channel and a hole for an outlet are tapped in the wall, removing the fittings along the way using a grinder. After this, the electrical cable is pulled from the panel to the outlet.

Cable brands, power ratings and cross-sections

Modern washing machines consume a lot of power, but manufacturers are trying to reduce this figure as much as possible. The average consumption level reaches 2500 W.

On the back of the device you can easily see what characteristics it has in this regard. The information is often contained in accompanying documents. To determine the cable cross-section, you should use a special table. They are located on specialized sites.

In practice, it is prohibited to use wires for which the following designations are used:

- PUNP.

- APUNP.

If the apartment is equipped only with old two-wire wiring, it is replaced with a three-wire analogue.

The copper three-wire type of wiring is most suitable for making connections. The use of protective additional devices is a mandatory requirement; such connection rules apply under any circumstances.

When a suitable section has been selected, you can safely go to the store to purchase a product with suitable characteristics. The main thing is to choose only manufacturers with a well-deserved reputation.

Residual current device

A residual current device (RCD) is designed to protect a person from electric shock in the event of breakdowns or contact with live parts of an electrical appliance, as well as to prevent short circuits and fires.

As a rule, an RCD for a washing machine is paired with a machine. But you can install one automatic device instead of these two devices; it will protect both people and equipment.

When choosing an RCD for a washing machine, they are guided by the power of the device. Most models consume about 2 kW, which exceeds the 10 A rating. Therefore, an automatic or automatic machine chooses one that operates at a current greater than 10 A. This is a 16 A device.

Is a residual current device (RCD) necessary?

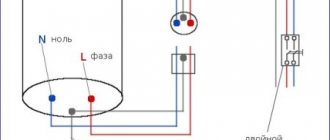

An RCD, in this case a grounding connection is not provided, so the wire is led directly to a grounded plate in the switchboard

The requirement for installing an RCD is not specified in the instructions for the washing machine. But this is due to the fact that in developed countries such devices are installed in the switchboard by default. In the Russian Federation, things are much worse with this. Therefore, it is necessary .

Why is a residual current device needed? Its function is to turn off the power supply when significant “leakage” of electricity occurs in the wiring, namely, electric shock. Accordingly, even if the washing machine breaks down or the insulation of the power cable, which someone takes hold of, is damaged, the RCD will immediately trip and the power will automatically turn off.

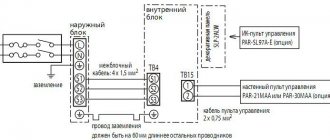

RCD connection diagram

Which RCD should be installed? The maximum load is calculated the same as for a socket (also indicated in amperes), but the setting should be no more than 30 mA . Otherwise, there is a risk that the RCD will not operate due to a short-term current leakage.

We recommend reading a related article on this topic about cleaning a washing machine with citric acid to remove scale and dirt. Information about the advantages and disadvantages of citric acid, step-by-step instructions for cleaning a washing machine.

Prices for various types of automatic machines

Difavtomat

Grounding

The place to install the unit is most often chosen in the bathroom. Working in conditions of high humidity automatically increases operating risks. Therefore, the latest models are equipped with Class 1 protection against electric shock. This is ensured by protective earthing.

If the house you live in was recently built, then no additional steps are taken to ground the machine. Such houses already have grounding and modern wiring with a built-in third wire.

In old houses, the washing machine is grounded from the electrical panel. A neutral wire is attached to it, which will act as grounding. The zero is bifurcated and special tires are fixed to both the neutral wire and the ground. From these buses they run wiring to the car and install a new outlet designed for grounding. In this way, they compensate for the lack of a third wire in old-style houses.

We provide protection against failures

High-quality grounding is the first step towards forgetting about most problems. But only recently have people begun to think about proper grounding for sockets that are supplied with devices.

The actions are described as follows:

- We bring out a wire that is intended for grounding to the desired wall of the house. The end of the wire should reach the foundation.

- A piece of reinforcement is driven into the ground to a depth of approximately 2 meters. The tip should stick out on the surface, about 30 centimeters.

- The ends of the wire must be completely free of insulation. Protruding ends need to be removed from dirt and rust. The exposed part of the wire must be tightly wrapped around the fittings. The connection can be secured with a small amount of cold welding to make everything more secure.

- The connection between the fittings and the wires is carefully wrapped with electrical tape. A piece of rubber hose of the appropriate diameter is placed on top of the fittings.

- Preparation of proper grounding ends here. Now the wire and socket connect without problems.

Surge protection

The difavtomat can handle the function of protection against power surges. This device helps protect against electric shock and switch off the load level on the machine itself during power surges. This eliminates the risk of personal injury and machine damage due to sudden changes in the network.

For washing machines, choose those differential current models that have a minimum current cut-off value at 16 A, and the cut-off level in automatic differential current mode is no more than 30 mA.

This is interesting:

The procedure for installing washing machines by level to prevent them from jumping

Dimensions of the built-in washing machine: width, height, depth

How to make a dryer for vegetables and fruits yourself

Connecting the machine via a residual current device

To carry out work on the electrical panel, you need to call an electrician to your home. The price of the service depends on the availability of special protective equipment. Carrying out electrical installation work on your own in the switchboard is prohibited, as you may have to turn off the general power supply to the network.

There are two options for connecting a machine via an RCD:

When connecting a washing machine through an RCD, the main factor is the correspondence of the electrical protection parameters with the power consumption of the unit.

Features of connection in the kitchen

Connecting a washing machine in the kitchen is not fundamentally different from connecting it in the bathroom. A dedicated power line is also connected to the device from the panel and a special European socket is installed. Other energy-intensive equipment is not connected to this line.

Attention . The optimal solution when placing the machine in the kitchen is to connect it to the panel using a three-core cable on which a circuit breaker is mounted.

Short circuit protection is provided by installing an RCD. The socket is mounted above the floor level at a height that will not allow water to enter it in the event of a leak. The socket must be grounded.

Typical errors when connecting a washing machine

In old houses, grounding to zero is a common practice. But doing this, of course, is not recommended.

The most common mistakes made when connecting washing machines to the electrical network are the following:

- Connection without grounding. Even if the machine operates in this condition for more than one year, sooner or later static will lead to failure of the control board. In the worst case, when you touch the body of the washing machine, you will receive an electric shock.

- Connection without RCD. Washing machines are directly connected to the water supply. If at some point the pipe breaks or the hose through which water is supplied bursts (and this may be due to a clogged filter), then a short circuit will occur almost instantly, which can lead to a fire. In this situation, the RCD will instantly turn off the power (whereas a conventional machine will only do so when the total load in the electrical network increases). And this is important, since modern washing machines support a delayed start function (for automatic washing using a timer).

- Grounding connection "to zero". When you try to start the washing machine in this case, the protection in the panel room is necessarily triggered and the electricity is completely turned off.

- Connection to an outlet that is not designed for high load. At best, soot will simply appear on it. At worst, it will begin to melt, after which it will simply stop working (due to melting of the contact plates).

- The position of the washing machine was not adjusted before the first start. In this case, the water presence sensor may not work correctly, so water will remain in the drum after washing. It is this that can accumulate static electricity, transferring it to the drum. For the same reason, you can get an electric shock when removing laundry, even if the washing machine is turned off from the outlet.

- After washing, do not unplug the machine from the outlet. Diode bridges, which prevent electrical consumption when turned off, can simply burn out over time. The residual electricity will subsequently go to the control board. Again, the manufacturer also clearly states in the instructions the need to turn off the washing machine when not in use. If it is difficult to get to the outlet, then it is permissible to disconnect the entire power line from the switchboard.

These are just common mistakes.

Video - How to connect a washing machine

Connection errors

List the most common mistakes made when connecting a device to a network:

- Use of non-standard electrical wiring (insufficient cable cross-section, single-layer insulation). This leads to overheating of the wires, melting of the insulation, and short circuits.

- Using existing old wiring of poor quality. The optimal solution is to connect via a separate three-core cable of the appropriate cross-section from the distribution panel with the installation of circuit breakers rated for a current of at least 16 A.

- Lack of grounding. High-quality grounding is the key to safe and long-term operation of the device. Unqualified local “grounding” of the grounding conductor does not provide the required quality of grounding and does not exclude the occurrence of emergency situations leading to electric shock.

- Using faulty or low-quality two-wire sockets without individual grounding. This leads to overheating of the wiring, melting, electric shock and damage to the device.

- Incorrect integration into the headset. This error is typical when placing the unit in the kitchen. The machine vibrates during operation and therefore should not be pinched by the walls or countertop.