Calculation of wire cross-section

The first thing that needs to be calculated is the cross-section of the wire through which the socket/machine that powers the washing machine will be connected.

The cross-sectional diameter is selected according to the possible peak load on the electrical network. That is, according to the maximum power consumed by the device (indicated in kilowatts or volt*amps). You can find out the parameters of a particular washing machine directly in the technical documentation. It is recommended to adhere to the following scheme.

Table 1. Scheme for calculating the cross-section of wires.

| Maximum current consumption | Cross-section of power cable wires (copper), mm | Cross-section of power cable wires (aluminum), in mm |

| Up to 1 kW | 1 | 2.5 |

| Up to 2 kW | 1.5 | 2.5 |

| Up to 3.5 kW | 1.5 | 2.5 |

| Up to 4.4 kW | 2.5 | 4 |

| Up to 5.5 kW | 4 | 6 |

Most household models of washing machines consume from 2 to 3.5 kW. The above table is valid only for a supply voltage of 220 V. Washing machines that require a connection to 380 V are not used for domestic use.

Stranded wire should not be used. It is recommended to buy a single-core one and lay it with a single circuit

Is it possible to use a wire of greater thickness than indicated in the table? Although this will be additional costs, this option is acceptable. The main thing is to lay it through a cable channel, the internal volume of which will be filled to no more than 60% (to ensure normal heat removal, which complies with SNiP standards).

What happens if the wire turns out to be thin?

If the wire is thin, then:

- There is a possibility of overheating of the supplied cable, which will cause its insulation to melt and a short circuit may occur in the future.

- Due to constant overheating, finishing materials will be damaged (even if the wire is mounted in a cable channel, the plaster often becomes covered with cracks, and dark spots appear on the wallpaper).

- Increased load on the terminal connections (in the panel, directly in the socket or machine).

Otherwise, using a wire that is too thin to supply power is a violation of fire safety rules. Active use of such an electrical network can indeed cause a short circuit and subsequent fire.

The most common consequence of using thin wires

Availability of grounding

The presence of grounding for a washing machine is a mandatory requirement. This is indicated in the technical documentation and in any other connection instructions. Without grounding, the static voltage generated on the drum of an automatic machine can “break through” to the body, and even to water pipes and taps (especially if the entire water supply is on metal pipes).

Plugs for connecting washing machines most often look like this. The side contacts are just for connecting the ground to a compatible outlet

Also, static voltage can damage the vulnerable internal components of the washing machine. Most often, control boards “suffer” from it. And repairing such a breakdown can cost half the cost of a new device. And, by the way, connecting the washing machine to the electrical network without grounding is a violation of the warranty conditions. If it fails, even due to a manufacturing defect, the manufacturer has the right to refuse to carry out repairs.

What should be the grounding? The standard currently used is TN-S. In old apartment buildings in the Russian Federation, TN-C is often used. Is it possible to connect the machine to a network with such grounding? In theory, yes, but in practice, the protection will be inadequate. In this situation, the installation of a so-called PEN conductor (often called a “bus”) is required, with its division into channels N (zero) and PE (for grounding). Any electrician can handle this without any problems (it is prohibited to do this on your own, since it requires a partial change in the connection configuration in the switchboard).

As for the cross-sectional diameter of the grounding wire, in most cases 1 mm for copper and 2.5 mm for aluminum are sufficient. And if a regular three-wire wire is installed to connect the power supply to the washing machine, then the cross-section will be the same as that of the supply wiring.

Is it possible to ground the water pipe or radiators? In no case, as this will lead to the spread of static to the entire water supply or heating pipeline in an apartment building. And if the wiring is also installed with a residual current device (RCD), then the grounding connection in such a non-standard way will lead to its automatic operation when the washing machine is turned on.

What to do in private houses where there is no grounding at all? Output it separately for the washing machine (you can also connect a boiler, pumping station, dishwasher to it - these are the devices that consume the most electricity in the house).

Option for grounding in a private house

Socket selection

In 90% of cases, washing machines are installed in the bathroom. And this is a room with high humidity. Therefore, an outlet is required with an increased moisture protection class. It is recommended to adhere to the following scheme:

- The socket is located at a distance of up to 0.6 meters from the bath/shower/sink. The socket housing must comply with IP X5 standards (there will be a different number instead of X - it indicates the class of resistance to dust and dirt penetration inside the housing).

- The socket is located at a distance of 0.7 to 2.4 meters. In this case, the housing must comply with IP X4 standards.

- The socket is located at a distance of over 2.4 meters. You can use a regular household outlet.

Another nuance - you should give preference to sockets with ceramic rather than plastic casings. Even with a short circuit or severe overheating, they do not melt or catch fire - this will be a kind of additional protection.

Symbol of “danger zones”. A socket should not be placed in zone 1

Is it possible to install a “circuit breaker” (circuit breaker) instead of an outlet? In principle, it is possible, but this scheme has several significant disadvantages:

- the machine must be enclosed in an additional sealed housing, which will protect the connection from splashes, moisture, and dirt;

- the machines are installed only externally, they can only be mounted into the wall by covering them with plasterboard; for miniature bathrooms, forming an additional false wall is not an option;

- By default, washing machines have an outlet specifically for the socket; to connect through the “automatic machine,” you have to cut off the plug, which is why the consumer loses the warranty (the manufacturer has the right to refuse service because changes have been made to the design of the device).

So it is recommended to install sockets. The presence of a protective “curtain” on it is not necessary. But you shouldn’t install so-called “smart” sockets (with remote control, measuring wiring temperature). Due to increased currents, control boards, as practice has shown, often fail.

The protective curtain provides virtually no protection from moisture. The main thing is the presence of internal protective membranes that automatically open when the plug is connected

Permissible load per socket

When choosing an outlet, you should also take into account the permissible peak load on it. Most household models are designed to operate on a 220 V network with a current of 16 A. This means that the maximum power of a washing machine connected to such an outlet should be no higher than 3.5 kW. (220V*16A=3520 W). If the device consumes from 3 kW. and higher, it is definitely recommended to install a socket with a permissible peak load of 25 A. In this case, the risk of overheating of the contacts and the housing itself is eliminated.

One of the common consequences of installing an outlet that is not designed for high loads. The same thing happens if the internal connection at the terminals is not of good quality

Is a residual current device (RCD) necessary?

An RCD, in this case a grounding connection is not provided, so the wire is led directly to a grounded plate in the switchboard

The requirement for installing an RCD is not specified in the instructions for the washing machine. But this is due to the fact that in developed countries such devices are installed in the switchboard by default. In the Russian Federation, things are much worse with this. Therefore, it is necessary to install an RCD.

Why is a residual current device needed? Its function is to turn off the power supply when significant “leakage” of electricity occurs in the wiring, namely, electric shock. Accordingly, even if the washing machine breaks down or the insulation of the power cable, which someone takes hold of, is damaged, the RCD will immediately trip and the power will automatically turn off.

RCD connection diagram

Which RCD should be installed? The maximum load is calculated the same as for a socket (also indicated in amperes), but the setting should be no more than 30 mA. Otherwise, there is a risk that the RCD will not operate due to a short-term current leakage.

We recommend reading a related article on this topic about cleaning a washing machine with citric acid to remove scale and dirt. Information about the advantages and disadvantages of citric acid, step-by-step instructions for cleaning a washing machine.

Selecting a residual current device (RCD)

Before deciding which wire for the washing machine (see photo below) to connect to, a number of issues must be resolved. And first of all, install an automatic packet switch (most often it is C16) and an RCD, placing it in front of the socket of the connected device.

For groups of devices operating in conditions of high humidity with separate access, the setting for the RCD is set to 10 mA. With this value for the differential disconnecting current, automatic shutdown devices are produced for an operating current value of no more than 16 A, which corresponds to the rating of the package switch. For single-phase electrical wiring, we select a two-pole electromechanical RCD type A (permanent leakage type), with a short circuit current of 6000 A.

Electrical connection diagram

Experienced electricians recommend installing the power supply for connecting the washing machine in a separate group directly from the panel. Additionally, nothing should be connected to this outlet (especially a boiler, pumping station, instantaneous water heater). The cable should be laid through a cable duct; the location of the phase/zero does not matter.

Schematic illustration of connecting a washing machine

If it is not possible to bring a separate power group under the washing machine, then the output is made from the distribution box instead. The most important thing is to ensure reliable connections of wires along the separating groups (the use of terminal blocks is mandatory). And after a test run of the washing machine, you should carefully check whether the wiring connections in the junction box are overheating (for this you can use either an infrared sensor, a thermal imager, or a thermocouple). If heating above 70 degrees occurs anywhere, this indicates errors or shortcomings in the connection.

Another nuance that many do not take into account is the presence of insulation under the washing machine. For this purpose, hardware stores sell special “mats” for the washing machine, which at the same time act as an insulator and partially dampen the vibrations of the body (the machine then “does not jump” when performing a spin cycle at high speeds). And even if water is accidentally spilled on the floor, this will not lead to a short circuit.

The same anti-vibration mat that also acts as an insulator

Advice! Also, you should not use grounding from another contact group of sockets - this can release static discharges into the network and disrupt the operation of other household appliances (especially those that are vulnerable to static: routers, laptops, mobile phones, computers, TVs). Zero should also be displayed separately. This is the most secure connection option.

Connecting the washing machine to the mains

Many craftsmen are also involved in the installation of household appliances, you should strictly comply with the requirements of the PUE, do not follow the lead of illiterate owners, do it as required or NOTHING, there may be consequences - it doesn’t seem to be enough!

Place the breaker or socket in a place convenient for turning off household appliances. I’ll deviate a little from the electrical topic (The same applies to the water supply tap. Install taps in an accessible place with a metal handle, plastic ones break, the consequences are known. THE END

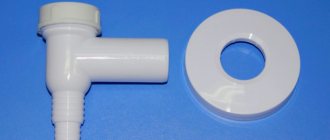

drain hose at the entrance to the sewer (pipe of larger diameter)

not lower

60 cm.

Otherwise, the appearance of a “siphon” is a matter of time; it does not apply to machines with an anti-siphon).

Circuit breakers should be installed close to the current consumed.

The short-circuit operating current for automatic machines is up to 10 ratings. Note A 10-amp machine has a short-circuit current of 100 amperes, and a 16-amp machine has a short-circuit current of 160 amperes!

Accordingly, the cross-section of the wires cannot be underestimated so that the machine has time to turn off before smoke appears from overheating of the wires; use a double-insulated cable; the laying height is not standardized for it. When laying in cable channels, use a multi-core cable that allows minimum bending radii; the bending radii of single-core cables are standardized according to the PUE.

For wet rooms (rooms with increased danger), install wiring through an RCD (PUE). At the same time, using ZERO (N) in front of the RCD, we get a third wire (PE) - a protective grounding wire in the “Euro” socket for connecting the KBT, if you do not use an RCD, then the grounding wire must (according to the PUE) be pulled from the panel with a connection under a bolt separate from ZERO .

In general, I consider the installation of an RCD mandatory at the KBT. When leaks occur, the RCD begins to disconnect the load, and the technician eliminates the defect before the Babach occurs, the most striking statistical example is Bosch washing machines, in which heating elements with a short circuit burn out and in half the cases the electronics also suffer, is repair possible?

It's cheaper to go to the Canaries!

When laying the wiring, proceed from the requirement of contact reliability. The behavior of the MCA is very typical when there is a weak contact in the power supply network - when turning on valves, motors, that is, a load with a reactive component, the machine stops after seconds and then the next attempt to start working, and so on endlessly, but on the module This is not reflected visually in the control. I even came across such an anecdote on the entrance pole to an apartment building. At the same time, devices with purely active loads (irons, kettles, etc.) work flawlessly

In junction boxes, solder all connections; if copper + aluminum are found, this is a galvanic couple; you cannot connect directly only through compressions (in twisted connections, oxidation of the connection occurs over time, an increase in resistance and, as a result, heating, then an inclined plane towards the fire), tighten all compressions until limit, to avoid weak contact, use clamps made of thermosetting plastic, and not from Chinese polyethylene, which melts at the slightest heat. Be sure to solder all splices of wires in the SMA, insulate them with heat-shrinkable tubes, do not use twisted wires and electrical tape (unwinds, unsticks and slides - not intended for elevated temperatures and vibration). When insulating splices of wires in ovens, breakdowns in the insulation of wires of electric ignition candles on gas surfaces and stoves, use silicone insulating tape, advantages: high heat resistance, super dielectric, self-vulcanizes and turns into a monolith, disadvantages: low mechanical strength, must be taken into account when using, therefore not suitable in SMA.

Typical errors when connecting a washing machine

In older houses, grounding to zero is a common practice. But doing this, of course, is not recommended.

The most common mistakes made when connecting washing machines to the electrical network are the following:

- Connection without grounding. Even if the machine operates in this condition for more than one year, sooner or later static will lead to failure of the control board. In the worst case, when you touch the body of the washing machine, you will receive an electric shock.

- Connection without RCD. Washing machines are directly connected to the water supply. If at some point the pipe breaks or the hose through which water is supplied bursts (and this may be due to a clogged filter), then a short circuit will occur almost instantly, which can lead to a fire. In this situation, the RCD will instantly turn off the power (whereas a conventional machine will only do so when the total load in the electrical network increases). And this is important, since modern washing machines support a delayed start function (for automatic washing using a timer).

- Grounding connection "to zero". When you try to start the washing machine in this case, the protection in the panel room is necessarily triggered and the electricity is completely turned off.

- Connection to an outlet that is not designed for high load. At best, soot will simply appear on it. At worst, it will begin to melt, after which it will simply stop working (due to melting of the contact plates).

- The position of the washing machine was not adjusted before the first start. In this case, the water presence sensor may not work correctly, so water will remain in the drum after washing. It is this that can accumulate static electricity, transferring it to the drum. For the same reason, you can get an electric shock when removing laundry, even if the washing machine is turned off from the outlet.

- After washing, do not unplug the machine from the outlet. Diode bridges, which prevent electrical consumption when turned off, can simply burn out over time. The residual electricity will subsequently go to the control board. Again, the manufacturer also clearly states in the instructions the need to turn off the washing machine when not in use. If it is difficult to get to the outlet, then it is permissible to disconnect the entire power line from the switchboard.

These are just common mistakes.

Video - How to connect a washing machine

Review of wire brands for washing machines

VVG cable is the most popular and widespread cable product, modifications of which are used for electrical installation work in apartments and private houses. It complies with domestic regulatory documentation.

The following types of VVG cable can be distinguished:

VVG

– basic type with polyvinyl chloride insulation and a common shell;

VVGng

– a power cable that has insulation and an outer sheath made of non-flammable PVC;

VVGng-

– a cable that has insulation and an outer sheath made of non-flammable, self-extinguishing polyvinyl chloride with low emission of smoke and combustion products;

VVGng-

– non-flammable cable product, with additional fire protection.

The main type - VVG cable has a fairly low price, but is not protected from fire. Therefore, such a cable is not used for electrical wiring in residential buildings. For such purposes, modifications of this cable in the “ng-LS” version are suitable.

NYM

is manufactured at domestic factories using German technology and also complies with GOSTs and other technical documents on cable products. Structurally, the NYM cable consists of several copper conductors insulated with PVC plastic, longitudinal non-flammable insulation and a PVC sheath. NYM cable has self-extinguishing properties and, when burned, emits a small amount of smoke that does not contain harmful components. It can be used to connect household appliances and electrical wiring in residential buildings.

Common wire brands: PVS, ShVVP, PVVP, PUNP

are not used when installing electrical wiring and connecting powerful electrical appliances for the following reasons:

PVS

– has a multi-wire core, which is why it can heat up more, which leads to wear of the insulation and, as a result, to a short circuit.

ShVVP, PVVP

– do not have non-flammable insulation, and also have a short service life due to the stranded core and thin insulation.

PUNP

– not suitable for modern loads due to their high power for this type of cable. These brands of wires can only be used to replace the power cord for a washing machine. There is a frequent situation when the standard length of wire from the washing machine to the outlet is not enough.

How to connect a washing machine - step-by-step instructions

In total, the procedure for connecting the washing machine should be as follows:

Step 1. Lay a 3-wire cable (with grounding) from the switchboard to the installation site of the washing machine.

Laying a 3-core cable

Step 2: Install a compatible outlet. If installation is carried out in the bathroom, then the socket must have a protection class of at least IP X4 or IP X5, depending on the distance to the shower, bathtub, or sink.

Connecting the outlet

Step 3. Connect the RCD (installed in the panel room, not near the outlet).

We connect the RCD

Step 4. Adjusting the position of the washing machine. To do this, just put a building level on top and adjust the position of the legs to set the air capsule to the zero position. Don't forget about the insulating mat.

Correct location of the washing machine

Step 5. Test run the washing machine. Spinning and heating of water are required - these are the functions that result in the highest energy consumption. If the machine is new, then before the first start you should also remove the transport bolts (on the back wall). If this is not done, it will vibrate excessively during operation.

Test run

By the way, the manufacturer must indicate all these recommendations in the instructions.

Those same shipping bolts. They must be removed before the test run.

Video - Connecting and installing washing machines

Features of connecting the washing machine to the electrical network

Like any other electrical appliance, a washing machine consumes electricity. Moreover, it belongs to the class of high-power consumers, as a result of which the connection must be made in strict compliance with a number of rules.

It is strictly forbidden to connect the washing machine:

- to a socket with visible damage;

- to electrical wiring made with a cable of insufficient cross-section;

- through extension cords or adapters;

- using a tee to a socket with a high-power electrical appliance already connected.

To protect the washing machine from possible breakdown, and yourself from a serious accident, you should select a separate outlet for connection, designed to operate in conditions of high humidity. The connection should be made using a large cross-section wire, and it should not come out of the nearest junction box, but directly from the panel. Otherwise, when the engine is turned on at maximum speed, the wire insulation may melt, which in turn can cause a fire.

If the owner plans to install several powerful devices in one room, for example, a washing machine with a dryer and a dishwasher, it is not necessary to lay a separate wire for each of them; it is enough to lay a copper wire, the cross-section of which is taken “with a reserve”, and wire it into two sockets in place.

Can I connect via an extension cord?

Not all bathrooms have sockets (especially in old Khrushchev-era apartments). They have to connect the washing machine via an extension cord. This option is allowed, but only if the socket, which is the main one, is designed for such loads, and the cross-section of the extension cord has a cross-section of 2.5 mm or more. (only copper is allowed, grounding is also required). The main thing is a reliable connection with a minimum of adapters.

Attention! When connecting via an extension cord, you must use its minimum permissible length. The remaining wire should not be twisted or placed “cue” in one place - this will also lead to its possible overheating.

Extension cord with moisture protection. These aren't cheap. Regular ones are dangerous to use

In total, when connecting a washing machine to the electrical network, it is necessary to take into account a lot of nuances, starting from the cross-section of the wire through which electricity is supplied, ending with the installation of RCDs, automatic circuit breakers, and grounding terminals. If at least one parameter is not taken into account, then there is a considerable probability of early failure of the equipment without the possibility of its repair under warranty.

Do you need a separate outlet?

To begin with, let’s answer the user’s natural question about why an automatic washing machine needs a separate, and even protected, electrical line, which, moreover, does not come from the distribution box, but directly from the panel? As you know, an automatic washing machine cannot:

- connect to the outlet via an extension cord;

- connect to an outlet to which a large consumer is already connected;

- connect to a weak outlet with unreliable wiring.

Why such restrictions? It’s all very simple - an automatic washing machine is a large consumer of electricity, creating a large load on the power grid. The wire experiences the heaviest load at the moment when the washing machine starts the spin program at high speeds. In such situations, the aluminum wires of the socket to which the washing machine is connected, which have a small cross-section, overheat and may well cause a fire.

There is only one solution in this case - before making repairs in the room where the automatic washing machine will be located, lay a separate wire of a suitable cross-section, made of a suitable material, directly from the panel, which will power a moisture-resistant outlet. This outlet will power your home assistant. If you do it differently, you risk starting a fire in the house or, at a minimum, damaging expensive equipment.

If in the same room you plan to connect, in addition to a washing machine, also a dishwasher, you don’t have to lay a separate line for it, just take a large-section copper wire (with a reserve) so that you can then power the second outlet from it.

Wiring and other components

First of all, you need to decide which wire to use. Namely, what cross-section will it have, how many cores will it have, and what material will it consist of? Let's start with the material. Experienced electricians do not recommend using aluminum wires to connect large consumers, and in general they say that wires made of such material should only be chosen as a last resort. Therefore, there is not much choice - we take copper wire.

Next you need to decide on the number of cores. According to technical regulations, any modern washing machine has a grounded power cord, which means we need to make a grounded socket for the washing machine. This means that we just need to take a wire with three cores: one core is phase, the second is zero and the third is ground.

Now you need to calculate the cross-section of this three-wire wire that will power the socket for the washing machine. We, of course, could give you a table that shows the wire cross-section, current and power for which a cable of the appropriate thickness is designed, but we will not do this. Firstly, the average power of any modern automatic washing machine is 2500 kW. Secondly, we had already agreed earlier that we would take a wire that has a power reserve, you never know what will happen in the future.

Therefore, guided by our own conclusions and relying on the opinion of authoritative experts, we take a three-core copper wire (cross-section 2.5 mm), with good insulation. In addition to the wire, we will need:

- moisture resistant socket;

- difavtomat;

- copper terminals and socket box;

- plastic cable channel.

A moisture-resistant socket is necessary, since the automatic washing machine is used mainly either in the bathroom or in the kitchen, and these are rooms where dampness and moisture reign. The difavtomat will provide universal protection against failures that periodically occur in the imperfect Russian energy system. The publication of the same name posted on the website will help you choose an RCD for your washing machine. Copper terminals are needed to ensure a reliable connection between parts of the electrical wiring, but it is better to do without connections at all.

Under no circumstances should you ever connect a copper wire to an aluminum one. Such savings will most likely damage electrical appliances powered from this network and may cause a fire.

To install a socket that is expected to bear a large load, take only the highest quality sockets. There have been cases when cheap plastic socket boxes caused a fire. It is also better to take a plastic cable channel of the highest quality.

Some electricians do not see anything wrong with laying the cable directly into the trench cut into the wall, because it has insulation. In our opinion, it is better to protect the wire additionally with a cable duct, you never know what situations may happen, because the electrical network will function for decades.

We pull electrical communications

Before stretching and connecting the cable, you need to determine the most advantageous location of the outlet. It is important to consider not only the height at which the outlet will be placed, but also its distance from the distribution board. You need to understand that the further the socket is from the switchboard, the higher the cost of components and the more you will have to trench the wall for the wire, and trenching is a very labor-intensive job.

Having laid out the route for the cable, mark it with a marker directly on the wall, also mark the place where you will need to drill a hole for the socket box. Further actions will depend on what material the wall in which the gutter needs to be made is made of.

If the wall is made of soft material, then gating can be done the “old fashioned way” using a hammer and chisel. If the wall is made of reinforced concrete, you will have to use a hammer drill and a grinder. We use a hammer drill to drill holes along the future gutter, and then connect them with a chisel and hammer. On the way we will definitely come across reinforcement. It is not advisable to pass a wire under it, so to partially remove it we will use a grinder.

We begin to pull the electrical cable from the panel to the outlet. We outline the connection points for the electrical cable (phase, neutral, ground), but we will not connect the wire yet. We will also have to install a difatomat in the shield. We run the neutral and phase wires through the difatomat, and connect the ground separately.

It would not be amiss to remind you that all connections must be carefully insulated.

We take the wire out of the electrical panel and pull it along the dug channel. At the same time, you can place a plastic cable channel in the grooved channel, enclosing a copper wire in it. Having brought the wire to the installation site of the socket, we leave it alone for now and move on to installing the socket itself.

- Use a hammer drill to drill a hole in the socket box (for convenience, you can use a special drill).

- We insert the socket box into the recess and “seat” it with cold welding or sealant.

- We bring the ends of the wires into the socket box.

- We unpack the new moisture-resistant socket and take out its “guts”.

- We connect the phase, neutral, and ground wires to the corresponding contacts of the socket.

- We fix the base of the socket in the socket box so that it “sits” firmly and does not dangle.

- We screw the plastic part of the socket and make sure that nothing is loose.

That's almost all. All that remains is to connect the phase, neutral wire and ground in the electrical panel and check the outlet by connecting, for example, a table lamp to it. You can use a tester to check whether there is power in the washing machine outlet. If the socket works normally, then we finally need to put the wall in order by covering up the dug-out recess with the wire and cable channel laid in it.

In conclusion, we note that electrical communications for the automatic washing machine should be taken care of in advance. It is important not only to choose the right wire, but also to plan the placement of the line, as well as its protection. If you are not confident in your electrical skills, it is better to call a specialist who will help you lay the cable and connect the outlet. Good luck!

Installing an outlet

After the wiring is laid along its entire length, you can install the socket. The sequence of actions is as follows.

- Installation of a socket box. To fix it, use the complete fasteners, but it wouldn’t hurt to additionally “seat” it with cold welding or sealant.

- The ends of the wire are inserted into the hole in the socket box.

- Unpack the socket and take out its inner part.

- The terminals are connected alternately: phase, neutral, ground. At the same time, you need to ensure that the ends of the wire are not too tight; do not forget that it is quite possible that the socket will have to be repaired.

- Using standard fasteners, the socket is securely fixed in the socket box. No play is allowed; it must “sit” motionless.

- Screw on the plastic cover.

After this, the wire is connected to the machine; of course, at the time of connection, the electricity in the apartment must be turned off.

How useful is such a device?

First, let's figure out how useful an extension cord with an RCD is for a person in general and for a washing machine in particular. An extension cord with an RCD is essentially an ordinary extension cord, the body of which has a built-in protective power switch. In the event of an overload in the electrical circuit caused by various reasons, the RCD urgently opens the circuit, de-energizing it.

In principle, it’s not bad if you use such a device somewhere on a construction site or during repairs to connect a hammer drill, grinder and other power tools. But we need to figure out the question: can such an extension cord be used to connect a washing machine? As a general rule, you can't. The fact is that a washing machine is a large consumer of electricity, which must be connected to a separate moisture-resistant socket protected by an RCD, and also so that the cable supplying the socket has a suitable cross-section.

The problem is that the washing machine does not produce a peak of power immediately, but at the end of the program during the spin cycle. At the same time, trouble can occur with the wrong socket and wiring.

In our case, there is an ungrounded “ancient” outlet with aluminum wiring, an extension cord with an RCD connected to it, and a washing machine is already connected to this extension cord. No matter how you look at it, the weak link in this chain is the socket and extension cord with an RCD here, “...what a poultice for a dead person...”. In this situation, three negative outcomes are possible:

- the circuit will break and the person will simply be electrocuted at the moment when, unfortunately for him, he touches the body of the washing machine, and the RCD will trip late;

- an overload will occur in the circuit, which can ignite the wiring and the socket itself, while the chances that the RCD will trip and prevent a fire are 50/50;

- a voltage drop will occur in the circuit, literally in a second it can burn out at least the washing machine's power filter, or at most the control board. The automatic washing machine will stop working, and the RCD will not react to this at all.

Well, do you think there is much benefit from an extension cord with an RCD that you equip your washing machine with? We think that, of course, there are benefits, but we also need to think about redesigning the socket with electrical wiring - there’s no way around it.

Basic principles for safe operation of a washing machine

It is advisable to turn off the batch switch after completing the wash, completely de-energizing the outlet, since if the grounding is damaged, electrical appliances with a plug connected to the network may receive an electric shock even when turned off. All disconnecting devices must be placed on the phase wire. For greater safety, it makes sense to use two-pole package switches; this will protect you from the theoretical possibility of a phase transfer to another wire, for example, as a result of an erroneous connection after replacing or checking the electric meter.

Features of choice

If you are convinced of the need to purchase an extension cord for an automatic washing machine with protection, you can, casting aside doubts, immediately proceed to discussing the features of choosing this item.

You can connect the washing machine through an extension cord that can connect the outlet to the power cord of the washing machine, that is, the device itself must have a power cord of sufficient length.

Extension cords with RCD lengths are available for sale:

- 1.5 meters.

- 2.5 meters.

- 3 meters.

- 5 meters.

It is quite rare, but you can still find extension cords with RCDs, in which the network wire has a length of 8, 10, 15 and 18 meters. Such extension cords, of course, are not used for domestic purposes. They belong somewhere on a construction site, however, the situations are different, so we found it necessary to mention them too.

Be careful! Some unscrupulous Chinese entrepreneurs supply extension cords with RCDs containing power cords with thin aluminum wiring. Such devices are potentially dangerous and should be avoided.

Next, you need to think about the cross-section of the extension cord for the automatic washing machine, as well as the maximum load that it can “hold.” Most RCD extension cords have 1.5 to 2.5mm copper cable rated at 3500W. Considering that most washing machines have a power in the range of 2000-2500 W, such extension cords are quite suitable for our purposes and there is nothing to choose here.

Review of similar devices

We have already figured out that you can purchase almost any extension cord with an RCD, and it will be suitable for our purposes. The exceptions are extension cords with too long power cords and low-quality devices, but we won’t talk more about them. Still, through which extension cord with protection is it better to connect the washing machine? What device do we need? A review of extension cords with RCDs that can be bought on the market today will help you understand this issue. Let's give this review.

- Extension cord with RCD Brennenstuhl. This is a very high quality device made in Germany. It is characterized by excellent copper wiring, a sensitive, adjustable RCD, a moisture-proof plug, and a good switch with an indicator. Disadvantages: high price, minimum wire length 5 m, bright black and yellow colors.

- Electrical extension cord with RCD UB-17-u. This is a Russian-made extension cord from. The device is 16A, cable cross-section is 1.5 mm, the RCD is sensitive, it triggers in a second. Power 3500 W. Disadvantages: the color of the cable and block with sockets is black, and the plug is red, the wire length is at least 10 meters.

- Electrical extension cord with RCD UB-19-u. The device is from the same company, but with slightly different characteristics. 16A, 2.5 mm cable, waterproof plug, power 3500 W. The disadvantages are the same.

That's probably all. Our specialists were unable to find more good extension cords with RCDs on the market. Everyone comes across some kind of consumer goods that are simply dangerous to use. We hope that more such electrics will appear in the near future and their quality will be better.

To summarize, let us note, is it possible to connect an automatic washing machine through an extension cord equipped with an RCD? Conditionally it is possible, but whether it is of any use is questionable. If you want your washing machine to work for a long time and safely, you should not rely only on an extension cord with an RCD. Make a normal outlet with grounding, and install high-quality wiring to it directly from the panel, and then you can say for sure that everything will be fine!