Nichromes

- These are alloys of nickel and chromium. They have high corrosion resistance and melting point, so they are used in electrical appliances and heating elements. Nichrome is wound in coils with a certain electrical resistance, and a current is passed through them, generating heat.

Fehrali

are ferromagnetic alloys whose electrical resistance properties are similar to nickel-chromium alloys. This makes them suitable for use in electrical heating systems. While the lack of nickel makes fechral less expensive than nichrome alloys, it also makes it more susceptible to corrosion. Care should be taken when operating fechral heating elements in dry conditions to minimize corrosion. Exposure to high temperatures can also lead to creep and embrittlement, but with appropriate support elements these problems can be avoided.

Use this online Nichrome and Fechral wire calculator to calculate the resistance, area, current and length of Nichrome and Fechral wire by simply entering the wattage and voltage.

Calculation of weight and length

11.3040

Calculate

Nichrome

Nichrome alloys typically consist of 80% nickel and 20% chromium

(nichrome 80/20), although other compounds can be found in varying ratios. Nichrome has a silver-gray color and is highly resistant to electrical flow and heat. It is also very resistant to corrosion and wear, very durable and has a very high melting point of around 1400°C.

Oxidation stability

makes nichrome a popular material for use in heating elements. For example, the heating elements in a household toaster are most often made of thick nichrome wire. When used in this manner, nichrome is usually wound in coils to a certain electrical resistance before current is passed to produce the heat generated. When nichrome is heated to high temperatures, it forms an outer layer of chromium oxide, unlike other metals, which can begin to oxidize when heated in air. This means that it is essentially impermeable to oxygen and therefore the heating element is protected from oxidation.

Nichrome alloys are known for their higher mechanical strength

at high temperatures compared to iron-chromium-aluminum (FeCrAl) fechral alloys, as well as higher creep strength. Nickel-chromium alloys also remain more ductile than iron-chromium aluminum alloys after long periods of exposure to temperature. Nickel-chromium alloys exhibit good corrosion resistance, except in environments where sulfur is present.

A noticeable increase in electrical resistivity is observed with increasing chromium additions. An addition level of 20% chromium is considered optimal for electrical resistance wires suitable for heating elements.

This composition combines good electrical properties with good strength and ductility, making it suitable for wire drawing.

Fechral

Alloys of iron, chromium, aluminum (FeCrAl)

are high resistance materials that are typically used in applications with maximum operating temperatures of up to 1400°C.

These ferritic alloys are known to have higher surface load capacity, higher resistivity and lower density than the alternative ni-chromium (NiCr)

, which can result in less material to apply and weight savings. Higher maximum operating temperatures can also extend cell life.

Iron Chrome Aluminum alloys form light gray aluminum oxide (Al2O3) at temperatures above 1000°C, which increases corrosion resistance and also acts as an electrical insulator. The formation of the oxide is considered self-insulating and protects against short circuits in the event of metal-to-metal contact. Iron-Chromium Aluminum alloys have lower mechanical strength compared to nickel-chromium materials, as well as lower creep strength.

Calculation of nichrome wire for a heater online

| 0.1 0.20,30,40,50,60,70,80,91,01,21,52,02,22,53,03,54,04,55,05,56,06,57,07 ,58,08,59,010,0 Diameter of nichrome wire, mm Required heater power, W Voltage, V Required wire length, m Current, A Some household heating appliances still use nichrome wire. It has high heat resistance, characteristic of an alloy of nickel and chromium. This material has good ductility, high electrical resistivity and a low temperature coefficient of resistance. Therefore, when calculating nichrome wire for a heater, these parameters must be taken into account. Otherwise, the calculation results will be inaccurate and will not give the desired result. Using an online calculator in calculationsQuick calculations can be done using an online calculator. With its help, you can calculate and approximately set the required length of nichrome wire. As a rule, we consider the brands that are most widely used in heating devices - X20N80, X20N80-N, X15N60. To perform calculations, mandatory initial data is required. First of all, this is the amount of heater power that is planned to be obtained, the diameter of the nichrome wire and the value of the supply voltage. Calculations are carried out as follows. First of all, you need to set the current strength in accordance with the specified parameters, according to the formula: I = P/U. After this, the resistance for the entire heating element is calculated. Next, you will need electrical resistivity for a specific brand of nichrome wire. This value will be needed in order to establish the most optimal length of the heating element using a different formula: l = SR/ρ. The correct choice of length will bring the heater resistance R to the desired value. After performing the calculations, it is recommended to check the obtained data using the table and make sure that the calculated current corresponds to the permissible value. If the calculated current exceeds the permissible limits, repeat calculations should be performed by increasing the diameter of the nichrome wire or reducing the power of the heating element itself. It is necessary to take into account the fact that all the parameters given in the tables are calculated for heaters located in a horizontal position and operating in an air environment. If you plan to use a nichrome spiral placed in a liquid, the value of the permissible current should be multiplied by a factor of 1.1-1.5. With a closed spiral arrangement, the permissible current, on the contrary, must be reduced by 1.2-1.5 times. |

electric-220.ru

Calculation of parameters of nichrome and fechral spirals from resistance

Everything here is very, very simple. You just need to know the initial parameters, which can be found by answering the questions:

- What power should the heating element you want to make have?

- What supply voltage will be supplied to it?

- What wire is available (material, diameter)?

Suppose you need to make a heater with a very small power of 12 Watts, which will operate on a 24 Volt network. Only a coil of nichrome wire with a cross-sectional diameter of 0.2 mm is available.

The formulas that we will use in calculations using this method are familiar to everyone from a school physics course. Power is equal to the product of current and voltage:

P (power) = U (voltage) * I (current)

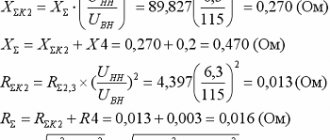

From this formula we can find the current strength in our heater. It will be equal

I = P/ U = 12/24 = 0.5 Ampere

Ohm's law goes like this: "voltage equals resistance times current"

U (voltage) = I (current)* R (resistance)

From here:

R (resistance) = U (voltage) * I (current) = 24 : 0.5 = 48 ohms

We can determine the length of the wire using the formula:

L (conductor length) = S (sectional area) R (resistance) : ρ (conductor density)

Determination of material resistance

In order to find out the resistance value of the conductor from which we will make the heater, you can use the formula and table of values. First you need to find out the cross-sectional area. If we have a wire with a circular cross-section with a diameter of 0.2 mm, then according to the formula for the area of a circle, its cross-section will be equal to 0.0314 mm2. Now let's look at the table with resistance values and look for a correspondence with the calculated cross-section. In our case it is 1300 mm.

We are done with theoretical calculations. Now we need to find out whether the diameter of our wire is sufficient to withstand this level of current. In the table below you can determine the maximum current value for each wire diameter. According to the table, for a wire with a diameter of 0.2, the maximum current is 0.65, which means that the 0.5 A indicator we calculated has an acceptable value.

Please note that the heating environment is also of great importance! To heat the liquid, you can increase the maximum permissible current, but for a closed circuit, on the contrary, you need to reduce it.

Online calculation of the length of nichrome wire, spiral, for a heater

For one signalman I know,

calculating the length of wire for a heater was a mega-task.

He didn’t worry about this issue at all, but simply snorted and measured the resistance of the spiral wire with an ohmmeter every twenty to thirty turns, all enveloped in cigarette smoke from the Prima. And he cursed if he reeled in too little or too much. However, he was a great guy and a telephony specialist. At this stage of my life, winding heaters is not particularly relevant for me, but I still decided to write this online wire length calculator . Maybe it will be useful to someone.

To use the calculator, enter the necessary parameters of the heater or electric stove in the appropriate fields and click the button “ Calculate the length of the wire for the heater spiral .”

The results obtained do not take into account the increase in the electrical resistance of the conductor with increasing temperature. Therefore, the actual power (as well as the current consumption from the network) is always slightly lower than the calculated values.

Required heater or electric stove power W

Supply voltage V

Select the wire material for winding the spiral

NichromeConstantanChromalFehral

Select the wire diameter from standard industrial sizes. Do not forget that the cross-section and diameter of the wire are different concepts. If we don’t know the diameter, we use a micrometer or caliper. I wonder why you need nichrome with a diameter of 10 mm, what do they even need to wind? Probably a detonator for a thermonuclear reactor.

0.10.20.30.40.50.60.70.80.91.01.21.52.02.22.53.03.54.04.55.05.56.06.57.07.58.08.59.010.0 mm

Permanent page address https://nemezida.su/online_raschet_dlini_provoloki_plita_nagrevatel.htm

www.nemezida.su

Calculation of a nichrome spiral. We are ready to make a nichrome spiral for you

How to calculate a nichrome spiral

When winding a nichrome spiral for heating elements, the operation is often performed by trial and error, and then voltage is applied to the spiral and after heating the nichrome wire, the threads select the required number of turns.

Typically, such a procedure takes a lot of time, and nichrome loses its characteristics with multiple bends, which leads to rapid burning in places of deformation. In the worst case, business nichrome turns into nichrome scrap.

To correctly calculate a nichrome spiral (mains voltage 220 V), we suggest using the data given in the table, based on the calculation that the resistivity of nichrome = (Ohm mm2 / m)

With its help, you can accurately determine the length of the winding turn to turn. Depending on the Ø of the nichrome wire and the Ø of the rod on which the nichrome spiral is wound. It is not difficult to recalculate the length of a nichrome spiral to a different voltage using a simple mathematical proportion.

The length of the nichrome spiral depending on the diameter of the nichrome and the diameter of the rod

| Ø nichrome 0.2 mm | Ø nichrome 0.3 mm | nichrome 0.4 mm | Ø nichrome 0.5 mm | Ø nichrome 0.6 mm | Ø nichrome 0.7 mm | ||||||

| Rod Ø, mm | spiral length, cm | Ø rod, mm | spiral length, cm | Ø rod, mm | spiral length, cm | Ø rod, mm | spiral length, cm | Ø rod, mm | spiral length, cm | Ø rod, mm | spiral length, cm |

| 1,5 | 49 | 1,5 | 59 | 1,5 | 77 | 2 | 64 | 2 | 76 | 2 | 84 |

| 2 | 30 | 2 | 43 | 2 | 68 | 3 | 46 | 3 | 53 | 3 | 64 |

| 3 | 21 | 3 | 30 | 3 | 40 | 4 | 36 | 4 | 40 | 4 | 49 |

| 4 | 16 | 4 | 22 | 4 | 28 | 5 | 30 | 5 | 33 | 5 | 40 |

| 5 | 13 | 5 | 18 | 5 | 24 | 6 | 26 | 6 | 30 | 6 | 34 |

| 6 | 20 | 8 | 22 | 8 | 26 | ||||||

For example, it is necessary to determine the length of a nichrome spiral for a voltage of 380 V from a wire Ø 0.3 mm, a winding rod Ø 4 mm. The table shows that the length of such a spiral at a voltage of 220 V will be equal to 22 cm. Let’s make a simple ratio:

220 V - 22 cm

380 V - X cm

Then:

X = 380 22 / 220 = 38 cm

Having wound the nichrome spiral, connect it, without cutting it, to a voltage source and make sure that the winding is correct. For closed spirals, the winding length is increased by 1/3 of the value given in the table.

Calculation of electric heating elements made of nichrome wire

The length of the nichrome wire for making a spiral is determined based on the required power.

Example: Determine the length of nichrome wire for a tile heating element with a power of P = 600 W at U network = 220 V.

Solution:

1) I = P/U = 600/220 = 2.72 A

2) R = U/I = 220/2.72 = 81 Ohm

3) Based on these data (see Table 1), we select d = 0.45; S =0.159

then the length of nichrome

l = SR / ρ = 0.159 81 /1.1 = 11.6 m

where l is wire length (m)

S - wire cross-section (mm2)

R - wire resistance (Ohm)

ρ - resistivity (for nichrome ρ=1.0÷1.2 Ohm mm2/m)

| Permissible current (l), A | 1 | 2 | 3 | 4 | 5 | 6 | 7 |

| Ø nichrome at 700 °C , mm | 0,17 | 0,3 | 0,45 | 0,55 | 0,65 | 0,75 | 0,85 |

| Wire cross-section (S), mm2 | 0,0227 | 0,0707 | 0,159 | 0.238 | 0,332 | 0,442 | 0,57 |

Our Company PARTAL is ready to produce nichrome spirals according to the customer’s specifications and sketches

Buying a nichrome spiral from PARTAL is convenient and profitable - order online

Delivery of orders throughout Russia, Kazakhstan and Belarus

Nichrome for high quality spirals only made in Russia. Strict compliance in quality and brand

partalstalina.ru

Application and calculation of an electric spiral made of nichrome

- July 19, 2021 at 09:18

- 2750

A nichrome spiral is a heating element in the form of a wire, rolled with a screw for compact placement. The wire is made of nichrome , a precision alloy whose main components are nickel and chromium. The “classic” composition of this alloy is 80% nickel, 20% chromium. The composition of the names of these metals formed the name that denotes the group of chromium-nickel alloys - “nichrome”.

The most famous brands of nichrome are X20N80 and X15N60 . The first of them is close to the “classics”. It contains 72-73% nickel and 20-23% chromium. The second is designed to reduce the cost and increase the machinability of the wire. nickel and chromium in it are reduced - to 61% and to 18%, respectively. But the amount of iron has been increased - 17-29% versus 1.5 for X20N80.

Based on these alloys, modifications with higher survivability and resistance to oxidation at high temperatures were obtained. These are brands X20N80-N (-N-VI) and X15N60 (-N-VI). They are used for heating elements in contact with air. Recommended maximum operating temperature – from 1100 to 1220 °C

Application of nichrome wire

The main quality of nichrome is its high resistance to electric current. It determines the applications of the alloy. Nichrome spiral is used in two qualities - as a heating element or as a material for electrical resistance of electrical circuits.

For heaters, an electric spiral made of X20N80-N and X15N60-N alloys is used. Application examples:

- household thermoreflectors and fan heaters;

- Heating elements for household heating devices and electric heating;

- heaters for industrial furnaces and thermal equipment.

Alloys Kh15N60-N-VI and Kh20N80-N-VI, produced in vacuum induction furnaces, are used in industrial equipment of increased reliability.

A spiral made of nichrome grades X15N60, X20N80 , X20N80-VI is distinguished by the fact that its electrical resistance changes little with temperature changes. It is used to make resistors, connectors for electronic circuits, and critical parts of vacuum devices.

How to wind a spiral from nichrome

A resistive or heating coil can be made at home. To do this, you need nichrome wire of a suitable grade and the correct calculation of the required length.

The calculation of a nichrome spiral is based on the resistivity of the wire and the required power or resistance, depending on the purpose of the spiral. When calculating power, you need to take into account the maximum permissible current at which the coil heats up to a certain temperature.

Temperature accounting

For example, a wire with a diameter of 0.3 mm at a current of 2.7 A will heat up to 700 °C, and a current of 3.4 A will heat it to 900 °C. There are reference tables for calculating temperature and current. But you still need to take into account the operating conditions of the heater. When immersed in water, heat transfer increases, then the maximum current can be increased by up to 50% of the calculated one. A closed tubular heater, on the contrary, impairs heat dissipation. In this case, the permissible current must be reduced by 10-50%.

The intensity of heat removal, and therefore the temperature of the heater, is affected by the pitch of the spiral winding . Densely spaced coils generate more heat, while a larger pitch increases cooling. It should be taken into account that all tabular calculations are given for a heater located horizontally. When the angle to the horizon changes, the heat removal conditions worsen.

Calculation of the resistance of a nichrome spiral and its length

Having decided on the power, we proceed to calculate the required resistance. If the determining parameter is power, then first we find the required current using the formula I=P/U. Having the current strength, we determine the required resistance. To do this, we use Ohm's law: R=U/I.

The notations here are generally accepted:

- P – allocated power;

- U is the voltage at the ends of the spiral;

- R – spiral resistance;

- I – current strength.

The calculation of the resistance of nichrome wire is ready. Now let's determine the length we need. It depends on the resistivity and wire diameter. You can make a calculation based on the resistivity of nichrome: L=(Rπd2)/4ρ. Here:

- L – required length;

- R – wire resistance;

- d – wire diameter;

- ρ – resistivity of nichrome;

- π – constant 3.14.

But it’s easier to take ready-made linear resistance from the tables of GOST 12766.1-90. You can also take temperature corrections there if you need to take into account changes in resistance when heated. In this case, the calculation will look like this: L=R/ρld, where ρld is the resistance of one meter of wire having a diameter d.

Spiral winding

Now let's make a geometric calculation of a nichrome spiral . We have selected the wire diameter d, the required length L has been determined, and we have a rod with diameter D for winding. How many turns do you need to make? The length of one turn is: π(D+d/2). Number of turns – N=L/(π(D+d/2)).

The calculation is completed.

In practice, rarely does anyone wind their own wire for a resistor or heater. It’s easier to buy a nichrome spiral with the required parameters and, if necessary, separate the required number of turns from it.

Source: https://www.elec.ru/articles/elektricheskaja-spiral-iz-nikhroma/

Basic information and brands of nichrome

Nichrome is an alloy of nickel and chromium with additions of manganese, silicon, iron, and aluminum. The parameters of this material depend on the specific ratio of substances in the alloy, but on average they lie within the limits:

- specific electrical resistance - 1.05-1.4 Ohm*mm 2 /m (depending on the brand of alloy);

- temperature coefficient of resistance - (0.1-0.25)·10 −3 K −1;

- operating temperature - 1100 °C;

- melting point - 1400°C;

In tables, resistivity is often given in µOhm*m (or 10 -6 Ohm*m) - the numerical values are the same, the difference is in dimension.

Currently, there are two most common brands of nichrome wire:

- Х20Н80. It consists of 74% nickel and 23% chromium, as well as 1% each of iron, silicon and manganese. Conductors of this brand can be used at temperatures up to 1250 ᵒ C, the melting point is 1400 ᵒ C. It is also characterized by increased electrical resistance. The alloy is used for the manufacture of elements of heating devices. Specific resistance – 1.03-1.18 µOhm m;

- Х15Н60. Composition: 60% nickel, 25% iron, 15% chromium. Operating temperature is no more than 1150 ᵒ C. Melting point – 1390 ᵒ C. Contains more iron, which increases the magnetic properties of the alloy and increases its anti-corrosion resistance.

You will learn more about the grades and properties of these alloys from GOST 10994-74, GOST 8803-89, GOST 12766.1-90 and others.

As already mentioned, nichrome wire is used everywhere where heating elements are needed. High resistivity and melting point make it possible to use nichrome as a base for various heating elements, from a kettle or hair dryer to a muffle furnace.