In addition to a wide variety of cable products that comply with state standards and PUE rules, there are several unusual products manufactured without GOST. One of these is the PUGNP wire.

The conductor is in demand among many specialists and is used for laying electrical networks in everyday life and at industrial facilities. However, this practice is risky, since a number of technical and operational parameters of the cable do not meet electrical and fire safety requirements. Let's try to figure out why PUGNP is relevant and what analogues can replace it.

Explanation of markings

PUGNP is mainly used for switching lighting devices or connecting low power devices. A characteristic feature of the cable is associated with its flat design, which is included in the abbreviation.

PUGNP stands for as follows:

- “P” – wire;

- “UN” – universal (used almost everywhere);

- “G” – flexible;

- "P" - flat.

Typically, in stiffer wires (which do not have the letter “G” in the abbreviation) the letter “A” is written at the very beginning. This indicates that the wire cores are made of aluminum. In addition to the standard PUGNP, there are additional categories:

- PUGNPng - a product equipped with insulating materials with a minimum level of flammability;

- PUGNPngd-LS is a non-flammable and at the same time non-smoldering product.

You may have noticed that when deciphering the abbreviation, the letters “U” and “N” were combined, although they are separated by “G”. Why the creators of this wire arranged the capital letters of the abbreviation this way remains a mystery. It may well be that an error was made during the initial registration of the product. It is useless to look for official information, since in accordance with the law, the use of PUGNP is prohibited.

The product is produced for one simple reason: the wording prohibiting use does not impose restrictions on production and sale. The cord remains popular due to its apparent practicality and low cost.

Decoding the abbreviation

A distinctive feature of PUNP and PUGNP is their flat shape, which is directly reflected in the abbreviation. For PUNP brand wire, the name decoding looks like “P” - wire (although essentially it is a cable), “UN” - universal (without any special restrictions in areas of application), “P” - flat (the cores are not located in a circle, but next to each other with a friend). If the abbreviation looks like “aPUNP”, it means the conductors are made of aluminum.

Accordingly, the decoding of the PUGNP wire is read as “P” - wire, “UN” - universal, “G” - flexible, “P” - flat. Due to the fact that this cable is flexible, aluminum is not used in its manufacture, so there is no prefix “A” before the name, but it still has additional varieties. This is PUNGPng, with an insulating coating of reduced flammability and PUGNPngd-LS, which, in addition to not burning, also does not smolder.

Why the letter “G” is in the wrong place in the name of the wire can only be guessed at - perhaps this is a banal mistake when registering the name, or maybe someone thought it was more consonant.

There will definitely be no official comments on this topic, since PUGNP is prohibited for use due to its non-compliance with modern fire safety requirements. True, “cannot be used” does not mean prohibiting production, which is still being done due to its high popularity due to its low cost.

With production, everything is also interesting - PUGNP does not necessarily have to have the manufacturer’s markings (it is affixed only on labels that are attached to a solid coil of wire). Accordingly, even if all the technical characteristics, GOSTs and technical specifications are known, it is quite difficult to control their implementation and no one guarantees this.

Design

The creators of PUGNP conceived a conductor that would be used to connect various devices in domestic and industrial buildings. However, despite its popularity, the attitude towards the cable on the part of electricians and installers is more than skeptical, and in most cases negative. Today's production of PUGNP is organized without clear coordination with GOST, so it is impossible to guarantee safe and efficient operation. Any documents that sellers will show are “fake”.

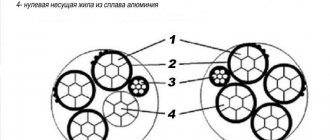

PUGNP is one of the varieties of PUNP cable, only with the prefix “flexible”. However, the product cannot be called a wire, since it consists of several insulated conductors with a common insulating layer. At the same time, it is impossible to call PUGNP a cable, since it does not correspond to this category in terms of technical and operational parameters.

The designs of PUNP and PUGNP include two/three current-carrying conductors, each of which has a polyvinyl chloride insulating sheath. The main difference between these two products:

- the first consists of single-wire conductors;

- the second is multi-wire.

The latter is directly related to the flexibility of the wire. If several thin wires break, the core will still be able to transmit current. On the other hand, technical and operational parameters will significantly deteriorate, in particular, the load will increase.

Since the PUGNP is flat, the cores are placed inside parallel to each other. Unlike most other products, they do not curl, but are held tightly inside a polyvinyl chloride shell. It is impossible to indicate the exact parameters of the wire, since some manufacturers use their own specifications and independently select plastic compound for insulation (one may not support combustion, the rest may not have this useful quality).

Thin copper wires are used to make the cores. While PUNP has an aluminum analogue, PUGNP does not have one. This is due to the impossibility of creating conductors of such a small cross-section from aluminum. In general, aluminum is worse than copper in terms of conductive parameters.

What is PUGNP used for?

Before deciding to use a conductor when switching electrical equipment or laying wiring, it is recommended to take into account the technical characteristics and level of protection, then create a work plan and calculate the future load on the line. PUGNP, despite the prohibitions, is used in several areas:

- Arrangement of lighting systems by switching the current source and electrical devices using this wire. The cable is run from the distribution board to the light sources, breaking the circuit with a switch. The maximum permissible voltage in the AC network should be no more than 250 V, otherwise the conductors will begin to get very hot, a short circuit or fire will occur.

- Connecting components inside lighting fixtures, including chandeliers and fixtures. We are talking about creating conductor fittings. Single- or double-core products with a cross-sectional area of 1.5 square meters are used. mm. With their help, distribution between lamps is organized.

- At your own peril and risk, you can use a conductor to install electrical wiring inside an apartment or rooms of a private house. However, in this case, only low-power household appliances can be connected to the network.

- To organize temporary wiring during repair work.

terms of Use

According to the manufacturers, PUGNP wires are designed for use in AC electrical networks with voltages up to 250 V and frequencies up to 50 Hz. The temperature at which the wire must confidently perform its functions should not be lower than -50˚C and not higher than +70˚C, but during installation the environment should not be colder than -15˚C. During operation, the maximum permissible heating temperature of current-carrying conductors should be no higher than +70˚C, and during operation no more than 8 hours a day and a total output of no more than 1000 hours - up to +80˚C. Operating air humidity is 100%, provided that the environment is heated no higher than +35˚C. The permissible bending radius formed during installation must be at least 10 wire diameters.

The insulation resistance of a 1 km long cable at a temperature of +20˚C depends on the total cross-section:

- 1 mm2 – up to 27.1 Ohm/km;

- 1.5 mm2 – up to 12.1 Ohm/km;

- 2.5 mm2 – up to 7.41 Ohm/km;

- 4 mm2 – 4.61 Ohm/km.

The operating current loads for PUGNP wires are not described in their specifications, so in this case you should focus on the requirements of the PUE:

- for wires with a nominal cross-section of 1.5 mm2: two-wire – 19 A, three-wire – 19 A;

- with a cross section of 2.5 mm2: two-core – 27A, three-core – 25 A;

- with a cross section of 4 mm2: two-wire - 38 A, three-wire - 35 A.

The estimated service life of PUGNP wires is 15 years. In a two-core version, PUGNP is produced with a total cross-sectional area of 1-6 mm2, and in a three-core version - 1-4 mm2.

Thus, the marking “PUGNP 2×2.5” indicates a two-core flat cable with a core cross-sectional area of 2.5 mm2. And “PGUNP 2×1.5” is for a three-core universal flat cable with a core cross-sectional area of 1.5 mm2. It is worth noting that on wires of this type it is not always possible to see external markings, because its absence is acceptable - information about the manufacturer, wire designation, length, specifications and date of manufacture can be obtained from the label on the coil.

The shelf life of PUGNP wires is not regulated by modern rules, and according to the climate category they should be stored under canopies or in enclosed spaces.

Preliminary conclusions about the quality of the conductor can be made using the following methods:

- visual inspection of the cores on the quality of insulation, the number of core wires, etc.;

- measuring structural dimensions (diameter of cores, wires, entire wire) with a special tool;

- measuring the resistance of current-carrying conductors using an ohmmeter with the appropriate limit.

Technical characteristics and operating conditions

We list the main technical parameters and operating conditions:

- When laying the cord, a stationary method is used.

- Current-carrying conductors are made from thin copper wires.

- Insulation is made of polyvinyl chloride, flame retardant or non-flammable.

- The insulating layer retains the declared properties during operation in the temperature range from -50 to +50 degrees. Celsius. The wire can be used for a long time at temperatures up to +70 degrees. Celsius.

- Installation possible in winter. In this case, the minimum room temperature should be -15 degrees. Celsius. If the parameter is lower, you will have to heat the conductor, otherwise the insulation will crack or break if kinked.

- The maximum permissible bending radius is ten outer diameters of the wire.

- The service life is 15 years. Manufacturers provide a two-year warranty from the date of commissioning.

Installation

Before purchasing a PUGNP cable, be sure to check the diameter of the entire product and individual cores using a caliper. If the final measurement result is lower by more than 15%, then it is not recommended to buy the product. If you really want to, you can reconsider the cost of the product, but remember that such a wire will have lower characteristics than stated in the passport.

Make a cut and check the color of the cores used. Use a magnifying glass to make sure the wires are uniform and free of any dullness or stains.

To increase safety during product operation, buy wires with a slightly increased margin compared to the tabular data. Be sure to add a reliable circuit breaker to the circuit you are installing to protect the equipment. To reduce current loads due to a large number of consumers, divide the wiring into separate groups (the more, the better).

When transmitting electrical energy, wires emit an electromagnetic field, having a negative effect on each other. This happens if they are placed in close proximity.

When laying in groups, be guided by the values of the dependence of power on current load from the table below (the indicator should not exceed the specified value):

| Core cross-section, sq. mm | 0,75 | 1,0 | 1,5 | 2,5 | 4,0 | 6,0 |

| Core diameter, mm | 0,98 | 1,13 | 1,38 | 1,78 | 2,26 | 2,76 |

| Power/current, kW/A for one wire | 2,86/13 | 3,3/15 | 4,4/20 | 5,94/27 | 7,92/36 | 10,12/46 |

| Two wires | 2,64/12 | 3,08/14 | 3,74/17 | 5,28/24 | 7,48/34 | 9,02/41 |

| Three wires | 2,42/11 | 2,86/13 | 3,3/15 | 4,84/22 | 6,82/31 | 8,14/37 |

| Four or more wires | 2,2/10 | 2,64/12 | 3,08/14 | 4,63/21 | 5,94/27 | 7,7/35 |

In accordance with the PUE, before connecting using screw terminals, the stripped edges of the cable should be crimped with a ferrule or tinned. To reduce the air flow in the event of a fire in the insulating layer when the wire overheats, avoid laying it in cable ducts and building voids. Lay the cable under the plaster without using corrugated pipes.

Technical characteristics of PUGNP wire

The electrical resistance of current-carrying conductors at direct current must be no more than that indicated in the table.

| Nominal cross-section, mm2 | 0,35 | 0,5 | 0,75 | 1,0 | 1,5 | 2,5 | 4 | 6 |

| Core resistance, Ohm/km | 77,4 | 54,2 | 36,1 | 27,1 | 18,1 | 10,8 | 6,8 | 4,5 |

Electrical insulation resistance is not standardized.

Finished PUGNP wires must withstand testing with an alternating voltage of 1500 V at a frequency of 50 Hz for 1 minute applied between the cores.

The wires must be resistant to winding (after exposure at a temperature of -15°C when testing for cold resistance and at +50°C when testing for heat resistance) onto a cylinder (drum) with a diameter equal to 10 outer dimensions of the wire.

Reasons for prohibiting use

The main reason for prohibiting the use of the PUGNP wire is related to the discrepancy in the thickness of the insulation of the current-carrying conductors. If the PUE states “in black and white” the minimum insulation thickness is 0.4 mm, then according to the specifications for the manufacture of PUGNP this dimensional value is equal to 0.3 mm.

Moreover, the specifications do not clearly describe the requirements for tolerances on the cross-section of conductors. The allowed error is 30%. As a result, when purchasing a wire with an area of 3 square meters. mm you can get a product from conductors with a cross-section barely higher than 2 square meters. mm. Because of this, when connecting household appliances with rated power, the conductor will not withstand the load, will heat up, and the insulation will begin to melt. Unofficial statistics are also not encouraging, according to which more than 50% of cases of wiring fires are associated with the operation of PUNP and PUGNP products.