Classification of cable joints

All cable couplings are classified according to their purpose and come in 5 types:

- Connecting.

Designed to create reliable electrical contact at the junction of cable products, as well as to realize high dielectric properties at the junction. A cable coupling can be used to increase the length of the cable or restore the integrity of damage, accompanied by either a rupture of the current-carrying core or a decrease in insulation resistance. Couplings, in turn, are divided into collapsible, designed for voltages up to 1000 V, and non-dismountable. used for connecting high-voltage power cables. After installation, non-separable couplings completely restore not only the tightness and high-quality contact between sections, but also the mechanical strength of the cable. - End

. They are used at places where cables are connected to electrical equipment and switching devices. This can be power equipment with low voltage and current levels, such as control or communication cables;

- Transitional

. In essence, they are a type of couplings and are designed for reliable splicing of cables with different types of insulation, as well as sections and materials of current-carrying conductors;

- Stopper

. This is another type of cable couplings that prevents impregnation from draining when laying cables with a significant difference in height;

- Branch

. Used when connecting a cable to the main power line.

| Cable gland type | Labeling designation and examples | Methods of application |

| Connecting | “C”, for example Stp, StpB (armored), StpO, (single-core). | Connecting two sections of cable to increase the length or renew a sealed connection. |

| End | KM (mast), KN (external installation), KV (internal installation) | To implement cable windowing and connect it to distribution devices, electrical equipment, and devices. |

| Transitional | Stp (connecting passages), Stp (stopping passages). | Sp - splicing of cables with PVC insulation with other types, Stp - power cables with one or several cores in paper insulation with different types. |

| Branch | "O", for example PTO | Designed to implement a branch from the main line in places where it is not possible to install distribution devices. |

Cable couplings are also divided into:

- the number of connected cores (single-core, three-core, multi-core - control);

- dielectric materials used for interphase insulation (heat shrink, epoxy, resin);

- by voltage value;

- current-carrying conductor material and cross-section range;

- protection from mechanical and chemical influences.

In any case, when ordering or purchasing a cable coupling, it is recommended to read the accompanying technical documentation, which should indicate all the parameters and features of the product.

Types of couplings, their classification

Cable fittings, depending on their purpose and scope of application, come in several types (GOST 13781.0-86). For ease of review, the data is summarized in the table:

| No. | Coupling type | Purpose | Designation |

| 1. | Connecting | Connecting cable sections | WITH |

| 2. | Branch | Connecting distribution cables to the main power path | ABOUT |

| 3. | Connecting and transitional | Switching of cables with plastic insulation and their analogues with other types of insulation | JV |

| 4. | Stopper | Connection of cables with insulation made of impregnated paper on routes with a large slope, to prevent the impregnating composition from running off | ST |

| 5. | Stop-transition | Switching of cables in several cores with insulation made of impregnated paper and single-core products with a different insulating sheath | STP |

| 6. | Ends for external installation | Cable termination outside premises | KN |

| 7. | End masts | Cable termination when exiting to overhead power lines outside buildings | KM |

| 8. | Ends for internal installation | Cable termination inside buildings and premises | HF |

The classification of electrical devices provides for their marking, which includes:

- Information about the insulation used: P – made of plastic (paper insulation is not specified)

- Information about the type of coupling (according to the table)

- Indications on the material of the product: Ch - cast iron, S - lead, L - brass, St - steel, E - epoxy resin, P - rubber compositions, t (tt) - heat-shrinkable tubes, tp - heat-shrinkable gloves, sl - self-adhesive tapes

- Designation of design features: single-phase - O, with a compensator - k, intended for use under water - in, (three-phase are not designated)

- Digital (numeric) value of the diameter of the neck part of the coupling or heat shrink

- The presence of the letter “T” means tropical design

- Information about the type of casing used (according to the table):

| No. | Types of housings | Purpose | Designation |

| 1. | Fire protection | Buildings, covered structures, tunnels | TO |

| 2. | Underground | Laying under a layer of soil | Kz |

| 3. | Underwater | Installation in aquatic environments | Kv |

- Material information: P – cast iron, P – plastic, Pa – reinforced plastic, St – steel

- Designation of design features: y – reduced, kb – presence of rings for installing armor, g – tightness

- Indication of the size of the neck part of the casing (diameter from 40 to 100 mm)

- Digital indicators for the number of cable cores and their cross-sections.

Couplings for paper insulated cables

The advent of heat-shrinkable tubing and gloves has made splicing, branching and terminating paper-insulated cables much easier. Most modern products include these items in the packaging list. Heat-shrinkable elements increase the protective insulating layer, prevent the paper casing from unwinding, and make the core switching process more comfortable.

The tubes are put on the core directly on top of the paper impregnation. The cutting root is filled with sealant or mastic and covered with a glove. The stripped ends are joined with bolted connectors, which are also placed in heat-shrinkable tubing to ensure an even layer of insulation.

An example of a connecting cable sleeve for a main line with three cores

This method is especially convenient when installing connecting-transition and stop-transition couplings, where conductors in paper insulation are connected with conductors in plastic insulation. Using tubes not only equalizes the thickness of the insulating layer, but also ensures shielding of the connection area.

Connecting adapter models for connecting cables with different types of insulation

Practical Tip: Epoxy, lead or brass electrical devices are recommended for paper insulated cables.

Couplings for cables with plastic insulation

The difference may be the use of a self-adhesive tape or a cotton strip impregnated with an epoxy composition, the so-called sealant tape, as a disconnector at the cutting root. The joining of the ends of current-carrying conductors is also carried out using a connecting sleeve and bolt fastening. These places are also placed in heat shrink tubes.

End coupling PKVTp using heat-shrinkable elements and sealant tape

Practical advice: For cables with plastic insulation, it is recommended to use cast iron or elastomeric (rubber) devices, although when terminating cables for indoor connections, PKVE, that is, epoxy products, are often used.

In real work, the use of various electrical devices is allowed. The main condition is compliance with operating conditions.

Heat-shrinkable cable sleeves

Thick-walled products under the influence of hot air tightly, reliably fit and take the configuration of the cable joint, ensuring its insulation and protection from external factors. The device includes a heat-shrinkable pipe with glue, bolted connectors or lugs for cable cores, which will ensure high-quality contact, both mechanical and electrical.

Rules for selecting cable sleeves

When choosing a cable sleeve that would meet the installation conditions, as well as the purpose of the circuits for which it is installed, you need to know the basic criteria for choosing this product:

- Rated voltage of the line in which the coupling is installed. All cable couplings are divided into two categories: high-voltage (from 1 kV) and low-voltage (up to 1 kV). The voltage value is a parameter that is determined from the type of electrical installation;

- The number of cores in the cable and their cross-section. The brand of the cable coupling contains encrypted information about the cross-sectional range of the cable cores for which it can be used. For example, the Stp 10/4*25-50 set is intended for 10 kV networks, and the cable cross-section is from 25 to 50 mm?;

- Type of insulation. The insulating material that is used as the main one must exclude not only breakdowns between phases, but also on the armored layer, which is grounded. Also, the selected coupling and its main insulating material must withstand long-term use and exposure to external factors. One of the most popular today is heat-shrinkable material that changes its shape and size when exposed to temperature. It has high dielectric properties and to install such a coupling you only need a torch or blowtorch;

- Cables that require a coupling can be armored steel strips, wire, or lead sheathed. In sets of cable couplings for armored cables there must be special materials connecting the armor;

- The type of coupling must correspond to the purpose; the end coupling cannot become a connecting coupling and vice versa.

Before purchasing a cable coupling, you need to look at its configuration; usually they are all equipped with lugs or self-breaking sleeves, but if they are not included in the kit, you will have to purchase such products separately.

Heat-shrinkable 4STp-1, 3STp-1

designed for connecting 4- and 3-wire lines with oil-impregnated paper insulation, with or without armor, with a common aluminum or lead sheath, for voltages up to 1 kV. Types of installed wiring: AABl, (A)SBl, (A)SBG, AAG, (A)SG, AABv, (A)SBShv, AAShv, (A)SShv, AAB2lShv, (A)SB2lShv. Insulating cuffs provide reliable and high-quality insulation of the connection points of the cores. The use of oil-resistant material tubes prevents oil from leaking out and drying out the paper insulation. Hot-melt adhesive applied to the inner surface of the connecting cuffs, gloves and casing ensures complete tightness after installation. Installation of the jumper wire connecting the sheaths and armor tapes at both ends of the cable is carried out in a combined way. The basic package includes constant pressure springs used to secure the ground wire to the metal sheaths. Fastening to armored belts is carried out by soldering. The presence of constant pressure springs for fastening the grounding wire to the metal sheaths of the connected cables ensures quick and reliable installation. The use of a spring eliminates the possible risk of thermal damage to the paper insulation under the aluminum shell in case of soldering using refractory solder. The kit is universal and allows you to use both crimp sleeves and bolted connectors.

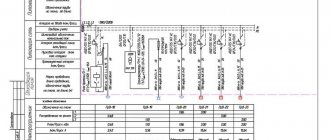

| equipment and name | number of cores | core cross-section (mm²) | |

| without bolt connectors | with bolt connectors | ||

| 4STp-1-25/50 | 4STp-1-25/50(B) | 4 | 25 — 50 |

| 4STp-1-70/120 | 4STp-1-70/120(B) | 4 | 70 — 120 |

| 4STp-1-150/240 | 4STp-1-150/240(B) | 4 | 150 — 240 |

| 3STp-1-25/50 | 3STp-1-25/50(B) | 3 | 25 — 50 |

| 3STp-1-70/120 | 3STp-1-70/120(B) | 3 | 70 — 120 |

| 3STp-1-150/240 | 3STp-1-150/240(B) | 3 | 150 — 240 |

Couplings for armored cable

Armored cable is used very often when organizing power supply to equipment, since it is not afraid of mechanical shocks during installation and operation. For this type of cable products, a special type of cable couplings is used, which are marked with a capital or small letter “B”; some manufacturers may not mark their products in a different way. The cable coupling for armored cable faces the task of not only high-quality and reliable connection of cores with maximum sealing, but also restoration of impact resistance and mechanical protection of the area where the coupling is installed.

At the same time, cable couplings for armored power cables can be designed for standard 3, 4, or 5 cores, but also designed for installation on a single-core cable.

In order to ensure and restore resistance to mechanical damage, cable couplings for splicing, branching or terminating armored cables are equipped with metal “stockings” and grounding conductors. Here are several brands of products for armored cable 3 PKV(N) Tpb1, 3PSTb1, 4STp1 (universal).

Control cable couplings

A control cable is often a multi-core cable product, each of the cores of which has its own insulation; its task is not to supply power supply voltage to electrical equipment, but to implement protection, signaling, and control circuits. This type of product also includes communication cables. In this case, lead couplings are used for communication cables, for example MS-20, which restores the protective sheath of the cable along with a single piece. All control cables are laid both indoors and outdoors and therefore very often require protection from mechanical damage. When marking cable couplings for a control cable, there are many, here is an example of the most common set - PSTk (connecting) or KKT (terminal), they are used for control cables with a number of cores from 4 to 37, the cross-section of which does not exceed 10 mm?.

Do you need cable couplings? Send your request and we will complete your order. We will select brands and give the best prices!

Send a request

Classification and marking of cable termination

In principle, the classification of cable joints is clear from the given marking example. Couplings for power cables can be:

- End or connecting;

- For installation outdoors (external), indoors (internal) and universal;

- With and without gloves. The glove forms a hermetically sealed connection at the interface between the cable sheath and conductors;

- Heat shrinkage of gloves, smoking and flammability of couplings, additional parameters for their classification.

- An important division according to the type of insulation. It must match the type of insulation of the cable being connected (terminated).

Related articles: Explosion-proof lighting and lighting technology

For example, the coupling from the example with plastic insulation is suitable for cables of the following types: (A) VVG, (A) PvVG, with aluminum (A) or copper conductors.

Particular attention should be paid to the grounding of the coupling, or rather to the method of connection to grounding. They can be bolted or soldered.