When you see photos of flower beds and paths decorated with colored crushed stone, the desire inevitably arises to create an equally beautiful corner next to you. However, many are so embarrassed by the high cost of purchased painted crushed stone that they abandon this idea and do the wrong thing.

There is an extremely simple technology for making colored crushed stone yourself. It does not require special skills or expensive equipment. I will try to briefly outline how to turn a pile of nondescript rubble into a decoration for your garden with your own hands in just a few hours.

Work technology

With the advent of painted crushed stone, the task of improving the space around the house became easier. The finished material offered by manufacturers has a high cost. Doing the work yourself is much cheaper.

There are 2 methods of painting at home: mechanical and manual. The choice depends on the volume of processing required.

- For production, it is better to take cube-shaped gravel with a fraction of up to 10 mm.

- To ensure uniform coloring, the products are divided into fractions. For sorting, a grid or sieve with a certain mesh size or a “screen” is used.

- Depending on the applied composition, the color coating can be either matte or glossy.

- The main requirement is adhesion. It can be good not only for natural stone, but also for crushed stone obtained from recycled materials.

- Paint consumption is small. The proportional ratio for mechanical application is 1 liter per 100 kg of gravel.

| Method | Equipment | Technology | Nuances |

| Mechanical | Concrete mixer; vibrating sieve for separating crushed stone into fractions (“screen”); shovels for loading and unloading stones; pallet; place to dry the finished product. | The washed crushed stone is poured into a clean concrete mixer. A special dye of the required saturation is added. Depending on the load, coloring lasts from 20 minutes to 1 hour. Then the gravel is poured out in an even layer to dry. | For high-quality coloring it is necessary to fill 1 /2— 2 /3 container volume. If the device is completely filled, the color will not be uniform. The dye is added in a ratio of 3:7 in relation to the total loading volume. Mixing in a concrete mixer continues until the grains are covered with a uniform film. When drying, a tray must be placed under the sieve to collect excess. |

| Manual | Storage tank; sieve; pallet; shovel. | Option 1. The stone is poured into a container with paint, thoroughly kneaded, placed on a sieve, and dried. Option 2. A large sieve with a reservoir is built on the frame; crushed stone is dipped in the composition and laid out to dry. Option 3. The gravel is painted by spraying an aerosol and then dried. | There is a possibility of uneven or weak coloring. The bottom will have a mesh pattern, which requires constant shaking and turning during drying to avoid. |

Before you start working, the gravel needs to be washed, dried, and slightly heated with a burner. This will improve adhesion and allow you to create the desired shade; in addition, unwashed stone will darken.

Errors and recommendations

To avoid miscalculations during painting, you need to know which paints are best to use and how to properly prepare.

1. You can sift gravel manually using meshes secured in homemade boxes.

2. High-quality pigment ensures color preservation for up to 5 years.

3. Painting can be done with any paints:

- polyurethane;

- epoxy;

- acrylic;

- alkyd;

- enamels;

- mixture with PVA glue.

The dye must be resistant to moisture, UV rays and harmless to humans and plants.

4. Varnish coating increases protection from external influences and decorativeness.

Drying the finished product naturally is a lengthy process. It can be accelerated by increasing the temperature and forced ventilation of the drying room. It is better to store painted crushed stone in a closed container.

| Related articles: | |

| What is recycled crushed stone? A few years ago, recycling long-wasted construction resources was a real... What crushed stone should I choose for building a foundation? Crushed stone is a building material that has a granular structure. They receive... Why add crushed stone to sand concrete? Sand concrete is used in the construction of buildings and structures for various purposes. Possesses... | |

This is interesting: How to connect a video intercom in a private house

Painting crushed stone

So, after the crushed stone has been sifted to the required fraction and thoroughly washed, you can begin painting it. Here, inappropriately, a concrete mixer will come to the rescue, of course, clean inside, without dust and, especially, cement mortar stuck to the walls.

The process of painting crushed stone in a concrete mixer is as follows:

- First, crushed stone is poured into the concrete mixer, approximately 2/3 of its volume;

- Then 30% of acrylic paint from the total volume of poured crushed stone is poured directly into the concrete mixer;

- After which the concrete mixer is put into operation for about an hour. After the crushed stone is completely painted on all sides, the concrete mixer can be stopped;

- Well, then the crushed stone painted in this way is laid out on a sieve and dried until the paint is completely dry.

As you can see, painting crushed stone at home is not at all difficult. The main thing is to avoid mistakes at the stage of preparing the material for this procedure. Only in this case will the colored crushed stone last for the longest possible period of time, and the flowerbed decorated with it will always delight you.

Painting in a concrete mixer

Painting crushed stone in a concrete mixer

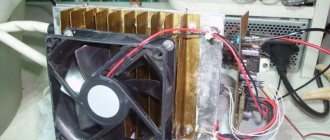

So, we need a bunker for painting crushed stone, and the most ordinary concrete mixer used for small construction projects (most often it has a volume of 0.7 m3) will serve excellently as it. The whole process can be divided into five main stages:

- The washed and dried material is poured into the drum, filling it 2/3 of the total volume.

- Now the crushed stone should be slightly warmed up, if, of course, it did not dry out in the heat in the sun. To do this, it is most convenient to use a gas burner - the flame is directed onto the drum while it rotates.

- Pour paint into the rotating drum at the rate of 3/7, as mentioned above in the text.

- Stir the resulting composition for 1 hour. This should be enough to evenly distribute the pigment over the stone.

- Pour the painted stone onto a grid with a tray.

Below you can watch the video of how this process occurs.

Video: Painting crushed stone in a concrete mixer

General information

Kinds

There are several types of crushed stone:

- Coil.

- Granite.

- Quartz.

- Slate.

One of the types - gravel - has a rounded shape, which appears when sharp corners are ground off during prolonged contact with water. Crushed gravel is mostly mined on the sea coast, as well as in river beds. Depending on the size of the pebbles, crushed stone is divided into fractions. When choosing crushed stone, the following parameters are also taken into account:

- Strength.

- Radioactivity.

- Frost resistance.

- Size and shape of grains.

- Ability to absorb water.

The optimal fraction of crushed stone for decorating paths will be about 0.5 to 5 cm. To fill flowerpots/beds of plants, you should take smaller crushed stone, and the size of the pebbles will be from 0.5 to 1 cm.

Colored crushed stone in landscape design

Crushed stone painted in various shades will perfectly combine with garden ornamental plants and make the landscape more diverse. Mulching with crushed stone helps prevent weed growth. Scatterings of pebbles with different colors retain their beauty throughout the year. In the cold season, when there is no greenery or flowering plants, colored crushed stone forms bright spots in a generally dull background, and also acts as the only garden decoration.

Areas of application of colored crushed stone:

- Protection of the soil surface from washing out and drying out.

- Creation of ground images and logos.

- Demarcation of different zones from each other, for example, flower beds from concrete paths.

- Pouring paths around the house.

- Decoration of flower beds and flowerpots with plants.

- Decoration of fountains and garden pools.

Colored crushed stone will make it possible to solve the main problem - it will cover areas of open ground. How to paint crushed stone with your own hands? If this is not done and the plot of land is not covered, sand and dust from the plots of land will constantly fall onto clean paths and other elements of the landscape design, and all “patch” of bare earth should be covered with a grass lawn, or covered with gravel. Crushed stone, unlike a lawn, will not require watering and mowing, and will not depend on seasonal weather fluctuations, that is, it is more universal.

DIY decorative crushed stone - a practical novelty

Decorative crushed stone has recently appeared on the construction market - manufacturers of this building material are just beginning to master the technology of painting it on an industrial scale. The technology involves the use of paints that are resistant to external factors, non-toxic and harmless to the soil and plants. The production of colored crushed stone promotes the use of this material in landscape design - these include colored garden paths, rainbow flower beds and flower beds, the creation of all kinds of inscriptions on the ground, filling around the walls of houses and cottages, framing monuments and creating a bright bottom and bank in artificial streams and ponds, design of children's playgrounds and much more.

In addition to external beauty, it is also practical, and in this aspect of the issue, the Europeans, who were the first to master the coloring of crushed stone, certainly know a lot - according to their calculations, the use of such an element in the future significantly reduces the cost of maintaining a beautiful appearance in parks, around monuments and in flower beds. Indeed, backfilling with colored crushed stone is an extremely durable way to solve various problems. Crushed stone inhibits the growth of weeds, prevents the soil from weathering, allows moisture to pass freely and promotes its retention in the soil, and if necessary, it can be collected and used elsewhere or even used for construction purposes.

You can either purchase ready-made decorative material or paint it yourself. When purchasing, be sure to ask what paints were used to give the corresponding color - polymer paints can retain their color for several decades. In addition, do not be shy to look into the bag - the material must be of the same fraction, evenly colored and without signs of premature peeling of paint.

Details

How to paint material for mulching or decorating an area

Painting crushed stone yourself at home gives you the opportunity to save a lot of money. The price for small colored crushed stone will be from 20 to 31 rubles per kg. This will mean that you will need to shell out a large amount for decorating a flower bed or creating a path. At the same time, the cost of ordinary crushed stone of a fraction of 0.5-1 cm is 1000 rubles per cubic meter. Such a difference in spending will be a strong argument in favor of creating colored crushed stone yourself. This operation can be carried out manually or through mechanisms. The choice of method depends on how much gravel you need to paint. If everything is done correctly, then after a couple of days you can get the required amount of cheap and at the same time beautiful material, and with a small volume of crushed stone, the whole job can be completed even in a day.

Required equipment and tools

Painting crushed stone requires a minimum number of tools. All garden owners will have some of them, and only the missing items will remain to be purchased. The list of tools is as follows:

- Shovel.

- A mesh with small cells for drying crushed stone after washing and painting.

- A spacious container, for example, a bathtub fell into disrepair.

- Protective gloves.

- Sprayer for paint and varnish material (to paint a small volume of material).

- Bucket.

What about paint? Which paint material to choose

Decorative crushed stone can be painted in natural shades (gray, black or beige), neutral (green, blue or white), bright (red and yellow). Since crushed stone is intended for outdoor decoration, it must be coated with paints that are resistant to heat, frost, rain and friction. Such materials will be acrylic and polyacrylic enamels, as well as paints. Here are the paint options for crushed stone:

- Acrylic-styrene paint and varnish material AK-539 (paint based on acrylic-type copolymers, used for applying road markings, cost from 60 to 110 rubles per kg, drying time is ½ hour, and the colors are yellow and white).

- Acrylic-water dispersion VD-AK-191 (used for painting concrete, the paint is low-flammable, resistant to water, and the cost is approximately 110 rubles per 1 kg, and it can be tinted with pigment fillers, drying time is about 5 hours).

- Paint and varnish material “Akrodom-F” (based on acrylic-styrene resins, fits perfectly on a stone surface, retains color in outdoor conditions for up to 5 years, has 28 shades, and the drying time is 2 hours, and also costs about 240 rubles per 1 kg ).

- AK-511 paint (it is also needed for road markings, and can be yellow/red/white/black, dries in ½ hour, and costs about 120 rubles per 1 kg, the material is flammable).

- Alkyd enamel PF-115 (pentaphthalic paint, the first digit in the number, one, means that the paint and varnish material is suitable for outdoor conditions, and the drying time can be from 16 to 24 hours, depending on the color, the cost of 1 kg is from 65 rubles).

How to paint crushed stone at home, we will consider further.

Dyeing technology

The first stage of work will be preparing the crushed stone for painting, or more precisely:

- Removing excess particles and large fragments (ideally using a “rumble” sieving apparatus).

- Wash with soapy water or soap.

- Drying by blowing air or using a natural method.

The crushed stone will have an uneven surface and a lot of weight. When processing large volumes of crushed stone, it is difficult to achieve uniform coloring manually, and therefore it is better to use a concrete mixer. The dried and washed stones will be placed in a concrete mixer container and a primer mixture will be added, which consists of a small amount of paint and a suitable solvent. This operation is extremely important for crushed stone with a porous surface, and it also helps close the pores and achieve a more even color. Smooth stones can be painted without prior priming.

Paint and varnish material should be added at the rate of 1 to 5, where the coloring solution will be 15 of the main crushed stone mass. Afterwards, the concrete mixer is started for a few minutes to mix. The painted material should be laid out to dry on a tarpaulin or fine mesh. After drying, the colored material is ready for use. If several different colors are to be produced, the concrete mixer should be thoroughly washed after each batch.

How to paint crushed stone without a concrete mixer

If it is not possible to paint crushed stone with a concrete mixer, you can do everything manually. Typically, a small amount of material is painted using this method, but if necessary, all volumes of crushed stone can be processed manually. The only inconvenience in this case will be that you will need to paint in portions, and the process will take more time.

Algorithm for performing the work:

- Rinse the material with water from a hose, and the pressure should be high (it is better to soak very dirty raw materials in a soapy solution in advance, and use a stiff brush when cleaning).

- Lay out to dry on a tarpaulin or other suitable material.

- Place dry stones in a mixing container and add paint in an amount equal to 20% of the main volume of crushed stone.

- Mix the mixture thoroughly with a shovel until the color is even.

- Spread the gravel on a fine mesh grid in an even and not thick layer to dry.

If you need to paint just a little crushed stone, then after washing and drying it should be laid out on a tarpaulin and paint material should be applied to it from a spray gun. The stones should be laid out in a thin layer. After one side has dried, the stones should be turned over with the unpainted side up and the procedure repeated. We hope that such recommendations are enough to carry out the work yourself. And yet, the following video helps to better understand the dyeing process.

Range of applications

The demand for this material is due to the fact that with its help you can achieve a brighter and more stylish design of the adjacent area, as well as create entire picture-messages that reflect some idea. Painted crushed stone is used for the following purposes:

- creation of original flower beds and lawns;

- design of areas around artificial reservoirs;

- landscape works;

- filling terrariums and aquariums (fine crushed stone).

This is interesting: How to obtain permission to build a house on your individual housing construction plot in 2018

Choosing a paint product

In conditions where you plan to carry out small finishing work, you do not want to purchase a large amount of building materials, so it is better to produce colored crushed stone yourself, measuring out as much stone as you need for the task.

The good news for many will be that the production technology is simple, and the paint consumption for stone is small - only 1 kg of paint is used for 100 kg of crushed stone. This rule applies if you are going to paint in a concrete mixer, but with other methods, the consumption increases.

To achieve this task, you can use any coloring compositions: alkyd paints, water-dispersed paints, enamels, sometimes you even use PVA glue mixed with dye. But the most favorable option for this purpose is acrylic paint.

This is due to the fact that you need a substance that is resistant to moisture, and also does not fade in the sun, and can hold color for a long time. This is exactly how the above paint is characterized, but besides this, it is also harmless, both for humans and for nature.

How to paint crushed stone with your own hands - step-by-step diagram

Step 1: Prepare the place for installation

In the place where the material will be poured, it is necessary to remove about 10 cm of the top layer of soil. Pour the soil into a wheelbarrow - there will probably be a place in your garden where you can put it later.

Step 2: Place the borders

If you decide to make a regular garden path, all you need to do is add borders. They can be used as natural stone, or plastic and metal strips. The borders should sit securely on the surface, you can even dig them lightly into the soil.

Step 3: Prepare the base

After installing the borders, it is necessary to pour a layer of sand of at least 5 cm. Level it around the perimeter and pour water for better shrinkage. Let the sand dry a little and proceed to the next stage of preparing the base - lay insulating material over the sand. Manufacturers offer special synthetic materials with ready-made holes through which water flows. You can also use regular plastic film, in which you make a sufficient number of holes in advance for water drainage in case of precipitation. Another layer of sand is poured onto the polyethylene, this time smaller - 2-3 cm.

Step 4: Prepare the stencil

If you are planning to make a path or other surface multi-colored, for convenience, prepare in advance internal borders from strips of metal or plastic. Thanks to them, the crushed stone will not mix with each other, and you, in turn, will be able to form any geometric patterns. This step can be skipped if the material is the same color.

What is crushed stone, what does it come in and where is the best place to buy it?

Crushed stone, or crushed stone, is pieces of hard rock. They are formed as a result of crushing large stone blocks of various origins. Crushed stone is an irreplaceable building material. It is used when laying the foundations of buildings, to strengthen road surfaces and embankments, and as a filler in concrete structures.

There are several types of crushed stone:

- granite;

- slate;

- quartz;

- coil.

One of the varieties - gravel - has a rounded shape, which is formed as a result of grinding off sharp corners during prolonged contact with water. Crushed gravel is mined mainly on the sea coast and in river beds.

Depending on the size of the pebbles, crushed stone is divided into fractions. When choosing crushed stone, the following parameters are also taken into account:

- radioactivity;

- strength;

- size and shape of grains;

- frost resistance;

- water absorption capacity.

The optimal fraction of crushed stone for designing paths is from 5 to 50 mm. To fill flowerpots with plants or flower beds, you should take smaller crushed stone, with pebbles ranging in size from 5 to 10 mm.

Preparing the stone before painting

When buying crushed stone, you get a heterogeneous composition; the size of each stone can vary from 10 to 30 mm. There are also smaller fractions that are more suitable for interior decoration. Therefore, packaging by size is necessary.

This can be done manually on a sieve with the required mesh size, or, which is faster and easier, use a “screen” machine. Any of the above technologies provides for the separation of excess litter, too small pebbles, and sand.

But in order for the acrylic paint to adhere well, the crushed stone also needs to be washed. This will ensure better adhesion of the dye to the surface of the stone and will allow you to create exactly the shade that you want, since if the stone is not washed it can darken.

You can wash it directly on the screen, using a hose or water from a bucket. Due to the fact that the machine creates shaking, cleaning will take place from all sides. After this, spread the washed mass in a uniform layer on a wire rack and dry it in the open air.

The process of creating painted crushed stone

There is only one way to paint crushed stone, and it is almost automatic, since your participation in the main process will be minimal. The most effective and time-consuming technology involves the use of a concrete mixer. After you have properly prepared all the components, you can proceed to the painting itself, which consists of several stages:

- Crushed stone should be placed in the concrete mixer to two-thirds the volume of the machine (if the capacity is 0.7 cubic meters).

- Pour in paint in a ratio of 30 percent to 70 percent stone.

- Start the mechanism and wait 40-60 minutes until the stone is completely covered with a colored layer.

- At the end of the “kneading”, drying follows - lay everything out on the mesh, placing a tray underneath, where the remaining paint will run off.

It is not advisable to store dried, painted crushed stone outdoors; it is better to use closed containers.

To protect against external influences, it is possible to use stone varnish. This will give the material an additional decorative effect.

How to make colored crushed stone with your own hands - step-by-step diagram

Step 1: Preparing the Material

Manufacturers of crushed stone for construction work do not specially prepare granite crushed stone for painting, so you may end up with stones of very different sizes in the general pile.

Manufacturers of colored crushed stone use a special device called a “screen” to separate larger pieces of stone. With its help, bulk materials are sorted into small and large fractions using the screening method. It’s unlikely that you have a “rumble” lying around in your barn, but you probably have a metal mesh. Before you paint the crushed stone yourself, pull it at an angle of at least 60° and shovel the crushed stone to the very top to ensure a larger sifting scale. Larger pieces will roll down the mesh, while smaller pieces will fall to the ground underneath the mesh. For painting, it is best to use pebbles about 10 mm long - such crushed stone is most convenient for filling garden paths. Smaller ones will also be useful for decorating flower beds and flower beds, and you can always use large pieces for construction purposes.

Step 2: Painting the crushed stone

The sorted material must be poured into a concrete mixer. By the way, you can make a concrete mixer yourself if you have an unnecessary metal barrel. Paint of the color we need is poured over the crushed stone - you can use both polymer and acrylic paints. To achieve the best color, the volume of paint should be at least a third of the volume of crushed stone loaded into the concrete mixer. Having started the unit, you can calmly rest for the next 40-60 minutes - this is exactly how much time is needed for uniform coloring.

Step 3: Drying the Stones

While your DIY decorative crushed stone is taking on a new color, you can prepare a receiving container if you haven't already. The container is a large box with a mesh stretched around its perimeter. If it is a metal mesh, then it can be stretched a short distance from the bottom of the box; if you are using a regular mesh, stretch it to the very top of the container. Thanks to this device, excess paint will flow freely to the bottom of the box, and the painted material will remain on the mesh.

Remove the crushed stone from the mesh and spread it outdoors to dry, lined with plastic wrap. The paint remaining in the box can be reused to paint a new portion.

How to paint landscaping material

The cost of colored stone is 20 times higher than that of ordinary stone. You can reduce costs by making bulk material yourself, following step-by-step instructions.

Purchasing or preparing raw materials yourself

You can buy ready-made chips at a garden center or hardware store, or purchase raw materials in the form of unpainted crushed stone and give it the desired shade. Suitable for painting are granite, marble, limestone of any original color, as well as more expensive and rare ones: shungite, quartzite, and serpentine.

If there is a coarse stone available, it can be crushed using a crusher

What can be used as a dye?

To add color, they usually use acrylic paints and polyacrylate-based dyes or special facade compositions to look like stone, weather-resistant enamels, and even PVA glue.

In order for the decorative stone not to change its color brightness under heavy rain, snow and sunlight, the paint must have the following properties:

- water resistance, weather resistance;

- resistance to mechanical stress, in particular abrasion;

- frost resistance and environmental friendliness.

You can purchase these materials at any hardware store; they are quite affordable.

Preliminary preparation

Stages of preparatory work:

- In the purchased crushed stone there are stones of different fractions. For painting, the ideal size is about 10 mm; in order to remove large pieces, as well as debris, you need to sift the mass through a metal mesh located at an angle. This device is called the “rumble.”

Large parts and debris will roll down the mesh, and those suitable for painting will fall through the cells.

- Now you need to wash the crumbs, removing dust for better adhesion to the paint.

- Clean gravel should be dried.

Coloring

Coloring stones can be done in several ways.

Manually:

- Pour a portion of crushed stone into the container.

- Pour paint of the desired shade 20% of the volume of raw materials.

- Stir with a shovel until the stones are evenly colored.

- If the amount of gravel is small, then it can be spread out on polyethylene and covered with a layer of primer and then paint from an aerosol can.

In a concrete mixer:

- Fill in 2/3 of the volume of gravel and pour in 1/3 of the dye.

- Stir for at least 40 minutes.

It is advisable to load the concrete mixer completely to reduce the number of approaches

- Pour onto a mesh with a tray.

Drying

Drying freshly painted gravel is easy on a fine-mesh metal mesh with a tray to drain excess paint. The resulting smooth and evenly colored crushed stone must be laid out on plastic film until completely dry.

It is important that all fragments of crushed stone are painted evenly

Crushed stone painting technology

Crushed stone of any size is suitable for painting, but screening with a fraction of 10-30 mm has a higher decorative effect. In order to obtain high-quality material at the output, the crumbs must first be thoroughly washed to remove any remaining sand and dust, then dried. The moisture content of clean, ready-to-paint crushed stone should be no more than 20% of its specific gravity.

For painting you will need the following tools: vibrating sieve, washing grid, concrete mixer, drying tray. Also, high-quality painting material is required.

It is important that the coating has high resistance to ultraviolet radiation and moisture.

Typically, acrylic, alkyd or water-dispersed paints are used to produce decorative crushed stone.

Paint for crushed stone color-bol54

Stages of coloring stone screenings:

- Pour the prepared crushed stone into the concrete mixer, filling it 2/3 full.

- We turn on the concrete mixer and begin heating the crushed stone with a gas burner to a temperature of 40 to 60 degrees.

- Next, pour paint on top of the crumbs in a percentage ratio of 20:80 or 30:70 to the volume of crushed stone. Consumption per 60 kg of crushed stone: 1.8 kg of dye.

- Turn on the machine and leave for 40-60 minutes. This will be enough to uniformly paint all edges of the stone.

Video instruction:

If the proportions are strictly observed, the output will be almost dry decorative crushed stone. However, before pouring the crumbs into storage containers or putting them into use, they must be further dried. To do this, the crushed stone should be placed on a drying tray in a thin layer and left in the fresh air until completely dry.