What does it look like

If there is no “A” in front of the name, this means that the wire strands are made of copper. In addition to the main symbols, J or O can be indicated through a dash - with or without a light green wire, this means a difference in grounding.

After the letters, numerical values are indicated, which indicate the number of cores and their cross-sectional area. For example, cable NYM-J 3×3.5 - 0.66 stands for:

- classic wire made with PVC insulation and outer sheath;

- has three cores with a cross-sectional area of 3.5 square meters. mm in each;

- used at voltages not exceeding 660 V.

Unfortunately, not all electricians will be able to decipher the markings on the wires. Therefore, it is advisable to work with professionals.

Main characteristics of the wire

Decoding the NYM marking

The marking includes an alphanumeric designation that characterizes the cable parameters.

Consider them in more detail:

- N - indicates that this brand is manufactured in accordance with the German Normenleitung standard;

- Y - indicates the insulation material with which the cable cores are covered, in this case it is polyvinyl chloride or PVC for short;

- M – indicates the presence of an outer sheath in the cable, comes from the German Mantelleitung;

- J – indicates that the cable is equipped with a PE protective grounding conductor with a corresponding yellow-green color;

- O - indicates that the model contains a neutral conductor N with the corresponding blue color.

Consider an example of decoding the markings for the NYM – J – 3 × 2.5 cable. Here is a model with polyvinyl chloride cable insulation, which has a dedicated ground wire. In total, the cable contains three cores with a cross-section of 2.5 mm2 each. The arrangement of all elements inside the NYM cable is determined by its design features.

What does the abbreviation NYM stand for?

NYM cable markings may include the prefixes “O” and “J,” which indicate the presence of yellow-green (grounding) and blue (working zero) cores in the conductor.

The abbreviation NYM itself stands for:

- N - means Normenleitung (classification according to the German standard);

- Y - polyvinyl chloride insulation;

- M - the cable can be used in various conditions.

You can often see the abbreviation “VDE” on the NYM cable.

This designation indicates that the conductor is manufactured in accordance with international standards, and it can be used even in fire hazardous facilities.

NYM cable - technical specifications

As mentioned above, the NYM cable insulation is made of non-flammable polyvinyl chloride. For the manufacture of conductor cores, a metal such as copper is mainly used. The cores can be either stranded or single-wire, separated from each other by an intermediate layer of non-combustible insulation.

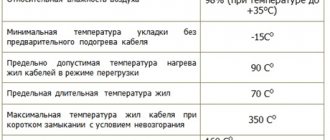

If we go directly to the technical characteristics of the NYM cable, then we should highlight the following:

- The cable can withstand voltages over 600 Volts;

- Its operating temperature ranges from -50 to +50 degrees;

- Recommended installation temperature for NYM cable is no more than -5 degrees;

- Minimum possible bending radius, no more than 4 outer diameters;

- Service life - 30 years (cable warranty is at least 5 years).

The NYM cable can be used in any conditions, both at home and in industrial enterprises. Its main feature is the presence of a non-flammable insulating layer between the conductors, so this cable can be used even for installing wiring in a wooden house. The cable can also be used outdoors, which significantly expands its scope of application.

Application area

This type of wire is intended exclusively for internal electrical wiring. The fact is that PVC plastic is not resistant to radiation in the ultraviolet spectrum, which is present in sunlight. It decomposes under the influence of ultraviolet radiation, so if it is necessary to stretch the NYM cable in an open place, it must be enclosed in a steel or plastic corrugated pipe.

This cable is used for power and lighting wiring inside any structures, including the first class of electrical safety. They can connect single-phase and three-phase current consumers in rooms with explosion hazard classes B1 b, B1 g and Vpa. In areas with explosion hazard class B1a it can also be used, but exclusively for lighting.

Scope of application and main advantages

The main advantages of using NYM cable:

- Fire safety. The product is manufactured in a protective shell made of a special material that is not subject to combustion. However, there is a risk of fire when laying wires in a bundle.

- Increased elasticity. The cables have a rubber seal.

- Various areas of application. Suitable for underground and overhead installations. With its help, you can make electrical wiring in wooden houses, over long distances and in hard-to-reach areas.

- Availability of color marking. Electrical installation work is carried out quickly and easily, due to the color indication of copper conductors.

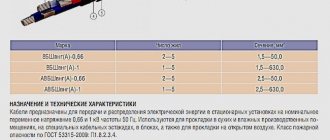

A wire with a conductor cross-section of classes 1 and 2 according to GOST 22483 is recommended for use in office and residential facilities. It is resistant to environmental influences and is suitable for installation not only in dry rooms, but also in facilities with high humidity, including industrial buildings and cable racks.

Cores with a cross section of 1.5-10 mm2 are single-wire, 16-35 mm2 are multi-wire. PVC plastic was used as a structural coating. In accordance with the standard, material of different colors is used, which greatly simplifies the installation process.

Experts recommend NYM cable to those who do not know what to choose to improve the fire safety of wiring. The effect of the non-flammable outer shell is complemented by internal filling of the distance between the cores with a non-vulcanized rubber mixture. Due to self-extinguishing, the product does not ignite even under direct exposure to fire.

NYM cable design features

Copper conductor is used to make cores. If its cross-section is from 1 to 10 mm², then the wire is single, and for cables from 16 to 35 mm², cores are made, twisted from several conductors.

Insulation and internal filling differ somewhat depending on the number of cable cores. When there are 4-5 of them, there is a PVC cord in the center of the wire, which prevents the conductors from moving. If there are 2-3 wires, then there is no need for it. In all cases, the NYM wire has three layers of insulation:

- polyvinyl chloride separately on each core;

- chalk-containing rubber is pressed into the empty space between the wires;

- The outside is covered with PVC plastic coating.

These wires are produced in two modifications, differing in the colors of the core insulation - for use in electrical circuits with and without grounding - they differ from each other by the use of the letters J or O on the external insulation.

- In the first case, the cable is marked as NYM-J, which indicates the presence of at least three cores, one of which is yellow-green in color.

- In the second case, the NYM-O marking is used, indicating that there is no yellow-green wire, but there is a blue wire for the neutral conductor.

NYM cable manufacturers

Currently, there are many factories producing cable products. To avoid falling for a fake, it is recommended to choose the most proven ones. If a person is at a loss as to which factory to choose, you can visit the forum of electricians, who will definitely suggest more popular companies. Below is a description of which manufacturer is best for NYM cable.

You may be interested in Heating wire for pipes

Cable products on reels

Helukabel, a German plant that opened its branch in Russia since 1998, has proven itself well in the market during this time. There are more than 30,000 cable sizes available. The manufacturer delivers products anywhere in the world. The minimum wire length upon request is 100 meters.

LappKabel

An international company founded in the 60s of the last century. It has more than 100 foreign partners and branches that produce products for industry, nuclear and oil plants, and deliver products in a short time by air or rail. The factory has many awards and victories in competitions.

TKD Kabel

One of the largest cable factories in Europe. Manufactures products using the latest equipment. There are more than 35,000 types of mark sizes available. It produces new models of wires that operate at the lowest possible temperatures, with protection from rodents or mold. There is a testing center on the territory of the plant, so before reaching the counter, products undergo thorough control.

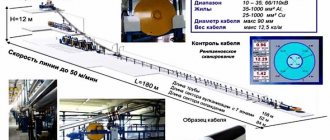

Manufacturing process

The NYM cable has proven itself in installations not only in industry, but also in everyday life. To choose the right product, it is recommended to focus on the descriptions of the above factories.

Specifications

To determine the possibility of using the NYM cable in certain devices, it is necessary to take into account its technical characteristics. These characteristics for NYM are:

- Rated voltage – can be used in electrical networks with a supply voltage of no more than 660 V and a frequency of 50 Hz.

- The rated operating current is determined by the cross-section of the conductor, as is the related parameter - the maximum permissible current that can flow for a short time in emergency situations.

- Temperature limits - the temperature value at which NYM can normally perform its functions without loss of specified parameters and destruction of any elements. For NYM cable the limit is from – 50ºС to + 50ºС.

- Core resistance is set individually for each specific cable and determines its throughput or permissible amperage.

- Insulation resistance - determines the dielectric properties of the insulating layer, both between conductors and from each conductor to conductive elements that may touch the outer sheath.

- Bending radius should not exceed 4 outer diameters of the cable itself.

Rice. 2: permissible cable bending radius

Differences in technical characteristics: VDE vs TU

Specifications may vary somewhat depending on the manufacturer. Wires manufactured in German factories are manufactured according to the VDE standard and are approximately the same in all cases. In the CIS countries, manufacturers are guided by local technical conditions (TU), so not only the properties of the cable are different, but also its marking.

Local manufacturers can save money by at least using filler, which is pressed into the space between the cores. In original cables it is chalk-filled rubber that does not support combustion, but in domestic ones another material may be used. As a result, original cables can be used even if there is minor damage, but in this case it is better not to use domestic cables.

It should be borne in mind that making electrical wires in makeshift conditions is a rather thankless task - whatever one may say, the wire requires copper or aluminum, since there is nothing special to save on here. As a result, all products of this kind are usually certified and if you look closely at the markings, it is quite easy to distinguish the original from local products, at least by the markings - German wires must have the letters VDE and NYM on them. If they are not there, then there is a domestic cable on the counter.

Additionally, it doesn’t hurt to look at the material filling the space between the cores - if there are drips there, then this is a reason to doubt the use of chalk-filled rubber, which should be used according to original standards.

Color coding

NYM cable produced in Russia or imported from Europe, if it is not a fake, always has color marking of conductor insulation that complies with the standards of Russian PUE (Electrical Installation Rules).

The colors of their internal insulation may vary depending on the number of cores.

- Single-core - color is not regulated.

- Twin-core type O - black and blue.

- Three-core type O - black, brown and gray.

- Four-wire type O - black, brown, gray, blue.

- Three-core type J - black, blue, yellow-green.

- Four-wire type J - black, brown, gray and yellow-green.

- Five-core type J - black, brown, gray, blue and yellow-green.

NYM Wire Laying Rules

When laying, it is necessary to install the power line in a place where the sun's rays do not reach and where temperatures are critically low. The NYM cable must be laid in a place protected from contact with children or animals. If treated with care, the cable will last its entire lifespan.

Gasket in the wall

When laying in wooden houses, it is recommended to install protective corrugation so that in the event of a fire the combustion does not spread to the building. When installing in the ground, it is necessary to install cable channels that will protect the product from excess load.

Operating and installation conditions

- Operating temperature – from -50 to +50 °C;

- The minimum service life of the NYM cable under normal operating conditions is 30 years;

- The main areas of application are indoor and outdoor installations. Outdoor use is only possible outside of direct sunlight.

- It is possible to lay the cable on top of, in and under plaster in dry, damp and wet rooms, as well as in brickwork and concrete, with the exception of direct pressing into vibro-filled and stamped concrete.

- Installation can be carried out in pipes, in closed installation and curved channels; gasket temperature – not lower than -5 °C;

- The size of the mounting bends is at least 4 shell diameters.

What errors occur when using NYM cable

NYM wire is mainly recommended for installation work in buildings in the construction of which wood or flammable materials were used.

It must be remembered that the wire does not spread fire only when individually laid. If you need to use a group gasket, then it is advisable to purchase products from other brands that are intended for this type of work.

Different sections

Many people are faced with the problem of laying wires in baths, saunas or steam rooms. It is allowed to install this wire in such premises. Because the rubber layer fits tightly to the wire insulation, thereby preventing moisture from penetrating into the cable. These are the only problems that may arise when using the product.

Scope of cable application

NYM cable is mainly used in various electrical installation works, no matter in the domestic or industrial sphere. This type of wire is mainly used for laying electrical wiring in rooms made of wood, because the cable design includes a special sheath that prevents the spread of fire.

You may be interested in this Features of the frls cable

Cable marking

Quite often it is used for installation outdoors, but on condition that direct ultraviolet rays do not reach the wire. For installation in a residential area, NYM multi-core wire is usually installed in a hidden way. This cable is used when connecting lighting groups or sockets. One of the advantages of the wire is that the conductor can also be used for installation in the soil, but it is recommended to place the product in a corrugation, thereby making it safe.

Classification and price

Cables are available with different numbers of cores. Their number is from 1 to 5. Some enterprises produce products with a number of cores up to 7.

The wire also varies in cross-sectional area of the conductors, ranging from 1.5 to 6 square meters. mm.

The level of prices depends on the characteristics of the cable and the pricing policy of the selling company. The cost ranges from 20 to 500 rubles per linear meter, taking into account the characteristics of the wire and the above conditions. By purchasing products in bulk, the client can receive a discount.

Design features

VVGng is a power cable with copper conductors. The core insulation is made of polyvinyl chloride plastic. The insulation material contains additives that make it flame retardant. This conductor is available with a number of cores from 2 to 5. For ease of installation, the core insulation is color-coded, which can be done by completely painting the core insulation, or with a colored stripe. The outside of the cable is covered with a sheath made of the same PVC plastic as the core insulation. The core can have a single-wire or multi-wire design. The cross-sectional shape of the core can be round or segmented.

Advantages and disadvantages

Compared to other cable and wire products available on the domestic market, NYM cable has a number of significant advantages:

- Not afraid of moisture - in comparison with domestic models with vinyl insulation, NYM is much less susceptible to moisture absorption. Due to this, NYM can also be laid in wet areas (basements, wells, mines, etc.) without additional devices.

- Flexibility - easily changes geometric shape and can be laid in the most difficult to reach places, make turns, etc. This property is ensured by the intermediate layer.

- Does not support combustion - due to the composition of the intermediate layer, the insulation does not burn, but only melts when exposed to a flame or spark. This property allows NYM to be used in areas with increased fire hazard.

- It has a wide variety of design options , both in the number of cores and in their cross-section, due to which one such cable can provide full power supply in circuits with a different number of phases, wires and for any load.

It should be noted that an important factor in all the advantages of the NYM cable is the manufacturers’ compliance with the international standard. Which ensures higher quality products in all respects.

But, in addition to the above advantages, NYM also has some disadvantages. Firstly, the high quality of all NYM brand cables also determines their higher cost in comparison with domestic analogues, for example, the same VVGng. Secondly, NYM is not recommended for installation in areas where it may be exposed to sunlight. Since its insulation loses its characteristics from the sun, and the cable fails much faster.

Advantages and disadvantages

Among many conductors, NYM cable is considered to be the “golden mean”. To better understand its quality, let’s consider the main advantages of this product:

- Increased elasticity, ease of installation and operation. This flexibility is due to the presence of an internal insulating layer of rubber. This advantage is very important when performing any installation work on electrical wiring, as well as when installing equipment in inaccessible or hard-to-reach places. The wire is not affected by dampness and moisture, so it can be laid along the ground over long distances.

- If we talk about NYM, manufactured according to German quality standards, then before entering the market it must undergo numerous studies and tests. The Germans have long earned the title of the most reliable and high-quality manufacturers of industrial and other products, so there is no doubt about the integrity of the insulation and the compliance of the cable with all the declared technical and operational properties.

- The product does not support combustion, which was made possible due to the choice of material for the inner layer.

- Most specialists and electricians recommend using the product to connect lighting systems and power circuits.

- Long service life spanning several decades.

The most obvious disadvantage of NYM cable is its high cost. There are many domestic analogues, albeit with worse characteristics, the prices of which are several times lower.