What do you need for daily cooking? High temperature and ability to control the heat source. As it turned out, there are not many types of home “hearth”.

- kerosene burner - 5 decades ago it was the main element in any kitchen;

- a gas stove is by far the most popular “hearth”;

- electric stove - can be a separate element or a built-in component of the kitchen.

Let's consider the last option in more detail. When visiting the kitchen was an exclusively utilitarian matter (that is, the housewife was only interested in the process of cooking), no one thought about the appearance of the electric stove.

Accordingly, from a technical point of view, it was a very primitive device:

- frame;

- heating element (spiral or heating element in its own housing);

- thermostat (not present in every model);

- mechanical heating regulator (spiral resistance switch).

It was possible to repair such a stove with a screwdriver and pliers in hand. Even the heating coil was easy to make with your own hands: nichrome wire was wound around an ordinary pencil. More advanced craftsmen used an electric drill and a wooden mandrel. The steel rod was inserted into the chuck and the winding process was much faster.

Modern hobs

Then fashionable trends in modern design came to the kitchen, and simple electric stoves no longer fit into kitchen corners and furniture sets. Hobs have appeared that are built into the countertop.

Such household appliances are not only beautiful, they are distinguished by advanced functionality. The heating element is controlled using electronic controllers, and various security systems are present. Most products are equipped with touch control panels; you won’t find a mechanical handle even in economy class models. To repair a modern hob yourself, you need to have basic knowledge of electronics.

Types of heating elements of a modern electric stove

The usual spiral in ceramic insulator holders has not been used for a long time. Instead, 3 types of electric heaters are used, both direct and indirect:

- The HiLight direct heater is nothing more than a progressive descendant of the nichrome spiral. It is a corrugated tape made of high-resistance metals.

Looks and works exactly like a wire coil. However, due to the design, it releases thermal energy more efficiently and lasts much longer. Some manufacturers produce stoves with traditional wire heaters. There is no fundamental difference (slightly lower efficiency and reliability). But repairing a burnt-out spiral is easier. The dishes (and their contents) heat up very quickly. However, such a system has a serious drawback: it is difficult to regulate the degree of heating. In fact, the heater operates in two modes: “on” and “off”. This does not mean that it is impossible to set the operating temperature, it’s just that this process is implemented somewhat unusually. The electronic controller periodically turns off the power and turns it on again. In this way the amount of total thermal energy is regulated. In this mode, it is difficult to cook dishes that require “low heat”, as on a gas burner. Another problem characteristic of this type of hob is the high temperature of the decorative surface. Externally, the plane does not look hot, so there is a danger of touching and getting a thermal burn. - Direct heating emitters "HaloLight" are made in the form of ordinary incandescent lamps that heat dishes using infrared radiation. Probably everyone has tried to put their hand near a working car headlight: the warmth is clearly felt. Kitchen appliances use halogen emitters, which have the highest efficiency when generating heat. Such heaters operate according to an algorithm similar to HiLight, only the heating and cooling speed is much higher. Manufacturers often combine HaloLight elements with others in the same burner.

The possibility of burning your hand is the same as with the previous design, in addition, there is one more drawback. Halogen heaters have a limited lifespan, so repairs to hobs with such heaters occur much more often. - Indirect heating induction burners. They transmit energy in the form of an alternating magnetic field with a high frequency, causing the metal in their area of action to heat up. Technically they are designed like a regular inductor, only the turns are located in the same plane (for compactness).

The system operates on the principle of a transformer. The high-frequency generator generates the corresponding alternating current on the primary winding (coil located under the burner). The secondary winding is a utensil, which must be made of a metal with ferromagnetic properties, otherwise the magnetic field from the “primary” will work idle. Suitable steel or cast iron (can be checked with a magnet or by the presence of the “for induction cookers” icon). Copper and aluminum cookware will not heat up on such a burner. Eddy currents in the bottom of the cookware instantly heat the metal, and the pot or pan acts as a heating element (that’s why this method is called indirect). Without utensils, the hotplate remains cold, which reduces the risk of scalding. This can be clearly seen in the illustration:

You can adjust the degree of heating, but many housewives are confused by the restrictions on the material of the cookware. In addition, some buyers are wary of induction radiation. In vain, this is not a microwave: the electromagnetic field is no higher than that of a switched-on iron. And malfunctions can only be associated with the electrical circuit: the coil does not burn out. The main disadvantage of an induction burner is its high cost, which somewhat limits mass promotion to the masses.

Once you understand the design of heaters, you can repair your own hob.

Design and principle of operation

The design of a gas stove from any manufacturer is not much different, with the exception of some features. The oven includes several systems, the operation of which is interconnected:

- Frame. Made of enameled steel, the body is durable and resistant to aggressive influences.

- Working surface. Usually coated with enamel with super-heat-resistant properties. Expensive models contain a stainless steel coating. On top there is an enameled steel or cast iron grate that protects the burners and the entire surface of the stove.

- Burners. The quantity ranges from 2 to 4 pieces depending on the model. Material - from ceramics to aluminum, different sizes. They release gas needed for cooking.

- Oven. Most models of gas stoves have it. Located under the work surface, it occupies a significant part of the entire device. Designed for heat treatment of products: baking, drying, etc.

- Gas equipment. Consists of distribution pipelines, shut-off valves, burners and burners.

- Automatic ignition system. This button, located on the front panel of the case, is needed to ignite the burners, and in some models, also for the grill, without the help of matches or lighters. Allows you to turn on the lighting in the oven.

- Gas supply, control and monitoring module. Has a built-in timer, thermometer, processor, and other devices.

The principle of operation of a gas stove is to use natural gas for heating the home and cooking:

- Gas enters the stove through a tube connected to the supply source. When the substance is supplied from a pressurized cylinder, propane is used as fuel.

- After passing through the burner, the gas reacts with air, turns into a gas-air mixture, which reaches the perforated part of the burner in the upper part, escapes through the dividers and ignites. Cookware placed on the wire rack becomes hot.

- The gas flow is regulated by switches located on the panel.

If the design of the stove is made with high quality, complete combustion of the gas occurs.

Hob malfunctions

If one of the burners does not work, you can survive it. But the breakdown of the entire slab is already a problem. You can take the equipment to a workshop, but in addition to the cost of spare parts, you will be charged money for the work performed. If you know how to hold a soldering iron in your hands and have at least a multimeter, you can repair the hob yourself.

All faults can be divided into 3 groups

- Broken heating elements: For spiral or halogen burners, this is more of a mechanical problem than an electrical problem; the parts are completely repairable. In extreme cases (for example, a halogen heater) a simple replacement. The induction emitter (winding) does not break in principle; the problem may be in the electronics.

- Failure of switching elements or conductors. These can be relays, contacts, thyristor switches. They are not the most difficult elements to repair.

- Electronic circuits: generator, transformer, controllers, control unit. Without deep knowledge of electronics, it will not be possible to repair these elements. In the best case, you can dismantle the faulty element and install a new one.

Advice:

Before you begin complex repairs, try to diagnose “problems” that can be fixed without disassembling the structure.

For example, check the power supply from the input circuit breaker before connecting the direct power cable from the panel (including the socket, if any). The presence of power is checked with a multimeter on the contact block of the stove.

If the control panel does not work, check that it is dry (if there are movable keys) and clean (in the touch unit). Often a layer of dried splashes simply prevents the touch buttons from “feeling” your fingers.

How to disassemble the hob

The most commonly used panels are those built into the kitchen worktop. The electrical appliance has an independent body with a decorative plane, under which heating elements are located. Carefully remove the panel and place it face down on a flat surface. Before starting disassembly, it is recommended to disconnect the power wires. It would not be amiss to remind you that the wiring must be de-energized in advance.

After carefully removing the cover, we get full access to the “internal organs” of the panel. Any design has a similar layout: all electrical elements are located in the so-called working “trough” without dividing barriers. The illustration shows an option where “HiLight” type heaters are installed on all burners.

Already at this stage, it is possible to visually diagnose the integrity of the wiring and spiral (band) heaters. All blocks and modules are connected using connectors or contact terminals. Once the fault is localized, you can easily remove the unit for replacement or a more detailed check.

For example, you can remove a heater in an insulating casing, apply power to it, and check its functionality using the device.

Why might the sensor not work?

Unfortunately, even such reliable equipment as a built-in induction surface can fail. Some manufacturers in the low-cost segment may use cheaper components, which inevitably affects the life of the panel itself. Also, do not forget about the operating rules. Often users neglect the information written in the instructions. This can also cause damage to the panel. Below we will look at possible failure scenarios and suggest ways to solve them.

Check the blocking

The first thing to do is check the hob lock. Many manufacturers equip their models with a special function for blocking controls, called “Child Protection”. This is very useful and allows you to turn off the sensor so that children and pets cannot accidentally turn on the stove or change its settings. Some users have been working with the panel for many years and are not aware of this feature. If you accidentally activated the function, you need to look in the instructions to see how the panel is locked and then disable the “Child Protection” mode. If this is not the problem, then you need to look for the problem further.

Wiring problem

You should also understand whether the hob is connected to an outlet. If the wires have not been touched, then there is a possibility of damage to the electrical wiring. The contacts may oxidize, or the wire itself may be damaged by rodents in a private home or pets in a city apartment. Try connecting the cabinet to a different outlet using an extension cord. If this does not help, then you need to use the services of a professional.

Control module malfunction

This malfunction is already an order of magnitude more serious than damage to the wiring. The presence of many sensors, a sensor, operating modes and a tangential cooling fan in the induction panel force manufacturers to install electronics inside the panel, which are responsible for controlling the device. It can be damaged either physically or software. In case of physical damage, the module must be repaired or replaced with a new one. And in case of a software error, perform the so-called “flashing”. Any manipulations with electronics must be performed by an experienced specialist who has a specialized education and is well versed in the electronics of hobs.

The sensor has failed

The last possible option is damage to the sensor itself. This error usually occurs after many years of use. If the sensor capacitors are damaged, then in theory they can be replaced. Unfortunately, most craftsmen do not carry out such repairs, and the surface can no longer be used normally.

Repair of direct heating hob (individual components)

Diagnosis of faults is carried out from simple to complex. After the fuse, we check the electrical wiring and the functionality of the heating elements. Control of turning the heating filament on and off is carried out using PWM (pulse width modulation). Don't let this bother you. All the same, power supply is supplied by conventional relays, which are checked with a multimeter.

A burnt-out spiral (tape) is usually replaced entirely; this is not the most expensive element. As a temporary measure, a mechanical connection can be made (rivet or screw for tape, and screw terminal connection for helix). This will allow the stove to work for a while. This “joint” will last for several days, so buy a new spare part as soon as possible.

Power relays cannot be restored; they definitely need to be replaced.

The same applies to halogen heaters. Thermal elements are not repaired (in fact, this is an electric lamp), they are replaced with new ones.

As for burnt wiring, you should select a wire with similar characteristics, make a complete harness, and replace it using end switches.

Before reassembly, contact groups are checked for strength and absence of thermal damage, cleaned and reassembled.

If after checking it turns out that all power conductors and elements (including heaters) are in order, the electronics remain. Self-repair is possible only if you have specialized skills and a detailed electrical diagram.

If you know for sure that it is the electronic module that is not working, and there is no way to professionally diagnose it, you can take this particular unit to a branded workshop. It will be tested (for a small fee) on a stand, or in a similar model of hob. You can install a repaired or new unit in place yourself.

For information:

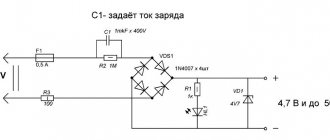

Some craftsmen restore the functionality of the hob by changing the control circuit. For example, you can power the heating elements from a homemade manual control unit located outside the main body. If the cost of restoring standard modules is too high, and the stove heats properly when connected directly, this method has a right to life.

Cleaning and prevention

It is better to prevent any malfunction than to eliminate it. By observing the operating conditions of the gas stove, you will extend its service life, avoiding unforeseen repairs. Preventative care and cleaning:

- Clean the surface of the stove from food debris after each cooking, waiting until the panel has cooled down.

- Do not leave the stove turned on unattended, as boiling liquid from the containers floods the flame of the burners, which leads to premature wear of the auto-ignition and gas control systems.

- Do not forget to lubricate the rubbing surfaces of the adjustment knobs.

- Cleaning of burners, jets, connections of regulators and switches is done with a needle or thin wire; metal brushes and brushes are also suitable.

- Maintenance is carried out periodically. To do this, the protective panel is dismantled, the studs are removed, the rods are pulled out, the parts are cleaned and inspected for mechanical damage and signs of wear. Contacting and mating elements are lubricated with graphite lubricant.

Repairing a gas stove seems like a difficult task. Armed with the necessary tools and troubleshooting instructions, you can repair your home appliances yourself and save a significant amount.

Source

Diagnostics and restoration of indirect heating panels

Repairing induction hobs can only be done by experienced electricians. Without knowledge of the material, with a simple multimeter and pliers, the operation is doomed to failure. At the same time, many problems are not malfunctions at all: a normal violation of the operating mode.

Typical malfunctions of induction heating systems

- The induction hob either does not turn on at all, or the power disappears immediately after starting operation. This may be a protective function: if you remove the dishes from the heating plane, or the size does not match the diameter of the burner, the automation blocks operation. The same applies to aluminum or copper cookware.

- The same problem (wrong cookware) can result in the induction hob not working at full capacity.

- The heater turning on independently may be due to contamination of the stove, or the presence of a massive steel (cast iron) object next to it.

Real malfunctions, not related to violations of the operating mode, appear in the inductive field generator circuit. As we have already noted, the winding fails extremely rarely.

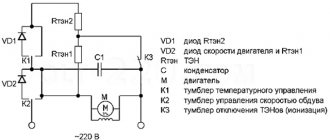

Typical diagram in the illustration:

In fact, there is no space technology here. The transformer converts the supply voltage, and the generator creates an increased frequency of oscillations of the electromagnetic field. After a visual inspection (for obviously “burnt” radio elements), the generator is checked using a home oscilloscope. If you have such a device, there is no point in explaining the principle of checking the inductance generator; your level is sufficient for repair.

If you do not have sufficient experience, you will have to turn to the experts. In any case, repairing a separate unit will not cost as much as buying a new panel.

Gas control repair

Such problems are mostly typical for hobs that have been used for a long time. The burners either take too long to light or go out after releasing the knob. The cause of this type of problem is a clogged thermocouple. This mechanism is responsible for supplying gas to the burner. If the burners go out quickly, disassemble the burners, find the thermocouple and clean them using available items. An ordinary wire, needle or knife will do here.

If the measures taken do not bring the desired effect, then perhaps the reason is a malfunction of the thermocouple or magnetic valve itself. These parts will have to be replaced.

Thermocouple

Causes of malfunctions

With the exception of a minimal percentage of real factory faults, most breakdowns occur due to improper connection and operation.

- Unstable mains voltage damages electronics;

- the use of cookware that does not correspond to the size of the heating surface leads to local overheating;

- Impacts and spilled liquid on a hot surface form cracks and chips through which moisture penetrates into the housing.

But still, the main reason for equipment failure is ignoring the requirements of the instructions.

No electricity

Symptoms: Indicators do not light up, control buttons and switches do not respond

This is one of the few problems that the owner of an electric stove can easily fix on his own, even if he does not have special tools. If the indicators on the electronic display of the hob do not light up, then most likely the stove is not receiving power at all. Naturally, absolutely fatal cases such as a power outage throughout the house or entrance are not considered here.

First, check the power cable: visually everything should be in order, the plug is intact and undamaged, the wire is not pinched or melted anywhere, the plug is not hot to the touch. If the problem is in the plug, then either replace it, or, if it is not removable, replace the entire power cable. If the power cable is pinched somewhere, then it is better, of course, not to risk it and replace it.

It is quite possible that there are some problems in the electrical wiring at the place where the electric stove is connected: it’s easy to install - plug into it the power cord of some other electrical appliance that you just checked in another outlet. You can try plugging the stove into a different outlet if the cable can reach it or you have a suitable extension cord. If no devices in the socket work, first start looking at the electrical distribution panel: if you have a separate circuit breaker for sockets in your apartment, then it could simply be “knocked out”, and just turn on the switch; However, the question remains, why did it get knocked out? In other cases, you are still better off calling an electrician. If other devices do not work in other sockets, most likely, the power supply circuit breaker for the sockets throughout the apartment has been knocked out - you again need to go to the panel. By the way, if, after turning on the electric stove again, the machine “knocks out” again, then your affairs are bad: such symptoms indicate the presence of a short circuit in the electric network of the stove, and here you cannot do without a technician.

It is possible that your power supply voltage is outside the limits allowed for this model: usually it is from 200 to 240 volts. If you have a voltmeter, check the voltage in the outlet: if it is not OK or there is nothing to check, you will have to call an electrician.