Cable design features

The presented photographs of the ASB cable show the complexity of its design, since each cord contains the following elements and layers (presented in order from the center (core) to the outer sheath):

- Aluminum conductors of round or sector cross-section, consisting of one or several twisted wires;

- Intermediate insulation made of fabric impregnated with a special adhesive mixture;

- Lead plate sheath;

- Filling “pillow”, depending on the model, presented in the form of crepe paper or polyethylene terephthalate;

- Intermediate armor made of encircling steel plates;

- The outer shell is a mixture of bitumen and glass yarn.

Design features

As for aluminum conductors, they can be either round or sector. Moreover, they can be monolithic (consisting of one wire) or multi-wire. The main type of insulation is paper impregnated with a special viscous composition.

Next, the lead sheath is installed. A so-called cushion is placed between it and the armor. This is essentially a bitumen layer covered on top with either polyethylene teraflate fibers or crepe paper. The next layer is steel armor made of two strips. And the last one is glass yarn impregnated with bitumen. Solid construction, multilayer, which is why the ASB cable can be used for installing an electrical supply network in the ground.

Manufacturers offer two options for marking aluminum cores: color and numerical (from 1 to 4). The cable cross-section varies from 35 mm² to 240. In the passport, the marking is made according to this template (for example): ASB 3x240, that is, a three-core conductor with a cross-section of 240 mm².

How to choose an ASB

If there is a need to purchase a power cable of a similar design, then before purchasing it is necessary to accurately determine the required parameters.

To do this, it is recommended to carefully study the technical tables, where you can find the required parameters and correlate them with a specific brand of cord.

The following tips may also help:

- The optimal sizes are 3*70, 3*95, 3*120, 3*150, 3*185, 3*240;

- Similar conductors (with similar design, characteristics and functionality) are represented by the brands TsASB (with paper insulation, containing ceresin) and ASBBShv (without a softening pad and with protection in the form of a hose);

- Proven factories that produce, among other things, asb: Kamkabel LLC, Sevkabel Group LLC, Kavkazkbel CJSC.

Most often, ASB is used on an industrial scale, but often when setting up your own mini-power plant in a private home or safer transmission of current, the power cable is also useful in domestic conditions. The main thing is to correctly calculate the load, select a conductor that meets the requirements and comply with individual installation conditions.

How to choose

If you need to purchase such a cord, then you should clearly determine the parameters that are expected to be obtained from the conductor. To do this, experts recommend carefully studying the technical characteristics of the cable or finding tables where you can view the parameters and check them by type of wire.

Here are some tips for choosing:

- Optimal cable sizes: 3 by 70, 3 by 95, 3 by 120, 3 by 150, 3 by 185, 3 by 240;

- It is worth paying attention to ASB analogues - TsASB and ASBShv, which have similar characteristics and design, and do not confuse them;

- Buy products from trusted companies, Sevkabel Group of Companies LLC, Kavkazkbel CJSC.

Multi-core ASB conductor made of copper

Product Description

Description and decoding of the ASB cable includes the following abbreviation. It consists of:

- A – the product contains aluminum conductors. They serve as an excellent semiconductor of electrical voltage;

- C – a reliable layer of lead sheath. This material is applied to the first level of additional protection;

- B is armor. It is fixed in the second stage of the protective coating.

Armor is usually made of heavy-duty steel. Between the first and second stages of protection, several layers of different materials are laid. There are two types of cable:

- ASB;

- ASB2l.

In order to distinguish the composition of the structure, there are multi-colored cores inside. As a rule, they are made in red, blue, yellow and green. Modern models can be numbered in accordance with the technical characteristics of the asb cable.

Explanation of the name, marking, scope of application of the ASB

The name of the conductor, which is an abbreviation of the letters ASB, stands for a cable with current-carrying conductors made of aluminum (A), in a lead sheath (C), with protective armor (B) made of steel tapes. The letter designation may also contain the symbols “l” or “2l”, which inform about the presence in the structure, under the layer of armor, of a cushion made of bitumen tapes - one or two, respectively, for example, ASBL or ASB2l (the tapes can be made of bitumen, creped paper and polyethylene terephthalate fibers).

The ASB cable has reliable protection from any external influences on it

ASB cable and wire products marking

Marking designations contain symbols in addition to the name of the cable, information about the number of main cores and their cross-section, the structure of the conductors, the presence of additional cores, as well as the voltage for which the product is designed. For example:

- ASB 3x70-1 – has three power cores with a cross-section of 70 mm², designed for an operating voltage of 1 kV;

- ASB2l 3x185ozh-6 – equipped with three single-wire conductors of 185 mm² each, for a voltage of 6 kV;

- ASBL 3x95+1x50-1, in addition to three main conductors of 95 mm², contains an additional one with a cross-section of 50 mm².

Purpose of the ASB cable and conditions of use

Laying in the ground is the most common method of installing ASB power cables.

ASB cables are designed to transmit electricity over long distances when laid in the ground, trenches, or indoors. The operating voltage can range from 1 kV to 10 kV. There are several conditions that must be met when using an armored conductor:

- Only horizontal or inclined laying of products with paper insulation impregnated with a flowing compound is allowed. Vertical hanging, even in small areas with frequent fixations, is prohibited

- The permissible corrosive aggressiveness of the soil should be low or medium activity. That is, it is prohibited to lay products in clay, peat, swampy soils, where, due to the high content of organic acids, high humidity, and, accordingly, electrical conductivity, electrochemical processes can occur that lead to disruption of the insulation of conductors

- Work on unwinding or installing cable products without heating must be carried out at a temperature not lower than 0°C

- When laying the cable, its longitudinal stretching is strictly prohibited. It must be laid freely, without any tension loads. This will preserve the insulating properties of the shell and extend the service life of the product.

For the operation of the ASB, the permissible range of ambient temperatures is from -50°C to +50°C. This makes it possible to use it in almost all regions of the country.

Internal structure of armored cable ASB

The design of ASB cable products is specially designed for the possibility of installation in the ground. Thus, a cushion made of bitumen, crepe paper and polyethylene terephthalate fibers (No. 7 in the figure) is resistant to organic and mineral acids and serves the function of protecting the lead sheath and waist insulation from their effects. Acids arise in the soil environment around the cable during the process of soil corrosion, which is a consequence of an electrochemical reaction due to the interaction of moisture, organic and mineral substances with electromagnetic radiation from the conductor.

The structure of the ASB cable has a complex structure that ensures its performance qualities

The main components of the cable are:

- aluminum conductors – 1 (can be single- or multi-wire);

- paper insulation of conductors – 2 (paper impregnated with a special insulating compound);

- cable filler – 3 (seal made of paper bundles);

- additional (waist) insulating layer of impregnated paper - 4 (same impregnation as No. 2);

- shielded shell – 5 (for products designed for 6 kV or more);

- lead shell – 6;

- bitumen cushion – 7;

- armor consisting of two steel strips - 8;

- outer cover made of fiberglass yarn - 9 (usually used in combination with bitumen, less often with chalk).

How to use the cable correctly and how to connect

Before laying the cord to the distribution panel, you need to take into account many nuances:

- Location of the shield;

- Whether it is outdoors or in a very humid area;

- What is the design of the distribution panel and where are its busbars installed;

- Where the input channels are located on the body of the shield for wires and cables.

First you need to plan which side the wire will approach the panel from. Usually, when producing any type of shield, places for cable entry from several sides are marked on its body. This allows you to instantly identify the hole and open it where necessary.

You may be interested in this Table of wire cross-sections and loads

Important! According to the rules, when using the shield outdoors or in a room with high humidity, it is necessary to start the wires only from the bottom. This minimizes the risk of moisture getting under the insulation and into the inside of the shield.

Before connecting the cable, it is cut. Most power cables for heavy loads have two or more layers of insulation, not counting the outer one. Therefore, for installation, press-on lugs are put on both ends of the wire. After this, using a special knife, the cord is stripped of 15-20 centimeters of insulation. When this is done, separate the wires and mark the cables and all its wires so as not to get tangled.

Installation of power ASB

The last step is to wire the factory into the panel and leave a margin of 50 centimeters in case the connection diagram changes. Especially for this purpose, I roll it up near the closet or place it inside it. The new type of shields have special holders for such sections of the cord, to which it is fixed with clamps or wire in any position. Inside the distributor, the cord is mounted so that it goes in the direction of the contact inputs of the automatic switch. To connect a wire, it is cleared of a couple of centimeters of insulation and lugs are placed on these ends, which are pressed with special devices. The contact tips located in the shield look like ordinary flattened holes for bolts with which the wire is pressed to the automatic switch bus.

Important! Some models do not have tips, since the exposed part of the cord is simply inserted into the contact group and secured with bolts.

In order for the contact to be as reliable as possible, the lugs or bare parts of the wires should be as close as possible to the busbars in the maximum area. This is what will ensure the normal passage of electric current.

Set of power cables of various designs

Decoding of the AVVG cable

Decoding the AVVG wire is quite simple; even a person who has never dealt with wires can figure it out. It means the following:

- And that means all the cores are aluminum.

- B – the core shell is made of polyvinyl chloride.

- B is a standard PVC outer sheath.

- G – the cable is bare, that is, there is no protective sheath.

In addition to the standard designations, you can also find the prefixes “P” and “T”. If you see a “P”, this will mean that the electrical cable is flat in shape. The letter “T” indicates that the cable is mold-resistant.

If we talk about marking cables with numbers, then it is worth highlighting the most popular cable AVVG - 660 3*25. In this case, 660 means the operating voltage, which is indicated in volts or kilovolts. The second number is the number of cores and its cross-section. If you see the additional prefix “ozh”, this means that all the wires are single-wire.

Structure of the ASB-1KV cable

ASB-1kV has the following structure:

- Aluminum conductor of class 1, 2 (GOST 22483-2012).

Core cross-section: single-wire shaped – from 25mm² to 240mm², round – from 16mm² to 50mm²; single-wire for single-core cables – from 70mm² to 240mm²; stranded round (for single-core cables) – from 70mm² to 800mm²; multi-wire shaped – from 70mm² to 240mm².

- Impregnated paper insulation. Thickness of insulating material: for single-core cables – from 1.2mm to 2.4mm; for three-/four-core cables from 0.75mm to 0.95mm.

- Belt paper insulation (in multi-core cables) with a thickness of 0.5mm to 0.6mm.

- Lead sheath (GOST 24641-81).

- Protective shell type “B” (GOST 7006-72).

- Armor made of galvanized or black steel strips with a minimum thickness of 0.3 mm.

- The outer shell is made of bitumen composition with a thickness of 2.0 mm.

Scope of application

Since this is a heavy and inflexible, but at the same time very durable wire, its main purpose is to lay high-voltage power lines directly in the ground, using the trench method. It can also be used for installation in shafts, sewers and similar places, but this is not advisable as there are more suitable types of cables for these.

Wire type ASB and ASBl can be laid in soil with low and moderate corrosive activity. Corrosivity is determined in relation to steel, lead and aluminum, since all three of these metals are present in the wire. The main indicator is the pH value, plus the presence of ions of some active substances in the soil.

The only thing that should not be in the soil in the area where the cable route passes is the interference of stray currents. In addition, the wire should not be subjected to loads applied longitudinally, as it is susceptible to stretching. Aluminum is not tensile enough.

Cable type ASB2l can be used in chemically active soils with a high degree of corrosive activity. Although it must be taken into account that nature is fickle, and over time the properties of the soil can change significantly.

Scope of application of ASB

The ASB power cable is used for energy distribution in electrical networks with voltages up to 10 kV.

It is well suited for laying cable lines in trenches, however, certain conditions must be met: - in the presence of stray currents, the corrosive activity of the soil must be at a low level; — in their absence, corrosion activity can reach an average level, but tensile effects on the cable should be avoided. Some specific ASB cable sizes are also used in trolleybus and other electrified transport networks. There are varieties of this cable with one, three and four conductors for alternating voltages of 1, 6 and 10 kV.

Technical feature

This cable has the following technical features. These include:

- the voltage ranges from 1 to 16 thousand volts. This depends on the application and type of cable;

- The resistance of the asb cable reaches up to 28.11 ohms. These values are for single-wire products. Stranded wires have values within 29.4 ohms;

- bending radius reaches 26 units. own diameter of multi-wire products and 15 for single-wire wires.

- surface heating is 95 o;

- the permissible current of the asb cable is from 100 to 1000 AM;

- The operating temperature ranges from -60 to +60o. The photo of the ASB cable shows modern product models.

Cable laying is carried out in positive temperature conditions. This will avoid deformation of the product and preserve its semiconductor properties.

terms of Use

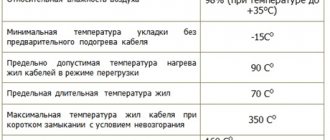

The main technical characteristics of the ASB cable are:

- Operating voltage 1, 6 or 10 kV.

- AC frequency 50 Hz.

- Operating temperature is from -50 to +50°C, with the maximum permissible value being +70°C if the rated voltage is 10 kV and +80°C for a cable rated at 1 or 6 kV.

- Maximum heating temperature of current-carrying conductors during a short circuit: +200°C, during overload mode – +90°C.

- Laying at a temperature not lower than 0°C is allowed.

- The minimum bending radius is 25 outer diameters for single-wire conductors and 15 for multi-wire conductors.

- The specific resistance of current-carrying conductors per 1 km of cable length at a temperature of +20°C is not less than 29.11 Ohms for single-wire conductors and not less than 29.4 Ohms for multi-wire conductors.

- Specific insulation resistance per 1 km of length at a temperature of +20°C is not less than 100 MOhm for an ASB cable designed for a voltage of 1 kV and 200 MOhm for 6 and 10 kV.

- Service life 30 years.

We have discussed in detail the technical characteristics of the ASB cable, such as weight and outer diameter, in the table:

Important indicators when choosing

When purchasing a cable, you need to know its weight and diameter. Mass is usually measured in kilograms per kilometer, and outer diameter in millimeters. Weight and diameter depend on the number of cores and their cross-section.

The lightest is the one with three thin cores with a cross-section of 35 square meters. mm, weight - 1947 kg and diameter - 30.1 mm. The heaviest one has three cores with a cross-section of 240 square meters. mm, outer diameter - 63.7 mm, and weight - 8371 kg. The most common brands of ASB are three-core with a cross-section of 70, 95, 120, 150, 185, 240 square meters. mm.

Many factories are engaged in production.

The following enterprises produce the highest quality products:

- "Sevkabel";

- "Kamkabel2;

- "Kavkazkabel";

- "Moscabel".

Technical parameters and operating conditions

The industrial purpose of the ASB power cable is determined by its exceptional technical characteristics:

- The range of conductor cross-section includes values from 35 to 240 sq. mm;

- The permissible current for the cable is within 50 Hz;

- Operational life – about 30 years;

- Construction length – not less than 350 m;

- The outer diameter of the asb cable is from 30.1 to 63.7 mm;

- Estimated weight – from 1947 to 8371 kg/km;

- Rated voltage – 1, 6, 10 kV;

- The permissible bending radius is determined by the number of wires in the core: for one - 25, for many - 15.

Read here! Wire stripping - proper cutting and removal of insulation. 115 photos of tools and work techniques

Separately, it is necessary to monitor the temperature. Optimal performance indicators are considered to be in the range from -50°C to +50°C, but some types of conductor can withstand +70°C (with a voltage of 10 kV) and +80°C (if the permissible load is 1 or 6 kV). At the same time, the cores can withstand +200°C when the circuit is closed, and 90°C when the network is overloaded.

The resistance of the asb cable is considered for each kilometer at an external air or soil temperature of +20°C and is:

- For cores made of one wire - from 29.11 Ohms;

- For many - over 29.4 Ohms.

Also significant is the resistivity of the insulating shells, which under identical conditions should be in the range from 100 MOhm (with an operating voltage of 1 kV) to 200 (for 6, 10 kV).

The variation in parameters is determined by the number of cores, cross-section and brand, so it is better to clarify information on a specific type in special tables that show all available combinations.

The most common mistakes when using ASB cable

- Unwinding a cable from a drum lying on its side. Such unwinding is unacceptable according to all current standards. The fact is that when the product is thrown off with rings, it twists, and when trying to align, longitudinal tension may occur, which is strictly prohibited for a cable.

- When laying open, to overcome obstacles, the product is suspended in the air at a short distance. This is also a gross violation of technology, because the significant weight of the product will certainly lead to its sagging, which means stretching, and when using ASB, this is unacceptable.

- Exceeding the load on the cable (the core cross-section has a smaller area than required) through the connection of additional consumers. Such a violation can lead to significant heating of the phase conductors, as a result of which the properties of the insulating material will be impaired and further operation of the product will become unsafe.

In conclusion, I would like to note that work on unwinding, installation and switching of power cables should be carried out by specialists who have the appropriate education, skills and permission to carry out these activities. Compliance with operating rules will help extend the service life of the cable, which has a significant service life and is designed for more than 30 years.

What problems occur when using a cable and how to avoid them

One of the most common mistakes that can cause many problems is incorrect cable installation or cords that do not meet specifications. About 10 - 15 years ago the choice was poor - only two or three cable types. This could not raise any questions. Today, when installing wires in premises, according to fire safety techniques, there are more than ten cables. All of them have several categories dividing them according to the non-propagation of combustion.

Problems also arise when people do not follow simple safety or operational rules. Among them:

- Unwinding a cable from a drum lying on its side. This is absolutely unacceptable, since when removing the winding rings and aligning them, tension appears, which is contraindicated;

- Suspension of cable when overcoming obstacles. This also causes tension, since the cord sags under its own heavy weight - a gross violation of all operating standards;

- Exceeding the load on the wire or using a cable with a smaller cross-section than required. The load can increase due to the connection of many consumers, and this leads to overheating of the phase conductors and damage to the insulating layer, without which the cord is extremely dangerous under such voltage.

You might be interested in Tee for TV cable

Drum with power unit

Installation features

It is worth considering that all the technical parameters given will work at full strength only subject to high-quality installation and compliance with the necessary operating conditions.

For example, when laying and using power cables, it is recommended to pay attention to the following norms and standards:

- Installation of a cord of this type is carried out only at positive temperatures, since “minus” will cause damage to the insulating layer, the appearance of microcracks, breaks, which can lead to current leakage.

- Corrosive activity levels no higher than average are considered optimal for underground installation of standard types of power conductor.

- Highly corrosive soil requires the use of insulation-reinforced ASB2l grades.

- Stretching the wire is unacceptable, as the structure may become unusable.

- When installing underground lines, you must make sure that there are no stray currents in the soil.

Design

The cable design is as follows:

Cable AABL design

- the conductor is made of aluminum. It can be multi-wire or single-wire. It differs in shape, it can be sector or round;

- the cores are insulated with impregnated paper;

- then comes semiconductive paper, it depends on the modification;

- the shell is made of aluminum;

- after that comes a steel pad for armor;

- the armor consists of two steel strips;

- There is also a protective outer layer of the conductor.

You can buy AABL cable in the clive store, which sets the lowest prices and ensures the high quality of its products. And we will remember the main modifications of this conductor that can be found on our territory.

ASB cable design

To make it clearer for you, I decided to depict this in a whole diagram. I would like to immediately note that the ASB 3x240, 3x120 cable has a similar design.

- Aluminum conductor.

- The insulation was made of impregnated paper.

- Belt insulation, find out more in the article: Wire insulation.

- Lead sheath.

- The pillow that is located under the armor.

- Double steel armor.

- Outer shell.

Related article: Wallpaper with gerberas - a bright solution for the interior of the house

How to lay an ASB cable underground: video

Specifications

One of the main technical characteristics of ASB cables is operating voltage. The fact that the ASB is designed for voltages of 1000, 6000 or 10,000 V has already been mentioned earlier.

Another equally important characteristic is the current frequency. For ASB it is 50 Hz, although it can also be installed in a network with direct current

When installing the cable, it is important not to forget that it has a certain operating temperature. ASB can be used at temperatures from - 50 to + 50 °C

Only in this case will it retain all its positive properties.

It is also important to remember the permissible operating temperature of the cores:

- If the network voltage is 1000 or 6000 V, then the conductors can be heated to + 80 °C.

- If the voltage is 10,000 V, then the conductors should not heat above 70 °C.

- In the event of a short circuit, the conductors can withstand temperatures up to + 200 °C.

ASB can only be installed at positive temperatures. The smallest bending radius is 15 outer diameters if the cable cores consist of several wires, and the aluminum core consists of only one wire.

The resistivity of aluminum cores in a cable depends on temperature and on how many wires these cores consist of, for example:

- At a temperature of 20 °C, a single wire 1 km long has a resistance of at least 29.11 ohms.

- The resistivity of a stranded conductor of the same length at the same temperature will be 0.29 Ohm greater.

- If the cable is designed for a voltage of 1000 V, then the resistivity of the insulating layer over a section 1 km long at a temperature of 20 °C is 100 million ohms.

- If it is designed for a higher voltage: that is, 6000 and 10000 V, then the resistivity of the insulation layer at 20 °C and with a length of 1 km will be 200 million Ohms.

If used correctly, an ASB cable can last 30 years.

Technical characteristics of the ASB

- The operating voltage has already been mentioned - it is 1; 6 or 10 kV.

- Current frequency 50 hertz. Although the ASB cable can also be installed in a network with direct current.

- Operating temperature from -50C to +50C. If the conductor is installed in a network with a voltage of 10 kV, then the permissible temperature value should not exceed +70C. With voltages of 1 and 6 kV, this figure will not exceed +80C.

- In the event of a short circuit, aluminum conductors can withstand temperatures up to +200C. In case of overload up to +90C.

- The cable can be installed at temperatures not lower than zero degrees.

- The resistance of the cores per kilometer of conductor length (for a monolith) is 29.11 Ohms, for a multi-wire one - 29.4 Ohms. This is provided that the operating temperature is +20C.

- The resistance of the insulating layer per kilometer of cable length is no more than 100 mOhm. This is for those that are installed in a 1 kV circuit. For a voltage of 6 or 10 kV, the insulation resistance will be at least 200 mOhm.

- Bending radius (minimum) – 25 diameters for monolithic conductors, 15 for stranded ones.

- Guaranteed service life - 30 years.

Technical and operational characteristics of ASB

Before putting into operation, each product is tested in specialized laboratories. The cable is tested by applying a voltage to it that is twice or more its rated value:

- for products designed for 1 kV – test voltage – 4 kV;

- at 6 kV – 17 kV;

- at 10 kV – 25 kV.

The main parameters characterizing cable and wire products are the following:

- rated voltage – 1,6,10 kV;

- current frequency – 50 Hz;

- long-term permissible temperature for products at 1 and 6 kV - +80°C,

- at 10 kV - +70°C;

- products with single-wire conductors – 15 D external,

It is more convenient to present other parameters of the most commonly used products in the form of a table:

| Number of cores and their cross-sectional area, mm² | R max at t +20°С, Ohm/km | Lead sheath, mm | External cable D, mm | Standard length supplied, m | Product weight, kg/km |

| 1000 V cables | |||||

| 3x35.0 | 0,87 | 1,11 | 30,10 | 450 | 1947 |

| 3x50.0 | 0,64 | 1,15 | 31,70 | // | 2157 |

| 3х70ozh | 0,44 | 1,21 | 34,50 | // | 2532 |

| 3х95ozh | 0,32 | 1,26 | 37,70 | 400 | 3077 |

| 3х120ozh | 0,25 | 1,32 | 40,60 | // | 3623 |

| 3x150.0 | 0,21 | 1,36 | 45,40 | 350 | 4458 |

| 3x185.0 | 0,16 | 1,42 | 48,70 | // | 5109 |

| 3x240.0 | 0,13 | 1,52 | 55,30 | // | 6548 |

| 3x50+1x25 | 0,64/1,2 | 1,21 | 34,40 | 450 | 2593 |

| 3x70+1x35 | 0,44/0,87 | 1,26 | 38,90 | // | 3375 |

| 3x95+1x50 | 0,32/0,64 | 1,32 | 42,70 | 400 | 4020 |

| 3x120+1x70 coolant | 0,25/0,44 | 1,45 | 46,0 | // | 4517 |

| 3x150+1x70 coolant | 0,21/0/44 | 1,45 | 49,70 | 350 | 5252 |

| 4x35.0 | 0,87 | 1,15 | 33,40 | 450 | 2353 |

| 4x50.0 | 0,64 | 1,21 | 36,20 | // | 2687 |

| 4x70.0 | 0,44 | 1,26 | 41,10 | // | 3674 |

| 4х95ozh | 0,32 | 1,36 | 41,90 | 400 | 3857 |

| 4x120.0 | 0,25 | 1,42 | 47,70 | // | 4831 |

| 4x150.0 | 0,21 | 1,46 | 48,80 | 350 | 5480 |

| 4x185.0 | 0,16 | 1,56 | 51,50 | // | 6208 |

| 6000 V cables | |||||

| 3x50.0 | 0,64 | 1,32 | 37,70 | 450 | 2928 |

| 3x70.0 | 0,44 | 1,42 | 42,40 | // | 3840 |

| 3х95ozh | 0,32 | 1,36 | 43,70 | 400 | 4014 |

| 3х120ozh | 0,25 | 1,42 | 45,90 | // | 4490 |

| 3x150.0 | 0,21 | 1,46 | 50,60 | 350 | 5400 |

| 3x185.0 | 0,16 | 1,52 | 53,40 | // | 6029 |

| 3x240.0 | 0,13 | 1,62 | 59,90 | // | 7560 |

| Cables 10000 V | |||||

| 3х95ozh | 0,32 | 1,46 | 47,60 | 400 | 4708 |

| 3х120ozh | 0,25 | 1,52 | 49,90 | // | 5219 |

| 3x150ozh | 0,21 | 1,56 | 52,80 | 350 | 5853 |

| 3х185ozh | 0,16 | 1,62 | 55,40 | // | 6536 |

| 3x240ozh | 0,13 | 1,68 | 60,10 | // | 7742 |

The cross-sectional shape of current-carrying conductors can be round or sector. This applies to single- and multi-wire conductors.

Storage and transportation requirements

Transportation and storage of ASB power cable is carried out on wooden drums

The product is released from the enterprise on wooden and metal drums No. 14-No. 22 with a neck diameter of 750-1320 mm and a length of 710-1000 mm. It is recommended to carry out transportation and storage on the same drums, and they should only be in a vertical position. Under no circumstances is it permissible to transport the drum with the cable lying on its “cheek”.

Cable Installation Requirements

One of the conditions for using ASB cable products is the absence of stray currents in the soil

This is especially important when installing products at 6 and 10 kV, when the presence of stray currents must be completely excluded for safety reasons. Particular attention should be paid to the impregnating composition used in the conductor. Laying an impregnated ASB cable from non-draining joints is allowed on almost any route slope. The use of fluid impregnation compounds imposes restrictions on the operation of the product:

The use of fluid impregnation compounds imposes restrictions on the operation of the product:

- the difference in levels should not exceed 25 m;

- If the height difference is more than 15 meters, the use of locking couplings becomes a prerequisite.

The depth of the cable in the ground must be at least 0.85 m. The bottom of the trench is covered with a sand cushion, on which the conductor is laid, and a layer of sand of approximately 20 cm is again poured on top. To mark the cable route and protect it from mechanical damage, a signal protective tape is laid along the entire length. After this, the trench is filled with soil.

When laid under the roadway, the conductor is placed in a cable duct and pipe

The minimum ambient temperature at which installation is allowed is not lower than 0°C, although after installation, in a stationary state, the cable remains operational at -50°C.

Technical characteristics of the ASB cable:

Urab - 1 kV, 6 kV, 10 kV. Rated frequency - 50 Hz. Operating mode, t - from -50 °C to +50 °C. Relative air humidity (at t0 +35 °C) – up to 98%.

Service life: 30 years. Warranty: 4.5 years (from the date of start of operation). To carry out installation work without preheating, t = 0 °C.

tmax additional heating of cores during operation - for 1 kV devices: +80 °C; — for devices at 6, 10 kV: +70 °C.

tmax additional heating cores: - in emergency condition: +90 °C. — with a short circuit: +200 °C.

Rmax of bending during installation: - for single-core cables - 25 external ?; - for multi-core cables - 15 external ?.

Construction length at cross-section: - from 70 mm2 - 300 - 450 m. - from 90 mm2 to 120 mm2 - 250 - 400 m. - from 150 mm2 and above - 200 -350 m.

More clearly presented in the table:

Explanation of the name

Explanation of the name ASB - everything is traditional here.

- A - aluminum conductors.

- C - lead sheath (first level of protection).

- B - armor (second level of protection).

Armor, unlike the first metal shell made of lead, is always made of steel. In addition, between the first and second layers of metal there are several more protective layers made of various materials. There are variations of the cable ASBl and ASB2l - the letter “l” in this case means one or two additional tapes made of bitumen - a resin obtained from petroleum products. These tapes serve to give the cable additional resistance to chemically active environments.

To distinguish the conductors in the cable, the marking is either standard color - red, blue, black, yellow-green - or digital: an Arabic numeral is applied to the individual shell of each conductor with a certain short pitch.

Classification and price

In addition to the main variety, ASBl and ASB2l cables are produced, which provide additional protection for use in aggressive environments.

Also read: Technical characteristics of the wire – PV-3

The cable differs in the following design features:

- number of cores – from 1 to 4;

- cross-sectional area, ranging from 35 to 240 sq. mm.

Depending on the specified features, the cost of a linear meter of this product ranges from 500 to 900 rubles and more. Also, the price depends on the policy of the company selling the products.