Design and principle of operation

All starters used for fluorescent lamps have a similar device, which looks like this:

- The device itself is a small-sized gas-discharge lamp that uses the glow discharge principle during operation.

- The flask is most often made of glass and contains an inert gas inside. In modern versions it can be neon or a mixture of hydrogen and helium.

- The flask is placed in a housing that performs protective functions; it is made of metal or durable types of plastic.

- The top cover of the housing can be equipped with an inspection window, if the design provides for its presence.

- The starter is equipped with two electrodes , which are made of bimetal; their design may differ for different models.

- Additionally, the design always contains a capacitor , which is capable of not only smoothing the closing moment and opening the contacts of the device, but also extinguishing the arc that forms between the contacts at the same time. Without a capacitor, there is a risk of welding the electrodes with an arc, which significantly reduces the service life of the starter.

The operating principle of such a device is as follows:

- Initially, both electrodes included in the starter design are in the open position.

- After connecting to the power supply network, a glow discharge occurs inside the device, the current value of which varies from 20 to 50 mA.

- The resulting discharge affects the bimetal electrodes, gradually heating them.

- The heating material provokes bending of the starter electrodes, which helps to stop the discharge and subsequent closure of the electrical circuit.

- Electric current begins to move through a closed circuit, it helps to heat the inductor and cathodes of the fluorescent lamp.

- Due to the disappearance of the glow discharge , the bimetallic electrodes begin to gradually cool down after a certain time. As a result of these changes, their extension occurs, which provokes chain rupture.

- The perfect action contributes to the generation of a pulse with a high voltage value, which acts on the throttle.

- The choke has a significant degree of inductance , so such an effect contributes to the ignition of the lamp.

- The glow of the lamp gradually increases and at the same time it begins to take large amounts of voltage from the electrical network. The starter has a connection parallel to the lamp, so it begins to lack power so that it can create a new glow discharge. Thanks to this, the electrodes subsequently remain in an open state.

Device and scope

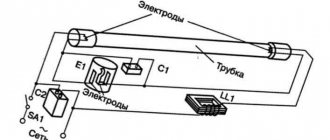

The design of the starter (OKPD code 31.50.42.190) is quite simple: a compact flask (cylinder) made of glass and filled with an inert gas (usually neon); metal or plastic case; two electrodes (one of which is bimetallic).

In essence, this element is a glow discharge lamp. For normal operation of fluorescent lamps, it is also necessary to select a ballast. The circuit that provides for an electronic type of ballast (EPG) usually does not include a starter.

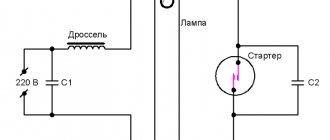

Diagram of a fluorescent lamp

Accordingly, the main direction of application of this element according to OKPD code 31.50.42.190 is to ensure acceptable operating conditions for gas-discharge lamps with electronic ballasts. The starting device is used both for single and sequential connections. In this case, it is allowed to use 220/240 V and 110/130 V networks as a power source.

Connecting fluorescent lamps via starter

Connecting lamps with a choke or ballast initially assumes the presence of a starter in the circuit. A similar example will be considered below; a lamp with a power of 36-40W, a choke with the same characteristics and a starter with a power rating of 4-65W were used for it.

The connection itself looks like this:

- The design of the lamp has output contacts, which are the leads of the bulb's filament; they look like small protruding pins. They require parallel connection of the starter.

- During this process, one contact must be activated on each side of the lamp.

- After this, free contacts remain, which are necessary to connect the inductor through them. It must also be connected in parallel to the mains.

- The last capacitor to be connected in this circuit is connected in parallel with the lamp power contacts. The presence of this element is necessary to eliminate interference occurring in the network, as well as to perform reactive power compensation.

There are 2 connection methods, which are fundamentally different from each other, they depend on the number of lamps:

- A circuit with one lamp involves connecting the inductor and the lighting source itself in series to the power supply; the starter is installed in parallel with the lamp. A capacitor can be installed at the lamp input terminals, which, during the operation of the circuit, will be responsible for improving the parameters of the electric current.

- When implementing a circuit with several lamps, you will need to connect all the lamps and the inductor in series to the power supply. After this, starters are connected in parallel to each of the lamps. An important condition: the total power of these devices must be equal to the power indicator that the throttle itself has.

Main characteristics

Thermal type starters have the following difference from analogues - this is a long time for starting a daylight source.

Devices of this type consume a large amount of electricity during operation, which negatively affects their efficiency. Another name for starters of this type is thermo-bimetallic; they are usually used when operating at low temperatures. The main difference from other types is that in the absence of voltage, the contacts are already closed, and when voltage is applied to the device, a higher impulse occurs.

Starters that use the glow discharge principle in their operation contain bimetallic electrodes made of alloys with different coefficients of thermal expansion. The operation of devices of this type is carried out as follows: when the lamp is turned on in the electrical network, voltage is supplied to the starter, the electrodes of which are open at that moment.

Under the influence of the applied voltage, a glow discharge occurs between the electrodes. A small electric current passes through the circuit and, under its action, the bimetallic electrodes of the starter heat up. They heat up and bend, which is caused by reactions taking place in bimetals under the influence of electric current, and this is what leads to the closure of the circuit.

After the circuit is closed, the glow discharge in the starter bulb stops. At the same time, the electric current heats the cathodes of the lamp, the starter electrodes are closed at this time and cool down, after cooling the starter contacts open.

Opening this circuit leads to the appearance of a special pulse with increased voltage, which is formed in the inductor and allows a breakdown of the gas in the lamp, and accordingly its ignition.

In starters that have a contact control system, switching processes turn out to be uncontrollable. In severe conditions, such as operation at low temperatures, the heating rate of the bimetallic contacts slows down, and accordingly the fluorescent lamp takes longer to light or even fails. However, the development of semiconductor electronics has made it possible to produce starters of a fundamentally new type.

Semiconductor starters are housed in a conventional standard housing containing semiconductor components. They meet all the requirements for starters in terms of power and supply voltage of the connected lamp. The operation of starters of this type, the formation of an impulse, occurs according to the principle of a key - heating and opening the circuit.

The most optimal parameters for this type of starter are devices with a standby ignition mode, in which the contacts open at the required voltage phase and at a sufficient heating temperature of the electrodes.

Of course, the use of electronic elements allows you to increase the life of the lamp and the life of the starter itself, in comparison with thermal and bimetallic analogs. The main disadvantage of this type is the cost; they are much more expensive.

In starters that have a contact control system, switching processes are uncontrollable

Types of starters for fluorescent lamps

Several different types of starters have been developed, but only one type has become widespread, the operating principle of which is based on a glow discharge.

Such devices have several different classifications, one of the main ones divides them according to the structural features of the electrodes:

- In the asymmetrical variety, one of the electrodes always remains in a fixed and motionless state. In this case, the second electrode can always move and several different metals are necessarily used as the material for its manufacture.

- A symmetrical variety in which both electrodes are of bimetallic origin. This type of starter is used much more often today, since it is much more profitable than its asymmetrical counterpart.

Also, in other cases, the classification of starters can be carried out depending on the following factors:

- The power of the lamps that the device must light, usually this parameter varies from 4-22V to 80-140V.

- Leading manufacturers engaged in the production of starters for lamps. Today, the leaders are Phillips, Narva, Osram and General Electric.

- Popular models taking into account their features.

Checking the functionality of the fluorescent lamp starter

Fluorescent light bulbs are very often used today as light sources. They have many positive aspects that make them indispensable both in the lighting system of an industrial facility and in home lighting.

But due to the structural features, such light sources can fail. In such a situation, you do not need to immediately send the lamp for recycling, but you can try to fix it yourself. To do this, you need to check the starter of the lamp for functionality. After all, it is in this detail that the reasons for the malfunction of the fluorescent lamp often lie.

Operating principle

The action of the starter is inextricably linked with the operation of the entire fluorescent lamp and occurs in the following order:

- Before starting work, the electrodes are open.

- After applying voltage from the network, a glow discharge occurs inside the flask with current parameters of 20-50 mA.

- The discharge begins to act on the bimetallic electrodes, gradually heating them up.

- Under the influence of heating, the electrodes bend, after which the glow discharge stops and the electrical circuit inside the lamp is closed.

- An electric current begins to flow through a closed circuit, heating the inductor and the cathodes of the lamp itself.

- After the glow discharge ceases, gradual cooling of the bimetallic electrodes begins. As a result, they open, unbend and the chain breaks.

- All previous actions led to the appearance of a high pulse voltage acting on the inductor. The inductor itself has inductance, under the influence of which the lamp begins to light.

- Gradually the lamp glow increases and reaches normal. Since the starter is connected in parallel with the lamp, it no longer has enough voltage to create a new glow discharge, since all the current is spent on maintaining the glow. Therefore, the electrodes remain open, but the lamp still continues to work.

Description of the operating principle

The starter used to ignite fluorescent lamps is characterized by a lower voltage than the mains voltage. In this case, the voltage of the starting device exceeds the similar operating parameter of the light source. When it is said that the starter of gas-discharge lamps is put into operation first, it means that when connected to the power supply network, all the voltage is applied precisely to this element, in particular, to its electrodes.

The result of this process is a glow discharge; through its current, the electrode of the starting device is heated, namely, with a bimetallic plate. This causes it to bend, which in turn completes the circuit. Then the current passes further: through the inductor and the fluorescent lamp. The circuit assumes a series connection of the two named elements, and the starter is connected in parallel to the light source.

Next, the operating principle of fluorescent lamps is described: the cathode warms up under the influence of current passing through the circuit, the duration of this process is determined by how long the electrodes of the starting device will be in the closed position; The light source is ignited under the influence of the throttle, in which a high-voltage pulse arose at the moment the starter contacts opened.

The classification of the starting device is based on differences in lamp power levels:

- from 4 to 22 W; from 4 to 65 W; from 4 to 80 W;

- 18-22 W, 18-65 W;

- 30-65 W;

- 70-125 W;

- from 80 to 140 W.

The type of starter used is determined by the power of the fluorescent lamps and the features of the circuit. There are a large number of different types of starting devices. For example, the ST 111 version (marked 220V 4-80W) is used in a circuit that involves the use of lamps with a power of 4-80 W and a voltage of 220 V. And the ST151 version is used when connected to a 110/127 V network (marked 127V 4-22W).

Parameters and markings

When choosing a starting device, you need to pay special attention to its parameters and technical characteristics:

- Service life established by manufacturers. The leaders in this indicator are Osram and Phillips, whose products can withstand at least 6 thousand on and off cycles. However, in practice, this parameter is not always observed for objective reasons, for example, due to surges in mains voltage.

- Operating temperature range. Usually set within 5-55C. If you need to use luminaires outside the established standards, then for these cases you will need special starters with a much higher cost.

- The time period during which the cathodes are fully heated. This factor determines the period that the bimetallic electrodes are in the closed position. This indicator may vary significantly among different manufacturers.

- Varieties and modifications of capacitors involved in a particular device. The service life of the device largely depends on its design.

- Rated operating voltage. This characteristic must be checked, since a device designed for 127 V and connected to a 220 V lamp will immediately fail.

All parameters are displayed on the device label. For domestic devices it looks like this:

- The letter "C" indicates that it belongs to the starter category.

- The numbers in front of the letter “C” indicate the power of the lamp for which this starter is intended.

- The numbers behind the letter “C” correspond to the operating voltage parameters, for example, 127 or 220.

Thus, the marking 60C-220, given as an example, indicates a device that is a starter for a 60 W fluorescent lamp operating on a 220 V network.

Starter ignition process

If the voltage is too low, the inductor does not receive enough current and is unable to light the lamp. This is why the lamp often blinks several times before turning on. This is because the starter automatically repeats its attempt to open the electrodes if previous attempts have failed. It will repeat the same action over and over again until it fails or the circuit trips causing the light to turn on. The standard electromagnetic starting system for fluorescent lamps ensures their ignition in a time range of up to 10 seconds. If during this time the lamp does not ignite, it means that one or another process in it has been disrupted, which resulted in a malfunction.

We recommend reading: Paths in a summer cottage

Checking the technical condition of the starter

In the event of any malfunction of a lighting device with fluorescent lamps, it is often necessary to separately check the functionality of the starter. In the general design, it is defined as a fairly simple part with small dimensions. A breakdown of the starter brings a lot of problems, primarily related to the cessation of operation of the entire lamp.

A common cause of malfunction is a worn glow lamp or bimetallic contact plate. Externally, this manifests itself as a refusal to start or flashing during operation. The device does not start either on the second attempt or on subsequent attempts, since there is not enough voltage to start the entire lamp.

The simplest way to check is to completely replace the starter with another device of the same type. If after this the lamp turns on normally and works, then the problem was in the starter. In this situation, measuring instruments are not required, however, in the absence of a spare part, you will have to create a simple test circuit with a serial connection of the starter and an incandescent lamp. After that, connect 220 V power through the outlet.

For such a scheme, low-power light bulbs of 40 or 60 watts are best suited. After switching on, they light up and then periodically turn off for a short time with a click. This indicates that the starter is working properly and its contacts are working properly. If the light is constantly on and does not blink, or it does not light up at all, then the starter is not working and needs to be replaced.

In most cases, you can get by with just one replacement, and the lamp will work again. However, if the starter is definitely working, but the lamp still does not work, it is necessary to sequentially check the inductor and other components of the circuit.

Why do you need a fluorescent lamp starter - how it works and how it works

Based on the name, it is clear that the starter (starter) starts the mechanism, converting the mains voltage to one at which the fluorescent lamp can operate. In 90% of cases, lamps without a starter explode when you try to connect them directly to the network.

The starter ignition voltage must be less than the rated supply voltage, but higher than the operating voltage of the fluorescent lamp. When switching the starting circuit to the network, almost all of its voltage will flow to the electrodes with an open starter.

Under the influence of this voltage, a glow discharge appears in the starter. The operating current of the glow discharge, from 20 to 50 mA, heats the bimetallic electrodes. Due to heating, bending occurs, the contacts close and the electrical circuit is completed. Electric current passes through the circuit connecting the chokes and cathodes of the lamp, heating them.

The time the starter electrodes are closed affects the duration of heating of the lamp cathodes. After cooling, the contacts open and the lamp goes out. It is for this reason that the lamp lights up and goes out. Several seconds should pass until the contacts are completely closed.

When the lamp is operating, the current in the electrical circuit is regulated by the rated operating current of the lamp, and the decrease in voltage in the power supply network is divided between the inductor and the lamp into approximately equal parts. The voltage on the starter, which is connected in parallel with the lamp, becomes insufficient to create a glow discharge, so the starter electrodes remain open while the fluorescent lamp is glowing.

How to choose: types and characteristics

For 2P base, the straightening speed should not be higher than 3 µm. It is advisable that the housing should be made of fire-resistant polycarbonate (optional). For 12 W lighting sources, the contacts should be no more than 2.2 cm long. It is advisable to choose orthogonal capacitors. It is this type of capacitors that will not cause problems with current conduction.

If you need to select a part for a 3P base, first of all, you need to pay attention to the inductance of the part. This parameter should be equal to plus or minus 2.5 Gn. In addition, you can choose the appropriate model by paying attention to:

- light source strength;

- starter type. This parameter depends on the type of throttle (electric, electromagnetic);

- the type of control mechanism that is located in the lamp;

- type of contacts (moving, asymmetrical, etc.);

- glow discharge current parameter;

- manufacturer.

One of the most important points when choosing a light source for fluorescent lamps is the company. A good thing cannot be cheap, so do not spare money on a quality manufacturer. Even consumables (such as a starter must be original and of high quality).

Let's look at the types of starters to understand which one is better and which one will be useful in each individual situation. Let us immediately note that there is no universal starter; everyone has pros and cons and specialization.

How to choose?

Today, these devices are widespread and their range can be found in virtually any retail outlet that sells household appliances.

When making a purchase, you need to pay attention to the following criteria:

- Starter manufacturer. Of the foreign companies, Phillips products are the most recommended; among domestic options, Osram is the undisputed leader. Also, there is a wide range of Chinese starters, which most often have similar names, but their purchase is not recommended, since the quality of such devices is always much lower, as is their service life.

- Rated voltage. When implementing a two-lamp circuit in practice, the starter must be designed for a voltage of 127V; this parameter is always indicated in the labeling.

- Power , which must correspond to a similar parameter of the light sources used.

- The material from which the body is made. During operation of the device, a number of potentially dangerous situations may arise, which are caused by possible overheating and the presence of an electric arc; for this reason, it is recommended to choose starters with a housing made of fire-resistant types of material.

Popular makes and models

Many well-known manufacturers of lighting equipment are also manufacturers of starters, the most famous are: Philips, Osram, Sylvania and others .

(Netherlands) produces a wide range of products, including starters. The most modern and advanced of them are the series: “Ecoclick Starters”, “Safety & Comfort Starters”, “Green Starters”.

(Russia) produces a wide range of starters for different types and purposes of fluorescent lamps. Some modifications have special advantages over analogues from other manufacturers.

Such devices are considered:

- Starter fuses – DEOS® ST 171, DEOS® ST 172 and DEOS® ST 173;

- Automatic starters – DEOS® ST 172;

- Universal – DEOS® ST 171, DEOS® ST 172 and DEOS® ST 173.

Automatic starters turn off burnt out or faulty lamps and also restart them.

Starters used for special lamps deserve special attention, such as lamps for solariums. This type of equipment, lamps and components is produced (Germany). The company's product range includes electronic starters of varying power, heating time and operating temperature.

Starters are resistant to ultraviolet radiation, voltage 220/240 V, designed for a single switching circuit:

- PureBronze PBS-25, power 4 - 65 W;

- PureBronze PBS-100, power 80 - 100 W;

- PureBronze PBS-160, power 80 - 160 W.

The range of other manufacturers is also wide and varied, which allows you to choose a device according to the requirements placed on it, however, it is important to remember that you should not choose cheap models, because they usually use cheap materials, and this will negatively affect the service life of the device.

Possible faults

When using any lighting source, the question of repairing it and replacing failed elements always arises.

One of the reasons for the fluorescent lamp not igniting may be a faulty starter, the malfunction of which can be expressed as:

- The lamp does not light up;

- There is a glow at the ends of the lamp, but the lamp does not light up.

To replace the starter, you need to perform simple operations:

- Turn off the lamp;

- Remove the lampshade or other protective element of the lamp;

- Remove the faulty element - starter;

- Insert a new device into the base;

- Reassemble the lamp in reverse order;

- Turn on the lamp.

Replacing the starter is not difficult when there is a spare one, but if there is no such thing, then you need to make sure that the one removed from the lamp is exactly the element due to which the lamp does not burn. Its functionality can be checked in a simple way.

It is necessary to turn on the incandescent light bulb in series with the starter and apply voltage to them. If the starter is working, the light will light up and periodically turn off, and a characteristic click will be heard inside the starter. If the light does not light up, or lights up and does not blink, then the starter is faulty and definitely needs to be replaced.

Theoretically, it is believed that the service life of a starter is equivalent to the operating time of the lamp it lights. However, it must be taken into account that with increasing service life of the device, the intensity of the glow discharge voltage for starters of this type decreases, which affects the operation of the latter. However, all manufacturers of fluorescent lamps recommend replacing starters at the same time as replacing lamps.

How long can a starter last and how to replace it?

With each on-off cycle, another charge occurs, wearing out the starter. The longer you use a fluorescent lamp, the weaker the glowing charge becomes with each switching on, which sooner or later will completely lose voltage. The contacts will begin to close and open spontaneously, causing the pulse to repeat in the circuit over and over again. From the outside, this will look like a continuous blinking of the lamp, which will not only be unpleasant for people to contemplate, but will also soon damage other components of the lamp, forcing us to replace not only the starter, but the entire mechanism as a whole. Every time you notice that the lamp does not light up the first time, sound the alarm. Your starter may have lost its functionality and needs to be replaced. If the starter is not replaced in time, you will constantly see the lamp blinking, wait longer than usual for it to turn on, and, as a result, will have to spend money on a new lamp. Do not save time and money and devote time to the fluorescent lamp starter in order to save a lot of money in the future!

Blitz tips

If necessary, choose a replacement for a failed starter as follows:

- Pay attention to the lamp supply voltage;

- Determine the required power of the device;

- Choose a manufacturer based on pricing policy and required reliability.

Technologies do not stand still. The starter is now mounted directly into the base of fluorescent lamps with a standard socket; these lamps are called “economy lamps”. They are similar in their operating principles to fluorescent lamps, only their appearance is greatly changed.

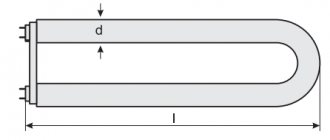

Replacing the lamp

Like other light sources, fluorescent devices fail. The only solution is to replace the main element.

Replacing a fluorescent lamp

Replacement process using the example of the Armstrong ceiling lamp:

The lamp is carefully disassembled. Taking into account the arrows indicated on the body, the bulb rotates along its axis. By turning the flask 90 degrees, you can lower it down. The contacts will move and come out through the holes. Place the new bulb in the groove, making sure the contacts fit into the corresponding holes

Turn the installed tube in the opposite direction. Fixation is accompanied by a click. Turn on the lighting device and check operation. Assemble the housing and install the diffuser lamp.

The contacts will move and come out through the holes. Place the new bulb in the groove, making sure the contacts fit into the corresponding holes. Turn the installed tube in the opposite direction. Fixation is accompanied by a click. Turn on the lighting device and check operation. Assemble the housing and install the diffuser lamp.

If a recently installed bulb has burned out again, it makes sense to check the throttle. Perhaps it is he who supplies too much voltage to the device.

Starters S2

Starters of this type are mainly manufactured by. The rectification coefficient of the models does not exceed 2.5 microns. If we talk about temperature parameters, then it is better not to use them in cold weather. Housings are most often made with polyurethane impregnation. In this case, the legs are used with small heads. Ballasts are standardly installed of the electromagnetic type. The starter choke is directly connected to the capacitor. However, in some models an additional lining is installed. The duration of heating of the cathodes in this situation depends on the power of the lamp. On average, a model of this type costs around 30 rubles.

S10 devices

Starters of this type are mainly manufactured by. If you believe customer reviews, their cases can withstand even extremely high temperatures. However, they are quite sensitive to high humidity. The rectification coefficient itself fluctuates around 3.5 microns. In this case, the inductance indicator does not exceed 5 H.

If we talk about design features, it should be noted that chokes are used with a glow discharge. However, in this case, much depends on the power of the lamp. If we talk about 20 V models, they use neon as a gas. Ballasts for such devices are suitable only of the electromagnetic type. The failure rate depends solely on the quality of the capacitor. Most often they are of the pass-through type. The capacitance of the capacitors fluctuates around 6.5 pF. A good starter for fluorescent lamps of this type costs about 40 rubles.

Starters

manufactures starters only using helium-hydrogen. In this case, there are many models on the market for P3 sockets. All starters have cylindrical bodies. Fire-resistant impregnation is provided in this case. The legs are directly installed with the heads. The capacitors in the devices are of the orthogonal type. Their capacitance fluctuates around 5 pF.

With interference suppression in starters, gaps occur quite rarely. The average failure rate is 0.2%. Radioactive isotopes are not used in the production of devices. It is also important to mention that the ballasts used are of the electromagnetic type. The average starter for fluorescent lamps from the presented company costs about 35 rubles.

Elements of “ignition” of light

The starter of various modifications ignites light sources that are powered by alternating current mains with a frequency of 50 Hz.

For this purpose, the lamp device has a ballast. In devices with glow discharge, after activation of the light source, increased voltage will begin to flow to the contacts.

The component itself is presented in the form of a small glass flask filled with gas. The flask itself is located in the inner part of the housing made of plastic or metal. In the lower part there is equipment consisting of two electrodes that come into contact with the lamp wires. Some models have a window at the top.

It is worth noting that it is the starters that most often break, after which the lamp cannot be turned on. But replacing them is not difficult if you know how to do it.

This component has the following functions:

- it starts first when connected to the network;

- responsible for heating the electrode;

- increases the current supply to the illuminator;

- closes and opens bimetallic plates;

- transmits current to the inductor.

If a part fails, the lamp simply will not turn on and begin to shine . Moreover, if a direct connection is made, the life of the lighting components is reduced. Starters are selected in accordance with the connection diagram.

Starters for lamps. Device and operation. Replacement and how to choose

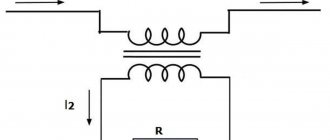

Starters for lamps are part of the ballasts, which are used to ignite fluorescent lamps when connected to a 220V network with a frequency of 50 Hz. In addition to starters, the EMPRA includes a capacitor and a choke.

How lamp starters work and how they work

The starter is a small gas-discharge lamp in which a glow discharge is maintained. Its body consists of a glass flask, which is filled with an inert gas. Neon or helium-hydrogen can be used as it. The flask contains two electrodes, most often bimetallic. One electrode is fixed, and the second is mounted movably. Two movable electrodes can be used, which increases the reliability and speed of the system. If the bending efficiency of one electrode decreases, the second one compensates.

When voltage is applied to the starter, a glow discharge occurs. It is maintained by a small current in the range of 20-50 mA. The glow discharge raises the temperature inside the flask, which causes the movable bimetallic electrode to heat up, causing it to bend and touch the second one. When the circuit is closed, the discharge passes to the connecting choke and subsequently to the lamp itself, causing it to heat up. At this time, the charging current in the starter itself stops, so its electrodes cool and unbend. As a result, a high voltage pulse is created in the electrical circuit, which is transmitted to the inductor and lights up the fluorescent lamp , provoking its persistent white glow.

The purpose of the starter is to heat the lamp, since otherwise it simply will not light when voltage is applied. A similar effect can be observed when trying to turn on a low-quality fluorescent light bulb in the cold. If it works flawlessly in warm weather, then it doesn’t shine in cold weather.

To ensure a long service life of the starter, a capacitor is required. Its task is to smooth out extra currents, thereby opening the electrodes of the device. Without a capacitor, the electrodes are simply soldered together. The capacitor has a capacity of 0.003 to 0.1 µF. Often, the design of fluorescent lamps, especially with E27 sockets, provides for the connection of two series-connected capacitors with a capacity of 0.01 μF each. This is necessary to compensate for the creation of radio interference, which is usually observed when operating fluorescent lamps.

The specific operation of the starter requires compliance with a certain voltage. If it drops to 80%, the light will not light up because the starter will not be able to warm it up properly. The fact is that the ignition voltage of the starter itself must be lower than the voltage in the network to which it is connected. In this case, the operating voltage that causes the fluorescent lamp itself to glow must be lower than that of the starter.

How to check if the starter is working properly

Despite the simplicity of the design of the part, its failure can significantly damage the light source.

Important! If you have a faulty lamp with fluorescent light sources, you first need to check the functionality of the starting device.

The easiest way to check such a lamp ignition element is to replace it with a similar device. Replacing the starter is quite simple. If the fluorescent lamp starts working after this, then the cause of its malfunction was precisely the breakdown of the starter.

You can also determine the serviceability of the starter if you have special measuring instruments - a multimeter or tester. The multimeter is much more multifunctional than its analogue (tester).

Selecting a starter for certain technical characteristics of a fluorescent light source is not difficult. The user only needs to be guided by knowledge of the design of the ignition element, as well as understand the features of its mechanical and operational characteristics.

Particular attention should be paid to the marking of the starter, especially the power indicator and rated voltage. The effective performance of the lamp and its service life directly depend on the choice of a high-quality starter.

Why is a starter needed in fluorescent lamps?

This element is the main one in the design of fluorescent lamps. Without it, electromagnetic ballasts will not be able to function. The main purpose of the starter is to start the mechanism and ignite the inert gas located in the gas-discharge flask. The starter works like a switch - it opens and closes an electrical circuit.

The installation of a starter is dictated by the need to perform two important functions:

- - circuit closure. Allows you to heat the lamp electrodes, thereby facilitating the ignition process;

- - chain break. Occurs immediately after heating the electrodes. As a result of the opening, an increased voltage pulse is formed, which causes breakdown of the gas gap of the flask.

The choke plays the role of a stabilizer and transformer. It maintains the required current of the lamp filaments, creates a voltage pulse necessary for breakdown of the lamp and stabilizes the arc burning process.