Tubular lamps and their installation

If with lamps with sockets everything is simple, just screw in the light bulb and it will light, then with a tubular lamp it is a little more complicated. The market offers many models of LED lamps for them, with the ability to install from 1 to 4 lamps at once. But many still have old fluorescent lamps, which, despite the sellers’ beliefs, are also suitable for LED lamps, subject to a little alteration. The dimensions of LED and LL lamps are the same, so old tubular lamps can be easily replaced with the same diode lamps. To remake a lamp, you need to understand a little about the operating principle of fluorescent and LED lamps, find their differences and remove unnecessary parts.

Luminaires with electromagnetic ballasts

What should you pay attention to when converting simple fluorescent lamps to LED lamps? First of all, its design.

If you have a simple old Soviet-style lamp with starters and an ordinary (not electronic ballast) choke, then in fact there is no need to modernize anything.

Simply pull out the starter, select a new LED lamp to fit the overall size, insert it into the housing and enjoy brighter and more economical lighting.

If the starter is not removed from the circuit, then when replacing the LB lamp with an LED one, a short circuit can be created.

It is not necessary to dismantle the throttle. For an LED, the current consumption will be in the range of 0.12A-0.16A, and for a ballast, the operating current in such old lamps is 0.37A-0.43A, depending on the power. In fact, it will act as an ordinary jumper.

After all the rework, you still have the same lamp. There is no need to change the fixture on the ceiling, and you no longer have to dispose of burnt lamps and look for special containers for them.

Such lamps do not require separate drivers and power supplies, since they are already built-in inside the housing.

The main thing is to remember the main feature - for LEDs, two pin contacts on the base are rigidly connected to each other.

And with fluorescent they are connected by a filament. When it gets hot, mercury vapor ignites.

In models with electronic ballasts, a filament is not used and the gap between the contacts is pierced by a high voltage pulse.

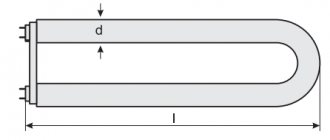

The most common sizes of such tubes are:

- 300mm (used in table lamps)

- 600mm (on the ceiling for Armstrong type lamps)

The longer they are, the brighter the glow.

Advantages of LEDs

Before specifying how to change a fluorescent lamp, you need to understand whether you need it. Replacing fluorescent lamps with LED lamps, despite the initial costs, is economically feasible. See for yourself:

- Remodeling or reconfiguration (LED lamps instead of fluorescent ones can be installed in old devices) is carried out quickly and without unnecessary expenses.

- LED inspections and maintenance are not required - it will be enough to wipe the dust from time to time and replace the tubes.

- You will save up to 60% on electricity when compared with the same LN models.

- The average lifespan of LED fluorescent lamps is 40 thousand hours - this is much longer than fluorescent lamps.

- Tubes with LEDs do not flicker and are an ideal choice for kindergartens and schools, clinics, and offices.

- There are no mercury or other toxic substances in LEDs, which means you don’t have to dispose of them in a special way.

- Even with a sharp drop in voltage within the network, LED fluorescent lamps continue to operate without failure.

That is, replacing fluorescent lamps with LED lamps provides a lot of advantages, although first you will have to spend money on their purchase. There are budget and premium options, so you'll find an 18W source in your price range.

Benefits of remodeling

This is due to the fact that in order to ignite mercury vapor at a low voltage in a fluorescent lamp, it is necessary to create clouds of electrons at its two ends using hot filaments. If everything is done correctly, it should immediately light up with a bright and uniform light without blinking. In order not to come under dangerous phase voltage, you need to turn off the voltage supply with the switch and check with the help of an indicator that there is no phase on the terminal block with which such lamps are usually connected to the electrical network. LED lamps instead of fluorescent lamps When entering almost any office space, school, kindergarten or office of any enterprise, you can notice that the lighting almost everywhere consists of so-called fluorescent lamps, i.e.

LED tubes spread light around them in all directions, so it is not so important to maintain the correct position. There are external and built-in drivers. Although the same parameters of lighting and objects are used in calculating the illumination of LED lamps, with the same light fluxes in lumens as fluorescent lamps, an LED lamp illuminates a place or room much better than fluorescent lighting.

The marking of the lamp socket or base indicates: G - pin connection system for the lamp, 13 - distance between the pins, expressed in millimeters. With this solution, you will not have to dismantle the cartridges.

This ensures that the lamp is pressed between the sockets and eliminates the influence of deviations in the geometric dimensions of the lamp fittings. As a result, less money and effort is spent on lamp installation.

It is enough just to change the chandelier itself or simply select an LED that is identical in size and connection methods to a conventional fluorescent light source. You can connect both wires coming from the socket to it, which, firstly, increases the reliability of the connection, and secondly, eliminates the need to insulate the wires. It can have a rigid fixation with the body part or be movable and rotating. How to replace a fluorescent lamp in a lamp with an LED lamp without modification

How to modernize an old lamp

To use new technologies, it is not necessary to purchase modern equipment if you order a universal kit for converting an Armstrong lamp into an LED one. This kit contains LED strips with ready-made mounting holes. It is worth noting that the products should not be deformed, create new holes or change the device in any way, as this will void the warranty in case of breakdown.

The Reled catalog presents LED lighting systems that are produced for a specific chip model. Thanks to its clever design, there is no need to use anything to provide additional cooling. The products operate in a comfortable temperature regime, which prevents the destruction of chips from exposure to high temperatures. Thanks to this, your purchase will last for a long period without failures.

How to convert a fluorescent ceiling light to an LED light?

Nowadays, fluorescent lamps are most often used in office and industrial premises, and in retail areas. In such luminaires, the current is controlled by a ballast choke (ballast). Fluorescent lighting is a more reliable and economical option compared to conventional incandescent light bulbs.

But a much more modern alternative is LED lamps. They are less likely to fail, do not emit mercury vapor, and energy is not wasted on maintaining the throttle operation. Therefore, such lamps will save even more electricity.

Types of lamps

LED lamps are classified according to several parameters, these are: purpose, design, type of base.

According to their purpose, they are:

- For administrative and domestic premises - with different types of plinth and type of construction;

- For lighting and design solutions (LED strips);

- For lighting the roadway and pedestrian areas, as well as lighting adjacent areas;

- For floodlights for various purposes;

- For decorative lamps.

By design, LED light sources are divided into:

- General purpose - with various types of bases;

- With directional luminous flux - for installation in floodlights and street lighting fixtures;

- Linear models - for installation instead of fluorescent lamps;

- Boards with lenses - for replacement in luminaires with previously installed incandescent and fluorescent lamps.

Based on the type of base, LED lamps differ as follows:

- E27 and E14 are standard sockets, usually used for screwing in incandescent lamps;

- GU10 and GU5.3 – pin connector, with a distance between pins of 10 and 5.3 mm, respectively;

- G13 – pin connector on LED lamps of linear models, the distance between pins is 13 mm;

- GX53 – pin connector for recessed luminaires, pin spacing 53 mm.

Differences in lamp operation

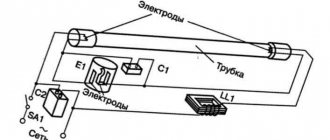

LL lamps do not have the ability to directly connect to the network; they can simply burst if 220V is applied to them, so lamps for fluorescent lamps are equipped with a special device - an electronic starting control device (BG), it is also called a ballast.

They can be designed for 1 lamp, or 2, or 4. There is a different ballast for different sizes and power of lamps. The input of the electronic ballast receives mains voltage, and from the output there are wires that are connected to sockets G13. The connection diagram for the cartridges may vary depending on the ballast model.

LED lamps do not require additional equipment, since the necessary drivers are already installed in the lamp bulb, and all that is required is to supply 220V voltage to its sockets.

In this photo you can see that the phase goes to one cartridge, zero to the other. Here is a graphical connection diagram:

Moreover, it doesn’t matter at all which cartridge the phase will go to and which the zero will go to.

It turns out that the main difference between LED lamps and fluorescent lamps is the presence of electronic ballasts, which means that in order to convert an LL lamp to LED lamps, you just need to remove the ballast from the circuit and connect the sockets directly.

LED lamps instead of fluorescent lamps: is it worth changing?

Replacing Armstrong lamps with LED ones is in most cases justified, since LED sources are superior to their outdated counterparts in almost all parameters. For yourself, calculate the initial expenses, compare the parameters of different light bulbs, recalculate the savings in the long term if LED lamps replace 18 W fluorescent lamps.

T8 fluorescent lamps:

- produce up to 10,000 hours, usually less;

- light is distributed in different directions and requires special reflectors;

- increase brightness when turned on incrementally;

- The circuit breaker often malfunctions;

- the luminescent surface layer gradually loses its qualities, the light flux decreases by a third quite quickly;

- mercury, the flask must be properly disposed of.

LED lamps T8:

- last up to 50 thousand hours (take into account the number of on-off switches);

- give directional light;

- immediately turn on brightly with full luminous flux output;

- there is no need to install drivers or chokes and starters;

- brightness is lost no more than 10% for every ten thousand hours;

- energy consumption from the network is minimal;

- environmental safety – 100%.

The light output of T8 LED lamps (with the same energy consumption as fluorescent lamps) is many times greater, and they very rarely fail ahead of schedule. When purchasing, you receive a warranty from the manufacturer or supplier. The ability to place a different number of LED elements inside the main bulb allows you to obtain any light intensity and any color temperature. Having weighed the strengths and weaknesses of the solution, we can say that LED lamps instead of fluorescent ones will be more profitable in the future. There is only one drawback - LEDs are more expensive.

Advantages of LED lighting

The two most important advantages are light transmission and low power. That is, a lamp that consumes less electricity than LL will shine much brighter. LED lamps also have additional advantages:

- LED lamps are more durable (from 30,000 hours to 50,000 hours).

- A simple design and connection diagram guarantee reliability, since electronic ballasts often burn in fluorescent lamps, and they cost a lot of money.

- LED lamps are more environmentally friendly and safe. The fact is that LL lamps contain mercury vapor, which, if the lamp breaks, can have a poisonous effect on humans.

As for the cost, at first glance LED lighting is more expensive due to the cost of the lamps themselves. One thing to remember is that it does not require additional ballasts, which cost the same as two good LED lamps. Therefore, the final cost of LED lighting will be lower than a lamp with LL.

Advantages of LED lamps

Modern light sources must be economical, efficient and safe. LEDs fully meet these characteristics. Light-emitting diodes require a small amount of power to operate and produce bright illumination with minimal heat. LED light sources have reduced sensitivity to network surges and have a large number of on and off cycles. When voltage is applied, they light up immediately, no time is needed to warm up. LEDs for lighting lamps compare favorably with other light sources with their long service life - up to 50,000 hours.

The safety of LEDs lies in the absence of harmful components in them. There are no mercury vapors or a mixture of inert gases in the flask, so they do not require special disposal conditions. Also, the LEDs are made in a durable, high-quality housing. The devices have a low pulsation coefficient, so they are safe for human health.

Removing unnecessary things

We immediately remove the old light bulbs. We take each one from both sides, turn it at a right angle, and take it out easily. Be careful not to damage the fluorescent lamps when dismantling them - because inside there is mercury, which is dangerous to our health.

In order for an LED linear lamp to work, you need to apply voltage from its opposite sides. To do this, one wire per base is enough. The rest must be turned off, or trimmed and isolated. It doesn’t matter which base will ultimately be connected to the minus.

Therefore, we do not need either a starter (a cylindrical part) or a choke (a rectangular box like a transformer). We remove the wires from them. It is also better to dismantle these parts themselves; they are no longer needed. How to remove the wires depends on the type of attachment. If this is a screwless method, gently twist the wire in different directions with little force. Repeat until it leaves the mount. In other cases, you can simply cut it off with wire cutters.

Types of lamps

The sockets of LED lamps with pins are designated by the Latin letter G. The following numbers indicate the distance between the central parts of the pins. If there is a numeric value, the second digit indicates the diameter of the circle to which the pins are connected.

For example, a G13 base with a distance of 13 mm can be connected to Armstrong, LPO and LVO lamps. Often, instead of the G13 marking, the T8 designation is used.

LED lamp T8 with g13 socket

Structural design of lamps

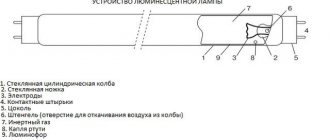

The optional device for linear light sources is represented by a driver and soldered LEDs placed on a getinax strip. All elements are housed in an elongated flask-shaped polycarbonate body.

Using such material, manufacturers were able to eliminate the problem of mechanical damage during installation work. Since the device already has a ballast device, the tube is connected directly to the mains without ballasts.

The power of linear tubes depends on the number of LEDs - the more there are, the more intense the light flow. They are adapted to replace luminescent analogues without mechanical intervention in the design of the lamp

LED tubes come standard with G13 socket. There are two pins on the inside of the flask, the distance between them is 13 mm. They are connected by copper wire, so electricity can be supplied to any of them.

Length can vary from 600 mm to 1.5 m, power 9-25 W. Savings on energy bills can be up to 65%. For example, if you install an LED lamp in place of a fluorescent lamp with a power of 18 W, its nominal value will correspond to 9 W.

Long tubular models are used for local illumination of necessary areas. It is easy to construct various shapes from them, which effectively decorates the room.

The lamp can be transparent or have a matte body. In the case where a diffuser is not provided on the lamp, it is better to opt for a matte version; if available, a transparent one will do.

Replacing fluorescent lamps with LED lamps: instructions

Any work on replacing fluorescent lamps with LED lamps must be carried out in compliance with all safety rules. The algorithm looks like this:

- Turn off the circuit breaker. Using a screwdriver with an indicator or a multimeter, make sure there is no voltage.

- Remove the cover from the lamp to reveal the contents.

- Get rid of the capacitor, starter and/or choke.

- Separate the wires connected to the terminals on the socket. Connect them with neutral and phase cables.

- Get rid of or insulate any remaining, unnecessary wiring.

- All that remains is to connect the LED lamp.

Features of connecting lamps for linear luminaires

As I noted above, in addition to linear lamps, the industry also produces LED linear lamps. They look the same as fluorescent tubes, only inside the flask there is not an inert gas with mercury, but LEDs. The devices are marked T8.

They can have different power, length, dispersion angle, color temperature. The only thing that remains unchanged is the standard G13 base and the standardized (albeit different) length. This is done so that, if necessary, they can be installed in a standard lamp using T8 fluorescent tubes.

LED (top) and fluorescent linear lamps have the same size and identical bases

Such lamps are produced in several versions:

- with built-in power supply;

- without power supply.

The former can be connected to a regular 220 V lighting network; for the latter, you need to purchase an appropriate power supply unit (PSU).

Lamps without a power supply can be designed for different supply voltages and types of current (DC/AC), so be sure to check this point when purchasing this lighting model. Otherwise, you may buy the wrong power supply and damage the equipment.

In terms of versatility, linear LED lamps with a built-in mains power supply are of greatest interest. You can connect them, as I already said, to a 220 V network directly. The connection diagram will look like this:

T8 LED lamp connection diagram

According to the diagram shown on the left, lamps without a built-in power supply are usually turned on, but some manufacturers of LED lamps can produce devices for such connection with a power supply and designed for 220 V.

Replacing a fluorescent lamp with an LED one

For such a replacement, nothing needs to be altered in the design of the lamp itself. The only thing is that the internal wiring diagram will have to be changed a little - after all, the LDS is turned on through a ballast choke and starter, which the LED source does not need. Below I present the original lamp circuit (on the left) and already converted to an LED light source with a built-in power supply.

Scheme of replacing LDS with LED with built-in power supply

If you have a lamp without a driver at your disposal, you will have to purchase one and change the switching circuit somewhat.

Turning on a lamp with an external network power supply

So we found out what linear LED lamps are, what they are like and what can be done with them. And if you decide to use linear LED lamps for lighting, then after reading this article you will be able to turn them on without outside help.