Starter in a gas discharge lamp: purpose and device

When connecting fluorescent lamps (FLL), a ballast is used. Its main elements are the starter (starter) and the throttle (electromagnetic ballast). The importance of parts is determined by their functionality.

A starter for fluorescent lamps (FL) performs the following functions:

- Closing the circuit. The ignition process is greatly simplified. The heating of the lamp electrodes is accelerated due to the occurrence of an increased electric current.

- Electrical circuit break. After applying voltage, current will not immediately flow through the LL, since the gas gap inside the light source acts as an insulator. For its breakdown, a voltage is required that exceeds the supply voltage. By breaking the circuit, the starter creates an increased voltage pulse in the inductor, and the light bulb quickly ignites.

Such devices are used in electrical networks with an operating frequency of 50–60 Hz, voltage of 220 V and below.

The technical characteristics of the design of the devices may differ slightly, but the main purpose of their operating principle is the same - the ignition of gas-discharge light sources.

S10 devices

Starters of this type are mainly manufactured by. If you believe customer reviews, their cases can withstand even extremely high temperatures. However, they are quite sensitive to high humidity. The rectification coefficient itself fluctuates around 3.5 microns. In this case, the inductance indicator does not exceed 5 H.

If we talk about design features, it should be noted that chokes are used with a glow discharge. However, in this case, much depends on the power of the lamp. If we talk about 20 V models, they use neon as a gas. Ballasts for such devices are suitable only of the electromagnetic type. The failure rate depends solely on the quality of the capacitor. Most often they are of the pass-through type. The capacitance of the capacitors fluctuates around 6.5 pF. A good starter for fluorescent lamps of this type costs about 40 rubles.

Starter for LL: operating principle

It is advisable to classify the triggering device into three types, based on the principle of operation, namely:

- Electronic starter. Housed in a regular case. Its semiconductor components must meet the basic operating requirements of the ratio of the power indicator and the supply voltage of the connected lamp. The operation of this type of device is based on the principle of the key - opening the circuit by heating. Devices of this type with such an important parameter as the standby ignition mode are considered the most efficient during operation. Through this, the opening of the contacts is realized in the required voltage phase and at optimal temperature parameters for heating the electrodes.

Important! The electronic elements used in this type of starter can significantly increase the service life of both the starter and the lamp itself. The only drawback, in comparison with analogues of an electronic starter, is the significant cost of the device.

- Thermal starter. A long startup time for the lighting source is typical with this type of starter. Poor efficiency (considerably consumes electricity) is compensated by thermobimetallic characteristics. This parameter allows devices to operate at low temperatures. The main difference from analogues is that in the absence of voltage, the contacts of the mechanism are already closed, and when power is applied, a very high voltage pulse occurs.

- Glow discharge devices. Starters, the basis of which operates on the glow discharge principle, are equipped with bimetallic electrodes. Their composition is metal alloys with different thermal expansion coefficients.

Important! The switching processes of starters, which are equipped with a contact control system, turn out to be completely uncontrollable. Starters with bimetallic contacts should not be used at low temperatures or similar unfavorable conditions. Due to poor heating of the bimetallic contacts, the lamp will take a very long time to light or will completely fail.

A starter for fluorescent lamps, operating on the thermal principle or through the action of a glow discharge, is necessarily equipped with an additional element - a capacitor.

The feasibility of using a capacitor

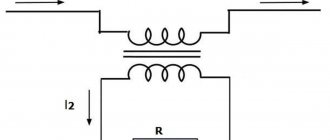

The circuit requires a serial connection of the inductor and the lamp, and the starter is connected to the light source in parallel. In addition, the starting device is connected in parallel with the capacitor.

Connection diagram for gas discharge lamps:

Connection diagram

In the figure, the starter is designated as St, the capacitor in question is C1, the lamp is L, the inductor is D. This option is not suitable for electronic ballasts (electronic ballasts). The task of capacitor C1 is to reduce the level of interference during the process of closing/opening the contacts of the starting element.

Starter device diagram

The structure of this device is simple:

The figure shows a diagram of the operation of starters. Main elements: 1 – contacts, 2 – fixed electrode, 3 – glass bulb, 4 – movable electrode with a bimetallic plate, 5 – neon lamp base.

How long does a starter last?

In theory, it is believed that the duration of operation of starters is equivalent to the life of the lamp. Over time, the intensity of the glow discharge voltage inside the neon bulb decreases noticeably.

Often, the electrodes of the starting device are closed when the lamp is on. This is another reason why electronic ballasts are better than electronic ballasts.

Capacitor in device operation

This design element maintains stable operation of the starter. The starter and capacitor are interconnected. Main functions of the device:

- reducing the intensity of interference that occurs due to the opening and closing of the starter electrodes;

- increasing the duration of the pulse that occurs during the opening of the electrodes;

- preventing the possibility of electrodes soldering, possible due to the high value of the pulse voltage.

The main difference between capacitors is their capacitance. Devices with a capacitance of 0.003–0.1 μF are more often used.

Starters of various types and modifications are structurally similar. Knowing the basis of their device, if necessary, the user can easily check its functionality.

Fluorescent lamp starter: device

The starter design includes the following components:

- Frame.

- Glass flask. Its internal inert gas environment can be filled with a helium-hydrogen mixture or neon.

- Anode and cathode are two electrodes. There are two possible design options, namely:

- symmetrical electrodes, moving contacts;

- asymmetrical elements, one moving part.

- The electrode leads pass through the sockets.

Worth remembering! More often used in practice are starter models with symmetrical electrode systems.

A cylinder with an inert gas environment is located inside a housing - metal or plastic, with an upper hole. A popular case material is plastic. Thanks to special impregnation, the case can easily withstand high temperatures; the operating functionality of this parameter may differ slightly. Any starter for LL is equipped exclusively with two contacts and legs.

Reliable operation of the lamp starter system directly depends on the voltage in the facility’s electrical network (heating of the bimetallic electrodes). If its performance decreases to 80% of the nominal value, the lamps may not light up. Only electronic components of certain types of starters are not so susceptible to a decrease in voltage in the mains.

Selecting a starter for a specific LDS is not difficult; you just need to study certain technical features of different models and manufacturers.

Elements of “ignition” of light

The starter of various modifications ignites light sources that are powered by alternating current mains with a frequency of 50 Hz.

For this purpose, the lamp device has a ballast. In devices with glow discharge, after activation of the light source, increased voltage will begin to flow to the contacts.

The component itself is presented in the form of a small glass flask filled with gas. The flask itself is located in the inner part of the housing made of plastic or metal. In the lower part there is equipment consisting of two electrodes that come into contact with the lamp wires. Some models have a window at the top.

It is worth noting that it is the starters that most often break, after which the lamp cannot be turned on. But replacing them is not difficult if you know how to do it.

This component has the following functions:

- it starts first when connected to the network;

- responsible for heating the electrode;

- increases the current supply to the illuminator;

- closes and opens bimetallic plates;

- transmits current to the inductor.

If a part fails, the lamp simply will not turn on and begin to shine . Moreover, if a direct connection is made, the life of the lighting components is reduced. Starters are selected in accordance with the connection diagram.

Choosing a starter: what to look for

The most common criteria consumers use to purchase lighting items for their home are manufacturer and price. Such parameters are important, but it is not always possible to choose a suitable design solution for a device, guided only by these points. When purchasing a starting element, you should pay attention to:

- Rated voltage. For a connected two-lamp system, a starter designed for 127 V is suitable. If the connection system is single-lamp, we will use a 220 V starter. This is indicated in the markings.

- Power. Depending on the power level of the lamps, it is customary to distinguish between starting devices, which also have different power indicators.

- High quality case. The main parameter is fire resistance. Since the design of the element does not exclude the possibility of fire due to an electric arc or overheating.

- Lifetime. This parameter is assessed differently by different manufacturers. For example, the service life of Philips starters, under normal operating conditions indicated on the packaging, implies a possible number of lamp starts exceeding 6,000 times.

- Duration of the closed state of the electrodes or cathode heating time. The spread in the values of this characteristic among different manufacturers is significant.

- Capacitor type.

Worth remembering! The labeling of domestic manufacturers differs from foreign ones.

Basis of marking according to GOST:

- The letter "C" is for starter.

- The numbers before “C” are the power of the light source (60 W; 90 W or 120 W).

- The numbers after are the voltage (127 V or 220 V).

Foreign markings:

- For lamps with a power from 4 W to 80 W and with a voltage rating of 220 V, starters are designated: S10; FS-U; ST 111.

- For light bulbs with a power of no more than 22 W and a voltage of 127 V, the starters are marked: S2; FS-2; ST 151.

Note! Markings in accordance with GOST of such parts for LDS are given on the starter body.

There are quite a lot of manufacturers of similar elements of the starter lamp ignition system. The main point that the buyer should pay attention to when choosing a model is the compliance of all technical characteristics with the prescribed profile parameters of GOST.

How to check if the starter is working properly

Despite the simplicity of the design of the part, its failure can significantly damage the light source.

Important! If you have a faulty lamp with fluorescent light sources, you first need to check the functionality of the starting device.

The easiest way to check such a lamp ignition element is to replace it with a similar device. Replacing the starter is quite simple. If the fluorescent lamp starts working after this, then the cause of its malfunction was precisely the breakdown of the starter.

You can also determine the serviceability of the starter if you have special measuring instruments - a multimeter or tester. The multimeter is much more multifunctional than its analogue (tester).

Selecting a starter for certain technical characteristics of a fluorescent light source is not difficult. The user only needs to be guided by knowledge of the design of the ignition element, as well as understand the features of its mechanical and operational characteristics.

Particular attention should be paid to the marking of the starter, especially the power indicator and rated voltage. The effective performance of the lamp and its service life directly depend on the choice of a high-quality starter.

Rules for choosing an igniter

When a fluorescent lamp stops working, there is a high probability of the igniter failing. You can easily replace it yourself and save on repairs from specialists or buying a new light bulb or even a whole lamp. But, as mentioned above, today the variety of fluorescent lamps is quite large. And a specific starter is suitable for each type.

Variety of starters

In this regard, you need to know how to choose the right igniter. There are several selection rules here:

- for a 2P base, the rectification rate should not be higher than 3 microns;

- the housing must be made of fire-resistant polycarbonate (recommended);

- for 12 W light sources, the legs should be no more than 2.2 cm long;

- It is advisable to choose orthogonal type capacitors. It is this type of capacitors that does not have problems with current conduction.

Note! Orthogonal type capacitors withstand negative temperatures very well.

If you need to select a part for a 3P base, you must first of all pay attention to the inductance of the part. This parameter on average should be at the level of 2.5 H. In addition, you can choose the right model by paying attention to:

- light source power;

- launch type. This parameter depends on the type of throttle (electronic, electromagnetic)

- the type of ballasts available for the lamp;

- type of legs (movable, asymmetrical, etc.);

- glow discharge current parameter;

- manufacturer.

One of the most important aspects of choosing an igniter for fluorescent lamps will be the manufacturer. If you want a fluorescent lamp to work for a long time, you need to give preference to trusted manufacturers. Here it is better not to save money and buy a part whose price and quality are equivalent. But in order to make the right choice of starter, you need to know what to choose from.