Features of the material

The following main properties are distinguished:

- Density of crushed stone.

- Flakiness (shape).

- Frost resistance.

- Strength.

- Radioactivity.

These values fully characterize the specified material. Next, we will consider in more detail such a property as the density of crushed stone. This is a significant definition.

Density of crushed stone

This property of the material is directly related to its strength. Density refers to the ratio of mass to volume. It is measured in tons or kilograms per cubic meter (t/m³, kg/m³). A distinction is made between the true density of crushed stone, without taking into account empty space, total and bulk, i.e. in an uncompacted state. Each of them has a corresponding meaning.

The true density of crushed stone is determined by the laboratory. That is, the mass per unit volume of small and dry material is measured. This method eliminates the presence of voids filled with air. This is how porosity is determined.

The term “bulk density of crushed stone” is used to denote the relationship between mass and occupied volume, taking into account the free space between particles. This parameter is necessary when calculating the composition of the concrete mixture.

Bulk density of crushed stone. GOST 9758

Type of crushed stoneFraction, mm Bulk density, kg/m3 BrandGranite20-401370-1400M110 40-701380-1400M110 70-2501400M110Limestone10-201250M110 20-401280M110 40-701330M110 Gravel0-51600М110 5-201430М110 40-1001650М110 More than 1601730М110 Slag 800М800 Expanded clay20-40210-340М200, М300 10-20220- 440M200, M300, M350, M400 5-10270-450M250, M300, M350, M450Secondary 1200-3000M110

During construction work, professionals are often faced with the need to order a certain amount of material. Density is one of the main parameters affecting the volumetric weight. The flakiness and weight of the stone are also very important. Let's consider its calculation based on crushed stone.

Density measurement

In this case, there are several ways to determine:

- Using a measuring vessel.

- Using tables.

Let's take a closer look at the first method

To carry out this process, it is necessary to completely fill a cylindrical measuring vessel with a volume of 5 to 50 liters until a cone forms at the top. Then the excess from the top of the mold is removed. The vessel is weighed. To determine the density of crushed stone, calculate the difference between a full and empty vessel, which is divided by the volume of the container. There is nothing complicated here. The formula in this case looks like this:

- Рн = (m2 – m1) : V,

where m1 is the mass of an empty vessel; m2 – with crushed stone, V – capacity of the measuring container.

Determination of bulk density

To find out the bulk density, crushed stone is freely poured into a container from a height of 1 meter, then the resulting “slide” is cut off and weighed. The weight of the container is subtracted from the result obtained, and then the weight of the crushed stone itself is divided by the volume of the container. This is how the bulk density indicator is obtained, measured in kg/m3.

For fine-grained high-strength crushed stone (granite, gravel), the bulk density will be higher; for coarse-grained material with a large number of voids, it will be lower.

The bulk density of a certain type of crushed stone can be found out without laboratory tests using special tables, but in this case the error is about 1%. Below are the indicators for the most common varieties.

Main criteria

To correctly measure bulk density, comply with the requirements of the state standard, these are:

- Use only specialized vessels, that is, a certain shape and size.

- The size of the container directly depends on the grain size.

- In no case is crushed stone specially compacted, since in this case the material will have different characteristics.

- The total density is necessarily higher than the bulk density.

The results obtained in the laboratory are indicated in the accompanying passport of a specific batch.

In addition to crushed stone, the density of sand, concrete and other materials is also calculated in a similar way. In this case, volume, grain size and space between particles are taken into account.

Density concept

The main parameter that characterizes crushed stone as a building material is its density. It determines what strength characteristics the prepared solution will have, and, accordingly, the future structure or road surface.

The density of crushed stone is determined by the ratio of its mass to the volume it occupies.

Most often, measurements of this physical quantity are made in kilograms per cubic meter (kg/m3) or in tons per cubic meter (t/m3).

This is due to the fact that usually quite a lot of crushed stone is required, so smaller units of measurement will not be optimal. More accurate density measurements can be obtained by measuring it in two different ways.

The first is a bulk indicator, which shows the density of the stones along with the air gaps that form in them. The second is the true density, which differs without taking into account free space, for which a special measuring container is used.

Density

It is necessary to understand the differences between different quantities in order to correctly operate with them when calculating the amount of material.

The true density is determined in the laboratory by completely crushing the crushed stone to a state in which there is a minimum amount of space between its particles.

This is required for high-precision engineering calculations, although in ordinary construction such measurements are not very useful. Bulk density is of much greater use, since it is in this state that crushed stone is used for preparing cement-sand mixtures.

Currently, quarry sand is the most common and sought-after material in construction. Here are the characteristics of this material.

Today it is impossible to imagine any construction or renovation without the use of cement. Here are the features of cement grade M400.

Tile adhesive is an important component of any repair and therefore it is worth thinking in advance about how much of it you need to purchase. By following the link you can see its consumption.

Various methods are used to measure bulk density, but they all represent approximately the same mechanism of implementation. The material is first poured into a special container, after which its weight is measured.

Definition using tables

This calculation of the density of these materials is also important.

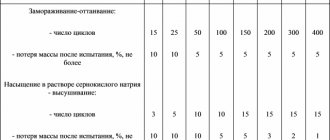

For large volumes or in cases where an error of approximately 1% is not critical, they resort to measurement tables with conditional conversion coefficients. The advantage of this method is time saved and simplicity. Minus - approximate, inaccurate result. Table: “Bulk density of crushed stone (GOST 9758)”

| Type of crushed stone | Fraction, mm | Bulk density, kg/m³ | Brand |

| Granite | 20-40 | 1370-1400 | M 1100 |

| 40-70 | 1380-1400 | M 1100 | |

| 70-250 | 1400 | M 1100 | |

| Limestone | 10-20 | 1250 | M 1100 |

| 20-40 | 1280 | M 1100 | |

| 40-70 | 1330 | M 1100 | |

| Gravel | 0-5 | 1600 | M 1100 |

| 5-20 | 1430 | M 1100 | |

| 40-100 | 1650 | M 1100 | |

| more than 160 | 1730 | M 1100 | |

| Slag | 800 | M 800 | |

| Expanded clay | 20-40 | 210-340 | M 200, M 300 |

| 10-20 | 220-440 | M 200, M 300, M 350, M 400 | |

| 5-10 | 270-450 | M 250, M 300, M 350, M 450 | |

| Secondary | 1200-3000 | M 1100 |

Density

According to certain accepted standards recorded in GOST 9758, the density of crushed stone of certain fractions is unified. This is due to the fact that only high-quality materials with certain characteristics and properties should be used for construction.

The bulk density of gravel crushed stone of a fraction of 5-20 millimeters and grade M110 can range from 1430 kilograms per cubic meter (kg/m3). It is this indicator that you should focus on when making calculations.

The true density of crushed stone of the 5-20 millimeter fraction is much greater - it can reach limits from 2500 to 3000 kilograms per cubic meter (kg/m3).

This indicator is often not required for normal construction. It is used primarily only by engineers.

It is also worth noting how the density of crushed stone of the 5-20 millimeter fraction differs from this indicator with regards to other materials. For example, the following pattern can be given:

- fraction ranging from 0 to 5 millimeters , has a rather high bulk density - up to 1600 kilograms per cubic meter (kg/m3);

Fraction 0-5 mm

- fraction ranging from 40 to 100 millimeters , has a bulk density that is also significant - up to 1650 kilograms per cubic meter (kg/m3).

Fraction 40-100 mm

- This is due to the fact that smaller stones ( 40-70 millimeters) in this case fill the air spaces between larger ones (100 millimeters);

Fraction 40-70

- the fraction exceeds 170 millimeters and has a bulk density exceeding 1730 kilograms per cubic meter (kg/m3).

The bulk density of granite and limestone crushed stones are slightly lower.

Regardless of the fraction, they range from 1250 to 1400 kilograms per cubic meter (kg/m3).

Lime

The lightest stone is made from slag and expanded clay . The bulk density of such crushed stone is several times lower than this physical value in relation to other types of rocks.

Expanded clay

Slag material has a density of up to 800 kilograms per cubic meter (kg/m3), while expanded clay - from 210 to 450 kilograms per cubic meter (kg/m3).

Slag

Advice

It should be remembered that bulk density is a natural, natural quality, excluding the possibility of subsequent compaction to eliminate voids.

For building materials it is one of the basic parameters. The strength of the final product and the indirect determination of voids filled with a less durable composition of other elements depend on this.

When producing concrete mixtures, they are guided by the rule: the higher the fraction value, the lower the bulk density parameters. Knowing its indicators allows you to save significantly. For example, with a low fraction value and high bulk density of cement, an order of magnitude less will be required. With knowledge of the exact volumes, transportation and storage are simplified. It becomes possible to calculate the material for transportation. Also in this case, you can take into account the carrying capacity of the vehicle.

Example

Let's say a car brought crushed stone to a construction site. How to take the necessary measurements? To do this, the volume of cargo and body along the filling boundary is calculated. The resulting values are then multiplied by the compaction factor. It is clear that the numbers will be different due to the “shaking” of the load during movement, but it cannot lose weight. In the first case, taking into account shrinkage, we can say that this is the total density of crushed stone or a value close to it. In the second - bulk.

For a better understanding, let's take another life example. We bought some sugar. Let's say a kilogram. We poured it into the sugar bowl and got the initial volume. They shook, knocked, compacted. Measured. The result was the final volume.

Influencing factors

This is important to know. The density is also influenced by the rock from which the crushed stone is made. With the same volume - 1 m3, the weight of granite will be 2.6 tons. However, for limestone due to impurities of quartz, dolomites, etc. - 2.7-2.9 tons. With the same weight, the volume will differ.

As a result, large, uncrushed rock takes up less space than processed rock. This is due to the space between the elements. The difference in volumes with the same mass will be indicated by the true and bulk area of crushed stone. This is a reliable fact. So, for example, the true density of granite crushed stone with a fraction (grain size) from 5 to 20 mm will be 2590 kg/m3, and the bulk density of the same material will be 1320 kg/m3. Thus, knowing this definition, you can significantly save on reducing costs in mixing concrete mortar, as well as on transportation means and storage places.

Physical properties of gravel

Properties of gravel

Gravel is considered a loose granular rock. According to the predominant particle size, it is divided into several fractions: from 1 to 3 mm, from 3 to 5 mm, from 5 to 10 mm, 1 – 2 cm, 2 – 4 cm, 4 – 7 cm.

The strength of particles depends almost entirely on their chemical composition and internal structure. Particles consisting of granite, feldspar, marble, and quartz are considered the most durable. To determine this indicator, gravel is placed in a steel cylinder and checked under what mechanical stress they begin to break into pieces.

The ability of particles to maintain their shape and size is determined in a special installation (drum). Metal balls are placed there along with the gravel. When this device operates, they rub against each other. By reducing the size and mass of grains, the abrasion index is determined. It is expressed as a percentage.

The frost resistance indicator is determined by the number of freezing-thaw cycles during which the particles do not change significantly. There can be from 15 to 300 such cycles.

The ability to absorb water depends on porosity: the higher it is, the greater this ability. The most porous is expanded clay - a material that looks similar to gravel, but is obtained by firing clay artificially.

The thermal conductivity of gravel determines its ability to retain heat. On average it is 0.93 W/m2.

Gravel Density

This indicator is especially important in road construction, where embankments made from this bulk material are used. It is also important for those who decide to purchase it to build their own home.

The density of sand and gravel can be defined as the density of the rock that makes up the particles that make it up, or as the density of the bulk material, which is called bulk density. In any case, gravel made from heavy rocks (eg granite) will weigh more than, for example, gravel made from quartz or limestone. Density can be defined as the weight of a cube (cubic meter), which is measured in kilograms. On average, gravel has a density of 1.4 - 1.7 tons per cube. It is also called volumetric gravity or specific gravity.

However, the density of gravel placement is also important for construction. It is different for particles of different shapes and sizes. Bulk density, that is, the weight of 1 cubic meter of gravel in KamAZ, usually decreases as the size of its constituent particles increases. For coarse gravel it is, on average, 1500 kg per 1 m3, and for small gravel - 1700 kg per 1 cubic meter. The density of crushed stone and sand is approximately the same.

Humidity also affects the density of gravel. Heavily moistened material will have greater mass than dry material.

Determining the density of a material with known values of mass and volume is not difficult.

Other options

In this case, the following can be distinguished:

- Fraction – the size of the grains of the material. There are standard (5-10 mm, 10-20, 5-20, etc.), non-standard (10-15 mm, over 15 to 20 mm, etc.) and euro-crushed stone (3-5 mm).

- Brand of crushed stone by strength. There are several types. Namely: normal strength M 800–1200; high – M 1400-1600; medium – M 600-800; weak – M 300-600; minimum – M 200.

The entire combination of fraction, grade and source rock will affect the bulk density.