Frameless installation of gypsum boards on unleveled wall bases offers a number of significant advantages. But quite often, when planning such work, a logical question arises: is it possible to glue drywall with glue? Manufacturers of this material answer that it is definitely possible, only for this you need to choose the right adhesive mixture, and the gluing itself is carried out under several conditions.

And here another question of interest arises: what kind of glue can be used to glue drywall or which one is most suitable for this: mounting glue, or special glue for gypsum boards? This review will examine various adhesive options, methods for this type of work, and offer general requirements and recommendations.

Advantages of installing gypsum boards

The procedure for covering walls and ceilings with plasterboard is carried out to perfectly level their surface. For this type of work, the technology uses a lattice frame to make from guides and rack profiles made of thin sheet iron or aluminum. But also, along with this method, there is a method of frameless cladding.

The frame procedure has undeniable advantages in the following cases:

- When you need to make a flat surface.

- Increase the quality of heat and sound insulation.

- Hide all communications - wiring and pipes running along the wall.

- When exclusive decorations are required - shelves, niches, arches, slopes and other decorations in the style invented by the designer.

The peculiarity of gypsum board is that during installation it is not subject to deformation, its surface remains perfectly flat and smooth. This is very convenient if you do the following work: painting, laying ceramic tiles, wallpapering.

There are different types of this material that should be used for installation in certain rooms:

- Gray plasterboard is suitable for cladding in rooms with little humidity.

- Green cardboard is used for rooms with high dampness and humidity, such as a balcony, kitchen, bathroom, etc.

- Pink cardboard is used in rooms where there are heat sources, such as a stove or fireplace.

As mentioned above, for all these types there are 2 installation methods - on a frame, made of thin sheet iron, and a method without using a frame, on glue, with its composition correctly selected.

Advantages of gluing with glue:

- Very quick and easy installation on uneven ground.

- This method is the most economical when compared with the first. There is no need to purchase expensive profiles and fastenings.

- Frameless cladding does not reduce the area of the room.

- Minimum tools required.

The main disadvantage of this method is the inability to cover electrical wiring, pipes and other communications in the premises.

Summary. Useful tips

As you can see from the article, gluing drywall to a wall is not that difficult. And with constant practice, frame fastening is even easier and faster.

Depending on the condition of the walls

Several different methods can be used in one room. For example, a frame with insulation is made on the external wall of a house, and slabs are simply glued to the internal walls.

For each specific case, use the most suitable option. Do the work slowly. Having previously made all measurements and markings. This way you will save yourself from many mistakes and rework.

Drywall is the material of the future. Easy to use, it retains its qualities for a long time. Don't be afraid to try it once and you will realize that it is a comfortable and good material to work with.

source: //mrgipsokarton.ru/uroki/kak-prikleit

The installation method, in which a sheet of drywall is attached to a vertical surface with glue, has a number of undeniable advantages. It allows you to simultaneously glue the material and level the walls, protect the coatings on the reverse side from the effects of aggressive environments and the harmful effects of microorganisms, thanks to the ease of installation technology, you save your budget and personal time.

Installing drywall with glue saves space in the room, which, if the frame was installed, would be 5-6 cm less on the side of each wall. To perform a quality installation, you will need:

- decide on the choice of glue;

- prepare the surface;

- Follow the installation instructions.

The process of gluing a gypsum board sheet

When is it permissible to glue drywall with glue?

It is recommended to glue gypsum boards in the following cases:

- When it is impossible to reduce the area of space due to the small size of this room.

- The walls are almost smooth, and if there are irregularities, they are practically invisible and amount to no more than 5 cm.

- In order to glue drywall to the ceiling, although this is very rarely practiced, you need to purchase the highest quality glue, and you also need to additionally attach the sheet with self-tapping screws.

- Processing of door and window slopes.

Can it be glued to uneven walls?

As mentioned above, if there is a slight difference in the base, it is possible to glue the gypsum board with glue. But when using this method, there are a number of features that anyone who wants to tackle walls with plasterboard without using a frame needs to know.

Basic Rules:

- The material is selected taking into account existing differences, levels of humidity and dampness, as well as room temperature.

- It is important to remember that this method is effective only in cases where the unevenness of the base is less than 5 cm.

- To carry out such work, all relevant rules of this method must be strictly followed.

- The adhesive must be selected for each individual case, based on the rough finish of the uneven wall to which it is planned to install the gypsum board.

The cladding will last a long time and will delight the owner if all gluing rules were followed during installation.

Characteristics of adhesive mixtures and their manufacturers

To install a sheet of drywall on a wall using the adhesive method, use products from two reputable manufacturers: Knauf (Perlfix series, Germany) or Volma (Montazh series, Russia). The use of a domestic brand is preferable for the following reasons:

- the cost is lower;

- the mixture consumption for applying a layer with a thickness of 1 mm and an area of 1 m² per serpyanka is only 2-3 kg, compared to 5 kg of the Knauf brand;

- The complete drying period for Volma glue is 24 hours, for the Knauf mixture it reaches 7 days;

- strong adhesion to the surface due to the content of gypsum fibers;

- the setting time of the mixture on a flat surface is 1 hour, with Perlfix this threshold occurs 30 minutes after mixing; if the mixture is applied to a sickle tape, the setting period is even less (40 and 15 minutes, respectively);

- It easily takes the shape of irregularities and does not shrink after hardening.

For DIY installation, it is preferable to use Volma glue. For a beginner, the packaging form of the material is also convenient - 5, 15 and 30 kg. This makes it easy to calculate the material, save on costs, determine the amount of work in advance and have a certain period of time left before the mixture has time to set. Knauf adhesive mixture is designed for a professional approach. Packaging form: 30 kg.

To glue a sheet of drywall to a wall with Knauf mixture, you will need professional skills to work at a fast pace. Packaging form Perlfix – 30 kg. The optimal temperature for the mass to acquire its properties is +5 degrees under normal humidity conditions.

Volma glue packaging form Installation

What kind of glue can I use to glue drywall?

The answer to the question whether it is possible to glue drywall with glue sounds affirmatively yes, but for this you will need to use the right glue, which will be discussed here. The choice of mixture will largely depend on the factors present in the room.

Today, the following types of mixture are offered on the market and in construction stores:

- "Perlfix" is a specialized adhesive for gypsum products from the manufacturer, "Volma-montazh".

- “Start”, “Finish” - a mixture for plaster and putty, made on a gypsum base. Read also: How long does it take for plaster to dry on walls?

- “Knauf-fugen” is a putty mixture also based on gypsum.

- “Ceresit-SM 11” is a cement-based composition for ceramic tiles with some fillers.

- “Liquid nails” - a silicone mixture made of polyurethane and acrylic, assembly adhesive.

- “PENOSIL Premium Fix&Go Montage” – foam mounting adhesive. Remember, you need to select a mixture with a “min” coefficient.

As for sealants, they can be used on surfaces consisting of brick, concrete, or foam block.

Assortment for gypsum boards

There are several types of adhesive compositions that are used for gluing plasterboard sheets (GKL) to walls:

- Perflix is perfect for gluing drywall to brick walls. A simple and relatively cheap version of the adhesive composition that can be used at home.

- “Fugenfüller” - in the form of putty, which must be diluted with water, requires manual mixing, the applied layer must be thin.

- Silicone glue will glue ceramic tiles or mirror surfaces with gypsum plasterboard well.

- "Knauf Fugen" (putty) is suitable for gluing sheets to smooth wall surfaces. The mixture is plastic due to the polymer additives included in its composition. Must be applied in a thin layer.

- Foam adhesive for drywall or assembly adhesive is convenient, easy to use, and inexpensive. Ideal for home use, for this reason this composition is most often recommended for gluing plasterboard sheets to the wall.

- “VOLMA-Montazh” is a dry installation mixture based on natural gypsum, mineral filler and modifying additives that provide high adhesion and allow for the installation of PGP, gypsum plasterboard, gypsum fiber board, and thermal insulation sheets indoors.

Various adhesives src=»https://kak-sdelano.ru/assets/uploads/2020/06/kleim-gkl-2.jpg» class=»aligncenter» width=»900″ height=»344″[/img]

When choosing adhesive, you should take into account the evenness of the wall.

Drywall gluing technology

Features of Knauf Perlfix

Perlfix glue copes best with the task of gluing gypsum boards to a foam block base. The most effective gluing will be when the following conditions are met: holes are made in the drywall every 40 cm and with a diameter of 2 to 2.5 cm.

After this, the material is leaned against the rough finish and the space between the sheet and the wall is filled with glue, the plasterboard is pressed forcefully against the foam block, thereby the excess glue coming out through the holes serves for additional fastening, the excess glue is removed using a spatula.

Features of "Ceresit-SM 11"

You can effectively install drywall using tile adhesive, provided that the base has unevenness up to 1 cm. If the walls have large unevenness, then it should be taken into account that over time the drywall may detach from the base. We recommend that you read the information about how long it takes for tile adhesive to dry from our review.

When using tile adhesive, the material is additionally fastened to the wall with self-tapping screws or dowel nails.

In conditions of a double layer of plasterboard sheathing, when the first layer of sheets is attached, an adhesive thickness of 0.3 to 0.5 millimeters is used. Next, a second layer with additional fastenings made from self-tapping screws is attached using exactly the same amount of glue.

Features of "PENOSIL Premium Fix&Go Montage"

There are 2 ways to install drywall on foam:

- The material is attached to the base with dowel nails, then the voids are filled with foam through the holes made in the sheet.

- First you need to apply foam to the drywall, and then lean it against the wall to be glued.

1st method

It is necessary to lay the material on a flat surface, the floor of the room. Then drill 9 to 12 holes. Afterwards, drywall is applied to the rough finish that is to be leveled, and future holes for the dowels are marked. Then the sheet is removed and holes for the dowels are drilled in the wall.

The material itself is attached to the wall using self-tapping screws, and all available space between the sheet and the wall is filled with foam. When screwing self-tapping screws into a dowel, you must use a level to level the sheet.

2nd method

The polyurethane foam should be applied to the lying sheet of gypsum and pressed against the surface to be leveled, held until the sheet is completely glued to the rough finish. You can find out in detail how long it takes polyurethane foam to dry from our publication.

Installation on brick and concrete walls

There are 2 methods for installation from such materials:

- Fastening with glue.

- Installation using polyurethane foam.

In order to decide which method to choose for a particular room, you need to determine the humidity in the room and how crooked the walls of the room are.

Basically, all rough concrete bases are smooth, so before treating such surfaces with sheets of plasterboard, they are first treated with a primer, and then the material is glued.

The peculiarity of gluing gypsum to brickwork is that gluing occurs using polyurethane foam. The adhesive is applied to the sheet, and then applied to the wall for 2-3 minutes, for the required exposure. After the foam begins to expand, the sheet should be pressed to the base, maintaining a vertical level.

Installation on wooden surfaces

Methods for finishing wooden walls:

- First, before installing the drywall, the base is treated with an antiseptic.

- Irregularities are marked with beacons.

- From the installed beacons, holes for dowel nails are drilled every 30 centimeters.

- Sheets of drywall are glued with an adhesive mixture, with additional fastening with dowels.

Before gluing, the working surface of the wall should be treated with a primer. You can find out how long it takes for the primer to dry on the walls from our review.

Preparing walls and material for gluing drywall to the wall

Before gluing drywall to the wall, it needs to be additionally prepared, namely:

- Completely remove any remnants of old wallpaper from the walls, strip down to concrete, brick or plaster. If you plan to glue drywall to old plaster, make sure that its contact with the wall is strong;

- If the wall is painted, it is necessary to remove the paint using abrasives or use special primers that improve contact between the material and the wall;

- Prime the prepared surface to ensure reliable and uniform adhesion of the glue to the wall;

- All communications and wiring must be carried out in the main wall before cladding with plasterboard slabs begins. Cables in grooves must be secured with ties every half meter.

Helpful advice: in case of failure of individual sections of the wiring, or if it is necessary to replace them after the expiration of the wires' service life (which is up to 20 years), use a corrugated cable.

Embedded into the wall at the initial stage, a corrugation of round cross-section and small diameter, with a lingering conductor, will make it possible in the future, if necessary, to simply pull sections of wires out of the wall without destroying the external finish. With low cost and ease of installation, it pays for itself many times over. Being, among other things, additional protection for your wiring.

Plasterboard slabs must be laid out along the walls in advance on a flat surface, face down. Cut them so that during installation there is a gap of up to one and a half centimeters from the floor and ceiling. It is needed for ventilation and as a heat shrink seam. Leave the corners untouched for now; they are tiled last.

Install supports 10-15 millimeters high along the wall; you will place the slabs on them during the installation process.

Before gluing plasterboard boards, clean the surface of your walls by removing all remnants of old wallpaper or plaster.

Preparatory work

In order to facilitate the work and correctly glue the drywall with glue, it is necessary to prepare a certain set of tools, materials and prepare the walls.

And so it follows:

- Before starting work, decide on the type of gypsum board; it can be moisture resistant or regular.

- Dowel nails or self-tapping screws.

- Selected adhesive mixture for installation.

- Hammer and construction mixer.

- A plumb line, usually a knife, a level.

- Spatula, prepared adhesive mixture.

- Primer, roller, brush.

After selecting the required number of necessary tools, it’s time to prepare the wall for leveling:

- The walls are cleaned of everything unnecessary.

- If there are holes or cracks, they are processed and removed by rubbing with cement mixture, putty, etc.

- The prepared wall must be primed.

- After preparing the walls, they begin to prepare the drywall.

In order for the work to be carried out at the proper level, and for the repairs to last for many years, it is necessary to dilute the glue properly.

Glue recipe:

- A certain amount of water is poured into a specially prepared container.

- Then add a mixture of dry glue to this amount of water and mix everything thoroughly using a mixer.

- After this, add a little PVA glue and mix the resulting mixture thoroughly again.

- After preparation, it is necessary to keep the solution for 5 minutes to completely dissolve the entire composition of the mixture.

You can learn more about how to dilute tile adhesive from this review.

Completion of work

After the adhesive has completely dried, after 2-3 days, start filling the joints: apply putty for leveling, then press the reinforcing tape into it. Once everything is dry, apply another leveling coat of joint compound to the joints and any protruding nail heads (if used).

Puttying gypsum board joints

For leveling, you can use the same mixture that was used for gluing the plasterboard.

Seal gaps along the floor with caulk. Finishing work can begin only after the joints have completely dried.

Step-by-step installation instructions

After we have decided whether it is possible to glue drywall with glue, in what cases this is allowed and what kind of adhesive mixture is best to use, and we have also carried out the necessary preparation of the walls and prepared the required amount of the mixture, the time comes to attach the material itself to the walls.

There are 3 solutions for this problem:

- A notched trowel is used to apply the glue.

- The glue is applied in small quantities, in the form of heaps.

- Using beacons and foam or plasterboard substrates. This method is most effective for leveling curved walls.

Methods are chosen depending on the unevenness of the wall.

Gluing the first sheets

The adhesive mixture is applied to the sheet, and the applied layer can be in continuous form using a notched trowel or applied in piles in the best places for gluing. After this, the sheet is pressed to the base and raised 10 centimeters from the floor upward. Then they are leveled horizontally and vertically using a level and supported with special supports.

The second sheet of gypsum is leveled, corresponding to the first, and glued only after the first one has completely adhered to the base.

Corner processing

To process a corner, plaster is overlapped on each other; to paste external corners, you need to change the distance between the corner and the glued sheet.

Grouting joints

After all the work has been completed, they begin to hide all the resulting seams:

- All seams are treated with a primer mixture.

- After this, the joints are treated with putty.

Basic ways to stick drywall to a wall

There are three main methods that are used when you need to fix drywall with glue to the wall. The choice of one method or another depends on the curvature of the walls on which installation is carried out:

- If the walls are fairly even and the curvature of individual sections does not exceed 5 millimeters, the simplest method is used: after all the preparatory procedures, putty or special glue is applied to the slabs laid out along the walls using a notched trowel; the glue is applied around the perimeter and in the center of the slab. If the slab is thinner than 10 millimeters, two strips of glue are applied in the center. In areas to be finished with tiles, the adhesive is applied in a continuous layer. The adhesive layer is from 5 to 15 millimeters.

- The technology for walls with a curvature of 5 to 20 millimeters is different in that the glue is applied with a trowel, in a layer of 25 to 35 millimeters, in piles, in a checkerboard pattern, every 30 centimeters. In this case, the height of the glue is adjusted to suit specific areas of the walls.

- For walls with a curvature of more than 20 millimeters, a third method is used: installing beacons. Before installing the slabs, strips of plasterboard 10 centimeters wide are glued to the wall. They are attached every half meter, aligned with the rule. Glue is applied to them in the same way as in the second installation method. After drying for a day, the slabs themselves are glued onto the lighthouses; the glue is applied using the first method.

Advice from an experienced craftsman: how to glue tiles to drywall beautifully and securely

What you can’t do without: after installing the slabs, do not rush to immediately seal all the joints and seams - let the glue dry thoroughly, this will take 48 hours, during which there should be no drafts, sudden changes in temperature and humidity in the room. After this, all seams and joints can be sealed.

We glue gypsum boards onto very uneven walls

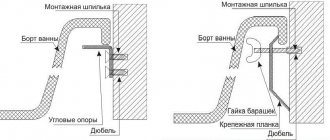

When the walls are completely uneven, then installation of drywall will be impossible without the use of a small frame. Only the frame is made not from a metal profile, but from the same plasterboard.

GCR is cut into strips 10-15 cm wide - the so-called beacons. These strips should be glued to the wall along the entire perimeter and vertically after about half a meter. Each strip is leveled using a rule or level and pressed against the wall. The evenness of the wall is achieved by using different layers of glue in different places of the beacon.

//www.vashgipsokarton.ru/www.youtube.com/watch?v=dH5aFLGi9RQ

As for the wiring, in this case the wiring can be hidden directly into the wall without grooves, placing it between the beacons.

After the glue under the beacons has hardened, we glue the drywall to the walls. To install drywall on the wall, use the simplest gypsum glue. Note that it can be glued to any adhesive, including polyurethane foam. Glue or foam is applied directly to the places where the sheet will stick to the strips. When installing on foam, the composition is applied in a small amount, and it must be pressed firmly against the beacons until it hardens completely, otherwise the foam will collapse. It will be very difficult to tear the gypsum plasterboard from the beacons, so if you do not press the foam in time, the resulting bumps will be impossible to fix, only to break and completely redo. Therefore, if you do not know how to handle foam, then it is better to use gypsum glue.

We glue gypsum plasterboard onto less even walls

Scheme for leveling a wall with plasterboard.

To glue drywall

A brick wall that is not level will require a thicker layer of adhesive. Note that the preparatory work will be the same as in the previous case, that is, the walls are grooved for wires, holes for sockets and switches are drilled, and the walls are primed.

In this case, you should use a different glue - Perlfix is most often used. In this case, the glue is applied in a different way. It should be applied using a regular trowel (or use a trowel) in slaps across the entire sheet of plasterboard with a distance of approximately 250mm between slats.

In addition, glue can be applied not over the entire sheet, but along the perimeter and in the middle of the sheet, as in the previous case. In this case, the distance between the slats should be approximately 250 mm around the perimeter, and along the middle of the sheet it is advisable to make two rows of such slats with an interval of 500 mm from each other. The distance between the flip flops should be approximately 300 mm.

Next, just as in the previous case, the sheet is placed on linings and leveled using a rule or level, and then pressed down. After the glue has hardened, the pads are removed.

We glue gypsum boards onto relatively flat walls

This method is applicable for concrete walls. Of course, concrete walls cannot be called absolutely smooth, but they are still much smoother than brick walls. The adhesive layer with this method of installing drywall will be quite thin. The wiring cannot pass under the sheet - in this case it is laid in pre-drilled holes in the wall.

Scheme for attaching drywall with glue

The concrete wall must be primed with a regular primer. You may need a special primer if the concrete wall is not initially bare, but painted. In this case, applying a special primer is much easier than washing off a layer of paint. It is necessary to mark and drill holes for sockets and switches in the concrete and on the sheet in advance.

After the preparatory work, we directly glue the drywall to the walls. Mix the glue according to the instructions on the package, but do not mix it too much as the glue sets quickly and may dry out. Glue is applied to the gypsum board using a notched trowel along the perimeter of the sheet and in the middle.

Next, the slab is installed on the wall on pre-prepared pads, which can be pieces of the same drywall, and the ends of the wires are brought out from behind it. Then the sheet must be leveled using a rule or level, and only then press the sheet against the wall. The pads should only be removed after the adhesive has hardened. After installing the plasterboard boards, the joints are finished, which we will discuss below.

Work options

The good thing about covering walls with plasterboard on glue is that you won’t disturb your neighbors with the roar of a hammer drill, and you won’t have to spend a long time checking the plane of the frame. For inexperienced developers, this is the simplest option; the wall is covered entirely from floor to ceiling and the work progresses quickly.

Preparatory stage

First, let's figure out what is needed, especially since the list of basic materials and tools is the same for all options for carrying out the work, only their quantity changes. As for materials, we need the following:

| Materials | Description |

| Drywall | We will use a wall version with a thickness of 12 mm; we should not use ceiling sheets due to their low strength. Naturally, for rooms with high humidity you will need a moisture-resistant material; it is green in color. |

Sometimes you need to level the base with cement mortar or seal the cracks in it with foam. We will not consider these work options, since we assume that you have a more or less finished surface that can be finished.

Gluing drywall is done using special compounds

You cannot do without a certain set of tools; its list is not as extensive as in the case of constructing a frame:

- Since the adhesive composition sets within 30 minutes, it must be prepared often and in small portions. That is why it is better to have a drill with a mixer attachment on hand, otherwise you will very quickly get tired not from the main work, but from mixing the glue, and this takes a fair amount of time;

The mixer attachment is suitable for both drills and hammer drills

- The composition is best stirred in a convenient container with low sides; its volume should be at least 10 liters;

- It is very important to have a long level or a rule with a level on hand, because we will constantly check the plane of large sheets and we simply cannot do without it. This is the simplest weapon; if desired, you can also use laser devices that the pros love so much;

- Application of glue can be done with a notched or regular spatula, trowel, or small spatula. You need to choose what is most convenient for you in a given situation.

You can apply glue with any tool convenient for you.

Technology No. 1 – for smooth walls

If your walls are almost perfectly smooth, which happens on concrete or plastered surfaces, then gluing drywall to them will be done according to the following scheme:

This is what the correct sequence of work looks like

- Since we will be attaching the sheets close to the wall surface, it is necessary to lay all the wires in advance . To prevent them from creating interference, grooves of the required size are made on the surface, into which the cable is secured; after laying the wire, it can be covered with cement mortar. Wires are brought out in the required places and holes are made for sockets and switches; special crowns of the required diameter are used for the work;

- The surface is cleaned of dust, after which a primer must be applied to it; if you have a regular plastered or concrete wall, then it is best to use a strengthening compound. Sometimes there are situations when the surface is painted with oil or other paint and the adhesive composition will not stick to it. In this case, a special adhesive composition with quartz filler is used; after this treatment, the glue will hold perfectly;

Applying concrete contact significantly improves the adhesion of the adhesive composition

- Before gluing the element to the surface, it needs to be prepared. If necessary, part of the sheet is cut to the required height, and holes are also cut for sockets and switches. The work is done using simple crowns, which cost a penny and can even be installed on a screwdriver; drywall is not a hard material, so more power is not needed;

Making a hole in drywall is not difficult

- As noted above, the adhesive composition hardens very quickly, so you need to prepare it for 1-2 sheets, especially at the beginning, when you have not yet gotten your hands on it and have not gotten into the rhythm . The composition is applied to the surface using a notched trowel with a tooth size of 8-10 mm, this will ensure good adhesion and economical consumption of the mixture. Excess is removed; it may interfere with the alignment of the element;

This application option ensures a strong hold on a flat surface.

- The sheet is placed face down where it will be installed. In general, you can immediately put it in place and apply glue there, this will even simplify the work process. Naturally, you need to place boards under the material so that it does not get damaged on the floor or get dirty;

- Before gluing the drywall to the wall, you need to carefully lift it and pull the wires through the holes; if you forget about this, you will have to either tear off the sheet or cut it;

- Gluing drywall is very simple: first, the sheet is gently pressed against the wall, no need to press hard. After this, using the rule, the places where the material should be pressed are determined; this can be done by simply tapping with your hand (usually this is how I correct most flaws) or by applying a board and hitting it with a mallet or something else. You don’t need to be too zealous; it’s better to hit it again later than to overdo it right away.

When we glue drywall to the walls, we constantly check the position of the sheet with a level

Under no circumstances should you hit the level, as this will damage the tool faster than leveling the walls. This is a very precise tool and using it for leveling is not a good idea.

Technology No. 2 – for moderately uneven walls

If your level differences on the wall are up to a couple of centimeters, then the previous option for carrying out the work will not work. Let's figure out how to attach drywall to the wall with glue in another way; it has a lot in common with the option described above, but there are a number of differences. Instructions for doing the work yourself consist of the following steps:

- Preparing the base, priming it and laying the cable is carried out in the same way as in the case described above. The same applies to the preparation of sheets, so we will omit these points and immediately move on to considering the workflow;

- Before starting work, you need to prepare an adhesive mixture; in this case, its consumption will be much higher, since application will be done not with a notched trowel, but in dots or piles on the surface. With their help, you can compensate for unevenness and at the same time firmly secure the material;

- The sheet is placed on the pads at the place where it is glued (work usually starts from the most protruding section of the wall), after which glue is applied to it. The points are made around the entire perimeter and are located in increments of 25 cm, in the middle of the sheet - placed every 40 centimeters, there should be no large voids , as this will negatively affect the reliability of the fastening;

Special care is not needed here, the main thing is that the height of the points is greater than the differences in wall level

- Gluing drywall begins by pulling the wires, if available, and lightly pressing the element to the surface; it should simply catch on the wall. It is best to work together, so that one person constantly holds the sheet and helps press if necessary, this is both easier and faster;

- Before gluing the drywall thoroughly, you need to carefully check the plane in all directions, and then determine in which places the material needs to be pressed. After the initial leveling, another check is carried out, if necessary, individual sections are tamped down, and so on until the result completely satisfies you. If you do not complete the work, it will be even more difficult to align the next sheets, remember this.

If everything is done carefully, then you get a smooth wall in literally a matter of hours.

Here you need to consider another option, when drywall is glued to walls made of aerated concrete or foam concrete. In this case, we glue the gypsum board in reverse, applying the composition not to the sheet, but to the wall, this ensures a more reliable fixation of the material. I would like to note that this option is less convenient and requires more care when installing the sheet; it can be very easily skewed.

This way you can attach the sheets not only to a foam block wall, but also to brick surfaces, but I repeat once again, it is more convenient to apply the composition to the sheet

Technology No. 3 – for walls with large irregularities

One of the common questions is whether it is possible to glue drywall to surfaces with large differences without continuous plastering. Everything is quite feasible, but the technology will differ noticeably from the options described above; the process looks like this:

- First of all, you need to remove from the surface all pieces of plaster that do not adhere well. That is, there should be no elements on the surface that could fall off later;

- Priming is also a mandatory step; the composition allows you to strengthen loose areas and reduce surface absorption, thereby improving the adhesion of the glue. You need to apply the primer so that it gets everywhere, so on uneven surfaces it is better to use a paintbrush rather than a roller; it distributes the solution better;

The soil must be distributed over the entire surface

- Next, we need to prepare the beacons; 100 mm wide strips are cut from plasterboard, which is what we will use to create a flat base . The number of elements depends on the area being tiled; the elements are located along the perimeter of the wall, as well as vertically every 40-60 cm, based on this, calculations are made;

The material is marked, after which the paper layer is cut through the front side with a knife, and the sheet is broken

- Next, you need to place the beacons; to do this, first mark the surface around the perimeter so that you can see which line to place the elements on. They are also fixed using glue, the layer of which is adjusted depending on differences in the level of the walls. I recommend sticking the elements around the perimeter first and waiting for them to dry, especially since this will only take half an hour;

- Then you need to glue the vertical posts, they are leveled, it is important to control the position of both each element individually and the surface in general. Check entire sections of the wall and adjust the position of the guides while the adhesive has not yet hardened;

Gluing drywall in strips allows you to correct even large differences in level

- When the glue on the structure has hardened, you can begin gluing the base material. To do this, the adhesive composition is applied in lines along the width of the guides, after which the element is carefully lifted and pressed against the surface. If you have leveled the base well, then at this stage it will not be difficult to level the drywall; the end result will be a structure like the one in the picture below ;

It turns out two layers of glue and drywall, so you can compensate for large unevenness

- Work is carried out until all surfaces are covered. Further finishing is no different from the usual version, the main thing is that the adhesive composition dries.

Sometimes, to save drywall, beacons are made not in stripes, but in the form of points; in this case, it is easiest to first set the topmost elements and hang a plumb line from them to control the vertical. How to glue sheets correctly in such a situation? It’s simple: the composition is applied not to the sheet, but to the resulting areas, so you don’t have to rack your brains about how to place the glue where you need it.

Here is the answer to the question, is it possible to glue the material not to stripes, but to dots?