Bulk building materials, as well as soils, can be loosened or compacted under various physical influences. Moreover, their density fluctuates over a fairly wide range - up to several tens of percent. In construction, 2 relative values are often used - the compaction coefficient during transportation Kut and the soil (base) compaction coefficient Ku. In essence, they reflect the same phenomenon - a change in volume due to a decrease in porosity, but are calculated and applied differently.

Density characteristics of building materials

If in a quarry the rocks are in a dense monolithic state, then during mining they loosen and become more porous. Raw materials go through many manipulations - excavation, washing, sifting with distribution into fractions, storage. During shipment, the materials are again loosened, and during transportation they are compacted. At the final stage, they are placed into the structure and compacted again. Throughout the process, humidity changes, which inevitably affects the density.

Bulk materials - crushed stone, sand, sand-gravel mixture ASG, etc. - consist of individual grains, between which there are voids. During development, loading and unloading, the solid skeleton is loosened, the volume of pores and voids increases.

The loosely poured state of the material is characterized by bulk density, that is, the ratio of mass and volume occupied by it:

ρн=m/Vн

It is measured by weighing a standard measuring vessel with a volume of 5-50 dm³ without preliminary compaction. The container size is selected based on the largest particle size. During testing, you can immediately find voidness as the ratio of the volume of voids to the entire volume of the material. It is determined in %. Thus, the bulk density of sand is 1600 kg/m³, crushed stone is 1310-1400 kg/m³, ASG is 1340-1500 kg/m³ (depending on the size of the fractions). In a loose state, a certain volume of air remains between the particles. The voidness of sand, crushed stone and ASG is 30-45%, 20-50% and 30-50%, respectively.

If you remove all the pores from the material, you will get a solid monolith. Its density is called true. It is much larger than bulk: for sand it is 2500-3000 kg/m³, crushed stone - 2700-3100 kg/m³, ASG 2500-3100 kg/m³. This is a constant value and is necessary to calculate the porosity of the material.

True density is determined experimentally. The raw material is crushed into powder, then its mass and volume are determined (based on the volume of water displaced from the vessel). Using the formula ρ=m/V, the specific gravity of the material without pores and voids is calculated.

What is the compaction factor used for?

This dimensionless value allows you to determine how much the actual density differs from the bulk or maximum:

- during transportation, the coefficient is agreed upon between the customer and the supplier who ships the raw materials from the quarry, warehouse or factory;

- when constructing a foundation for any structure, Ku is specified by the design as a ratio to the maximum density of the soil.

These are 2 different scenarios, respectively, the calculation is carried out completely differently.

Transport compaction coefficient Kut

During transportation, due to vibration, smaller particles move down and fill the voids between large grains. Accordingly, the volume of cargo decreases and the density increases.

Acceptance of non-metallic materials is usually carried out by volume or mass. To avoid unpleasant surprises when receiving your cargo, you need to take into account the inevitable shrinkage during transportation.

If materials are accepted by volume, the delivery is measured, that is, the size of the filled part of the railway carriage or car. Then the resulting value is multiplied by the coefficient Kut.

The behavior of the material during transportation and warehouse processing depends on the particle size distribution, humidity, caking ability during storage, abrasiveness of particles, as well as the type of transport and climatic zone. According to GOST 9757-90, the compaction coefficient of sand and other non-metallic materials must be agreed with the manufacturer, but is accepted to be no more than 1.15, i.e. volume loss should not be higher than 15%. Kut is always greater than one, since it is calculated as the ratio of the initial volume of material to its volume after transportation.

If acceptance was carried out by weight, weight units are converted into bulk volume by dividing by bulk density using the formula:

V=m/ ρн

Example.

The supplier shipped 6 m³ of sand into the back of a truck. After delivery, the volume naturally decreased. When measured, it was found to be 4.8 m³. You need to determine whether there was a short delivery.

Multiply 4.8 by Kut = 1.15. We get V=4.8x1.15=5.52 m³. There is an underload of 0.8 m³.

If acceptance is carried out by weight, after weighing a car with sand, the mass of material with a volume of 6 m³ (with a standard bulk density of 1600 kg/m³) should be m=6x1600=9600 kg.

Technological losses during transportation by rail, road or water transport without overload, by weight no more than:

- crushed stone, gravel, slag - 1.15-1.24%;

- sand, ASG, screenings, expanded clay - 1.2-1.34%.

With overloads from one transport to another for all materials, the loss rate is 1.50-1.54%. If there is more shortage, the supplier has allowed an underload, which is already a reason for the customer to file a claim.

Determination of compaction factor

The maximum density - the density of the soil skeleton - is determined in laboratory conditions using the standard compaction method. It consists of placing soil in a cylinder and compressing it, striking it with a falling load. The maximum density depends on soil moisture, the nature of this dependence is shown in the graph:

Dependence of maximum soil density on humidity.

For each soil there is an optimal moisture content at which maximum compaction can be achieved. This humidity is also determined in laboratory tests of soil at different humidity levels.

The actual density of the soil during foundation preparation is measured after compaction work. The simplest method is the cutting ring method: a metal ring of a certain diameter and known length is driven into the soil, the soil is fixed inside the ring, then its mass is measured on a scale. After weighing the soil, subtract the mass of the ring to obtain the mass of the soil. Divide it by the volume of the ring - we get the density of the soil. Then we divide the density of the soil by its maximum density and calculate the soil compaction coefficient.

A set of rings for determining soil density.

How to calculate material requirements taking into account the compaction coefficient

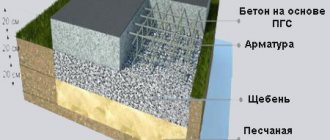

For any construction work, it is necessary to determine the consumption of materials as accurately as possible. For example, crushed stone preparation with a thickness of 20 cm is carried out on an area of 100 sq.m.

Finding the volume of the pillow:

0.2*100=20 m³

Taking into account the crushed stone compaction coefficient of 0.98 during laying and 1.15 during transportation, we find the required volume of material that the supplier must release from the quarry:

20/0.98*1.15=23.5 m³.

Considering the standard KamAZ body volume is 6 m³, we need to order 4 cars.

Soil compaction coefficient

When constructing bases and foundations, an important characteristic is the density of the soil. It determines its load-bearing capacity, behavior under load, and tendency to subsidence.

Soil density depends on the mineralogical composition, porosity and humidity. The densest ones are composed of granite, basalt or silicon rocks. Their specific gravity is over 3000 kg/m³. The lowest density of peat bogs and bulk soils is no more than 700-900 kg/m³.

The compaction coefficient is a dimensionless quantity equal to the ratio of the actual density of the soil to its maximum density:

Ku=ρ/ρmax

The physical meaning of Ku is easy to understand if you first imagine a monolithic block, and then it in a crushed but compacted form. The ratio of densities of the same substance, but in different states, is the compaction coefficient. Unlike Kut, which is always greater than one, Ku cannot be greater than 1, since the numerator is the actual density of the material with pores, and the denominator is without air voids.

Soil compaction coefficient

The soil compaction coefficient is the ratio of the actual density of the soil (soil skeleton) in the embankment to the maximum density of the soil (soil skeleton).

What does a compaction factor of 0.95 mean?

A soil compaction coefficient of 0.95 means that the actual soil density is 95% of the maximum possible soil density (determined in a soil laboratory).

Standard compaction factors are given in the table at the end of the page.

This coefficient is determined by the following methods:

1. Cutting ring method - soil samples are taken from the compacted layer and tested in a soil laboratory in accordance with GOST 5180-2015 “Soils. Methods for laboratory determination of physical characteristics." The main disadvantage of the method: long-term testing (transportation and testing in the laboratory)

Cutting rings for determining soil compaction coefficient

2. Dynamic soil density meter (DSG) - the operating principle is based on the falling weight method, which measures the impact force and soil deformation. Used in conjunction with the cutting ring method to speed up the determination of soil compaction coefficient.

- At the initial stage, the DPG is calibrated at several sampling locations according to test data using the cutting ring method (GOST 5180-2015)

- Then, based on the calibration data, the compaction coefficient is determined at the remaining points, which allows you to obtain results immediately on site.

The required soil compaction coefficient (according to SNiP 3.02.01-87) of backfill or embankment is presented in Table 1.

Table 1. Soil compaction coefficient

| Soil type | Control values of compaction coefficients kcom | |||||||||||

| under load on the surface of compacted soil, MPa (kg/cm 2 ) | ||||||||||||

| 0 | 0,05 – 0,2 (0,5 – 2) | St. 0.2 (2) | ||||||||||

| with total thickness of fill, m | ||||||||||||

| up to 2 | 2,01-4 | 4,01-6 | St. 6 | up to 2 | 2,01-4 | 4,01-6 | St. 6 | up to 2 | 2,01-4 | 4,01-6 | St. 6 | |

| Clayey | 0,92 | 0,93 | 0,94 | 0,95 | 0,94 | 0,95 | 0,96 | 0,97 | 0,95 | 0,96 | 0,97 | 0,98 |

| Sandy | 0,91 | 0,92 | 0,93 | 0,94 | 0,93 | 0,94 | 0,95 | 0,96 | 0,94 | 0,95 | 0,96 | 0,97 |

Thus, for example , the soil compaction coefficient of a backfill made of sand, a backfill thickness of 2.5 m and a load on the embankment of 0.3 MPa is 0.95

Source

Maximum soil density: method of determination according to GOST 22733-2016

Tests are carried out in laboratory conditions using a special tamping unit. Their essence is as follows:

- At the construction site, soil of natural moisture is selected. The sample should contain no more than 25% of solid particles larger than 2 mm, and there should be no freezing or waterlogging.

- Portions of soil are placed into the mold, which are then compacted on the installation in 3 steps of 40 blows.

- The weight of 1 liter of compacted mass is measured and the density is determined.

- Then the humidity is increased in steps of 2%, and a similar test cycle is carried out.

- Based on the results, a graph of density versus humidity is plotted. At the inflection point, the maximum value of ρmax is fixed at optimal humidity.

Determining the highest soil density allows you to understand at what value of ρ the shrinkage under the foundation will be the least. Under construction site conditions, the maximum density value is unlikely to be achieved. Therefore, a coefficient is introduced that helps to establish how close the actual density of the base is to the maximum possible.

Ku is set by the project. It is calculated depending on the load and is usually 0.96-0.98. This means that when compacting the soil or sand cushion, the density will be slightly less than the maximum with a slight deviation of 2-4%.

How to find out the compaction factor

The easiest way is to take data on the compaction coefficient from GOST standards. They are designed for different types of material.

| Name of material | Compaction factor |

| PGS | 1,2 |

| PShchS | 1,2 |

| Sand | 1,15 |

| Expanded clay | 1,15 |

| Crushed stone | 1,1 |

| Multicomponent soil mixture | 1,5 |

In laboratory conditions, the compaction coefficient is determined as follows:

- The total or bulk density of the material is measured. To do this, measure the mass and volume of the sample and calculate their ratio

- The sample is then shaken or pressed, the mass and volume are measured, and then the maximum density is determined

- Based on the ratio of two indicators, the coefficient is calculated

The documents indicate average values of the compaction coefficient. The indicator may vary depending on various factors. The numbers given in the table are quite arbitrary, but they allow you to calculate the shrinkage of large volumes of material.

The value of the compaction coefficient is affected by:

- Features of transport and method of transportation

If the material is transported over potholes or railways, it is more compacted than when transported along a flat road or sea - Granulometric composition (sizes, shapes of grains, their ratio)

If the composition of the material is heterogeneous and the presence of flaky particles (flat or needle-shaped), the coefficient will be lower. And in the presence of a large number of small particles - higher - Humidity

The higher the humidity, the lower the compaction coefficient - Tamping method

If the material is compacted manually, it is not compacted as well as after using vibrating mechanisms - Bulk Density

The compaction coefficient is directly related to the bulk density. As we have already said, during the process of compaction or transportation, the density of the material changes, as there are fewer voids between the particles. Therefore, the bulk density during shipment to the vehicle at the quarry and after arrival at the customer is different. This difference can be calculated and verified precisely thanks to the compaction coefficient. You can read more about this on the page

- Significant factors and properties

Not only specialists from design organizations, but also operators who directly carry out work on construction sites regularly encounter the concept of sand compaction coefficient.

The soil compaction coefficient is one of the main criteria for the quality of preparatory work on construction sites

and serves to compare the actual achieved soil density in the prepared area with the standard value.

Also, the concept of compaction coefficient is widely used for volumetric accounting of bulk materials. The most accurate accounting method is the weight method

, however, in practice its use is often impractical due to the lack of or inaccessibility of weighing equipment. The use of volumetric accounting does not require complex equipment, but it poses the problem of comparing the volume of material in a quarry (during mining), in storage areas, in the back of a car (during transportation) and when used at the site.

Determination of Ku in laboratories or field conditions

Having in hand a project with a given compaction coefficient of ASG, sand or soil, it is necessary to determine whether the actual density of the base corresponds to the desired value. Various techniques are used for this.

Through sampling

This method is the most accurate, but not very fast. The participation of a laboratory is required, since it is difficult to create favorable conditions for measurements on construction sites.

For experiments, cutting rings of known volume are used. Without disturbing the structure of the material, samples are taken and further weighed.

The soil sampled at several points on the site is packed into a sealed container and sent for research. After receiving the weighing results, the dependence of soil density on moisture is determined and the actual compaction coefficient at each sampling point is calculated. After assessing the degree of soil preparation, a decision is made to continue or terminate soil compaction work.

Dynamic density meter (penetrometer)

The measurements are used as an express method to assess the degree of compaction of the base in the field. The dynamic density meter is a pointed steel rod with a handle and a striking pad. A load of a certain mass is movably attached to it.

The density meter is installed vertically on the base. The weight is then lifted and dropped onto the impact pad. In this case, the rod gradually sinks into the ground. The number of strikes is counted.

After the tip has completely descended below the surface, the compaction coefficient is determined using a special table. If it is less than required by the project, additional compaction is performed. If Ku corresponds to the desired value, the base is ready for further work.

Penetrometer

Vibrating plates, manual and automatic tampers are used for compaction. The closer the Ku coefficient is to unity, the fewer voids there are in the soil, and the correspondingly higher the density.

Electromagnetic method

With this method, the density of the soil at the construction site is compared with that previously established in the laboratory. The measurements are carried out with a special device that initiates an electric field. It transmits an electromagnetic pulse, which passes through the soil and is recorded by a sensor, and the density is determined by the change in value.

For testing on the site, at least 5 points are selected, located according to the cloverleaf principle. A large error is caused by humidity, large solid inclusions, and soil heterogeneity. Measurements take a relatively long time compared to other options, where the result can be obtained in one session.

Stamp method

With this method, the dynamic modulus of elasticity of the soil is determined, which is directly dependent on its density. The device consists of a load plate, a force strain gauge, a rod with a load and an elastic element, an accelerometer and an electronic unit.

When the load is dropped onto the platform, it returns to its original position thanks to the elastic force. Interaction parameters are read and processed by the electronic unit. Based on the test results, the modulus of elasticity, deformation and load are determined. Information is presented graphically or numerically on the display. The density meter can archive and send data to a PC, which creates the prerequisites for more detailed processing and construction planning.

Direct volume replacement method

According to the GOST 28514-90 standard, soil density can be measured using a sand loading device or a cylinder with a rubber balloon. Before testing in laboratory conditions, the density of sand is determined; in experiments it will be a sample for comparison.

To conduct tests on a compacted base, a hole with a diameter of 100 mm is selected. Sand is poured into it from a sand tank installed on top. The loading volume is calculated using the scale on the tank. Next, the weight of the excavated soil is measured. With known environmental parameters (in this case, sand), the density of the soil is calculated using the formula:

ρ=m*ρ0/m0, where ρ0 and m0 are the density and mass of sand filling the hole.

In the rubber balloon technique, water is used as a medium, which is poured into the apparatus. The cylinder is placed in a dug hole and filled with water. The volume of soil is determined by the amount of water spent. Next, by measuring the weight of the sample, you can find the desired density and compaction coefficient.

This method can be used if the amount of solid large particles exceeds 25%. These are crushed stone and gravel bases, as well as cushions made from mixtures of ShchPS or ASG.

Ways to increase soil density

The characteristics of the soil depend on its composition and humidity. If its density is very low, there is a tendency to deformation and subsidence. These are highly compressible peat, silt, sapropels, plastic clays, etc. In most cases they are not used as foundations for construction. It is necessary to increase their strength properties, which can be solved using various methods:

- injection of fixing solutions;

- heat treatment (firing);

- electrochemical method;

- reinforcement;

- installation of sheet piling;

- filter loading;

- mechanical methods.

If the surface density of the soil is insufficient, the top layer is compacted using tampers, rollers, and area vibrators. Deep compaction is carried out using piles, vibration, soaking, and directed explosions. At high humidity, the groundwater level first decreases, then preliminary compression is carried out.