Main characteristics

Sand used in the construction and industrial sectors must meet a specially established standard. Therefore, when selecting bulk material, its certain characteristics are taken into account.

Specific gravity

This indicator is necessary when designing various building compositions. The value is determined in the ratio of the mass of dry sand to the volume it occupies.

The following factors influence the specific gravity value:

- origin of sand;

- density;

- grain;

- humidity percentage;

- the amount of impurities included in the composition.

Therefore, the specific gravity of construction sand can fluctuate between 2.55-2.65 units.

Density

The bulk density value depends on the amount of clay included in the material and its moisture content. The last factor significantly affects many characteristics and quality of construction sand. Its density without various impurities is 1300 kilograms per cubic meter.

Fraction size

According to the size of the grains - particles that make up sand, there are three main fractions:

- small – up to 0.5 millimeters;

- average - from 0.5 to 2 millimeters;

- large - from 2 to 5 millimeters.

Coarse sand for construction

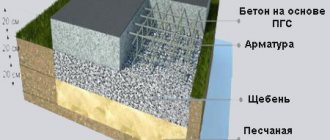

The size modulus has a direct impact on the further use of sand. Often, in the manufacture of mortars, a mixture of bulk material of different fractions is used. Sand with large grains is used in the construction of building foundations.

Volume weight

This value indicates the total volume of sand along with all additives. Also, when determining the indicator, the moisture content of the material is taken into account. On average, one cubic measure holds 1500-1800 kilograms of construction sand. Moreover, specific mass and volumetric mass almost always have different indicators.

According to the characteristics, construction sand must meet the requirements set out in GOST 8736-93 and GOST 8735-88.

Material Specifications

If you want to get acquainted with all the characteristics of a consumable, you should look at the chemical composition. These parameters necessarily include the color of the components, their weight and volume. Based on this, experts distinguish yellow, gray and white sands. Their main elements are clay and quartz particles in certain proportions. Black materials are considered very rare. This happens due to dark minerals and rocks.

Upon careful examination, you will notice that there are significant differences in the shape of the grains of sand. It is immediately noticeable that the artificial material is heterogeneous and has sharp corners. And its natural counterpart is smooth to the touch. As for the sizes, they can be both microscopic and large (up to 5 millimeters). It depends on the deposit.

Properties of consumables

Regardless of location, sand types have the same physical characteristics. The main one is water permeability. Everyone knows that using consumables with other natural components like sawdust and coal makes an excellent filter for water purification. The key role is played by sand, because it holds all the particles.

Due to the fact that the material has a very hard structure, it is not afraid of any loads. It can withstand absolutely any weight. Therefore, the construction industry will never be able to do without it.

An important quality is density. It all depends on what percentage of clay or other impurities is located in it. Sand is considered very dense when it contains large amounts of clay and other elements.

Next to this point is humidity. Enveloping each grain of sand, water displaces air, so the material becomes heavier. And this is very important to consider when purchasing sand and weighing it.

Almost all species have the first class of radioactivity. This is a very low indicator, guaranteeing safety for people during the construction and operation of structures.

Important indicators of sand composition

Sand consists of granules of various sizes that contain chemical and mineral elements. Therefore, when determining the suitability of bulk material for construction work, the percentage of all its components is taken into account.

Chemical

The presence of chemical components affects the external characteristics of sand. The natural material containing metallic oxidized compounds has a light yellow color with orange and red hues.

In the presence of aluminum salts, grains of sand acquire blue and blue tones. A large percentage of the constituent chemical elements indicates the unsuitability of the material for many construction works.

Mineral

Construction sand, depending on its mineral composition, is divided into several types:

- limestone;

- feldspar;

- quartz;

- dolomite.

A special place is occupied by granular material with a high percentage of quartz. Such sand is characterized by good strength, and its use in construction significantly increases the service life of any structures.

In addition to quartz, the durability of the material is influenced by the presence of siliceous rocks, feldspar and mica.

Granulometric

To determine the grain composition of sand, a special sieve with 5 mm holes is used. To identify gravel or crushed stone, use a device with larger holes - up to 1 centimeter.

According to the standard, construction sand can contain no more than one percent of grains measuring 1 centimeter. The material is divided into three types depending on the percentage with a diameter greater than 5 millimeters:

- enriched – up to 5%;

- natural – up to 10%;

- crushed – up to 15%.

The granulometric composition has a direct impact on the voids of construction sand. Its lowest percentage can be achieved with an intermittent composition of the granular material.

Characteristics of sand

The material has a number of characteristics that determine the possibility of its use in various fields of construction. Basic parameters:

Volume weight. Depending on the fraction and origin of the material, the average weight per 1 cubic meter in its natural, uncompressed state is 1500-1900 kilograms. The predominant mineral base. Sand can be quartz, limestone, dolomite. Humidity. The average figure is 5 percent. Depending on the technical conditions of production, the influence of external environmental factors and other circumstances, the parameter ranges from 1-10 percent. For classic recipes for concrete and cement-sand mixtures, a humidity level of 3 percent is specified. If it is larger, then you need to add less water for mixing. If less, moisten the binder and fine-grained aggregate more intensively. In “field” conditions, it is easy to determine the lack of moisture - sand does not form a plastic mass, it behaves like gravel, but in miniature. Too high a parameter value appears when a handful of material is squeezed in the hand: if it does not crumble, a lump is formed, then the relative humidity exceeds 5 percent. Bulk density. Correlates with the ability to transmit moisture. The indicator is determined in laboratory conditions. According to the packing density, the products can be loose, medium density or dense. Based on specific indicators, the porosity coefficient is calculated for silty, small, medium and large varieties of sand fractions.

Currently reading: Wood concrete (arbolite)

Grades and fractions of sand for construction work

In construction, sand is marked according to its strength:

- M300 – sedimentary rocks;

- M400 – rocks of metamorphic type;

- M800 – igneous deposits.

This marking allows you to choose the right sand for various construction works. In this case, the size of the fractions is taken into account.

Coarse sand is used for load-bearing structures, various types of coatings, foundations and other structures onto which the main load is subsequently distributed. Material with medium grain size is used for concrete mixtures. Fine sand is widely used in the production of dry construction compounds.

Types of sand depending on production

According to the type of origin, construction sand is classified into three types:

- river;

- career;

- artificial (quartz);

- nautical.

Each type of granular material has its own scope of application in the construction industry.

Career

Sand mined in special quarries contains many additional impurities - clay, plant debris or other organic substances. The material consists of different grain sizes, which makes it quite dusty.

Construction quarry sand

Quarry sand has a fairly wide range of applications:

- production of concrete solutions;

- finishing of buildings;

- plaster and masonry mixtures;

- construction of the foundation;

- cement strainer;

- brick production.

Sand in quarries is cleaned of clay and dust using water. In the construction industry, alluvial granular material is used. A sieve is used to remove clay from it.

River

Bulk material is removed from the river bottom. It contains a minimal amount of stones. There are no clay impurities in it. This composition makes river sand a good component for concrete mixtures.

Scope of use of this type of bulk material:

- brick making;

- drainage devices;

- concrete solutions;

- sand-cement screeds;

- preparation of asphalt concrete.

River sand is added in the production of grouts or dyes. The material consists of medium-sized grains, so it is perfect for finishing work.

Sand extracted from the river can settle in the prepared mortar over time. Therefore, all liquid mixtures should be stirred periodically during operation.

Nautical

Sea sand has the same properties as river bulk material. But its cost is much higher. This is explained by the high costs of its extraction and the need for additional processing.

The result is a high-quality material that is used in various construction industries:

- construction of drainage systems;

- concrete production;

- construction of the foundation;

- creation of landscape designs;

- construction of roads and buildings.

Sea sand is distinguished by its uniform granular composition and has high mechanical properties.

Quartz

This sand is used industrially for the production of building materials. It is obtained by crushing rocks containing quartz. It has a uniform structure and high strength.

Construction sand quartz

Quartz bulk material includes:

- concrete blocks;

- silicate bricks;

- construction dry mixtures;

- concrete solutions.

Quartz sand is often used in landscape design. Also, high-quality facade plasters are made on its basis.

Construction sand of artificial origin

Artificial sands are successfully used in the construction industry. They are obtained through the process of mechanical separation into fractions of various rocks. For these purposes, special equipment is used that makes it possible to grind natural material of volcanic and sedimentary origin.

Artificial sand comes in several types. Each has its own technical characteristics and application features.

Expanded clay

The material is obtained from expanded clay gravel by crushing, foaming and heat treatment of the raw material. No additional components are used during the manufacturing process. Therefore, the sand turns out to be environmentally friendly.

In appearance, ready-made loose expanded clay resembles gravel. The particles of this sand come in different sizes. Their porous structure is hidden by a shell formed during thermal exposure. The maximum size of expanded clay sand fractions is up to 5 millimeters. The material is durable and has low water permeability.

Scope of application of expanded clay sand:

- production of lightweight concrete blocks;

- production of soundproofing materials;

- insulation of various areas of buildings.

Loose expanded clay has an affordable price and good performance properties.

Perlite

Sand is formed by heating volcanic rock to a temperature of 1150 degrees. At the same time, perlite increases ten times in size. This expanded environmentally friendly artificial sand has high thermal insulation properties.

In the construction industry, perlite material is used as insulation. It is added to mortars for finishing and laying light bricks. For waterproofing, elastic and durable mastics are made from perlite sand and bitumen. Before use, the material should be slightly moistened as it generates a lot of dust.

Marble

The material is formed during the friction of pieces of natural marble. The particle size of such artificial sand is up to 3 millimeters.

Construction marble sand

Marble chips are used in the production of:

- dry construction mixtures;

- paints;

- textured plasters;

- durable concrete;

- poured, mosaic floors;

- decorative facing material;

- tiles;

Marble sand is widely used in landscape designs. The cost of the material is relatively high.

Slag

This porous sand is made from industrial waste. Therefore, the material has a completely low cost. Basically, sand with pores is obtained from slag pumice.

Porous sand from industrial waste is used for the production of lightweight concrete and for road construction. The material is often used in the construction of buildings that are subject to freezing. But at the same time, structures must be protected from direct exposure to moisture.

When constructing buildings, both natural and artificial construction sand are used. Each type of bulk material has its own special qualities and scope of application. Properly selected sand significantly increases the strength and service life of buildings. Therefore, the technical characteristics of the material must meet quality standards.

Types of sands for construction

Experts divide materials according to educational criteria. There are natural and artificial varieties. The sands that arrived on the shelves of construction hypermarkets from the deposit are called natural. They appeared and developed in the wild without human intervention. The processing method distinguishes them from their artificial counterparts.

Regarding the place of formation, there are sands from:

- career;

- rivers;

- seas.

Quarry sand is born as a result of the destruction of rocks and minerals, which are located under the soil layer at an insignificant depth. River is mined at the bottom of the river. It is worth noting that in terms of purity and structure, this type has much greater value than the previous one. Marine appears on construction sites from the depths of the sea. Special equipment is used to lift it. This option outperformed the previously mentioned ones in all respects. Its composition is almost ideal, and its versatility allows it to be used everywhere.

There are several processing technologies, and therefore sand is divided into categories:

- alluvial (the principle is that the material passes through ablution);

- sifted (uses a special technical sieve to filter out impurities);

- enriched (additional components are added using technology).

As for artificial relatives, they appear due to the crushing of minerals and rocks using special industrial equipment. Therefore, to divide them into types, there are two main criteria.

The first lies in the nature of the raw materials from which the material is obtained:

- Quartz is one of the most common components when creating artificial sand. It is often found not only in the construction industry, but also in household (quartz watches).

- Marble is in great demand among customers and ordinary buyers. Typically, decorative elements are made from sand and used in large-scale industry.

- Granite is remarkable because the sand made from it gives strength to buildings and structures.

- Perlite and thermosite are often found at wholesale stores. They are distinguished by lightness and airiness.

Each of these types is obtained in different ways. This also plays an important role. Based on their origin, they are divided into crushed and screened. The first ones go through crushing using special construction equipment. The second is through filtration in order to get rid of impurities, that is, particles and stones.

Regardless of their nature, absolutely all consumables have significant differences in size. That’s why professionals highlight:

- small;

- average;

- large.