What is a concrete production business?

Modern realities are such that a business based on the production and sale of concrete is among the most profitable ways of making a profit.

Given the dynamics of the construction industry (especially in large cities with large populations), the demand for this material continues to grow. The demand for this building material will always remain high. And its largest buyer is companies specializing in the construction industry. If you are interested in investing in this area, then the most correct decision to purchase a mini concrete plant would be at the very beginning of the construction intensification season. As a rule, such a period is the month of May. This must be done because by the end of the season (that is, by November), you will be able to start promoting your business and make a good profit.

Studying the competitive environment between mini-factories

Before moving forward, it is worth drawing up a business plan for the development of a concrete production plant. You need to understand with whom and how you have to compete, and decide on a pricing policy. The main target consumer is developers, they will absorb up to 90-95% of your production volume (these figures are obtained based on market analysis data). The difference in the coefficient between the growth rate of the construction sector and the production of concrete is 0.9 units.

However, it is necessary to understand that a mini concrete production plant has certain specifics, in the form of geographic localization on the ground. The technology is such that it is possible to sell concrete profitably only within a radius of up to 50 kilometers from the location of the plant. Therefore, first of all, you have to assess the level of competition in the area where production development is planned. The current practice gives a real understanding that it will not be possible to win in the competition with the help of dumping in the price level of products alone.

Having studied the issue, you should understand that the vast majority of factories produce approximately the same brand of concrete mixtures and their characteristics are almost the same. Production and manufacturing technologies are well known, and anyone can master them. The company's sales volume depends only on how great the demand is in the area where your plant is located.

Serious competition can come from entrepreneurs engaged in the production and sale of construction products, using which the need to use concrete can be avoided. Problems will arise if, not far from your concrete production plant, there is an enterprise whose specialization is concentrated in the production of building structures and reinforced concrete profiles.

The ticket to the future, in which you can make systematic profits and grow your company, will be agreements with target consumers. It is important that these transactions have a long-term basis. Only in this way will you have the strength to withstand the competition.

Stages of concrete production

- Preparation of raw materials.

Preparation of raw materials includes processes such as:

- removal of impurities and dirt;

- crushing of aggregates.

As a rule, these processes are carried out at the stage of pre-sale preparation by companies producing raw materials. While directly at the concrete production plant the following activities must be carried out (if necessary):

- production of chemical solutions;

- heating of aggregates;

- grinding cement.

But at the same time, we should not forget that the operations carried out require the expenditure of enterprise resources (electricity, water, labor), and in order to carry them out it is necessary to purchase additional equipment, which also leads to an increase in the cost of the finished product, and therefore, if possible, one should refuse to perform these procedures.

A more detailed description of the ingredients preparation activities:

- Preparation of chemical solutions and additives is the preparation of a solution from additives in clean water with mandatory concentration control. To organize this process, you will need installations with a pipeline system that are designed for mixing solutions using compressed air.

- Cement grinding can be done either wet or dry. This process has a beneficial effect on the concrete hardening process, but most often this advantage is abandoned in production in order to reduce the cost of the finished product.

- Heating of aggregates is carried out in special bunkers or covered storage areas.

Heating of aggregates can be accomplished by one of two possible methods. The first is to pass heated air, steam or other gas through the filler. The second is the contact method, which is carried out by heating pipes or combs inside a hopper with filler. The first option is more cost-effective, but you must first consider a system that prevents the leakage of warm gas.

- Dosage of the mixture.

The process of dosing the mixture is measuring the required amount of raw materials for the production of concrete. For this purpose, it is most convenient in factories to use special weighing dispensers, with which you can measure the consumption of each individual ingredient. But when production is carried out in so-called domestic or home conditions, volumetric dispensers are used for measuring purposes.

It is very important to take into account the moisture content of all components and especially sand; the amount of water required for the mixture depends on this.

- Mixing components.

Mixing the components must be done until a homogeneous mass is formed. Depending on what characteristics of the concrete mixture need to be achieved, various methods of mixing components can be used in production. For example, when the concrete mixture consists of coarse ingredients and solid aggregates, then it is most appropriate to use mixing plants based on the phenomenon of gravity. With the help of such equipment, mixing ingredients is carried out by repeatedly raising and dropping the mixture from a certain height when the drum in the mixer rotates.

Mixing light and fine-grained mixtures is best done in mixers with a forced action system. In this case, a mass of uniform consistency can be obtained by mixing the ingredients with blades or other structural elements.

Another most effective method is vibration mixing. Thanks to its use, the strength indicators of the finished cement are improved. But at the same time, when using this method, it is necessary to strictly monitor the process time, since its insufficient duration will certainly cause deterioration in the characteristics of the finished product.

Registering a business and choosing a tax system

In the business plan being developed, it is imperative to include the issue of registering a legal entity, in our case it will be a Limited Liability Company (LLC). This step is important for several reasons. The first is that in case of any unforeseen situations, the LLC is responsible only with its authorized capital. Secondly, any company or organization will agree to work with an organization of a similar form of ownership.

To organize and conduct the production in question, the OKVED code is determined: 26.63. The production of ready-mixed concrete requires the following standards (they must comply with established GOSTs):

- “Concrete. Methods for determining frost resistance" (10060.0-95);

- “Concrete. Squad selection rules" (27006-86);

- “Concrete. Rules for controlling compressive strength for monolithic structures" (18105 – 86).

- “Concrete mixtures. Test methods" (10181-2000);

- “The concrete is heavy and fine-grained. Technical conditions" (26633-91);

Let's move on to choosing a taxation system; in generally accepted practice, this is the general taxation system, the simplified tax system for annual revenues of less than 60 million rubles. To maintain accounting records for an enterprise, it is necessary to hire an accountant. The taxation system of the enterprise under consideration is the simplified tax system “income-expenses” 7%.

Characteristic features of mini production

The sale of concrete mixtures is accompanied by a characteristic problem - solving difficulties with organizing the delivery of products to their destination. Concrete has certain properties that require it to be transported to its destination at a strictly defined time. If you linger longer than the technology allows, the composition may harden. The composition is delivered to the construction site in specialized vehicles called “concrete mixers.”

An alternative option is to produce finished molds on site. After hardening, these forms are transported to the building site. But the most advantageous option is production right on the construction site. This is precisely the reason that requires some geographical localization of production.

Raw materials used for production

Modern technology for the production of concrete solutions requires the following components:

- One of the main components of mixtures is water. It must be of high quality and clean, and not contain foreign matter. The volume of its supply is determined by the technologist.

- Ballast mixture, also called general mixture. This is a kind of porridge of sand and gravel. The most suitable proportion of components is three parts gravel to one part sand;

- Crushed stone - crushed gravel is used as this component (the most suitable, extracted from rocks), its standard diameter is about 5 mm. Addition of slags is allowed.

- Sand. It must meet the requirements of GOST 8736-93, where the diameter of sand grains is no more than half a millimeter.

- Cement. The main component of the mixture. This is a loose powder mass of a grayish tint. During the production process of the mixture, the powder crystallizes after adding liquid.

Depending on the required brand of concrete, the proportions between the main components differ. For example, to produce grade 100 concrete we need 1 kg. cement grade 400, 4.1 kg. sand, 6.1 kg. crushed stone and water

| Concrete grade | proportions cement: sand: crushed stone | |

| cement grade 400 | cement grade 500 | |

| 100 | 1,0 : 4,1 : 6,1 | 1,0 : 5,3 : 7,1 |

| 150 | 1,0 : 3,2 : 5,0 | 1,0 : 4,0 : 5,8 |

| 200 | 1,0 : 2,5 : 4,2 | 1,0 : 3,2 : 4,9 |

| 250 | 1,0 : 1,9 : 3,4 | 1,0 : 2,4 : 3,9 |

| 300 | 1,0 : 1,7 : 3,2 | 1,0 : 2,2 : 3,7 |

| 400 | 1,0 : 1,1 : 2,4 | 1,0 : 1,4 : 2,8 |

| 450 | 1,0 : 1,0 : 2,2 | 1,0 : 1,2 : 2,5 |

We will also give the consumption of materials per cubic meter of concrete.

| Concrete grade | Cement brand | Water-cement ratio | Filler grain size, mm | Water volume, l/m3 concrete | Cement weight kg/m3 concrete | Sand weight kg/m3 concrete | Weight of crushed stone/gravel, kg/m3 of concrete |

| M100 | M300 | 0,75 | Gravel 10 | 205 | 273 | 1092 | 1092 |

| 0,8 | Crushed stone 10 | 205 | 275 | 1100 | 1100 | ||

| 0,75 | Graphy 20 | 220 | 253 | 1012 | 1012 | ||

| 0,8 | Crushed stone 20 | 190 | 256 | 1024 | 1024 | ||

| M200 | M400 | 0,63 | Gravel 10 | 205 | 325 | 1300 | 1300 |

| 0,68 | Crushed stone 10 | 220 | 324 | 1296 | 1296 | ||

| 0,63 | Gravel 20 | 190 | 302 | 1208 | 1208 | ||

| 0,68 | Crushed stone 20 | 205 | 302 | 1208 | 1208 | ||

| M250 | M500 | 0,64 | Gravel 10 | 205 | 320 | 1280 | 1280 |

| 0,69 | Crushed stone 10 | 220 | 319 | 1276 | 1276 | ||

| 0,64 | Gravel 20 | 190 | 297 | 1188 | 1188 | ||

| 0,69 | Crushed stone 20 | 205 | 297 | 1188 | 1188 |

Approximate calculations - mini-factory

When operating a semi-automatic concrete mini-plant with a productivity of about 10 cubic meters of M-400 concrete per hour.

- mini-factory line - 450 thousand rubles;

- concrete mixer based on a KamAZ vehicle - 2.75 million rubles.

Total: 3.2 million rubles.

- crushed stone - 0.83 cubic meters;

- cement M-500 - 329 kilograms;

- sand - 0.43 cubic meters.

The approximate cost of the entire volume of the above materials is more than three thousand rubles. A standard business plan involves operating a production line on one shift, six days a week.

The minimum level of expenses for paying salaries to personnel is about one hundred thousand rubles, including round-the-clock security, as well as the work of a forklift driver and operator. It is necessary to include in this article payment for the work of an electrician and mechanic that may be required during the production process.

In addition, it is necessary to provide for the cost of an advertising campaign in the form of advertisements in the media and posters. The final cost option, divided by the planned volume of concrete produced, reflects the cost of a cubic meter of production and amounts to just over two thousand rubles. Net profit after deducting all taxes and fees will be equal to ≈ 300 rubles per cubic meter. The standard monthly production volume is ≈ 6 thousand cubic meters per month. Well-established sales allow you to recoup your investment in six months.

Staff

For smooth production and business operations at the plant, the following minimum number of workers is required.

| Job title | Qty | Salary | Salary | Total | |

| Human | rub/month | rub/shift | Payroll | ||

| RBU operator | 1 | 30000 | 1363,6364 | 30000 | |

| Loader driver | 1 | 30000 | 1363,6364 | 30000 | |

| Repairman | 1 | 30000 | 1363,6364 | 30000 | |

| Dispatcher | 1 | 20000 | 909,09091 | 20000 | |

| Technologist | 1 | 10000 | 454,54545 | 10000 | |

| Director of operations | 1 | 40000 | 1818,1818 | 40000 | |

| Director | 1 | 20000 | 666,66667 | 20000 | |

| TOTAL | 7 | 180000 | 7272,7273 | 180000 | |

Let's make a table showing the costs of the wage fund.

| Total | Total | Total | |

| 1 year | 2 year | 3 year | |

| RBU operator | 210000 | 210000 | 210000 |

| Loader driver | 210000 | 210000 | 210000 |

| Repairman | 210000 | 210000 | 210000 |

| Dispatcher | 140000 | 140000 | 140000 |

| Technologist | 70000 | 70000 | 70000 |

| Director of operations | 280000 | 280000 | 280000 |

| Director | 220000 | 240000 | 240000 |

| TOTAL PAYROLL | 1340000 | 1360000 | 1360000 |

And on payroll taxes.

| Total | Total | Total | |

| 1 year | 2 year | 3 year | |

| RBU operator | 63000 | 63000 | 63000 |

| Loader driver | 63000 | 63000 | 63000 |

| Repairman | 63000 | 63000 | 63000 |

| Dispatcher | 42000 | 42000 | 42000 |

| Technologist | 21000 | 21000 | 21000 |

| Director of operations | 84000 | 84000 | 84000 |

| Director | 66000 | 72000 | 72000 |

| TOTAL PAYROLL | 402000 | 408000 | 408000 |

It was decided to engage an accounting company under a contract for accounting services.

The amount of financial costs for the purchase of raw materials for concrete

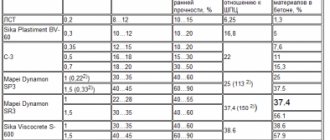

The most popular brand of concrete, the safest to start working with, is the M 250 and M 350 grades.

Cost calculation depends on the selected production technology. In our business plan, we made a calculation based on the M 250 grade, so based on the consumption of materials per 1 m3 of ready-made concrete, the following figures will be obtained:

- M 250: crushed stone – 1280 kg, cement – 320 kg, sand – 1280 kg, water – 205 liters

Materials are purchased from officially operating quarries in the city of Yekaterinburg and nearby cities that have the necessary certificates and strength test reports for their material, etc., the cost of the material includes delivery to our territory

The volume of material consumption per 1 m3 of the finished product will be 2000 rubles, water costs will be included in utility costs, because We do not purchase water, but get it from a well.

There are other associated costs - staff salaries, costs for work clothes and equipment for work, diesel fuel for the loader, payment for electricity and site rental. If all this is taken into account, then the production cost will increase to 2,250 rubles per 1 m3 of finished concrete. The next section of the business plan provides a detailed table of variable and fixed costs.

Concrete mortar production technology

Historical knowledge about the production of concrete dates back to the fall of 1824 and is associated with the name of J. Aspdin, a famous English mason who patented the gray substance, giving it the name “Portland cement” because the shade is similar to the gray rocky mountains located near the town of Portland. Since then, the use of concrete has gained widespread popularity throughout the world in the construction industry. Concrete mixtures are produced according to GOST 25192 and differ in classes, brands, and destination parameters. concrete made from cement may deviate from GOST based on individual recipes of the manufacturer, but not contradict the specified standards.

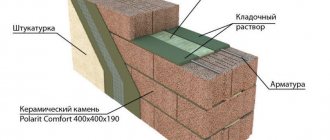

It should be noted that concretes are classified according to their composition and method of production. Most often, the production of heavy concrete is required, used in the construction of foundations, load-bearing and span structural elements, columns, and beams.

Basic raw materials for heavy concrete:

- Cement. It is the main component that makes up the concrete mixture. It has the appearance of a gray substance with limestone in its composition, which, when absorbing moisture, crystallizes and hardens. The grade of cement is determined by the project. Take three parts by volume.

- Large aggregate. It is gravel or crushed stone. Up to 25-40% coarse sand is allowed in the total mass of stone chips taken. It is best if the coarse aggregate has sharp chips, without rounded smooth surfaces (which significantly worsens the bond with the cement mortar). Crushed stone is extracted by grinding hard rocks. Granite rock is used in the production of concrete. Crushed granite is of high quality, resistant to frost and temperature changes, has high density and strength during industrial compression. Add 5 parts by volume to the mixture.

- Construction or quarry sand. The size of sand grains ranges from 0.65 mm to 2.5 mm. The areas for using sand from quarries are unlimited. In construction it is used both in masonry and plastering work, as well as in the production of all types of concrete. You need to take 3 measures.

- Water. It is important that this component is cleared of foreign impurities. It is not possible to unambiguously determine the initial indicator of water for a certain amount of mixture, since the initial moisture content of sand, crushed stone and the moisture requirement of the cement powder itself is unknown. The volumetric part of water is determined during the mixing process after the mixture of sand, crushed stone, and cement has been thoroughly mixed.

Approximate volumes of components for preparing concrete when pouring non-load-bearing elements indoors (in order to save money during construction):

- Dry cement M400 3 measures;

- Construction sand 5 measures;

- Crushed stone 8 measures.

In the sphere, it is preferable to use crushed stone with a fraction of 5:20 mm. Crushed stone consists of naturally occurring rocks combined with crushed river gravel. It is acceptable to use artificial crushed stone, expanded clay, and slag, but it is worth considering that the quality characteristics of such components in concrete will be significantly lower.

In general, the concrete production process comes down to:

- Accurate determination of volumes of mixed components

- Thoroughly mixing the ingredients until smooth

- Add water to the consistency of thick sour cream, when the finished solution is easy to “pour out”, and it should fill all the voids without forming air voids. Excess water is just as bad as too little: it will lead to shrinkage and cracking of finished products and poor quality strength indicators.

In such ratios and proportions, dry cement is a high-cost element in production. To obtain a concrete mixture with good wear resistance, you need to fill the mixture with cement of good quality and strength. A successful ratio of “Portland cement” to the filling component for external use will be proportions closer to 2, but most often a ratio of 1:3 is used.

Note:

For multi-storey, civil, and private construction, the design of the concrete grade and its strength characteristics must be determined by the project, and the composition of the concrete is calculated. You should not change its recipe in order to save money: its strength is significantly reduced, which will affect the service life and safety of the future building.

Concrete is the most important material for construction work. Uses it to create various structures, simple and those that are planned for operation under the influence of an aggressive environment. Naturally, the concrete mixture can be prepared in small quantities yourself. But when large-scale construction is planned, ready-mixed concrete is prepared in industrial conditions in concrete plants. For private developers and large construction companies, there is always the opportunity to purchase ready-mixed concrete of the required grade with the delivery of the material to the construction site. Manufacturers provide several compositions of ready-mixed concrete at different prices, which depend on the technical indicators and parameters of the material. So, ready-mixed concrete, what is it?