Relevance of this business

Nowadays, this project is in great demand. Beginning entrepreneurs are interested in how to launch this project to create high-quality material. It is attractive because the payback period is short, because many people use this type of stone in construction. Aerated concrete parameters: 10*30*60 cm and 20*30*60 cm. It has a large number of positive qualities:

- unpretentiousness to the foundation of the house, high strength, low weight;

- retains heat well, does not allow cold to pass through, and protects from external noise;

- easy to install, allows you to quickly erect a structure;

- easy to process, achieve the desired shape of the material;

- environmentally friendly material;

- earthquake-resistant;

- fire-resistant stone, with high fire safety.

Therefore, consumers choose this product. The product contains the following components:

- cement;

- sand (quartz is perfect);

- gas generator (this can be: aluminum powder, paste, lime, ash, gypsum).

Stages of organization

Determine how large your enterprise will be and what type of products you will produce. There are two types of material production:

- autoclave;

- non-autoclave.

In order to produce aerated concrete using method 1, you need to harden it in an autoclave with steam. To make the material using method 2, it is necessary to dry the aerated concrete using heating.

What you will need:

- rented or personal premises;

- line for the production of aerated blocks from scratch;

- workers.

From the data on what volume of production will be and what type of material is suitable, you can determine the area of the premises, the amount of equipment and the number of employees.

If you plan to produce up to 30 meters of cubic blocks per day, working an 8-hour shift, a room of 70 square meters will be enough for you. When producing 100 - 150 cubic meters, working around the clock, an area of about 600 square meters will be required. It is necessary to have warehouses for storing products, although it is possible to leave blocks in the open air.

To produce 1 cubic meter of blocks you need:

| 250 kg cement | 1,000 rudders |

| Fillers | 180 rubles |

| Aluminum powder, other additions | 150 rubles |

With such data, it turns out that the cost is 1,500 thousand. It turns out that the minimum price for 1 cubic meter is 2,500 thousand.

Business plan for the production of aerated concrete blocks:

- registration of an organization – from 7 to 10 days;

- finding rental premises – a month before the start of the enterprise’s activities;

- purchase of equipment - two weeks before the opening;

- installation of equipment and connection - before the start of activity;

- purchase of necessary raw materials - a week before the start;

- recruitment of employees - before the start;

- start of the production process - after registration papers are completed;

- finding buyers, establishing sales - from the moment work on the project begins;

- material sales;

- creation of reserves.

Content

- Business in the production of aerated concrete blocks: general information

- Brief description of aerated block production technology

- What investments will be required to open a business producing aerated blocks?

- Aerated concrete production: business plan

Important!

If you are new to a material such as aerated block, we recommend reading general information about it in the Wikipedia encyclopedia:

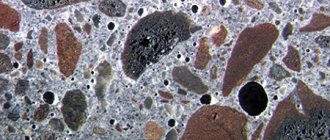

Non-autoclaved aerated concrete is a cellular material that hardens under natural conditions, that is, without excessive pressure and exposure to high temperature...

Read more

Search for clients

Manufacturers and buyers are pleased with the fact that the building material is suitable for any climate zone. It is usually used when constructing buildings:

- low-rise residential premises;

- industrial;

- agrarian;

- administrative;

- social.

The product is in demand both among large construction organizations and individuals with development rights.

You can sell goods to construction trade warehouses and markets. Distribute price catalogs to stores. Send business proposals to development companies. Publish advertisements for private clients.

Please note that the demand for this category of product is seasonal; advertising must be organized before the start of activity. Consider the efficiency of the equipment in use and the method of creating aerated concrete - it can be put on sale a month from the date of production.

Business in the production of aerated concrete blocks: general information

The aerated concrete business is gaining more and more popularity every year. This is due to the fact that the demand for aerated blocks is constantly growing: over the past 8 years, the demand for this material has increased 14 times ! In addition, to start your own production, you do not need large financial investments. And even if you don’t have the full amount on hand, leasing companies always accommodate beginning entrepreneurs.

For more information about the aerated concrete business, watch the video:

Necessary equipment

If you have a small organization with a small capital investment, use equipment for the production of aerated concrete using a non-autoclave method (drying of the manufactured blocks is carried out naturally). In this case, you will need pouring molds and a professional mixer.

If a discovery occurs that involves an autoclave method of creation with a more powerful production line, you will need, in addition to the usual devices, an autoclave (for the purpose of increased temperature treatment). Also required:

- vibrating sieve;

- compressor;

- dispenser;

- cutting devices;

- conveyor line.

- steam generator;

A vibrating sieve is needed to sift sand. The dispenser accurately determines the amount of required components. The steam generator provides steam for processing aerated concrete blocks.

With this set, the production speed will increase, but opening will require a larger sum of money.

Based on a productivity of 60 cubic meters daily, the cost of the minimum set is 790,000 rubles. The cost of delivery, VAT of installation, setup and connection of equipment to utilities is not taken into account.

Stages of the production cycle

Manufacturing technology of aerated concrete blocks

The manufacturing process includes a number of stages:

- Filling the mixer with all the necessary components

- Making the mixture

- Gas generator input

- Filling metal molds with the mixture while waiting for gas formation. This process usually takes about 3-4 hours.

- Correction of the form from excess mixture formed during gas formation.

- Aging of blocks in molds for about 12-16 hours

- Heat treatment of blocks in an autoclave for 24 to 48 hours or natural drying using a non-autoclave method for 3-5 days.

Making aerated concrete: a detailed overview of the material production process

Main types of production

There are only 2 main types of production of products from the material in question:

- Autoclaved

- Non-autoclaved

Each of them has its own advantages and disadvantages. Let's take a closer look at how to build a business on aerated concrete using each type of product production.

The autoclave method is that the gas block is placed in special ovens - autoclaves. Under the influence of high temperature and excess pressure, products harden.

Production diagram of a gas block-autoclave

The non-autoclave method is characterized by natural hardening or heat and moisture treatment. This method is less popular, since non-autoclaved blocks cause serious shrinkage to the building and are inferior in many respects to their competitor, the autoclave block.

The only noticeable advantage is the price, it is significantly lower than that of modern autoclaved aerated concrete. The photo below shows a diagram that consistently reflects the manufacturing processes of a non-autoclave.

Scheme of production of hydration-hardening gas block

Optimization methods

One of the options for optimizing aerated concrete using a non-autoclave hardening method is the use of various modified additives. For example, glass fiber or polymer fiber to improve reinforcing properties; calcium chloride, which accelerates the natural hardening process; microsilica, which increases performance properties.

Costs and profits

You will spend three months launching the business; you should start thinking about opening it in early spring. The size of your investment during this period will be equal to 4,378,000 rubles.

Costs in rubles:

| Enterprise registration | 10,000 rubles |

| Rent for 3 months | 240,000 rubles |

| Equipment | 909,000 rubles |

| Assembly and delivery of equipment | 150,000 rubles |

| Development of reserves of raw materials for the creation of aerated concrete | 800,000 rubles |

| Employees' salaries | 117,000 rubles |

| Processes of organizing and selling goods (for 3 months) | 95,000 rubles (285,000 rubles) |

All this is required to open a business. Every month you will spend certain amounts in rubles:

| Rent of space for warehouse and production processes | 80,000 rubles |

| Salary and contributions to the tax service for 2-3 employees | 117,000 rubles |

| Raw materials for the formation of starting material | 800,000 rubles |

| Various expenses of the organization | 95,000 rubles |

| Expenses (transport, storage) | 45,000 rubles |

| Bank commissions and maintenance of the created account | 2,500 rubles |

| Electric Energy | 9,200 rubles |

| Means of communication | 3,000 rubles |

| 5,000 rubles | |

| Consumables | 20,000 rubles |

| Payments | 10,000 rubles |

It turns out about 1,100,000 rubles every month.

Profitability at a high level. Payback period from 4 months to a year.

Possible income level

Income depends on productivity. You may have 3 predicted development options: pessimistic, realistic, optimistic.

With option 1 (loading power - 30%), your earnings are 331,200 rubles per month:

| 18 m cubic | aerated concrete daily |

| 23 | shifts per month |

| 1 242 000 | net income |

| 414 m cubic | produced monthly |

| 3,000 rubles | unit price |

| 1 year | project payback period |

Option 2 (loading power - 60%) assumes an income of 662,400 rubles per month:

| 36 m cubic | aerated concrete daily |

| 23 | shifts per month |

| 2 484 000 | net income |

| 828 m cubic | produced monthly |

| 3,000 rubles | unit price |

| Six months | project payback period |

Option 3 (load capacity – 90%) gives a profit of 993,000 rubles per month:

| 54 m cubic | aerated concrete daily |

| 23 | shifts per month |

| 3 726 000 | net income |

| 1,242 cubic meters | produced monthly |

| 3,000 rubles | unit price |

| 4 months | project payback period |

Productivity depends on you. Also influenced by the fact that the demand for this product is seasonal. It is advisable to launch production during this period and have time to sell all the goods.

Registration and registration of business

You need to register your organization in the form of “IP” or “LLC”. It is necessary to draw up a business plan for production, analyze the market situation, and identify competitors. Here are the step-by-step instructions:

- Summary of the enterprise;

- Marketing project;

- Organizational plan;

- Financial plan;

- Risk analysis.

If you understand that you cannot understand all the intricacies of the registration process, we advise you to contact specialists.

How to draw up a business plan for aerated concrete production?

A business plan for aerated concrete production should include:

1 . Initial investments and investments

This section includes all one-time costs necessary to start production: purchase of equipment, purchase or long-term lease of premises, state registration of an enterprise.

Record all these costs in a table and calculate the total investment costs.

| Most beginning aerated concrete producers in Russia choose the individual entrepreneur form based on a simplified taxation system “income minus expenses” with a rate of 15%. |

2. Production parameters

Determine the productivity of the line, the number of work shifts, their duration and the number of personnel in each. Enter them into the table, even though you know them very well. These numbers will be useful to you in further calculations. So they will always be before your eyes.

Example:

| Parameter | Value per day | Value per month |

| Line performance | 40 m3 | 880 m3 |

| Number of working hours per shift | 8 | 176 |

| Number of work shifts | 1 | 22 |

| Number of workers per shift | 5 people | |

3. Raw material consumption

Make a table indicating the unit cost of each type of raw material: cement, sand, water, caustic soda, aluminum powder, additives and plasticizers, don’t forget about mold release agent. Calculate the consumption of raw materials per 1 m3.

4. Payroll fund

List all the positions in your business and enter each person's salary to see your total monthly labor costs.

5. Tax and marketing costs

This is an important point, but many novice aerated concrete workers forget about it and are subsequently disappointed when actual costs exceed those predicted. This is a fairly large expense item.

If you do not choose a preferential taxation system, do not forget to take into account personal income tax, income tax, VAT, property tax, insurance premiums for yourself and for employees.

Decide what types of advertising you will use and how much you are willing to spend on marketing.

| OKVED code for the production of aerated concrete 23.61: Production of concrete products for use in construction. |

6. Profit and expenses

The main thing is not to forget anything. Include in this section rent, payments for electricity, water supply and water heating, heating costs and other utility costs, write down monthly costs for the purchase of raw materials, add payroll, taxes and advertising.

Set the price of 1 m3 of aerated concrete. Multiply by sales volume. Please note that sales vary significantly depending on the season. Calculate your profit.

After deducting all expenses, you will receive a net profit from the production of aerated concrete.

7. Economic indicators

This is an important point to analyze your business. Calculate the cost of 1 m3 of aerated concrete, payback period, profitability, determine the break-even point.

Now you can evaluate the results obtained. They will help you see what needs to be changed to get the desired result. You will be able to simulate some market situation and make predictions.

| It is better to write a financial model in a special program, using formulas, in order to be able to change the data and immediately get the result. For example, see how net profit will increase with an increase in productivity or with the introduction of two work shifts per day. |

The production of aerated concrete is not an innovative project, but a well-established technology. Therefore, if you are not going to win grants and business competitions, you do not need to draw up a business plan in the format of a research paper with outpourings like “Analysis of the market for the production of building materials for the period since 1900 makes it possible to imagine...”. It is enough for yourself to draw up a financial model of your enterprise.

An extended business plan may include the organizational structure of the enterprise with a detailed description of the responsibilities of each official, a description of the technology and market analysis, indicating risks and prospects.

Disadvantages and advantages of this business.

The positive aspects are:

- a sought-after product, the demand for which is constantly growing;

- low production costs;

- high profitability, short payback period;

- not a very large amount of initial capital is required;

The shortcomings are noted as follows:

- increasing and serious competition in this market;

- demand for goods is seasonal;

- the need for storage facilities;

- you need to constantly attract new customers.

Each region has its own specific case. When opening production, rely on data from your region.

What equipment is required?

In order for a mini-plant for the production of aerated concrete to produce high-quality products and make a profit, you should purchase specialized machines and mechanisms. Equipment for the production of aerated concrete blocks includes the following devices:

For production you will need equipment such as a drum-ball mill, which grinds sand.

- Drum-ball mill. Necessary for grinding sand so that after forming the blocks it is easier to process them.

- Container for the mixture.

- Steam generator. Needed for the production of water vapor with pressure exceeding atmospheric pressure.

- Mortar mixer. Mechanism for preparing aerated concrete mixture.

- Forklift. Machine for loading/unloading blocks.

- Machine for cutting finished shapes.

- Autoclave. An apparatus for heating material under pressure exceeding atmospheric pressure.

- Container for forming blocks.

- Dispenser. Necessary for the correct proportions of the components of the aerated concrete mixture.

- Sieve. It is used to sift the components of aerated concrete so that large impurities do not get into the material, and the mixture itself is homogeneous.

Useful tips and tricks

First, get to know your market. It is advisable to find buyers in advance; this will prevent the finished product from sitting idle.

Organize your enterprise in the spring, so that by the time construction work usually begins, the vases will have a supply of the finished product.

If you are going to produce non-autoclaved concrete up to 10 cubic meters of material daily, then you will spend about 200,000 thousand on equipment, if from 25 - 30 cubic meters, then about 450,000 thousand, if 75 - 150 cubic meters, then from 2,000,000 thousand . Decide how much product you can sell in your region. From this data, decide how much to produce.

It is profitable to create an organization for the production of aerated concrete. An aspiring entrepreneur needs to expand his knowledge in this area. Follow all instructions in your business plan before opening your business. If you organize your project correctly, success awaits you!