Advantages of foam block

- Light weight blocks.

- Standard sizes guaranteed by the foam block manufacturer.

- Minimum deadlines for completing work.

- The material lends itself well to processing.

- Good heat resistance is due to the porosity of the foam block.

- Sufficient margin of safety.

- Non-flammable material.

- Laying can be done by a person with minimal experience.

What is needed for foam block masonry

To begin with, you need industrially produced foam blocks made by autoclave with a density of at least D600 for load-bearing walls and D500 used for partitions. Now, due to the great demand for foam concrete, many unscrupulous manufacturers have appeared, where not only the production technology is violated, but also the compliance with the overall dimensions of such products leaves much to be desired. Therefore, it is necessary to purchase foam blocks from trusted manufacturers who comply with the rules for storing and transporting such material.

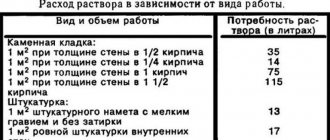

A binding solution for blocks, which allows not to increase the thickness of the seam, which in turn will improve the heat-shielding characteristics and save adhesive substances. Since the solution imparts strength as the main characteristic of the masonry, it is necessary to make a choice:

- sand-cement (4:1) mortar using foaming agents and plasticizers (if the edges of the block are not very smooth);

- The adhesive mixture is specially produced for laying walls made of foam blocks, which corresponds to the basic parameters of foam concrete.

Tool for laying foam blocks:

- rubber hammer for leveling foam blocks;

- building level;

- hacksaw or electric milling cutter;

- attachment for a perforator for mixing the solution;

- trowel and carriage for applying mortar to vertical and horizontal surfaces;

- grater, plane, wall chaser;

- cord, brushes.

How to calculate the cost of a house made of foam blocks?

Calculation of the cost of a building made from this material depends on:

- location of the object;

- area of the house;

- heights;

- the need to use additional building materials;

- degree of infrastructure development;

- pricing policy of a construction company.

On average, one square meter of a building made of foam blocks costs about 15,000 rubles . You can save money on workers if you can handle its construction yourself, but without certain skills it’s better not to even try.

Return to content

How to calculate the amount of foam block per house

The main standard sizes of foam blocks are 100x250x625 and 250x250x625 and 400x250x625. There are also other blocks that differ in length and width and are usually used in partitions. The most popular size is 200x300x600.

What you need for the calculation:

- what will be the thickness of the wall. Most often, the thickness of the walls for a temperate climate is 30-40 cm;

- calculate, based on the external dimensions of the foam block, how many blocks are in 1 m2;

- find their total number by multiplying the area of the walls being erected by the previous result;

- From the entire area of the walls, subtract the dimensions of the openings of windows and doors.

How many cubes of foam block are required for masonry? Having the number of blocks in 1 m2, you can calculate (with the same use of material) how many there will be in a cubic meter, and, accordingly, on the pallet in which the blocks are usually sold. There are three options: a pallet of 0.9 m3, 1.4 m3 and 1.8 m3. At the moment, prices for foam blocks vary from 3,000 to 4,000 rubles per cubic meter. To make calculations easier, you can use a calculator:

How many foam blocks per square meter

Sometimes, to calculate the required amount of masonry mixtures or plaster, it is necessary to determine the number of foam blocks per square meter of wall. This calculation will not be difficult if we remember how we calculated the area of the block.

For example, let’s determine the number of blocks in 1 m2 of the wall of our building. As you remember, we took the thickness of the outer wall to be 0.3 m. Thus, the two remaining faces will serve as the sides of a rectangle (this rectangle will be the outer side of the block), the area of which we need to calculate. Calculating the product (0.2 m x 0.6 m) we get 0.12 m 2. Now all that remains is to divide 1 square meter of wall by 0.12 m2 (1 / 0.12 = 8.33 pcs.). Now we know the number of foam blocks per square meter of wall and we can easily calculate the consumption of any dry mixture.

In conclusion, it is worth saying that it would be most rational to entrust the calculation of the number of foam blocks to the specialists of the ProfStroy company. By using this free service, you can significantly reduce the cost of purchasing building materials.

How to lay foam block correctly

- First, let's mark the walls.

- In the load-bearing wall, a reinforcing mesh is laid at its base.

- We stretch the cord along the entire marking.

- Before laying the first row, you need to arrange waterproofing (roofing felt or waterproofing) and cement mortar.

- The corner of the future building will be the beginning of laying the blocks. The most important thing is to ensure that the angle between the walls is straight.

- Special glue is applied along the entire length of the block and leveled with a spatula.

- The seam should be no more than 30 mm, so it is worth calculating the amount of solution applied.

- After laying, check the evenness of the wall using a building level, immediately removing any unevenness using a sanding tool (plane or sanding board).

- In subsequent rows, the thickness of the adhesive seam is reduced to 3-5 mm, both horizontal and vertical, and the pricking mixture is first applied to the vertical side of the block, and then to the horizontal.

- Each time after laying a row, the cord is transferred to a new row.

- The blocks are laid with an offset and it should be 40% of the block height.

- At the intersections of the walls, corners or ties made of stainless steel are laid.

- When laying foam blocks, they require additional moisture, because the foam block very quickly takes water from the solution.

How much does it cost to build a block house?

The house construction calculator assumes the influence of many factors.

- Cost of foundation. In the case of using foam blocks, the price will be kept within reasonable limits, because porous concrete is lightweight and does not require a massive foundation.

- The price of foam blocks for building a house, including their quantity, which can be calculated using the calculator offered by building materials manufacturers.

- The cost and quantity of the joining solution, which depends on the type of mixture used.

- The need for interior and exterior wall decoration, which is relevant for block masonry. Low aesthetic appeal implies the use of finishing materials.

- Application of heat and sound insulating materials. The need for their use is determined by the location of the site.

- The cost of roofing material, taking into account the hiring of workers.

- The price of a house made of foam blocks also depends on the cost of the construction company’s services.

It would not be amiss to include in the price the amount of project documentation, which will vary in each region. You can calculate the cost of building a house using a calculator on the websites of companies offering construction services.

Reinforcement of foam block walls

To make the walls more stable and durable, and also protected from chips and cracks, a reinforcement method is used (SNIP2.03.01-84). Foam block walls are reinforced in the following cases:

- between the foundation and the wall;

- between external and internal walls;

- in the corners of long load-bearing walls;

- where there is a change in wall thickness;

- where there is a difference in the height of the walls;

- in walls whose length exceeds 6 meters;

- where elements from other materials are connected.

Depending on what kind of solution is used, different types of reinforcement are used. For ordinary cement-sand mortar, a metal roll mesh is usually used; it is laid from the initial row and then through 3-4 subsequent rows, as well as in the last 2. This is due to SNIPs.

When it is not possible to use a metal mesh, polypropylene-based fiberglass is used to improve strength and laid together with the solution. The use of fiberglass helps to improve characteristics such as heat resistance and sound insulation of masonry.

The seam is thinner than the reinforcing mesh. Based on this, reinforcement occurs as follows: grooves are cut in the middle using a wall chaser (if the blocks are wide, 2 grooves are cut away from the edges of the block and from each other). Reinforcement with a diameter of 10-12 mm is placed in this groove and then the grooves are covered with mortar. In the corners of the walls, the reinforcement is bent to the required angle and welded together.

If floor slabs are used, then upon completion, a reinforced belt of concrete 10-30 cm high is poured onto the masonry walls, as well as on each floor, to evenly distribute the load on the foam block wall. Accordingly, such a belt must be insulated, since it will act as a cold bridge relative to all the walls.

A special U-shaped block of foam concrete is installed above the window and door openings, into which reinforcement is laid and tied and concrete mortar is poured.

Calculation result

Description of the results of calculating foam concrete blocks in the online calculator:

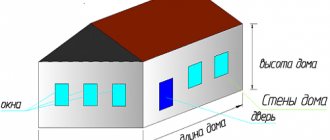

- The perimeter of enclosing structures is the sum of the lengths of all enclosing structures, units of measurement are meters;

- Wall area – the area of the external sides of the enclosing structures, excluding gables/doors/windows, units of measurement – square meters;

- The total area of the gables is the area of masonry on the gables, which is added to the area of masonry on the walls;

- The total area of windows is the area of all windows, which is subtracted from the area of the walls, units of measurement are square meters;

- The total area of the doors is the total area of the doors, which is subtracted from the area of the walls, the units of measurement are square meters;

- The total area of the walls is the area of the external sides of the enclosing structures, taking into account gables, doors and windows, units of measurement – square meters;

- Total number of blocks – the number of blocks required to construct a structure according to the specified parameters, units of measurement – pieces;

- The total weight of the blocks is the weight of all the blocks required to construct the structure according to the specified parameters, units of measurement are kilograms. A useful parameter when calculating delivery;

- The total volume of blocks is the volume of blocks required for construction, units of measurement are cubic meters. A useful parameter when calculating delivery;

- Total amount of mortar - the total amount of mortar required to erect a structure according to the specified parameters, units of measurement - cubic meters;

- The total weight of the mortar is the approximate weight of the mortar required for masonry according to the specified parameters. Weight may vary depending on the volumetric weight of the components and their ratio in the solution; units of measurement are kilograms;

- Total weight is the approximate weight of the finished walls, taking into account blocks, mortar and masonry mesh, units of measurement are kilograms;

- Wall thickness – the thickness of the finished wall including seams, units of measurement – millimeters;

- Number of rows including seams - the number of rows is given without taking into account the gables, depends on the overall dimensions of the selected block and the thickness of the mortar in the masonry, units of measurement - pieces;

- Quantity of masonry mesh - the total amount of masonry mesh used to strengthen the structure being built, units of measurement are meters;

- The optimal height of the walls is the height of the walls, excluding the gables, which is obtained when laying blocks, the selected size and thickness of the mortar in the masonry, units of measurement are meters;

- Load on the foundation from the walls - this parameter is necessary for choosing a foundation. Given without taking into account the weight of the floors and roof.

What to pay attention to

Cement and sand are cheaper than special glue for foam blocks, but:

- It is not economically feasible to use a cement-sand mixture solution since its consumption is 4 times greater than that of glue;

- The compressive and bending strength of the masonry will improve when using an adhesive mixture.

- the use of an adhesive mixture is more effective if the blocks have a groove-ridge.

Since the foam block is a fragile material, special anchors and self-tapping dowels for foam blocks are used for hanging.