Preparatory stage

As a rule, paving is carried out at the stage of site improvement, upon completion of construction of a house and other capital projects. Considering that blind areas, paths, recreation areas and parking are not only functional, but also decorative elements of landscape design, preparation for paving is carried out at the design stage. Ideally, a full-fledged landscape design project is developed, based on the characteristics of the site (soil type, topography, groundwater level, etc.). And based on the chosen style of design of the yard, taking into account the expected loads and paving conditions, the thickness of the tiles, the design of the paths, and the shape and “pattern” of the installation are selected.

As with the construction of any structures, be it a permanent house, a seasonal dacha, a utility block, a garage or a gazebo, when landscaping a yard in general and paving in particular, you need a project, at least at the level of visualization in the editor or a sketch by hand. For those who prefer to do it on their own, manufacturers offer a universal “memo”.

Roman ChizhovChief technologist of the Steingot plant

Before you start laying tiles, the following preparations must be carried out:

- The geology of the site is determined: heaving and bearing capacity of the soil, freezing depth, height of groundwater. Based on the results, the optimal paving design is selected (laying depth, composition of the pie).

- The load is determined: the thickness of the tiles, the depth of the base and the composition of the preparation layers depend on the trafficability and the expected load.

- The paving is marked according to the project, to calculate the number of consumables: squaring of tiles with an allowance of 5% for scraps, volume of crushed stone and sand, amount of geotextiles.

- Calculations are made of the number of consumables for paving, as well as related elements: curbs, storm drainage trays, etc.

The nuances of constructing a base for paving

Vibration-pressed tiles are considered the optimal material for paving, as they combine high decorative properties with versatility, practicality and durability. But even the most durable and reliable tile will “work” flawlessly only if the base is properly prepared. There are two main paving technologies:

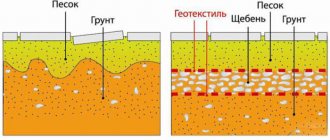

- On a permeable base - a layer-by-layer “cushion” of sand and crushed stone with geotextiles to separate the layers.

- On an impermeable base - reinforced concrete preparation.

In the segment of private suburban housing construction, when the yard is not a parking lot for heavy trucks and the load is limited to pedestrians and passenger vehicles, paving is most often done on a permeable base. The technology allows you to do without labor-intensive and expensive concreting with the installation of a reinforcement cage and is suitable even for difficult soils.

Victor292FORUMHOUSE Member

I’m going to plan the site, and accordingly make paths, driveways, etc. The soil is clay, it moves back and forth depending on the time of year. Please tell me what nuances we should strictly pay attention to when preparing the base for paths and blind areas? How to properly make a foundation for such soils.

Roman ChizhovChief technologist

The basic rule is to replace heaving soil with non-heaving materials: crushed stone and sand. To correctly calculate the foundation and type of materials, you need to invite a specialist who will accurately determine the type of soil on your site and prepare the most suitable solution for your conditions, including the installation of a drainage system.

On heaving soils with high groundwater level, storm sewerage is often not enough to effectively drain water from the site and prevent stagnation and seasonal deformation of paths. It is necessary to install not only a foundation, but also a radial (to drain the area) drainage system, including laying drains at the base of the paths.

As for the concrete base, which was once considered the only option, especially for paving parking lots, today it is practically not used.

MelodySweetFORUMHOUSE Member

We searched through a bunch of information, but did not find a clear answer. The question is the following - on an area of 35 square meters. m need to lay paving slabs under the car parking area (not permanent, only on weekends). Which is the best way to lay tiles - on sand or on concrete? Have you heard that tiles are laid on a sand bed only under garden paths, and with pouring concrete - for cars. Is it so? Now this area is just dirt. I would be grateful for your answer.

Roman ChizhovChief technologist

Sand itself cannot serve as the only base layer for paving slabs - it is the topmost layer, under which there are others: geotextiles, crushed stone. Even if there is already a ready-made concrete base, there should still be compacted sand between it and the tiles. According to all current standards, the underlying layer under paving slabs must consist of crushed stone and sand. Depending on the type of soil and loads, the number of layers, their thickness and composition are calculated. An important requirement is that the base must allow water to pass through well. A concrete base does not meet this requirement.

However, many people still do it the old fashioned way by first pouring concrete and then wondering what’s next.

Sergey23rusForumHouse Member

Please tell me how to properly lay paving slabs on a concrete base? Do you also need a layer of crushed stone/sand or can you do without it? And if it is needed, then what thickness?

Roman ChizhovChief technologist

If you already have a ready-made base and the tiles will have to be laid on it, then crushed stone is not needed. A layer of sand of no more than 5 cm will be sufficient. It is important to provide for effective drainage of water from the concrete base: at a minimum, a slope angle of at least 1 cm must be maintained for each meter of surface, and drainage holes must be made to the ground in the base itself.

Which base device to choose for paving slabs

The laying sheet is made up of several materials, which together form the underlying layer. These materials are laid one after another on the prepared soil surface, subjected to sequential compaction. The base consists of components such as sand, crushed stone, screenings, cement-sand mixture, etc. Substrate layer

required for:

- Preventing deformation of the paving stones due to soil movement due to seasonal changes and natural influences;

- Decorative design of the territory by leveling the soil surface and raising it to the desired level.

Underlay pillow

includes:

- Natural soil;

- A layer of crushed stone up to 25 cm thick, fractions 5-20 and 20-40 can be used;

- A layer of quarry sand up to 10 cm thick (no larger than 2.5 mm, can be replaced with the material remaining after sifting);

- A layer of granite screenings up to 3 cm thick (or a cement-sand mixture);

- The tiles can be used both vibro-cast and vibro-pressed.

Depending on the loads and location of the base, various technologies

his preparation.

First option

used on moving natural soil, it causes a lot of problems with the coating. Used in areas where heavy vehicles and trucks move. In this case, to make the underlying layer, cement mortar is used (layed in a layer of 3 cm) and reinforced concrete (layer no more than 10-15 cm).

Second option

used for paving in situations with more favorable natural soil. It is also suitable for roads where passenger vehicles are expected to travel. The underlying layer is made of a cement-sand mixture up to 3 cm thick, then sand or screenings (10 cm) are laid out, and then crushed stone in a layer of up to 20 cm.

Third option

Suitable only for footpaths with stable ground. For its base, pour a 3 cm layer of cement-sand mixture, sand (10 cm) and crushed stone (10 cm).

The choice of methods will depend on the requirements

the owner of the future paving slabs. When using paving stones by pedestrians, there is no need to concrete the path. In this case, using concrete will be a waste of time and money. But it happens that the path itself is not intended for high-intensity use, but the clay soil has a tendency to significant subsidence. For such soils, option No. 2, intended for road use by passenger vehicles, is more suitable.

It is important to take into account all the nuances, so to choose a technology it is better to contact an experienced specialist. In addition, in addition to simple and understandable installation cases, there are also combined options, when several methods are used on the same object (for example, option No. 2 + No. 3). This combination helps to achieve not only the best result, but also makes spending more reasonable and thoughtful.

In addition to the three listed methods, there is another - cheaper - installation of paving slabs on sand or screenings

.

Conditions for

using this technology:

- High density of natural soil, the surface of the earth has been compacted over several decades;

- There is no danger of sand being washed away from under the paved path. To eliminate this possibility, the joints between the curbs on both sides are coated with a solution, and storm drains or drainage trays are installed on the solution.

If the right materials are initially selected, the technology for their installation and laying is fully followed, and your tiles are laid correctly, then they will serve you for a very long time, without requiring any repairs or special care.

Installation of a permeable base for paving with tiles

When installing a permeable base, you should also not “reinvent the wheel,” even on the advice of “experts.”

Ivan1985FORUMHOUSE Member

I have a question. I was planning to make paths on the site. I turned to specialists. One suggests doing it according to the following option: 30 cm. PGS, then PCS and tiles. The second offers the same option, only the PDS layer - look locally. The neighbor's foreman suggests putting 10-20 cm of sand on the seeded sand (he's had it using this technology for about five years - it's good, only grass sprouts here and there). Spent several hours on the forum. However, I don’t fully understand the logic behind the tile pillow:

- Why not really put 10-20 cm on the seeded sand - this will protect against swelling, drainage, and the tiles should not play, since the sand is compacted, and there is a border on the sides?

- in theory, if you just lay it on the ASG, then the tiles will play on the gravel;

- What is the purpose of the PDS - is it really for setting the tiles, there are reviews on the forum that just sand is enough, why pay more? Doesn't the PDS deteriorate over time?

I found an answer on the forum that crushed stone directs the vertical load into a horizontal one. That is, you need to understand that the tiles will not sag over time. PGS performs a similar function, one might think? Maybe just seeded sand is enough for a pedestrian path, but for a car to drive in?

There is a standard technology recommended by manufacturers.

Roman ChizhovChief technologist

None of the three proposed options corresponds to the recommendations of tile manufacturers and the paving rules recorded in the document STO 46505580-002-2020.

The composition of materials for the base is simple: crushed stone, sand, geotextiles. Fractions of crushed stone and sand, the number and thickness of layers are calculated based on the type of soil on your site and future loads. Neither PGS, nor even more so PDS are recommended for installing a base for tiles.

PCB in our country is still used more by tradition than by necessity, since it does not have any advantages in terms of load-bearing capacity, water permeability and service life. In addition, it is prohibited to sprinkle the seams with a cement-sand mixture when laying vibropressed tiles, as this leads to a change in color and provokes the appearance of efflorescence.

When preparing a permeable foundation, the main parameters are the excavation depth and the thickness of the preparation layers. They are selected based on geology and loads, but you can also use visual instructions.

Roman ChizhovChief technologist

When preparing the base for paving, the following recommendations must be strictly followed:

- Maintain a slope of 0.5 cm/1 m of the surface when installing each layer.

- Thoroughly compact each base layer using a vibrating plate; the finishing layer (tile) is compacted with a vibrating plate with a rubber shock-absorbing coating, 1 cm thick.

Advantages of using concrete for paving

Despite the higher cost of a concrete base, the prospect of preserving the paving stones in proper form for many years determines the customer’s choice.

Diagram of a concrete base for laying paving slabs

Before deciding whether to use it as a base for paving slabs, you need to understand what advantages the material provides compared to laying it on sand and crushed stone.

Characteristics of concrete:

- strength;

- density;

- plastic;

- waterproof;

- fire resistance.

Durability that increases over time

The material has the ability to resist loads without collapsing, which determines its high load-bearing capacity. This characteristic of concrete depends on many conditions: the activity of cement, the quality of the constituent elements - sand, crushed stone, gravel, water. Conditions also influence:

- kneading;

- transportation;

- styling;

- hardening;

- age of concrete.

Density

The basis of the indicator is the ratio of solid matter in the material and pores that are formed as a result of the penetration of air or water into the mixture. For example, a concrete density of 0.9 means that the mixture is 90% solid and 10% voids. The denser the mixture, the better. In this indicator, the crushed stone base is significantly inferior, since its density is lower.

Plastic

The concrete mixture is more mobile compared to the crushed stone-sand mixture. This factor determines the ability of concrete to fill the most inaccessible places during installation, the bends of structures, avoiding voids and cavities.

Water permeability

This is the ability of a material to pass water. In concrete it is small and can be reduced even further by adding modern technological additives and fillers.

Additive to concrete to improve water resistance

Water resistance depends on different conditions:

- age of the material;

- density;

- structures.

In this regard, the advantages of a crushed stone base can compete with a concrete base in the sense that moisture from crushed stone penetrates well into the soil. Moisture from the concrete will transfer into the tiles, which can lead to their rupture in winter. On the other hand, the tiles are laid on a cement-sand mixture, which protects it from moisture.

Fire resistance

Refers to the ability of a material to resist destruction under the influence of fire or high temperature. Concrete retains its properties at temperatures up to 250°.

Laying paving slabs on a concrete base

Laying vibropressed paving slabs

The final stage of paving is laying paving slabs (paving stones) on the prepared base according to the chosen pattern. Whether it will be a complex geometric pattern or an emphasis on the tile itself due to the original texture, shape and palette is determined when developing the project. Fortunately, for almost every collection there are several layout schemes used when paving different areas of the site.

It is advisable to carry out installation in dry, warm weather - precipitation and frost not only complicate the work, but also negatively affect its quality. The standard algorithm looks like this.

- The tiles are laid away from you, from the curb or edge, starting from the lowest point to the high one.

- The bulk of the collections require the presence of joint formers (rusts) on each tile, ensuring an even seam between the elements.

- When paving with tiles from the Color Mix series, stones are used simultaneously from several pallets.

- During the installation process, it is necessary to control the plane - for this purpose, they use both the simplest building level and a string on pegs, as well as high-tech laser levels. Rubber mallets are used for trimming.

- After laying, the seams are sprinkled with washed or quartz sand, alternating backfilling with compaction until completely filled.

- For final leveling after laying, use a vibrating plate with a rubber shock absorber (up to 200 kg, up to 20 kN). If the paving area is small, you can get by with a heavy rubber mallet. It is also worth replacing the vibrating plate with a mallet when choosing tiles without chamfers to avoid possible damage to the edges.

What can paving slabs be laid on?

What can paving slabs be laid on so that over time the coating retains its original appearance for a long time? The question is far from idle and requires a creative attitude. The fact is that there is no strict recommendation on how to equip the base (pie) for paving slabs. The composition of the pie will depend on the condition of the soil and the expected load on the paving surface. Although the material for the base of the path is quite well-known and includes sand, crushed stone, plywood and geotextiles, we’ll figure out in what case and in what sequence to lay it - we’ll figure it out in this article.

Content

- Causes of sidewalk destruction.

- Pie on normal soils.

- Foundation on clay soils.

- Pie composition on soft soils.

Reasons for the destruction of the sidewalk path

The main reason for the destruction of a sidewalk path is frost heaving of the soil under the patty or heaving of the sand cushion under the tiles. The thing is that no matter how low the air temperature is, the soil always remains “warmer” and, naturally, this leads to the formation of condensation, which, rising to the surface, destroys the pavement covering. That is, moisture freezes at the surface and tends to expand along with the coating.

Therefore, the main function of the composition of the base under the tile (pie) is to drain condensate back into the soil. The best option for removing moisture is gravel of various fractions, which has high capillarity. What about sand, why is it needed? Many people believe that sand also serves to drain condensate, but this is a mistaken opinion. Yes, water passes through sand, but due to its low capillarity, the process takes a long time and during this time the moisture turns into deep ice. The only role of sand in the pie is that it is convenient to lay paving slabs on it. That's all!

Another reason for the destruction of the sidewalk covering is poorly compacted soil onto which the components of the pie are poured. This must always be remembered: the soil, its composition, as well as compaction are the determining factors that influence the quality of the finish surface of the path.

Pie on normal soils

If you are going to lay a sidewalk path on normal soil, that is, in your area the groundwater is deep, the top layer of soil consists mainly of chernozem, then the composition of the pie is as follows:

- Gravel of fractions 10–15 with a layer thickness of 10–15 cm.

- Fine-grained sand 10 cm thick.

You can limit yourself to this, but if large gravel is laid (fractions 20–30), then you will need to lay geotextiles between the sand and gravel so that the sand does not go into the gravel.

Foundation on clay soils

Clay soil is distinguished by the fact that it has very low capillarity - it does not allow water to pass through well. Based on this, the composition of the cake should be such as to limit the flow of moisture into the clay as much as possible. The composition of the base can be as follows:

- The bottom is compacted clay.

- Then comes a layer of gravel.

- Layer of sand.

- The top layer of the cake is a prawn with a metal mesh.

If anyone doesn’t know what prancing is, let us explain. Gartsovka is a dry mixture of cement and sand, which turns into concrete at the first rain. And one more thing you need to take into account: in order for less moisture to get into the clay, the form of laying paving slabs should have a curvature on both sides so that water drains from the path.

Pie composition on soft soils

On soils that are oversaturated with moisture, on loam (a lot of clay and sand), sandy loam (a lot of sand), the composition of the cake for laying paving slabs should not only retain moisture, but also prevent the entire path from sagging. After all, at its core, the base itself for the tiles is a long beam, which under load can bend, sinking into soft soil. This can be avoided by laying geotextiles on the ground before the cake layer.

It must be remembered that geotextiles not only have filtering ability, but have sufficient tensile strength that will keep the entire layer of the cake from sagging.

The composition of the cake for weak soils looks like this:

- Geotextiles are laid at the bottom of the ditch.

- Then gravel.

- Layer of sand.

- Concrete base.

Let's sum it up

To make paving not only practical and durable, but also aesthetically pleasing, careful planning and design are required. Manufacturers recommend installing a permeable base not only for paths in pedestrian areas, but also for entrance areas and parking areas. This will save not only money, but also time and effort, without compromising the technical and operational characteristics of the coatings.

The outstanding characteristics of vibropressed tiles are due to the peculiarities of the production cycle. About the popular shapes and installation patterns - in the previous thematic material. In the video - planning a garden plot, advice from a landscaping engineer, in simple language.

Subscribe to our Telegram channelExclusive posts every week