In recent years, paving slabs have been taking away more and more space from asphalt. Roads, courtyards, garden paths, tiled, have a modern and at the same time pleasant appearance. In addition, unlike asphalt pavement, paving slabs do not harm the environment, do not create difficulties during installation, last a long time and are available in a variety of colors. This allows you to lay out a variety of patterns and ornaments on the paths. To bring a road composition project to life, you need to know the correct dimensions of paving slabs.

What determines the size and weight of paving slabs?

The specialized press and specialized advertising publications are filled with advertisements for the sale of paving slabs. Posters are placed on highways and roads leading from major cities to rural areas.

Prices and sizes of paving slabs have a wide range, since tiles are used for laying in courtyards, parking lots, and park paths (sometimes even good quality asphalt is removed to lay tiles). What is causing this rush of demand? The production of mainly small batches does not require the purchase of expensive equipment. The ease of production processes and the absence of the need to invest huge amounts of money attracts small investors and private firms. At the same time, there is impressive competition in the paving slab production segment, due to which entrepreneurs have to keep prices low to maintain their customer base: reduce production costs to maintain profitability, purchase new equipment and technologies, produce more and more new types and types of paving slabs , including concrete. For a variety of reasons, new methods are chosen mainly by large enterprises, while small firms and individual entrepreneurs most often take other paths.

Paving slabs have a number of advantages:

- High quality;

- Easy to install and maintain in good condition. A damaged element is very easy to replace;

- Presentable appearance;

- A variety of types of paving slabs in size, color, pattern and texture.

There are two main methods for producing paving slabs: vibrocompression (including the most advanced technology - hyperpressing) and vibration casting.

The vibratory casting method involves filling special forms with concrete mass located on a vibrating table. Oscillations lead to compaction of the mass and its uniform distribution in shape. After the mass hardens, the mold is removed. To speed up the process, special warm solutions and heat chambers are used, which reduce the hardening time of the mixture. However, all this leads to increased production costs.

The vibropressing method involves the use of a special semi-dry mass that has a very low water content. This mass is filled into the molds of a vibrating press. Due to pressure and vibration, the mass quickly compacts, and the molds are sent to a heat chamber with elevated temperature and humidity. There the tiles acquire special strength. This method is characterized by increased productivity, since all its stages are automated.

The hyperpressing method is distinguished only by the components of the mass for the form - minerals are included in it. The humidity of the mass does not exceed 10%, and the pressure rises to 20 MPa.

Vibro-cast tiles are considered more attractive to consumers in terms of appearance: they have a glossy finish and allow for a variety of color options. However, when choosing tiles, in addition to attractiveness, it is worth paying attention to such criteria as standard size and reliability in operation. The latter characteristic is more consistent with tiles made by vibration pressing.

What sizes of paving slabs are used in installation

Any type of paving slabs has dimensions that meet the requirements of state standards (GOST). When selecting a coating, it is very important to choose a standard size of paving slabs so that during the installation process there are no problems with joining the pattern - neither during normal installation, nor when creating complex patterns and ornaments.

The following types of paving slabs have dimensions:

- "Clover": 295x295 mm.

- “Brick”: 100x200 mm.

- “Reel”: 200x168 mm.

- “Turtle”: 300x300 mm.

- “Well”: 300x300 mm.

- "Florida": 300 x 300 mm.

- "California": 300 x 300 mm.

- “Checkers”: 300x300 mm.

- “Square”: 500 x 500 mm.

- "Four": 300x300 mm.

- "Eight": 400x400 mm.

- “Old Town”: 120x90 mm, 120x120 mm, 120x180 mm.

- “Pavement”: 140x70 mm, 140x140 mm, 210x140 mm.

In addition, paving slabs vary in thickness. Pedestrian paths and sidewalks that bear light loads can be covered with tiles 3 centimeters thick, but for areas with more significant loads, five-centimeter models should be used. Walking areas must be covered with tiles 5-6 centimeters thick; for an access road or parking lot, you should choose tiles of the greatest thickness.

GOST sets the following standards for tile thickness:

- 3 cm – “Clover”, “California”, “Well”, “Florida”, “Turtle”, “Four”, “Checkers”;

- 5 cm – “Figure Eight”;

- 6 cm – “Old Town”, “Brick”;

- 7 cm – “Square”;

- 8 cm – “Reel”, “Brick”, “Pavement”.

Sometimes models with a thickness of only two centimeters and samples of increased strength are used - up to 10 centimeters.

Types of paving slabs

According to the manufacturing method, paving slabs are:

- vibropressed. It is produced by pouring the mixture into a mold, followed by vibration under pressure. This type of tile produces straight lines with a rough surface. Most often, such paving stones are used for paving city streets, squares, sidewalks in public places;

Vibropressed tiles.

- vibratory casting. The tiles are made from concrete mortar with plastic compounds, poured into vibroforms. The resulting paving stones are more durable, have a perfectly flat surface, and can be produced in various shapes. It is most often used in private construction, when paving walkways near houses.

Vibrocast tiles.

Paving slabs also differ in their design: color, shape and size. This makes it easy to choose the best option for any architectural solution.

Available and most purchased sizes of paving slabs

Tiles size 100*100 mm

Despite the relatively small size, this type of paving slabs is practically the most popular. This is no coincidence: tiles of this format are common “Paving stones”. Paving slabs “Paving stones” have a thickness of 3 to 10 centimeters and a weight of one and a half to three kilograms.

When choosing such paving slabs, remember that they are produced by vibration casting, so their thickness cannot be more than six centimeters. Thick tiles are made using vibration pressing.

The use of tiles of greater thickness is rational only if cars will drive into the area with such a coating - they will not cause any harm. Also, vibropressed paving stones are not affected by salts and other de-icing agents that are used to pave roads. This property makes vibropressed tiles suitable for covering car parks.

Tiles sizes 250*250 mm and 300*300 mm

Tiles of this size have an optimal width-to-weight ratio. The most popular types of tiles are “Parquet”, “Tuchka”, “Gossamer”, “Fantasy”, “Sicily”, “California”, “Grid”, “Circle” and “Flower”. They are suitable for covering almost any area. Typically, these tiles are quite thin and light in weight, making them cost-effective to ship. At the same time, it does not deform under the wheels of cars if it is not impacted too often. However, if such tiles are laid on a dry mix coating, they will be able to withstand a greater load.

Tiles size 400*400 mm

Tiles of this size are also used quite often. The following types are considered the most popular: “Openwork”, “Fresco”, “Shagreen”, “Eight Bricks”, etc. Such tiles have one important advantage: they do not visually narrow the paths covered with them, and no matter how they were made laid out in one or two rows. It is worth noting that if the tiles are laid in two rows with borders along the edges, the width of the path will be exactly one meter. According to most experts, this size is the most preferable.

Paths with a pattern of tiles imitating wooden boards look very attractive. These tiles are so close to the pattern of real wood that it seems as if the yard is decorated with natural covering.

Tiles size 500*500 mm

These paving slabs are suitable for laying in parking lots and garden paths. Its main advantage is that even when laid in one row, it forms a path along which a person can calmly walk. In addition, laying tiles in this way can be done very quickly, which will save materials, time and money. Considering these advantages, it is worth giving preference to such tiles when covering the area around the building.

However, such tiles also have some disadvantages. The main ones are heavy weight and fragility. One tile of this size weighs about 28 kilograms, and special care must be taken when transporting it, as the tiles easily break.

In order for this tile to last as long as possible and not crack, it must be laid exclusively on a reliable, well-made coating. It is especially important to follow this rule if you are laying out a path along which cars drive. Without a reliable foundation, the tiles will not withstand heavy loads.

Monolithic coatings

Paving slabs for monolithic products reach a thickness of 70 mm or more - depending on the upcoming tasks. This product has a high price, which corresponds to the cost of installation.

The coating is suitable for mass parking, locations where trucks regularly pass through, and for many other areas whose operation involves heavy loads. Such tiles fully justify their cost, as they perform their functions remarkably well under any circumstances.

Paving slabs of large and small sizes: pros and cons

On pedestrian paths and garden plots, you should not lay large and small tiles at the same time. Which tile should you choose? It is difficult to give an unambiguous answer to such a question. Therefore, we will talk about the advantages of each tile size separately.

Laying large-sized paving slabs (30*30 or 30*40 centimeters) is easier than laying small ones. In addition, with the right choice of pattern and texture, such tiles will emphasize the beauty of the area on which they are laid and hide its shortcomings.

Large tiles are produced for laying on large-scale areas: central parks and city squares, monuments and monuments, as well as other large projects.

Experts are confident that large tiles in relatively small areas of local areas cannot produce the desired aesthetic effect. In addition, they do not recommend this coating for DIY installation.

Large paving slabs, which can be purchased wholesale and retail, require special knowledge and skills from the installer, because the slightest flaws made during installation will be visible in the area covered with such tiles.

Do not forget that large-format coatings are subject to mechanical damage, and it is often very difficult to restore cracked tiles so that no traces of repair are visible.

What are the advantages of small format tiles?

Small sizes of paving slabs are the most popular and make up the largest share of the total sales of materials for arranging country and garden plots.

The modern market offers a large assortment of vibration-cast slabs of various shapes, textures and colors, thanks to which designers can use the decorative advantages of small format slabs with maximum benefit:

- Small-format tiles can also be produced using the vibration-pressed method. The largest part of such coverings offered for sale is the famous “Paving stones”, which is a good alternative to expensive natural coverings;

- Small format tiles give scope to the designer’s imagination when creating various patterns, ornaments, mosaics, and aesthetically attractive arrangement of roadsides and playgrounds. While laying small tiles, you can acquire basic installation skills, because this coating is less demanding in terms of strict adherence to horizontal and vertical laying planes;

- Small tiles withstand increased loads well, and damaged tiles can be easily replaced or repaired with full restoration of the aesthetic functions of the tiled structure.

Experts know that excessive brightness and flashiness of the tile or the wrong color scheme can ruin the entire impression of the coating. Therefore, when arranging your site, you can use a ready-made project from a famous designer.

Dimensions of borders for paving slabs

The main functions of the curb are to separate the sidewalk from the road and strengthen the boundaries of tiled paths. The sizes of sidewalk curbs vary; they are selected separately for each location: the structures are used to fence paths for pedestrians and cyclists, change the height of the path relative to the lawn, and prevent the spread of grass.

Advantages of borders:

- Reliability;

- Clean surface;

- Attractive geometric shape;

- A variety of colors, thanks to which borders do not require additional color coating.

The variety of shapes and sizes of borders presented on the modern building materials market meets the most demanding tastes. Today, enterprises produce the following types of products:

Curbs for paths:

- 500x210x35 mm;

- 500x210x45 mm;

Park blocks:

- 500x211x70 mm

Road fencing structures:

- 3000x600x200 mm.

The price of borders varies from 60 to 270 rubles per piece.

Some Russian companies produce universal fences for sidewalks and paths using the vibration casting method. Their standard parameters are 475x200x50 mm. If the customer presents the appropriate requirements, fiberglass can serve as a reinforcing material for such a border. The cost of the design will range from 70 to 140 rubles, depending on the volume of purchase.

Curbs are most often made in a rectangular shape with a length of no more than one meter. For fencing sidewalks, curbs are produced with a height of 30 centimeters and a width of 15 to 20 centimeters. Park paths are framed with lightweight curb stones measuring 20x8 centimeters.

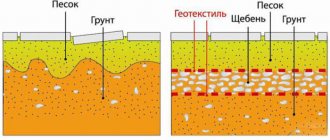

The main parameter influencing the choice of curb is the type of soil on which the installation is made. When laying small borders, it is necessary to prepare the base in advance. Sometimes a concrete solution is used for this, which significantly increases the strength of the structure.

Paving slabs and paving stones. Variety of forms

The size of the tile also determines its consumption. Depending on its length and width, experts calculate the number of blocks required to create a path or area of the required size.

Today there are hundreds of options for tiles and paving stones on the market, all of them differ in their sizes. Although, in this market, there are some standards. Let's look at them in more detail:

- Square , with identical edges 30x30, 35x35 or 40x40 cm. Larger blocks (50x50 cm in size and above) are rarely used in summer cottages. They are mainly used for paving large areas with tiles;

- Rectangular . They resemble a brick in shape. As a rule, they have side dimensions of 20x10 and 25x12.5 cm. Although other formats may come across;

- Figured blocks are available in various lengths and widths. The most common sizes of paving slabs are: 20x16, 12x18, 12x19 cm, and equilateral 29.5x29.5x29.5 cm.

All types of tiles are suitable for arranging garden paths. However, if you are planning to buy paving stones for paving a parking lot or driveway, it is better to choose blocks of greater thickness and small size. As practice has shown, such surfaces are more durable under high loads.