Cost of parking made of paving slabs

Any paving slab coating absorbs vertical load and transfers it to the underlying layers of the base. The cost of parking for a car made of paving stones is formed from the cost of the tiled covering itself and the preparation of the base. We recommend two types as a base for a car platform:

- Sand and gravel base (sand 15 cm + crushed stone 15 cm).

- Concrete base (reinforced concrete 15 cm + crushed stone 15 cm + sand 15 cm).

The design features of each type of base are described below in the “Technologies” section. Our engineer gives specific recommendations on the choice of foundation when inspecting the site. He takes measurements, on the basis of which an estimate is prepared for constructing a parking lot from paving slabs. Prices for laying a platform of paving slabs for a car with an area of at least 50 square meters. m. are shown in the table below:

Parking lot made of paving stones on a sand and gravel base

| Types of jobs | Price, rubles | Units |

| measuring/drawing up a project | 3000 | oper. |

| parking lot markings on the site | 55 | sq. m. |

| digging a pit for a future parking lot | 1100 | cube m. |

| installation of a sand base with a 15 cm layer of tamper | 825 | sq. m. |

| installation of side stone | 600 | linear m. |

| laying geotextiles | 30 | sq. m. |

| filling of crushed stone with a layer of 15 cm with compaction | 825 | sq. m. |

| production of a leveling layer from a cement-sand mixture (gartzovka) 3-4 cm | 220 | sq. m. |

| paving stones | 900 | sq. m. |

| filling seams | 50 | sq. m. |

Minimum order quantity 30 m2

Parking lot made of paving stones on a concrete base

| Types of jobs | Price, rubles | Units |

| measuring/drawing up a project | 3000 | oper. |

| parking lot markings on the site | 55 | sq. m. |

| digging a pit for a future parking lot | 1100 | cube m. |

| installation of a sand base with a 15 cm tamper | 825 | sq. m. |

| laying geotextiles | 30 | sq. m. |

| filling of crushed stone with a layer of 15 cm with compaction | 825 | sq. m. |

| placing formwork | 385 | linear m. |

| knitting reinforcement mesh | 550 | sq. m. |

| pouring a 15 cm concrete slab using a vibrating screed | 1035 | sq. m. |

| coating of concrete with a protective (hydrophobic) composition | 55 | sq. m. |

| paving paving stones on a leveling layer of paving stones | 900 | sq. m. |

| production of a leveling layer from a cement-sand mixture (gartzovka) 3-4 cm | 220 | sq. m. |

| fixing the outermost row of paving stones with mortar | 175 | linear m. |

| filling seams | 50 | sq. m. |

Prices for parking tiles depend on the area of work. They can be clarified by calling the phone number listed on the website.

Calculate cost Order service

Paving slab laying technology

Paving paving slabs consists of performing a number of stages, following the order of which, the work is carried out with your own hands:

Parking lot laying methods

The service life and reliability of the surface depend 90% on the correct adherence to the technology for laying paving slabs under a car and the preparation of layers.

Attention! Remember that the first cause of destruction of coatings is considered to be water and temperature fluctuations.

Paving slabs can be laid in one of the selected ways:

Tools

To lay a tile platform, the following tools are required:

Excavation work, planning, marking

After this, the top layer of earth, which is 300-350 mm, is removed from the marked area. If the site is large, then in order not to do it yourself, they hire a backhoe loader for the work, which will easily and accurately remove the soil and move it to the right place. At this stage, you can provide a slope for water outflow, which is 5 mm per meter.

A 20-30 mm layer of sand is poured onto the bottom, which is compacted with a construction tamping machine (vibrating plate). Geotextiles are spread on top: the strips of the fabric overlap by 100 mm, the sidewalls are turned up by 250 mm.

Attention! The geotextile layer protects against the germination of weeds, the spring rise in groundwater levels, and provides a beautiful appearance to the surface.

Filling the drainage layer, installing the curb

Afterwards, crushed stone is poured onto the canvas, and fine gravel is evenly distributed on top. The entire amount of the drainage layer is compacted. The height of the layer is 20 cm. Additionally, a masonry mesh is sometimes laid under the layer of sand.

Before laying the tiles, you must first install the curb stone. Where vehicles move, they are secured so that they are not damaged in case of an accidental collision. When installing, you should pay attention that the curb rises a maximum of 14 cm above the surface of the sidewalk, otherwise the car bumper will be damaged.

Curb elements are laid on both sides of the driveway and parking lot. It is economical to use concrete material of size 100 × 30 × 15 with a weight of 100 kg. The curb area is equal to the perimeter of the parking lot and twice the length of the driveway.

It is mounted on a concrete base. At the installation site, crushed stone is raked, concrete is laid at a depth of 5 cm, and then a curb is laid. The elevation above the curb is 5 cm. The 5 mm gap between curb stones is filled with cement-sand mortar.

Concrete screed

A sand cushion 70 mm thick is poured over the drainage layer. The layer is filled with water and compacted. Then the next layer of 70 mm thick CPS is poured. The layer is made with a slope away from the buildings.

The next layer is a mixture of cement and sand: 4 parts sand, 1 part cement, which is leveled using the rule. This composition is sufficient to fix paving slabs and prevent the base under the paving slabs from moving under the load of passenger vehicles. Large areas of paving slabs can be reinforced with mesh.

Before and after laying tiles under a car

By moving the slider to the sides, you can evaluate how the area has changed after parking for a car was installed on it. By clicking the “right” and “left” arrows, you can see different parking options at your dacha.

Base for tiles for a car park in a country house

According to building regulations and our many years of experience, the optimal and reliable solutions for parking bases are:

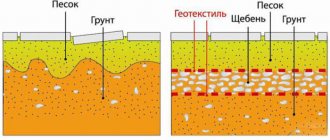

1. Sand and gravel base for tiles.

This is a lightweight, non-rigid structure, which is often used in areas that do not require winter parking.

Fast in construction; laying is possible immediately after filling.

Possibility of year-round construction.

It is not rigid, and therefore susceptible to the formation of ruts over time, especially in the spring.

It is necessary to install curbstones around the perimeter to hold the paving slabs.

Device technology:

- Excavation of soil to a depth of 40 cm.

- Laying geotextiles with a density of at least 200 g/m2.

- Filling and compacting sand with a layer of 15 cm.

- Optional - another layer of geotextile.

- Filling and compaction of crushed stone with a layer of 15 cm.

2. Reinforced concrete base for tiles.

This is a reinforced slab on which paving slabs are laid. Usually arranged for year-round check-in and parking of equipment.

Rugs do not form even under trucks.

No side stone installation required.

Laying tiles is possible no earlier than 28 days after pouring concrete.

Device technology:

As for sand and gravel base +

- laying the film in 2 layers;

- laying out reinforcement and knitting mesh from AIII reinforcement with a diameter of 10 mm;

- installation of formwork from boards 150×40 mm;

- acceptance of concrete and compaction of concrete.

Paving paving slabs for parking

If the tiles are laid on a sand and gravel base, then curb stones are installed during its preparation. Next, paving slabs are laid on the prepared base. The recommended thickness of tiles for parking passenger vehicles is 6 cm, and for trucks - 8 cm. Paving is done over a layer of cement-sand mixture, which varies from 2 to 5 cm.

The paving surface must be dry, so work is carried out during periods when there is no constant precipitation. The products are laid as closely as possible to each other, checking their height position with a building level. Leveling the tiles is done using a rubber hammer. The final upsetting is carried out using a vibrating plate with a rubber mat.

When laying tiles on a reinforced concrete base, the outer rows are fixed with cement mortar. Immediately after paving, the surface of the machine area is sprinkled with dry sand; it is recommended to repeat the operation until the sand stops settling in the seams.

How to choose paving slabs for car parking: useful recommendations

Not only a clean area, but also neatly laid paving slabs for parking a car can give a parking lot a well-groomed appearance. They often resort to this particular parking option because it has clear advantages:

- long service life;

- visual appeal;

- significant cross-country ability;

- simple exposure to cleaning procedures.

The use of paving slabs is justified both in the courtyard of your home and in service parking lots. And thanks to the variety of appearance of such coverage, you can make the parking lot visually attractive and aesthetically pleasing.

To achieve this result, you need to approach the selection process wisely. You can do this yourself, having previously studied useful information, or you can ask specialists how to select and lay paving slabs https://alfaplitvrn.ru/. If everything is done correctly, parking will be very practical and attractive.

Timing for laying parking tiles

It is better to carry out work on paving a parking lot with paving slabs in dry weather when the outside air temperature is above zero degrees. We usually start constructing a paving stone platform for a car at the end of April and carry it out until the first frost in November. In other months, work is complicated by freezing of bulk materials.

We complete a standard 4 by 6 meter parking lot on a sand and gravel base in 3 working days, including laying the tiles. If the base is reinforced concrete, then the preparation time for the base is 4-5 days. This is followed by a technological break of 28 days for the concrete to gain strength. Laying tiles on a concrete parking lot up to 50 sq. meters takes no more than two days.

Car styling

Let us describe the installation process on a crushed stone-sand bed. Laying paving slabs under the car will be carried out in the following sequence:

- Cleaning and marking work is carried out;

- A recess is dug along the entire marked perimeter with an approximate height of 30 cm;

- The bottom of the “pit” is leveled and compacted;

- A curb stone is installed (when choosing a specific type of pillow, its presence is mandatory - it will prevent the modules from spreading);

- Large crushed stone is poured in and also compacted;

- A layer of coarse sand about 5 cm high is created on top;

- The last ball of the base is covered with fine sand (it can be mixed in a ratio of 6 to 1 with cement to further strengthen the road surface);

- An artificial stone is installed on a leveled base, leveling it using a level (it is also worth focusing on the “beacons” installed in advance);

- The gaps between the elements should be within 4-5 mm (for evenness, use plastic crosses);

- The seams are rubbed with sand or its mixture with cement in the above proportions.

If you have problematic soil, be sure to use geotextiles, or better yet, order - the TURNKEY price will certainly please you.

As you can see, laying paving slabs under a car with your own hands is quite simple.

Frequently asked questions about paving slab parking

1) How to choose a base for parking from paving slabs?

Answer

If you plan to use the parking lot all year round, we recommend a reinforced concrete base. Next, you should proceed from your budget capabilities.

2) Is it possible to save money and lay 4 cm thick tiles on a concrete base?

Answer

No manufacturer recommends doing this, because the tiles may burst under the wheels of a car.

3) Which tile is better to choose for paving a parking lot in a country house?

Answer

We recommend using large or “Star” vibropressed paving slabs. Unlike cheaper vibrocast tiles, pressed tiles always have the correct geometric dimensions and do not create problems during installation.

What are the requirements for paving slabs under a car?

It is difficult to imagine a garden area without paving stones. The advantages listed in the introduction really make this material more and more popular, and the price becomes more affordable over time. But if everything is clear with the technology of laying paving slabs in the country, then what to do in situations where increased strength of the product is required? And what general requirements should be applied to such paving stones? Here are the key points:

Among people who have little understanding of installation technologies, there is an opinion that installing a product under a car is not much more complicated than laying out a garden path or a blind area from paving slabs. But that's not true. The process must be supervised by a professional who will accompany you at all stages and give practical advice. will help you not only buy material from the manufacturer, but also provide comprehensive services.