Requirements for road surfaces for vehicle passage

Features of laying paving slabs for possible passage and parking of a car are associated with a large weight impact on the paved surface. In this regard, they are subject to the following requirements, compliance with which is mandatory:

- the coating must be stable and not move under heavy weight pressure;

- the surface should be smooth and dense, without loose seams between the tiles;

- the base of the road surface must be made very dense, without air voids between the components;

- the mandatory presence of a drainage drainage layer, since water can affect the strength of the base;

- use of paving slabs of increased strength and frost resistance;

- installation of stone border fencing.

In order to prevent subsidence and destruction of the coating, it is necessary to apply reinforced base technology and use materials of increased strength.

Difficulties that may arise

Experts recommend that when laying paving slabs in a garage, take into account how often the room is used and what work is planned to be performed in it. For example, if a car owner washes a car in a garage, then the tiles must be laid at an angle towards the gate so that water subsequently drains and dampness does not accumulate.

Also, in order to avoid any distortions, it is recommended to start laying the tiles, focusing on the goal line, but it does not matter from which corner the installation of the material begins. Property owners rarely encounter any difficulties during the process of laying paving slabs. The main thing is that when leveling it, you should not make too much effort when striking. Otherwise, the material may enter the sand mixture too deeply, and then other elements will have to be laid in the same way.

Selection of required materials

Manufacturers of building materials offer clinker and vibropressed paving slabs on the market. The first type of materials is distinguished by bright, rich colors and a variety of shapes. Tiles made by vibration pressing are more modest in appearance, but have increased strength and frost resistance.

If the weight of the car does not exceed 1 ton, then clinker paving slabs can be used for laying. In the case when the weight of the machine is over 1000 kg, then you are better off opting for pressed products. The thickness of the tiles must be at least 60 mm.

When buying tiles, ask the seller to show a cut sample from the batch being sold. He is obliged to do this, and if he refuses, then simply do not buy such a product. The cut should have a uniform density and should not contain any foreign inclusions. Their presence indicates the low quality of the material.

We won’t talk about the importance of appearance, but checking the tiles for abrasion is easy. Take 2 stones and rub them together face to face. Look at the result: if the surfaces remain the same, then the material is good, otherwise it is better not to take such a tile.

Features of materials

In order to lay out a platform of paving slabs in order to create a neat parking space, you need to pay special attention to the materials used; for this purpose you will need:

- Sand. Used for laying in several layers: as a primary substrate and for a cushion into which the tiles are compacted. Ideally, you should take river sand after washing with a particle size modulus of no more than 2 millimeters.

- Crushed stone. Used as a substrate to ensure water outflow and uniform load distribution, the average fraction is 30-40 mm.

- Gravel. This material is laid on top of crushed stone and fills smaller voids. Performs almost the same function. The crumb size should not exceed 25 mm.

- Cement. Used for preparing concrete to strengthen the boundaries of the site. The optimal brand is M500. Cement is also used to strengthen the fixing layer of sand.

- Geotextiles. This fabric, made of high-strength synthetic threads, does not rot and helps strengthen the site, increasing its resistance to stress, evenly distributes the mass, and prevents sand from being washed out.

- Paving slabs. The main external element of the parking area must have increased strength and abrasion resistance, as well as thermal stability, especially to low temperatures.

Paving slabs for a car must have increased strength

Marking and excavation work

Preparation and marking using pegs and cord.

Laying paving slabs under a car begins with marking the area intended for paving. The width of the road should be at least 2.2 meters, and the parking area should be at your discretion. Car access to the house can be arranged close to the pedestrian path. Pegs, a strong cord and a tape measure are used for marking and measuring. The distance between the pegs should ensure good tension on the cord.

After this, in accordance with the marked contours, the top layer of soil is removed to a depth of 30-35 cm. If the area is large, then it makes sense to hire a backhoe loader to do this work. He will be able to carefully remove the fertile layer and transport it to the storage location or scatter it in the right place.

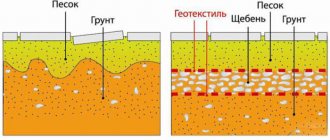

Schematic options for bases for laying paving slabs.

The bottom of the resulting trench should be sprinkled with sand in a layer of 2-3 cm and compacted well using a construction tamping machine or vibrating plate. Geotextiles should be spread over the compacted sand so that adjacent sheets overlap by 8-10 cm, and the sidewalls are turned up by 20-25 cm.

This layer will prevent weeds from growing through the base and will keep the coating looking beautiful for a long time. In addition, it will stop the possible rise of groundwater in the spring.

Which garage floors are better?

In general, there are three types of floors made in garages:

Earthen ones. The cheapest option, but with a lot of disadvantages

It’s just compacted soil – “native” or imported – it doesn’t matter. There is no other coverage. Concrete

It is very durable and reliable, but requires significant costs and a significant amount of time for its arrangement: sand and gravel backfill, waterproofing, and, if desired, insulation, reinforcement, and a rough screed are required, on top of which a finishing coating is applied. It can be different: finishing screed; floor tiles or porcelain stoneware; self-leveling floors, including polymer ones; rubber floors (rolls, slabs or crumbs);

wooden (stationary or ladders).

Wooden. This option is good because it regulates humidity; a garage with wooden floors is warmer than one with concrete or earthen floors. Disadvantages: fragility, tendency to rot, high absorbency. Paving slabs. As one of the options for a “cold” floor. Paving slab floors in a garage are durable, easy to repair, neat and practical.

As you can see, there aren't many options. Let's look at their advantages and disadvantages in more detail.

Advantages and disadvantages

Earthen floors in a garage are very simple to install, require virtually no material investment, and you can replace a damaged section of the earthen floor at any time. These are, perhaps, all the advantages. The downsides are more serious:

- in dry weather they get dusty, in rainy weather they get wet;

- spills can only be removed by replacing part of the coating;

- cold, no possibility of insulation;

A dirt floor in a garage can be made as a temporary option or as a base for wood. Such floors can be found in garages at dachas, where the car is located for a very short period of time. In major garages, they still make a more solid foundation.

Garage floor made of paving slabs

A garage floor made of paving slabs can be considered as one of the earthen floor options. It's just more practical. There are more layers when constructing it, as well as more money is required for its installation - more crushed stone and sand are poured onto the ground, into which the tiles are laid. But the functionality of this option is much higher. Disadvantages - possible increased humidity, and if the sand and gravel cushion is insufficiently compacted, the floor may “sag” in places of greatest stress, and if the quality of the tiles is low, it can be destroyed under the influence of aggressive substances, of which there is more than enough in the garage. Another minus is that dirt gets stuck in the seams, it’s not easy to clean, and the problem of absorption remains: paving slabs are hygroscopic.

Not everyone is happy with a wooden garage floor because it is a fire hazard and prone to rot. Although, if the groundwater is low and the floor is made correctly, it will not rot. Fire hazards can be combated by impregnating the boards with fire retardants - agents that reduce the flammability of wood. But these are not all shortcomings. It’s also not very pleasing that the boards absorb dirt and spilled liquids, which do not have the most pleasant smell. A wooden garage floor looks very untidy, and there is no way to remove all of the wood fibers.

Wooden floor with expanded clay backfill

The advantages of wooden floors include the fact that they are warmer than the other two options. In addition, when installing a plank floor in a garage on joists, the gap between them can be filled/filled with thermal insulation materials, which will make it even warmer. It’s difficult to talk about the price: in some regions, boards, even thick ones, are inexpensive, in others they cost a lot of money.

Concrete garage floors are the most common and popular. It is durable and can be insulated. Moreover, in recent years, concrete flooring has not been left so often - many materials have appeared for finishing the floor in the garage, which make its operation much more comfortable.

The finishing coating can then be laid on the concrete floor.

The disadvantages of a concrete floor in a garage have already been mentioned: it is a large amount of work, a long period of time required to install it, and a fairly high price, even if you make a concrete floor in the garage with your own hands. If the final coating is the same as concrete, then it also adds absorption of liquids and odors, which are also impossible to remove. The unpleasant thing is that concrete absorbs moisture from both the soil and the air. This is not good for concrete - it only becomes stronger, but for a car it is not good. So, if the groundwater level is high, it is necessary to do good waterproofing, and, possibly, a finishing coating that does not allow moisture to pass through. An excellent option is polymer self-leveling floors or rubber coating for the garage.

Backfilling the drainage layer

Compacting a drainage layer of crushed stone and gravel.

A curb stone is installed along the edges of the driveway and site. The installation height is adjusted by adding sand mixed with gravel. Vertical fastening of the curb from the inside is carried out by driving in persistent pegs, and from the outside by adding crushed stone, gravel or sand. Now a layer of crushed stone 12-15 cm thick is poured onto the textile covering and compacted. A layer of gravel mixed with sand in a ratio of 2:1 should be laid on top of the crushed stone to level the surface. After this, you need to compact the surface and cover the drainage layer with geotextile.

Construction of the base on a sand cushion

A cushion of clean river sand 5-7 cm thick is poured over the drainage layer, spilled with water and compacted well. For the next layer, you need to prepare a dry cement-sand mixture in a ratio of 1:4 and pour the base onto the sand in a layer of 6-7 cm.

Schematic images of installation options on sand or dry mix.

It also needs to be compacted and leveled using a plaster rule. For more accurate leveling, you can install metal longitudinal beacons, securing them to bulk heaps made of the mixture.

Laying paving slabs

Laying paving stones on concrete.

After preparing and leveling the cement-sand base, paving slabs are laid under the car. It is very important that no precipitation occurs during the period between installing the top layer and laying the tiles. The surface on which the paving stones will be laid must be dry.

For the outermost row of paving slabs, pull the cord at the appropriate masonry height. Lay 1 row along the curb and 1 row across the driveway. Now begin to fill the required area, laying tiles in 1 m2 segments, moving from one section to another across the driveway.

Constantly check the height of the tiles using a building level. The tiles must be placed as close as possible to one another. Leveling the tiles is done using a rubber hammer.

After finishing the masonry, sprinkle a little dry cement mixture on the surface and use a brush to fill the seams between the tiles.

Choosing slabs for the garage

In order for the slabs to last a long time, you need to choose the right one. The slabs are used in front of the garage and in the garage. It is necessary to purchase the material in the required quantity to eliminate the need to purchase additional tiles.

When choosing, consider the following:

- The tile elements are visually aesthetic; chips, unevenness, cracks or bulges are excluded.

- The thickness of the tile module is more than 8 cm for reliability, strength and resistance to damage.

- Check manufacturing technology. Rub two slabs against each other; if there are chips and dust, it is better to refrain from purchasing the material.

- The tiled color should be calm and harmonious. Excessive brightness and saturation indicates that the composition contains a lot of dyes.

Paving slabs in the garage and in front of the garage

When purchasing slabs, pay attention to the cut. It should be homogeneous, without a porous structure. The rest says that the tiles are unlikely to last long and may be damaged when installed in the garage. If you purchase slabs for a garage in a specialized store, the seller will show you a cut of the tile. In other cases, it is better to look for quality material.

Another indicator to pay attention to is cost. Price is an important criterion. In order not to make a mistake, before purchasing, familiarize yourself with the average price range and focus on it. Low prices indicate a low-quality product, high prices mean you can find another store.

Garage flooring