The variety of covers for reinforced concrete fence columns and brick gate posts is amazing. Why are there so many types of materials and shapes for making pole tops? The answer is simple: aesthetic perfection gives the fence completeness and perfectly supports the overall style of the building, and the protective characteristics protect the fence posts from the negative influence of the external environment, be it precipitation, sub-zero temperatures or ultraviolet rays.

- Why are caps needed on concrete/brick fence posts?

- What else are they called?

- Which material should I choose?

- What types/forms do they come in: photo

- How to make a cap for a pole with your own hands: step-by-step instructions for making it from concrete

- Where to buy ready-made concrete covers?

- How to attach caps to fence posts: step-by-step instructions

- How to paint concrete caps on a fence?

Why are caps needed on concrete/brick fence posts?

Fence caps are decorative architectural elements that perform a protective function in addition to an aesthetic one. This includes protecting brick pillars from the harmful effects of rainwater, snow mounds, icing, sunlight, and frost. All of these natural phenomena negatively affect the mortar of masonry and brick, forcing them to collapse. Also, well-chosen hats for poles protect them from physical or mechanical wear, chemical exposure and biological influence (mold, insects).

As for the aesthetic side of the issue, pole heads are used to draw attention to the area of the house. Thanks to them, it becomes possible to evaluate the overall style of the facade and determine the taste of the owner. The types of tops on pillars and their color variety allow you to realize any architectural plans.

What happens if you don't install them?

Without the use of fence caps, brick pillars lose their performance characteristics: their initial strength and corrosion resistance are significantly reduced, the mortar and the brick material itself are destroyed. The service life of a fence without finials is extremely short, which guarantees significant financial costs for its repair and subsequent restoration.

Why are caps needed on fence posts?

A typical mistake of many unprofessional or too economical developers is the refusal to use additional parts of barrier systems, such as parapets and plugs. The cost of the finials is relatively small, as is the installation time, but the consequences of their non-use are extremely dire. In addition, if you buy a cap for a fence post from our company, which is both a seller and a manufacturer, then financial costs can be kept to a minimum.

Use the opportunity to inexpensively purchase the tops of brick supports to:

- prevent wind and mechanical damage from deteriorating the practical properties of the structure;

- prevent structural changes in the pillars by protecting them from precipitation;

- create a unique entrance group that will match the landscape design and facade of the building in terms of style and color scheme;

- significantly reduce the risk of chipping along the edges of the brickwork;

- make the service life of the structure 20-30% longer and reduce current costs for repairs and restoration work.

Which material should I choose?

The most common materials for caps for gates and fences include: concrete, metal, polymer, wood, clinker, stone, bitumen. They all have certain advantages and disadvantages, which we will discuss in detail below.

Metal: galvanized, tin, corrugated sheet, corrugated sheet, forged

Metal caps are made of iron, galvanized, tin sheets or corrugated sheets. Forged elements are also used, but they serve a decorative role rather than a protective one, since they often take the form of interweaving patterns and lines.

Ease of manufacture and versatility, combined with low cost, are the main advantages of this material. The disadvantages of metal tops include weak strength characteristics regarding mechanical stress (deflections under the weight of snow) and the susceptibility of the material to corrosion due to precipitation. In addition, painted metal is subject to fading due to the negative effects of ultraviolet radiation, and unstable weather conditions (rain, hail) cause unpleasant noise when in contact with the surface of the covers.

Plastic, polymer

Plastic caps on gate and fence posts primarily perform a protective function: they are inserted into the metal profile of the post in order to protect it from moisture penetration into the frame. As a rule, they are manufactured in small sizes: 100x100, 150x150 mm. The disadvantages of plastic material include the small size of the products and the scarcity of shapes. In addition, it is not advisable to attach plastic plugs to brick pillars - there are more suitable materials for this.

Polymer-sand (polymer-sand)

Polymer-sand caps for fence columns are a relatively new development by manufacturers. They are made by hot pressing and consist of ¼ polymer composite, ¾ sand and dye. The most common type of polymer sand topping for a fence is “Gerbil”. These products are characterized by a long service life, resistance to aggressive environments, strength and other protective characteristics. The disadvantages of polymer sand hats for columns include their low flammability. This means that if exposed to direct fire for a long time, they will begin to char. In addition, plastic reduces adhesion to the mortar masonry of a brick pillar, and the price of products is often overpriced.

Wooden

Wooden caps on fence posts look unusual. Using special equipment, wood is given a non-standard shape or intricate carvings. Elements are created that correspond to the general style of the house facade. The material itself is easy to process and design, the products are made in any color. The protective characteristics of wooden fence tops include sufficient strength and resistance to temperature changes. The disadvantages of this material are that without special treatment with protective primers and impregnation with fire retardant, the caps are extremely vulnerable:

- they can easily catch fire if a fire occurs;

- absorbed moisture will quickly destroy first the tops, and then the mortar masonry of the pillars;

- Fungus and mold form on the surface, and in winter, due to a decrease in temperature and freezing of damp wood, the “cap” will crack.

Ceramic, clinker

Ceramic or clinker tops for brick pillars are made of ceramics with or without a polymer coating. Clinker caps are resistant to mechanical and chemical influences, they prevent moisture from entering the surface of the pillars and are fire resistant. The options for all kinds of colors and beautiful textures are surprisingly varied, but the disadvantage of the presented material is its cost. The high cost of products is associated with the difficulty of the manufacturing process and the large amount of time spent.

Made of stone (granite)

A granite head on a brick column has characteristic advantages and disadvantages. The advantages of stone material include its durability, resistance to aggressive chemical environments, precipitation in the form of snow and rain, frost and sunlight. The disadvantages of products made from granite or artificial stone include the difficulty of making an individual shape of the top (since the stone is difficult to process) and their fragility. In addition, the material described is not cheap, so for simpler fences it will be easier to use other products, for example, concrete, which have much better protective characteristics and aesthetic diversity.

From soft tiles

Headers made of soft tiles (bitumen) are made from liquid rubber or soft roofing. To make covers for poles, solid material or its remnants from the installation of a waterproofing layer of the floor or after the roofing process are used. The advantages of bitumen caps on pillars are their high rates of hydrophobicity (water displacement) and adhesion (gluing) to the surface of the pillar. The disadvantages include the impossibility of installing bitumen caps at temperatures of 5 degrees and below and the fragility of the material, which over time will have to be replaced with another, more reliable one.

Concrete/cement

Concrete caps for brick pillars are steadily popular in sales because they have all the necessary advantages related to protective characteristics and decorative features.

Technological characteristics of concrete:

- high strength and abrasion rates;

- low hygroscopicity;

- resistance to fire and chemicals;

- high tolerance to temperature changes;

- anti-corrosion;

- environmental friendliness;

- resistance to ultraviolet rays.

Concrete caps on enclosing structures protect the surface of the pillars and the brickwork mortar from the destructive effects of rain, snow, hail and sunlight. It should be noted that drips are cut out on the inner surface of the top to prevent water from entering the top of the posts. The concrete composition of the canopies does not allow the formation of mold or rot on the top of the fence; termites and other insects bypass concrete caps. Physical or mechanical impacts do not cause any particular harm to cement products, and sudden temperature changes do not affect the strength characteristics of concrete.

As for aesthetics, concrete caps on brick fence posts give the landscape image of the house completeness and a certain architectural expressiveness. The versatility of shapes and colors will appeal to everyone.

Durable, resistant to environmental influences, relatively inexpensive, aesthetically attractive - concrete caps will be an excellent option to complement the image and style of your home.

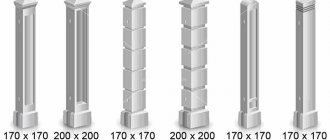

What types/forms do they come in: photo

There are a great variety of fence head shapes. Spherical, round, flat, single-slope, two- and four-slope, double, figured, round, lantern, medusa-shaped, peak, complex configuration... There are a lot of them. Let's look at the most common options for caps.

With a ball

Tops for fences and poles in the shape of a ball are easiest to make from concrete.

Gable

Gable caps are made from any materials at the request of the home owner.

Jellyfish

The best material for this type of head is concrete, since a similar shape is difficult to create from stone or metal.

Round

The round tops of brick pillars are most often made of a cement mixture, painted in any color that suits the style.

With a lantern (lantern)

Heads with a lantern are often made on a metal frame, but there is always the possibility of mounting them on a cap made of any other material. Lamps installed on the “top” of brick pillars perform the function of illuminating and decorating the space in the dark.

Flat

Flat tops are less common than others in the construction environment. Usually made of metal, concrete or plastic.

Double

Double canopies for brick pillars are made from any of the above materials.

Figured

Curly tops on pillars always attract attention to their appearance, so they are easiest to make from wood, stone, concrete and other materials that are workable and aesthetically attractive.

Chinese fence cap

Chinese caps for fences and posts are made primarily of metal, since tin bends best at the right angles, creating a resemblance to a Chinese pagoda.

On a round fence table

For round brick fence posts, mainly concrete tops are provided. As a rule, they are made in the form of cones, diamonds or other geometric shapes suitable for the desired image.

How to make a cap for a pole with your own hands: step-by-step instructions for making it from concrete

Making tops for fence posts with your own hands will not be difficult for any beginner in this business. But to simplify the task, you should decide on the material of the caps. The most suitable in this case would be wood, brick, metal and concrete. So which material should you choose?

The most rational option for the production of hats on poles is concrete. Brick and wood serve, rather, as temporary protection for the fence from the influence of weather conditions; metal requires the skills of a tinsmith. Concrete will satisfy all the necessary technological and aesthetic parameters: it will protect the pillars from destruction and give them the finishing touch.

Sketches/drawing/template

If ready-made concrete caps do not fit your parameters or you have your own idea of the shape of the product, then you should decide on a sketch of the future cap for the brick pillar. The drawing gives an approximate idea of the desired dimensions of the product, the complexity of its production and the total cost of the product.

In addition to the plan and section of the pommel, the drawing shows its pattern or development. Its image gives a more complete idea of how the cap is assembled.

The pictures show types of cutting galvanized metal sheets for making covers for fence posts.

For more accurate implementation of the project, it is necessary to indicate:

- general dimensions of the pommel or more in-depth parameter data (if the product is complex);

- dimensions of the site for installing the future cap;

- the material from which the pole will be made;

- desired top color;

- production time of the product.

Based on the finished drawing, we begin to manufacture the selected tops for the brick pillars, having previously prepared all the necessary tools and materials.

Form

To pour/cast a concrete product with your own hands, you will need a special mold made of ABS plastic using thermal vacuum molding.

The LOBAS company produces and supplies not only concrete caps, but also plastic molds for creating fiber cement caps. If you need to make molds according to your parameters, we will always help you at all stages of the production cycle: from creating templates and sketches to the subsequent casting of a plastic mold of individual sizes.

Our plastic molds are designed to be reused at least a hundred times. They are not affected by climatic conditions and physical impact, since ABS plastic has increased protective characteristics and resistance to mechanical damage. A unique property of this material is its maintainability. If cracks or chips appear during long-term use, the molds are subject to repair and are then ready for reuse.

Fill

The process of pouring a concrete cap is carried out in stages. To do this you will need the following tools and materials:

- plastic molds;

- concrete mixer or drill with attachment;

- raw materials (water, cement mixture, aggregate - river sand, plasticizers, coloring pigments).

The order of work is as follows.

- First, mix the concrete mixture in a proportion of 1 part cement to 2.5 parts sand with the addition of plasticizing additives and dye. Add water to the resulting mixture and get a concrete solution.

- Next, we place the resulting mixture in a plastic mold and place it on a vibrating table for further compaction. This is necessary to improve the characteristics of concrete in terms of strength and frost resistance. We form droppers to drain water and cover the product with plastic film.

- If plasticizing additives were used during casting, the product is removed after 18 hours; if no plasticizer was used, the concrete caps are kept in the mold for 48 hours.

- The finished product is sent to a temporary storage warehouse, where it gains the necessary strength over the next 6-7 days.

Making concrete caps for poles with your own hands requires a certain amount of effort and time. If you want to receive a finished product made with high quality and on time, we recommend contacting specialists.

Pros and cons of different types of caps for brick fence posts

To suit the changing and varied tastes of customers, we offer a variety of head options. You can get acquainted with the main assortment in our online catalogue, and for those wishing to purchase exclusive caps for brick fence posts, it makes sense to make a list of requirements and immediately call the manager.

The main difference between pommels is the material from which they are made: it determines how the product will look, how well it will protect from external dangers, and also how long it will last. Metal variations are suitable mainly for fences made of wood and metal; they are suitable for painting, but are susceptible to corrosion. Plastic and wooden ones are used extremely rarely due to their low strength and lack of protection; moreover, plastic can release toxic substances when heated. Concrete caps for brick fences are traditionally considered the most successful choice - they are environmentally friendly, do not require special care and are inexpensive.

Also, caps may differ in width, height, thickness, shape and presence of decorations, color and suitability for installing lighting fixtures.

Where to buy ready-made concrete covers?

The LOBAS company has been producing and installing concrete products since 2005. Our products have all the necessary technological characteristics:

- high strength;

- moisture resistance;

- frost resistance;

- resistance to chemically aggressive environments;

- fire resistance;

- low percentage of abrasion;

- environmental friendliness.

We will help you select concrete caps for brick pillars of gates or fencing structures in accordance with your preferences in shape, size and color of the products.

Standard sizes of concrete caps: 300x300, 380x380, 390x390, 400x400, 430x430, 440x440, 470x470, 510x510, 550x420, 550x550, 560x560, 700x700, 710x71 0 mm. If necessary, we make custom-made products to individual sizes and shapes.

Our products are manufactured in accordance with GOST standards and regularly undergo quality checks in independent laboratories. You can order ready-made concrete caps for poles on the website, via email or [email protected] , by phone 8 (800) 333-16-86 or personally in our office at the address: Nizhny Novgorod, st. Pravdinskaya, 16. Our managers will provide you with the necessary information at any stage of the construction process: from the creation of drawings, sketches and product templates to their shipment to the construction site. Concrete products from the LOBAS company will serve you faithfully for decades.

We make a pattern or template ourselves

The screenshots below show a template that is made to a given size.

The following drawing will show the size. Let's set arbitrary dimensions, for example an umbrella 300 x 300 and a height of 160 mm. The height is considered to be the bottom of the cap and the center of the top.

Let's draw a right triangle 160 mm high with a lower base of 200 mm. Why is this so, because the size of the square pillar on which the cap or umbrella is placed is 300 x 300 mm. A skirt is put on the brick pillar, the bottom of the cap to which the cap is attached. So we add 50 mm on each side and get 400 mm.

Now we need to find the correct slope. Figure A shows what the length is. The length turned out to be 256 mm.

Next, we transfer 256 mm to the height of the new triangle as shown in Figure B. From the upper center, draw such a triangle and cut it out.

Figure B shows us to trace the resulting triangle four times around it. Add 10 mm to the bends inside the umbrella, cap or head . This is done for rigidity, so that the product does not sag, and also removes uneven traces of cutting metal with scissors and your hands from cuts.

Read: How to make electrical wiring in an apartment with your own hands

The most important things are marked in orange. Before cutting out the template, you need to draw a place for bending as shown in the picture. Take the width from 30 - 40 mm. A bend is needed when connecting products together into a single whole. Below in the screenshots you will see the correct connection of the part.

Of course, you won’t have a special sheet bending machine; be smart about how to bend the product correctly. You can place a corner under your foot and press down the part with your weight. Make bends according to the markings; it is also possible to bend at a corner.

How to attach caps to fence posts: step-by-step installation instructions

Materials and tools for attaching concrete tops to poles:

- primer solution and brush;

- adhesive composition or cement mixture;

- spatula or trowel;

- drill (for installing light lamps).

Instructions for installing concrete caps on brick pillars are presented below.

- First of all, the surface of the brick pillars is prepared: it is cleaned of dirt and dust and coated with a primer for better adhesion to concrete.

- Next, either a cement mortar or a special glue with anti-frost additives is applied to the cleaned and degreased surface with a spatula. The applied layer is carefully leveled over the entire cross-sectional area of the pillar.

The adhesive should be selected in accordance with the region of construction to avoid its incorrect interaction with the concrete product. Instructions for using assembly anti-frost adhesive are always included with the package.

- The next step is to place the concrete cap on the brick pillar and secure it, aligning the sides of the product relative to the axis of the pillar. It is important to attach the product as correctly as possible to avoid possible destruction of the top or mortar of the pillar's brickwork due to incorrect installation.

- The resulting seam should be additionally rubbed with a solution.

When the caps also perform a lighting function, through holes are additionally drilled into them to allow the electrical cable to pass through.

On average, concrete tops are completely ready for use already on the third day after installation.

The price of installing caps on fence posts depends on many factors: the material of the cap, the number of products, the selected adhesive material (cement or glue).

General technology for installing a cap on a fence post

The method of installing the cover depends on the material from which it is made. For ceramic and concrete models, you can use the following instructions:

- Thoroughly clean the top surface of the support.

- To ensure more reliable adhesion, treat the post with a primer, and to protect it from moisture - with a waterproofing compound.

- Apply cement composition (for concrete overlays) or glue (for ceramics) to the prepared surface.

- Place the cap on top and center its position. If necessary, wedges can be used for leveling.

- Rub the seams between the post and the cap, leave the joints to dry for several days. If the lining does not have eaves overhangs, treat the seams with a moisture-repellent compound.

Please note: it is better to install the decorative element when the glue or solution is completely dry. 2-3 days are enough for this.

In the case of metal plates in the support, you must first drill holes for fasteners. To do this, the overlay is first installed on the pole and the attachment points are marked. Then holes are tapped according to the finished markings. For additional fixation, an adhesive composition is applied to the top of the support. Only after this can you install the cover itself and secure it with self-tapping screws and dowels.

Important: if you plan to install lighting fixtures on the fence, you must pre-drill holes for the cable.

General diagram of installing a metal cap on a pole

How to paint concrete caps on a fence?

Concrete caps are tinted during the process of making the concrete mixture or after casting the product. When producing concrete mortar, a coloring pigment is added as an additional component. When the tinted concrete product has reached its design strength, it is coated with a special impregnation for stone and concrete. It penetrates deep into the structure of concrete through the pores and fixes the color with the finishing layer, making it resistant to the negative effects of moisture and sun.

Acid paints are also very popular as concrete dyes. These are chemical substances made on the basis of an acid solution and metal salts. They penetrate into the concrete to a depth of 1-2 mm and become a full part of it, which maintains the brightness of the color throughout the entire operational period. Apply acid paint using a sprayer or brush to a clean, unpainted concrete surface.

The most common types of shades used when painting concrete caps: brown RAL8017, green RAL6005, dove RAL6020, burgundy RAL3005 and many others.

When painting concrete caps on fence posts, we recommend covering them with a varnish with a wet stone effect - this will not only give them a more expressive appearance, but also provide the coating with additional protection from external weather conditions.

Installation of concrete caps on brick pillars of gates and fences is necessary not only as an artistic expression of the appearance of the adjacent territory, but also as protection of the upper part of the fence from the effects of negative environmental factors and mechanical damage. Concrete tops are distinguished by high performance characteristics, a variety of shapes and colors, ease of manufacture and installation, as well as low cost of products.

Why do you need a cap on a fence post: purpose, types, installation methods

A cap on a fence post is a mandatory element of the fence, which prevents it from prematurely collapsing from external factors. It is the pillars that play the most important role in the structure, since sections of the fence are attached to them.

They need protection most of all, which is why caps are used. They have a simple design and are easy to install. They also allow you to place accents in the appearance of the fence, thereby highlighting it against the background of the general building.

Fence cap design

Looking at the photos of caps on fence posts , you can see that in general these elements have a very simple design that looks like a pyramid. The design of the product includes:

- The upper part is in the form of gentle slopes, which ensure the outflow of moisture, preventing it from penetrating to the base of the column. The slopes have grooves on all sides that are necessary to remove moisture. It is the upper part that performs both protective and decorative functions.

- The lower part necessary for fixing the element to the support. The bottom (“skirt”) of the overlay is placed on the pole. Against the background of the top, the lower part is almost invisible.

Thanks to its secure fit on the pole, the cap provides it with good protection from external influences. The cover has reliable and invisible fastenings that do not spoil the appearance of the product. Caps are made in different ways: casting, stamping, welding, etc.

Functions of fence hoods

Before choosing caps, you should understand what they are intended for. Both the appearance and design of the element will depend on this. If we consider the functions of the cap, they include:

- Protection of hollow supports from moisture and precipitation entering the material from which the post is made.

- Protection against freezing of ice, which destroys the seams of the brickwork.

- Safe placement in the cavities of cable supports, which are necessary for connecting lighting elements, locking and security systems, and CCTV cameras.

- Protecting the territory from intruders. For this purpose, pointed caps are used.

- Creating the finished look of the fence. In order for the caps to fulfill their decorative function, they are made to match or contrast the color of the fence itself.

- Placement of lighting fixtures. Using caps under the lantern, you can make the fence even more aesthetically pleasing. Its perception changes especially strongly at night. Judging by the reviews, it is better to use lamps in the shape of a ball, since they are easier to wipe off dust and wash during use.

Why you can’t do without a fence cap

A fence made of the highest quality concrete or brick without protection from moisture will collapse. Rainwater in summer will wash the solution out of it. During frosts, the water in the pores of the material will begin to freeze and, expanding, will lead to the appearance of microcracks.

Please note: the durability of a brick fence primarily depends on the quality of the masonry. If you do not have experience in this area, it is better to contact an organization that performs masonry work at a professional level.

After the first winter, the fence will not be the same as it was immediately after construction. And with each freeze-thaw cycle, the destruction will be even greater. All these processes are called atmospheric erosion. Caps help fight them. They allow you to avoid premature fence repairs.

The decorative function of the caps is no less significant than the protective one. To do this, they are made in unusual shapes - in the form of Chinese pagodas, turrets or houses. Also in the photo of caps on fence posts, you can see that sometimes the top of the element is crowned with figurines of fairy-tale characters or geometric shapes.

Please note: according to experts, caps on pillars, like chimney caps, are important in creating the first impression of the architectural appearance of a house. Therefore, when choosing these elements, there are no trifles. Shape, color, and size are important.

Types of caps for poles

The main difference between pole caps is their shape. Classic models are made in the form of a pyramid. The following forms are no less common:

- gable,

- domed,

- cone-shaped,

- semicircular.

Overlays are often decorated not only with sculptural figures or lamps, but also with tall, sharp spiers:

- Size. Standard models have dimensions of 60x60 or 45x50 cm in plan, but there are other options.

- Color. The products are painted in various shades. Special caps according to RAL are produced for painting.

- Material. Galvanized steel is considered the most reliable, but there are also caps made of aluminum, brass, tin or copper. An additional polymer coating may be present on top of the main layer, which allows the product to be made in almost any color.

Metal caps are lightweight and easy to install. If the artistic value of an object is important, you can choose forged models that look especially impressive. It is important that the forging elements in the overlay match the pattern on the wicket, gate or fence.

If durability is a priority, you should pay attention to brass and copper products - they can last for more than a century without replacement.

Important: metal hollow linings are optimal for cable routing. A lamp socket can easily be placed under them. Light can be made both around the entire perimeter, and only at the gate or gate to illuminate the entrance. If you use LED lamps with a special controller, you can create various lighting effects.