Blocks for fence posts: general characteristics

A vertical structure assembled in the form of a column with a tubular core inside is called a support and is installed on the foundation to ensure the stability of the entire fence. Outside, the load-bearing part of the pillar is lined with decorative blocks made of concrete. Facing elements are characterized by the following indicators:

- dimensions: 25x25x25, 30x30x15, 40x40x20 cm;

- shape in plan - circle, square, rectangle, letter G (when two parts of the element are combined, a cavity is formed);

- the weight of one section is 14-25 kg.

Concrete blocks for fence posts are always made hollow in order to fill the interior space with concrete during installation. The outer surface of the edges imitates the texture and colors of natural stone or brick. The upper part of the inlaid support is covered with a head 130-350 mm high in the shape of a pyramid, ball, or cap to protect it from the destructive effects of rain and snow. Umbrella material: concrete, metal, fiberglass (can be illuminated from the inside).

Types of concrete blocks

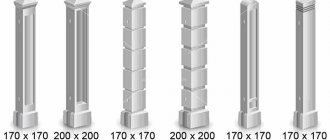

The design of the facing sections of the fence supports can be with or without grooves, a smooth facade or with a texture, angular. The blocks for the pillars also differ in the manufacturing scheme of the stacked racks - there are 2 types of them.

Decorative

Sections consist of two L-shaped parts. During installation, they are stacked in pairs, forming a cavity inside.

Decorative blocks for fence posts are placed over a support pipe or metal core. The operation is performed in stages from bottom to top, followed by filling the internal void with concrete mixture.

Splitter

The first difference between the design and the decorative sections is that the dimensions of the splitter modules are larger. This allows you to quickly assemble block pillars from such elements. The second feature: the typesetting blocks for a fence post of this type are 2 halves of a solid element.

The assembly of racks of elements is carried out in the same way as the decorative sections are assembled. A concrete mixture is poured into the resulting cavity with a bundle of metal reinforcement.

Technological process for manufacturing fence blocks

The raw materials for the production of decorative sections are crushed natural stones. Mixed in the right proportions and placed in molds, they are subjected to vibration and pressure on machines. The components of the mixture for the manufacture of sections are loose aggregates (expanded clay, sand, crushed stone), binding material - cement, dyes, and other additives that improve the properties of concrete.

Vibrocasting

When making blocks for fence posts, the mixture is molded with the addition of water in an amount sufficient to ensure the plasticity and workability of concrete. The forms with the solution are placed on a vibrating table and are not closed; pressing is not performed.

The compaction of the mass occurs due to vibration for several minutes. The block dries in the mold itself, after which the finished product is removed.

READ ALSO: What are the names of the flowers that climb on fences?

Vibration pressing

This method involves preparing a mixture using semi-dry concrete technology: an insufficient amount of water is added to the bulk components to achieve plasticity. The mass is compacted due to two forces: horizontal vibrations of the machine platform and vertical pressure on the mixture from above.

The optimal ratio of components is selected by trial. Finished products are laid out on pallets for natural or forced drying.

Types of concrete blocks

Fence blocks are classified into two main groups:

- Construction models are of a standard shape with a cavity inside. The blocks are used to strengthen the structure, so they are not aesthetically attractive. After completion of the installation work, the external finishing of the fence is carried out with plaster or decorative panels.

- Decorative models - made in an artistic form, quite accurately imitate natural stone, wood or brickwork for an attractive design. The material is very durable. When constructing the structure, no additional external finishing is required.

Hollow concrete blocks are suitable for signaling, lighting and communication systems.

Advantages and disadvantages

Each of the technologies used for the manufacture of concrete sections gives the product qualities that distinguish vibration-cast blocks from vibration-pressed ones. The former have a smooth surface, but less strength and frost resistance. The latter can withstand a greater number of freeze-thaw cycles and are stronger, but their surface is rough. Both pillar blocks have common advantages in comparison with natural stone and brick:

- Solidity. It is achieved by reinforcing the void and pouring concrete. This design is more resistant to mechanical stress than a support made of brick or stone.

- Quick installation of the pole. The decorative block is larger than a brick, which speeds up installation, but selecting boulders along their edges is a difficult task and takes time.

- Large selection of compositions due to the variety of textures and colors. Posts can be built for any fencing blocks.

- The costs of erecting a fence on supports made of concrete sections are lower than the costs of constructing the same structures from brick or natural stone.

Stacked sections of posts have good compatibility with any fencing materials, be it corrugated sheets, forged metal or wood. Like natural stone, block products last for decades. The only drawback concerns all heavy supports: a foundation needs to be laid under them.

Advantages and disadvantages of decorative blocks for pillars

Among the positive qualities of decorative concrete blocks are:

- Reliability. A concrete post with a metal core is an impressive and solid fencing element.

- Durability. Concrete products last for decades without losing their appearance or strength characteristics.

Decorative block pattern for fence posts

- Resistance to negative atmospheric influences: frost, heat, moisture.

- Easy installation. Installing block elements will not be difficult. They are quite light and have the correct shape.

- Economical. Compared to pillars made of brick or natural stone, concrete fence posts are an opportunity to save money. Large block sizes allow you to replace 6 - 7 bricks.

- The ability to make blocks for pillars with your own hands.

- Compatibility with any fence materials.

- Aesthetics. Decorative concrete blocks have an attractive appearance.

Return to contents

Block cost

You can buy ready-made concrete sections in hardware stores or online. At stands and in supplier catalogs there is always a selection of fence blocks for posts. Their cost depends on the following indicators:

- section dimensions - the larger, the more expensive;

- shape - a circular product is valued higher;

- texture - a brick imitation block is cheaper than a natural stone one;

- brand of cement used to make the concrete mixture for making sections: the binder component of the M500 brand gives greater strength to the solution, the block is more expensive.

A high-quality textured section costs approximately 320 rubles per piece, and a smooth block for a pillar costs 120 rubles. Products are supplied wrapped in film and placed on pallets. The production of decorative sections is not a complex process: you can make artificial stones for fence supports yourself.

Technology for installing pillars made of concrete blocks

The construction of the fence begins with markings: the installation points of the support posts are marked on the ground. Depending on the design of the fence fabric and the properties of the soil, the type of foundation for fence posts made of blocks is determined. The final stage is the installation of inlaid supports. All work can be done manually, without the use of construction equipment.

Construction of a columnar foundation

A hole under the base of the stand is dug below the freezing level of the soil by 20-30 cm to prevent movement of the support when the soil heaves. The depth of the excavation does not exceed 1.5 m, and the plan dimensions are taken according to the dimensions of the block plus 50-100 mm. When the pit is ready, proceed as follows:

- 30 cm of sand and gravel are poured onto the bottom of the pit and compacted, after watering with water;

- a pipe Ø60-80 mm is driven into the center of the excavation, the above-ground part - along the planned height of the pillar;

- the pit is filled with concrete, compacting each layer.

READ ALSO: How to Stretch a Lace Along a Fence Level

For large volumes of excavation work, a excavation in the ground is made with a hole drill.

Strip foundation device

A more powerful foundation will be required when constructing a fence made of concrete blocks. A ditch for it is dug along the entire perimeter of the fence, its depth is 50 cm, and the width is determined by the size of the section of the type-setting pillar with an allowance for the strip foundation formwork. Concreting is carried out in the following order:

- They pour a cushion of sand and crushed stone along the bottom of the trench and line its sides.

- The ditch space is reinforced with the release of rods above ground level to tie the lower row of span blocks. The pillar cores are made from pipes or bundles of reinforcement and are brought to the design height of the fence.

- Concrete is poured.

After the foundation hardens, they begin to install the support blocks and lay the spans.

Features of the device of a strip-column base for pillars

We are talking about a combination of the first two types of foundations. Differences in technology appear already at the excavation stage. The features are:

- Along the bottom of the dug trench, in the places of future pillars, depressions are made for another 1 m. The principles for calculating the size of the excavation in plan and the equipment of the pit remain the same.

- Reinforcement begins with the installation of cores of stacked supports.

- Concreting. First of all, fill the recesses under the pillars with the mixture.

Further actions are carried out using the technology of constructing a strip foundation.

Installation of pillars

Installation of prefabricated supports is done in the warm season to prevent freezing of the cement mortar. The concrete base acquires sufficient strength a week after pouring. Pillars are assembled from blocks by stringing sections onto a pipe. In this case, the core remains in the column cavity. The process is like this:

- Lay out 3-4 rows, align them relative to the plane of the fence and level.

- The internal space of the blocks is poured with concrete, the mixture is compacted, displacing air from the uneven areas.

- The bundle is reinforced horizontally to the backfill mesh or rod.

The cycle is repeated until the full design height of the support is reached. Finally, a protective cap is installed on top.

Installation of pillars from decorative blocks

Installing decorative pillars from typesetting blocks is a simple process. Preparatory work will take more time:

- Digging holes for pillars. The size of the hole for the supports should be 15 cm larger than the block. The depth of the hole will depend on the height of the pillar. The steel base pillar or reinforcement is buried into the ground by at least a third of its length.

- Sand about 20 - 30 cm thick is poured onto the bottom of the hole. The sand cushion is spilled with water and compacted.

Scheme for installing a foundation for pillars made of blocks

- A steel pipe or a bundle of reinforcing rods (3 - 4 rods with a cross-section of 10 mm or more) is driven into the center of the pit. The height of the reinforcement frame will depend on the height of the post and fence.

- Concrete is poured into the hole in layers. Each layer is well compacted to remove air and voids. The foundation for the blocks should rise no more than 15 cm.

- The cement composition is left to harden for 2 - 3 days.

Return to contents

Installation of a concrete pillar

After strengthening the poured strip foundation, you can begin directly assembling the pillars. The blocks are installed on top of each other, connecting each other with concrete.

The cavities are filled with cement with the obligatory compaction of each layer. The fittings and pipe must be located strictly in the middle.

When installing a post, you need to take care in advance of attaching the mortgages for the fence crossbars.

Mortgages are attached to a post or reinforcement; they must protrude sufficiently beyond the post to attach the logs. A protective cap must be installed on top of the pillar; it will significantly extend the service life of the supports, preventing precipitation from getting inside the pillar and destroying it. The heads are fixed with tile adhesive or cement mortar. Decorative pillars made of concrete blocks are reliable, beautiful and uncomplicated; they will become a reliable basis and transform any fence.

When writing this article, we used material from the site https://proekt-sam.ru/zabor/dekorativnye-betonnye-bloki-dlya-stolbov-zabora.html

Do-it-yourself block production

You can look for raw materials for making concrete sections yourself in the vicinity of the fenced area; these can be sand, gravel, small stone chips, broken bricks. You will have to buy cement and molds.

Preparation of concrete composition

The grade of cement is not lower than M400, the aggregates must be dry and free of debris, the water must be clean. Proportions for preparing a concrete mixture for the manufacture of a decorative block of a type-setting support:

- cement - 1 part;

- sand with fine crushed stone - 2 parts;

- plasticizing additive - 0.3-0.5% by weight of cement, pre-dissolved in water.

The mixture is moist, crumbly and should not spread.

Molds for making fence blocks

The concrete mass is loaded into a matrix that has a contour in the form of a concrete block for the fence. To ensure that there is a cavity inside the mold, a void box, a metal container, is inserted. Matrix materials:

- fiberglass - hard and durable;

- PVC - products made from it are inexpensive and provide good quality;

- polyurethane - allows for the application of complex patterns.

It is better to buy molds rather than try to make them yourself.

Basic recommendations for manufacturing

At home, you should use the vibration pressing method - the blocks for the pillars are more durable. Tips for craftsmen:

- follow the recipe for the concrete mixture, add water gradually, mix thoroughly;

- lubricate the working surfaces of the molds and void box with machine oil before loading;

- compact the filled mass with a wooden block, striking the other end with a hammer;

- remove the hollow core upon completion of pressing and disassemble the mold.

The finished block needs to be dried for at least two days, and it will gain its final strength in 28 days. To obtain the desired color, dyes are added to the concrete solution.

]]>

Scope of application

Concrete block for a fence is usually used to decorate a certain section of the fence. The material can be installed both outside and inside the building, depending on the design features of the fence or design project.

Our products allow you to build a fence that does not require additional finishing, which helps save the customer’s money. Using such structures, you can create original cladding for the basement floor, steps, and partitions at any construction site.

Fencing suburban areas, restaurants, cafes, administrative and commercial buildings is the main purpose of concrete blocks.