Beton-House.com

Website about concrete: construction, characteristics, design. We combine the experience of professionals and private craftsmen in one place

Fence made of decorative products

After the construction of a private house is completed, you can dismantle the temporary fence and begin constructing a permanent fence, which should become not only a reliable, durable barrier, but also a decoration of the facade of the house. No one doubts that a block concrete fence is considered one of the most reliable fences, and you can give it an aesthetic appearance by using decorative products in its construction.

Advantages and disadvantages of a fence made of decorative concrete blocks

Decorative fence

To fully characterize concrete fences, it is enough to say about their positive qualities:

- Such a fence is a capital and reliable structure;

- The use of the material in question helps to create a beautiful fence, made in any necessary style, which will harmoniously combine with the overall architecture of the house;

- This design is highly durable and durable;

- Simple installation, subject to the technology of constructing structures of this type;

- This design does not rot, does not mold, or becomes covered with moss;

- Concrete is resistant to precipitation and other aggressive environmental influences, such as gusty winds and hail;

- A concrete fence has high frost resistance;

- Concrete is fireproof;

- The construction of a block structure allows you to create a structure of any height and configuration in plan.

Among the disadvantages, it can be noted that the price of a monolithic concrete structure is quite high, in addition, you will have to build a fairly strong foundation, the calculation of which must be done by a specialist. But these disadvantages can be eliminated by choosing a combined option.

Advantages of colored blocks:

- They give the building a unique and attractive appearance.

- There is no need for finishing work.

- Natural ingredients are used for coloring.

- Reduce construction time and financial labor costs.

Building materials have high strength and a service life of more than 50 years, but some brands require additional insulation.

| No. | Name of product | Strength grade | Size, mm | Weight, kg | Number of pieces/m3 including masonry | Quantity on pallet, pcs. | Pickup cost, rub. | |

| per piece | per m3 | |||||||

| Expanded clay concrete blocks | ||||||||

| 1 | 4 - HOLLOW WITH LONGITUDINAL VOIDS | M30 | 390x190x190 | 7 | 63 | 120 | 42,50 | 2 677,50 |

| 2 | 2 - EMPTY | M30 | 390x190x190 | 9 | 63 | 105 | 46,00 | 2 898,00 |

| 23 | 2 - VOID HEAVY | M35 | 390x190x190 | 12 | 63 | 105 | 40,00 | 2 520,00 |

| 3 | 4 - EMPTY | M35 | 390x190x190 | 9,5 | 63 | 105 | 48,00 | 3 024,00 |

| 4 | 4 — HOLLOW “ECONOMY” | M35 | 390x190x190 | 12,5 | 63 | 105 | 45,50 | 2 866,50 |

| 5 | 4 – HOLLOW “ECONOMY” WITH LONGITUDINAL VOIDS | M35 | 390x190x190 | 11 | 63 | 105 | 45,50 | 2 866,50 |

| 6 | 4 — HOLLOW “ECONOMY” | M50 | 390x190x190 | 15 | 63 | 90 | 43,00 | 2 709,00 |

| 7 | 7 - SLOT | M35 | 390x190x190 | 11,5 | 63 | 120 | 51,00 | 3 213,00 |

| 8 | 8 - EMPTY | M35 | 390x190x190 | 11,5 | 63 | 90 | 51,00 | 3 213,00 |

| 9 | 10 - SLOT | M35 | 390x230x190 | 15 | 50 | 90 | 57,00 | 2 850,00 |

| 10 | 13 - SLOT | M35 | 390x280x190 | 19 | 43 | 60 | 78,00 | 3 354,00 |

| 11 | FULL BODY | M75 | 390x190x190 | 17 | 63 | 90 | 66,00 | 4 158,00 |

| 24 | FULL BODY | M75 | 390x280x190 | 23 | 43 | 60 | 85,00 | 3 655,00 |

| PARTITION EXPANDED CONCRETE BLOCKS | ||||||||

| 12 | 2 - EMPTY | M35 | 390x120x190 | 7,5 | 96 (12.5 pcs/m2) | 156 | 35,00 | 3 360,00 |

| 13 | HOLLOW (2 or 3 voids) | M35 | 390x90x190 | 6 | 125 (12.5 pcs/m2) | 192 | 27,00 | 3 375,00 |

| 14 | FULL BODY | M35 | 390x90x190 | 6,8 | 125 (12.5 pcs/m2) | 192 | 31,00 | 3 875,00 |

| 15 | 2 - EMPTY | M50 | 390x90x190 | 7,8 | 125 (12.5 pcs/m2) | 180 | 21,00 | 2 625,00 |

| 16 | 2 - EMPTY | M50 | 390x120x190 | 9,3 | 96 (12.5 pcs/m2) | 156 | 32,00 | 3 072,00 |

| 17 | FULL BODY | M50 | 390x80x190 | 8,6 | 125 (12.5 pcs/m2) | 180 | 23,00 | 2 875,00 |

| 25 | 2 - HOLLOW SAND CEMENT | M50 | 390x90x190 | 11,5 | 125 (12.5 pcs/m2) | 120 | 18,00 | 2 250,00 |

| SAND CEMENT, FOUNDATION BLOCKS | ||||||||

| 18 | 4 – HOLLOW SAND CEMENT | M50 | 390x190x190 | 19 | 63 | 75 | 39,00 | 2 457,00 |

| 19 | 4 - HOLLOW SAND-CEMENT WITH LONGITUDINAL VOIDS | M50 | 390x190x190 | 19 | 63 | 75 | 39,00 | 2 457,00 |

| 20 | FULL SAND CEMENT | M75 | 390x190x190 | 30 | 63 | 48 | 52,00 | 3 276,00 |

| 21 | FULL SAND CEMENT | M150 | 390x190x190 | 30 | 63 | 48 | 59,00 | 3 717,00 |

| 22 | FOUNDATION SOLID (WITH CRUSHED STONE) | M200 | 390x190x190 | 32 | 63 | 48 | 65,00 | 4 095,00 |

Types of fences using decorative concrete material

The use of the material in question allows the construction of combined types of fencing. These are lighter structures that will have less impact on the base.

The essence of such fences is that the supports and lower part are built from decorative stone, and the spans between the posts are filled with shields made of any material. Even a fence made of ordinary corrugated board acquires solidity when framed by decorative pillars.

Using material for constructing corrugated fence posts

The use of metal, plastic or wooden picket fences allows you to build durable, but visually lightweight structures.

Metal horizontal picket fence

Lightweight forged elements can be balanced by the massiveness and reliability of concrete supports.

Forged fragments

A traditional wooden fence, in company with decorative concrete pillars, will sparkle in a new way. Moreover, wood and stone are two natural materials that always combine harmoniously.

Wooden fence combined with decorative material

Production and advantages

Modern block production technologies provide the building material with high density, which makes it frost-resistant. The main components of the product are cement, sand, additives, fillers and dyes. Visually it is difficult to distinguish a structure made from blocks of torn stone from a natural building material. And many indicators even surpass it:

- the shape of the products can be angular or straight, but extremely regular, which facilitates the laying process;

- a variety of sizes, textures, colors provides freedom of choice for the consumer;

- the product has a front view on both sides, which allows for high-quality double-sided masonry;

- the entire perimeter of the product has an edge;

- blocks are combined with other materials, such as plastic, wood or artistic forging, which makes it possible to introduce all kinds of architectural solutions;

- in comparison with natural material, a fence made of torn stone block is more advantageous in terms of construction speed, cost, geometry and ease of installation;

- due to the clear form of the material, the cost of the solution is significantly reduced;

- laying of products is possible both with traditional mortar and with frost-resistant glue;

- the fencing structure does not require constant additional finishing.

The erected fence will be distinguished by its severity, beauty, reliability and durability.

Option 1 of a fence made of blocks under a torn stone

Option 2 of a fence made of blocks under torn stone

Description of concrete blocks with decorative coating

Decorative material

The production of a concrete product occurs through vibrocompression of the concrete mixture in special forms. The basis is cement with various fillers - expanded clay, gravel, granite screenings, glass, slag, concrete or brick waste. Products can be hollow or solid.

Hollow decorative product

Decorative solid concrete blocks

The decorative layer can be applied on one or both sides. Products also vary in shape and size.

Some types

Some varieties

The material in question consists of two L-shaped halves.

The product consists of two halves

The front surface can imitate any natural material, brick or wood.

Concrete pillars imitating wood

The photo below shows a product with imitation of natural wood.

Block imitating natural wood

Thanks to the double-sided pattern, the erected structure has a decorative appearance on both sides. Laying is carried out using reinforcement, making the structure strong and stable.

Fence made of decorative products

Blocks with imitation of split stone have gained the greatest popularity; they are called “Ragged Stone”. They look especially interesting in combination with a material that has a smooth surface.

Combination of smooth and embossed blocks

For the construction of fences, in addition to standard blocks, splitter blocks are used.

Splitter view

These are hollow blocks consisting of two halves. Their peculiarity is that during the construction of the enclosing structure or a pillar to it, the voids are filled with reinforcement and concrete mixture, and the material itself, in fact, is permanent formwork.

Its advantages include:

- Easy installation, which you can do yourself;

- Resistance of the decorative front covering to fading and loss of color under the influence of the external environment;

- The fence does not need to be further finished;

- Blocks of this type have a variety of colors;

- The cost of this material is in an affordable price range;

- The presence of voids allows for hidden communications in the body of the fence.

Installation of an electrical cable in a fence made of decorative blocks

Types of concrete blocks

Concrete blocks are produced by vibrocompression in special forms. The basis of the decorative block is cement with various types of filling:

- Expanded clay;

- Gravel;

- Granite screening;

- Glass;

- Slag;

- Concrete or brick fighting.

Concrete blocks can be of two types:

- Solid - monolithic heavy block.

- Hollow - usually a double-hollow block, very light and durable. The voids are intended to be reinforced and filled with concrete.

According to the location of the pattern, the decorative block can be:

- double-sided;

- one-sided.

In addition, the shape and size of the block may also vary. The standard unit is with dimensions of 200 x 200 x 400 mm. For fences and posts, a decorative block with dimensions of 390 x 140 x 188 mm is used.

Decorative blocks

Decorative concrete blocks consist of two L-shaped halves.

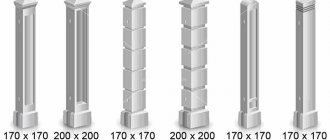

Several types of fence posts made of concrete blocks

The front surface of the block has a relief that imitates natural stones, brick and even wood. Two elements laid together form a hollow rectangle.

Decorative blocks are decorated with a pattern on both sides, so the finished fence will be decorated from the street and yard. The blocks are laid around the installed reinforcement, each row of the fence is filled with a cement composition. The finished fence made from decorative blocks has unsurpassed strength and solidity.

Ragged Stone

The production technology in forms with different reliefs makes it possible to obtain a variety of textures on the surface of concrete.

Imitation of split stone is the most common and sought-after type of decorative block.

Often, blocks with an imitation of torn stone are combined with matching or contrasting blocks with a smooth surface.

Splitter decorative blocks

In addition to standard blocks, there are so-called splitter blocks.

This is what splitter decorative blocks look like

A splitter is a hollow block consisting of two halves. During installation, the voids are reinforced and filled with concrete and the block, in fact, plays the role of decorative permanent formwork. Advantages of a splitter block:

- Easy installation;

- Color fastness of the face covering;

- Environmental friendliness;

- Does not require additional finishing;

- Large color range;

- Affordable price;

- Possibility to install hidden communications in the fence.

Advantages and disadvantages of decorative block products for pillars

Concrete pillar block

Products intended for the construction of fence posts are a hollow block of rectangular or square shape, which is placed on a support and concreted, forming a rigid, durable structure.

Decorative blocks of this type have the following positive qualities:

- They are reliable, especially for products that have a metal core;

- They are durable and do not lose their qualities for decades;

- Such products withstand any environmental influences with dignity - precipitation, wind, low and high temperatures, exposure to direct sunlight;

- They are light in weight, so installation is not difficult;

- Due to its size, one block can replace 7 brick products, so the savings from using this material for the construction of fence posts are obvious;

- They are combined with any artificial and natural materials;

- The decorative appearance allows you to create beautiful fences that decorate the facade of any building.

Decorative fence posts

Decorative blocks in stock, no prepayment, all colors

/ OLD VERSION OF THE SITE / Decorative blocks

We can produce decorative blocks for the fence, split from any side, we also invite you to choose the shade of the manufactured blocks in our office, we will be happy to offer you samples of the finished product so that you can imagine the future structure. Decorative blocks (textured blocks) made of concrete are a reliable and durable material that is used in construction without restrictions. Lifetime warranty.

The main use of decorative blocks is in the construction of fences in villages and other residential buildings. Split blocks are a material with a lifetime guarantee of product quality!!!

price list for chipped blocks from 05/20/2021. //// price list for hyper-pressed brick from 05/20/2021.

| Product name | Brand strength | Frost resistance | Coefficient patient thermal conductivity (W/m C) | quantity in (m2) (m3) | Weight, kg.) | quantity in a pallet (PC.) | color | price on gray cement | price on white cement | |||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Face wall stone ordinary 1 sided block-390x190x188 | m150 | F75 | 0,67 | 12,5 62,5 | 19 | 72 |

|

Production of decorative blocks

In the manufacture of decorative concrete products, vibration casting technology is used using various forms that allow imitation of brick, natural and crushed stone, slate on the concrete front surface.

Release forms can be made from various materials:

- Polyurethane molds are strong and durable. Due to their high elasticity, it is possible to produce blocks with complex patterns. A feature of the polyurethane mold is that there is no need to clean it or wash it after use;

Polyurethane molds

- ABS plastic molds are rigid and are used to create products with the correct geometric dimensions;

- PVC molds have an affordable price and a long service life;

- Fiberglass molds are more expensive, but due to their strength properties, they quickly pay for themselves.

Casting molds

Structurally, decorative blocks can be:

- With grooves;

- Without grooves;

- Have a smooth surface;

- Be embossed.

Types of blocks

Important! Before starting work, the mold must be lubricated with machine oil so that when removing the finished product, its surface is not damaged.

Stages of material production:

- For pouring, use a slightly damp cement composition of grade M400 with the addition of sand and plasticizer;

- The solution is poured into the mold assembled in accordance with the desired parameters of the block, filling the container to 1/3 of the total volume, then the solution is compacted. Gradually, alternating pouring and compacting, fill the entire mold. Excess is removed;

- To create a durable product, the mold is placed on a vibrating table - this promotes uniform distribution of the solution in the mold and its high-quality compaction;

- The block is removed after a short period of time, disassembling the mold, after tapping it with a hammer.

In order for the resulting block to gain the necessary working strength, it must be left for several weeks.

Vibrating table

Advantages and disadvantages

A fence made from “torn stone” blocks has its advantages and disadvantages. The main advantages of decorative concrete fencing are strength and durability, aesthetic appeal, and speed of construction. Concrete surfaces can be painted, whitened, plastered. But blocks with a torn stone finish do not require additional decoration.

These building stones have only one drawback: hygroscopicity. Its indicator is small, but concrete still absorbs moisture, which leads to its premature destruction. In order to protect this material, special additives are introduced into the blocks to increase their resistance to moisture. Penetron is most often used for these purposes. The required amount of additive is determined according to the manufacturer's instructions.

The disadvantages include such a characteristic of concrete blocks as their fairly large weight. This increases the labor intensity of fencing construction.

Construction of a fence using decorative concrete block products

A concrete fence resembles brickwork, the difference is that the blocks are larger in size.

Foundation structure

First you need to build a strip foundation. Instructions for constructing a strip foundation are given below:

Important! It is the design of the strip foundation that can provide a solid foundation for the masonry and its immobility.

- Using a cord and pegs, mark the territory and determine the axis of the fence;

Marking

- Dig a trench twice as wide as the thickness of the masonry, and add 40 cm to this dimension. The depth of the trench should be about 70 cm;

Trench for strip foundation

- The bottom and walls of the trench must be tapped with a shovel and compacted. Then, a sand cushion 10 cm thick and a drainage layer of crushed stone of the same thickness are laid at the bottom of the trench. Next, roofing material is laid at the bottom of the trench and along the side walls;

- Concrete solution is poured into the trench 10 cm deep and, after it sets, formwork is installed;

Formwork

In order for the formwork structure to be strong, it is fixed from the outside using spacers fixed into the ground. And from above, both side faces are connected using wooden blocks, maintaining the same distance between the formwork panels throughout the entire structure;

- Reinforcement is placed in the formwork to provide rigidity and strength for the future foundation and support posts are installed;

Reinforcement and support posts

- Concrete solution is poured. For better distribution of the solution in the formwork, a construction vibrator is used. The formwork can be removed after a week.

Ready-made strip foundation for a fence