Peculiarities

The use of wooden beams in construction is relevant when constructing walls made of concrete, metal, gas blocks, bricks and other materials. It is successfully used due to the fact that it can withstand severe mechanical loads. This building material is often purchased for load-bearing and interfloor structures.

Before starting installation, it is necessary to inspect the wall. If it has an uneven or deformed surface, you should consider eliminating these defects . This can be done by choosing the fixing elements in height, and the cross-sectional size of the beam also matters.

The specific distance between the material fastenings depends on these two parameters. It is necessary to calculate the gaps between the fixing parts of the profile depending on the chosen finishing: it is the cladding that determines the size of the building material. In general, fastening timber is a relatively simple process if you know the rules and limitations of its installation.

Environmentally friendly, practical, durable and easy to process, timber is certainly an ideal material for suburban construction. However, this wood material cannot be poured with concrete mortar, installed in brickwork or plastered.

Mounting options

U-shaped hanger for fastening

To get the job done efficiently, several mounting options are used:

The soft one was considered very simple, since to perform it you will need to fix special brackets made of metal and U-shaped on the wall plane. The distance between them should not be more than 40 cm. The brackets themselves should be securely fixed, and a wooden beam can already be fixed to them.

Before choosing a fastening option, you should accurately calculate the future load and find out the characteristics of the base.

Self-drilling screws are used for rigid fastening

The rigid fastening option requires the use of a variety of fastening elements, which are selected depending on what materials the wall is made of. It can be:

- self-tapping bolts;

- dowel nails;

- anchor bolts;

- plastic or metal dowels.

The degree of difficulty of the work depends on the quality of the walls, but all experts advise fastening the timber beams using a rigid method, as this will make it possible to avoid subsequent deformation of the assembled frame.

In many cases, it becomes necessary to attach the timber to a brick wall. It is necessary to know certain properties and subtleties of the process in order to achieve a good result.

Flat installation on masonry

To install the beams on a brick wall with a full fit along the plane, you need to prepare the following tools and materials:

- electric drill;

- hammer-in dowels with plastic plugs;

- drills and drills with a diameter corresponding to the size of the dowels;

- hammer;

- measuring devices;

- pencil.

First of all, you need to make a marking, determining the position of the block on the wall, and outline it with a pencil. Then mark on the surface of the timber the places for drilling holes, which should be at a distance of 20-30 cm from each other. Further actions are performed according to the algorithm:

- Select a drill according to the diameter of the plastic insert for the dowel and drill holes in the block.

- Take a drill whose diameter is twice the original and make indentations so that the fastener heads go into the “sunk hole”.

- Attach the block to the designated location on the wall and apply markings to the brick through the prepared holes.

- Place a drill bit in a drill and drill blind holes in the brickwork. Place the timber, insert plastic plugs and nail it with dowels.

The length of the dowels must be selected so that they plunge into the wall by at least 50 mm. If the load is significant, then the distance between the attachment points is made smaller (10-15 cm), and the recess into the wall is larger (80-100 mm).

Fastening to anchors is carried out in the same order, the difference is in a more careful selection of the diameter of the drill and careful drilling.

If the hole is too large, the shank of the fastener will rotate inside and it will not be possible to tighten the anchor.

Fastening to aerated concrete and plasterboard walls

Aerated concrete blocks are a soft material; screws with full-length threads are suitable for them, but it is better to use anchors, mechanical or chemical. To properly install an anchor with bending ribs or a wedge-shaped one, pre-drill a hole with a diameter slightly larger than the anchor. One type of anchor is perfect for hollow blocks and blocks made of cellular concrete - foam blocks, gas blocks, etc.

Chemical anchors hold even more firmly; they are suitable for all wall materials made of lightweight concrete and plasterboard, and for any wall materials. The principle of operation is the ability of synthetic resins to penetrate deeply into pores and adhere to the base. The weak link of fastening to porous blocks and drywall is not the fastener, but the base material, especially under the action of a vertical load, and chemical anchors help solve these problems.

A chemical anchor is inserted using a special gun. The adhesive mass is squeezed into the drilled hole under pressure, and a fastening element is immediately inserted - a threaded pin or rod. The adhesive composition fills the pores of aerated concrete or other porous block, and after hardening it forms a strong and reliable fastening.

The pullout force of a chemical anchor from a brick is more than 500 kg. The service life of chemical anchors is tens of years, they do not deform due to temperature changes, and are inert to aggressive environments. The latter is very important when working with aerated concrete, which is aggressive to metals. All fasteners for aerated concrete must have an anti-corrosion coating.

For attaching a block to aerated concrete or plasterboard, the anchor method of fastening is the most durable, although costly. It all depends on the density (grade) of aerated concrete and the required load. To fasten the sheathing, it may be sufficient to use mechanical anchors - wedge-shaped or "spiral nails" type. The latter are convenient because they are mounted into a wall made of aerated concrete, driven in with an ordinary hammer. When driven, the spiral nail is screwed into the block without disturbing its porous structure.

The dowel, which in its working position resembles the spokes of a half-opened umbrella, bears the affectionate name Molly and is excellent for attaching wooden blocks to plasterboard partitions in order to secure paintings, light shelves or lamps on them. Molly is a type of expansion anchor bolt that has a sleeve with longitudinal slots, which, when the thread of the inserted screw is tightened all the way, folds and turns into an umbrella.

By using drywall, all kinds of structures are created and rooms are decorated. This material is quite fragile, so installation of heavy structures, for example, wall cabinets, is not provided for it. In order to reduce the load, fasteners are installed during installation of drywall.

Installation process:

- The wooden beam is fixed in the place where the cabinet will hang. It is fixed with self-tapping screws after installing the drywall.

- If the beam is light and has a small cross-section, then it is secured with dowels or drop-down anchors. Inside the drywall, the fastener opens and secures the structure. This happens after screwing in the screws.

If the cabinet is too heavy, the fasteners may not support the weight and come off. This will cause the drywall to break. Therefore, you need to carefully calculate the weight. Attaching the beam to a concrete base

The construction of a wooden log house still requires a concrete foundation. It can be strip, pile or slab. In any case, the question arises of how to fasten the wooden beam of the lower crown to the concrete. After all, the stability of the entire building depends on the quality of its fastening.

There are overhead installation and rigid fixation.

The first method implies that, laid on a flat base, the beam will be supported by the weight of the structure. The method is effective. It is used in cases where it is necessary to save time and money.

If there is no confidence in the reliability of the overhead installation, rigid fixation is used.

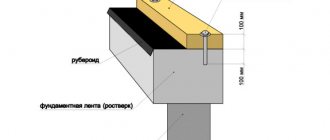

If the foundation is strip or slab, you need to make a decision in advance, because in this case it is necessary to pour special bolts into the grillage, to the studs of which the crown will subsequently be attached.

We suggest you familiarize yourself with How to insulate the walls of a bathhouse from the inside

Holes are made in the beams according to the location of the bolts. The foundation is covered with waterproofing. All unevenness in the concrete must be eliminated in advance. Then a wooden structure is placed on top so that the studs fall into the prepared holes and secured with locknuts.

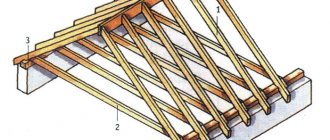

To install the crown on a pile foundation, U-shaped brackets are used. First, the timber is cut and laid on piles to determine the size of the brackets. For accuracy, the latter are welded from corners and installed on the pile heads.

Waterproofing is laid, and a wooden crown is placed on top. It is worth taking a responsible approach to the issue of connecting corners. The staples are connected to the wood using self-tapping screws. Then you can proceed to the construction of walls.

You can attach logs to a concrete floor using the method of attaching to a wall, but they do not use choppers, but plastic dowels or the locking part of the anchor. Sometimes logs are laid on insulation that has been laid in advance, fixing the position with a strong bond to the floor covering. It is important to choose the right type of wood depending on the purpose of the part. Before proceeding with installation, the wood must be treated with antiseptic and water-repellent coatings.

Selecting mounting and fastening methods

The need to join the timber to the wall arises when installing ceiling slabs and beams, interior partitions and suspended ceilings, door and window frames. Wall-mounted furniture, bookshelves, cladding and design elements are attached to the bars. For large design loads, it is recommended to use a hard fastening method; to attach light structures, use a soft method.

The fastening method is chosen taking into account the load and material of the walls; the following types of timber fastening are distinguished:

- Sealing into grooves;

- Laying under support;

- Installation on brickwork;

- Dowel fastening;

- Use of metal supports.

Construction adhesive and polyurethane foam have become new fastening materials that have received high praise from professional builders.

Fastening a wooden beam to a brick wall

You can firmly fix the timber to the brickwork in the following ways:

- Seal in the groove. This method is used to install load-bearing interfloor and ceiling joists. The ends of the beam are installed in special grooves up to 150 mm deep. Brick is a fragile material; it can crack when gouging out recesses; it is better to make the landing groove in advance when laying the walls. U-shaped frame anchors can be used to secure the joists. When installed on external walls, the ends of the beams are treated with sealant, and the free space is filled with insulation. The edges of the beams in the wall space are wrapped with roofing felt.

- Installation of supports. In this case, the timber serves as a support for laying the boards. The support is attached to screw anchors; the number of anchors depends on the diameter and design load. For example, for a beam with a cross-section of up to 50 mm, the distance between the anchors should be no more than 30-40 mm. The technology is used for laying floors and installing wooden ceilings in brick houses. The junction of the support with the external wall is laid with roofing felt.

- Installation on brickwork. In this way, the rafter mauerlat is fastened and the first - the tying crown of a two-story house, where the first floor is made of brick, and the second is planned to be made of timber. To securely install the mauerlat and the tying crown on the brickwork, embedded anchors are used.

Fastening timber to concrete and brick walls

You should drill the brick carefully, strictly at a right angle, without “losing” the drill, so as not to split the brick. Splitting can cause the brick to fall off. if a brick gets into the cavity, you will have to use an anchor-type dowel, which, when screwed into the wall, forms a knot, or a spacer dowel. Tighten the dowel carefully. Mechanical anchors for fastening wooden beams to brick walls are much better than self-tapping screws and nails, both technologically and in terms of fastening strength.

Fastening the timber to the suspension

In interiors, decorative elements are sometimes used that require the beam to be fixed to the ceiling on a free suspension or to imitate such a suspension. Sometimes beam suspension is needed for structural reasons. This type of fastening is performed using a special suspension designed for a certain load. A suspension system of this type may have the additional ability to adjust the height of the beam suspension.

The suspensions are attached to the ceiling with dowels, and the second part of the fastening is installed on the beam, then the elements are connected. Practice shows that such fastenings, contrary to expectations, can withstand considerable loads. But it’s still better not to have such a risk factor over your head, and for the design, imitate a suspension, and attach the beam securely to the wall. In this case, the suspension system is installed to strengthen the fastening, and for design purposes, “for beauty.”

Installing sheathing on walls

Installation work depends on the material and design of the balcony parapet (fencing). If it is brickwork, which is quite rare, it is enough to screw bars of the appropriate section to it with dowels (the height depends on the intended insulation). For leveling, just like on the ceiling, you should use spacers or secure them with galvanized hangers.

In case of large differences, we attach them to drywall hangers

A more common situation is when a welded metal structure is installed as a fence, insulated with glass wool and sheathed on the outside with flat slate (built during the USSR). In such cases it is necessary:

- Partially disassemble the fence (remove insulation, sheathing and cut off some metal elements with a grinder);

- Install vertical bars. Fixation is carried out using metal corners, which are attached from below - with self-tapping screws - to the concrete (via a dowel) and to the beam, and from above - to the window sill.

- Cover the outside of the fence. For this, galvanized steel sheets can be used, onto which a mounting beam is pre-attached. After the preparatory work, the assembled structure is screwed with self-tapping screws to the previously installed vertical blanks on the inside of the balcony.

- Next, the horizontal elements of the sheathing are mounted (20x40 lath). The distance between the slats is no more than 40 cm, while a gap of 1 cm should be left between the bottom rail and the floor.

It is not always necessary to disassemble the outer casing; in such cases, installation work will be limited to points 2 and 4.

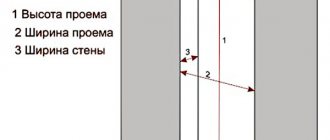

If there are door or window openings to be lined, the sheathing should be installed along their entire perimeter (except for the floor), as well as on slopes.

Installation of galvanized profile sheathing

On the side of the walls, at the corners of the balcony and on the door/window openings, U-shaped guides are mounted vertically. A rack profile is inserted into these guides (thus it is fixed at the edges). The profile is fastened along its entire length on mounting hangers using special self-tapping screws at intervals of 40-50 cm.

For more tips on installing beam sheathing, watch our video:

How to attach wood sheathing to a brick wall. Attaching a board to a brick wall

During construction, the question arises of how to attach wooden sheathing to a brick wall, as well as timber and other wooden elements. For this, anchors, dowels, and cement mortar are used. The option for fixing wooden elements depends on what function they will perform and how much weight needs to be supported. The moment of installation is also important: during construction, the boards go into the walls, and then they are attached to it.

In what cases may it be necessary to fasten the board?

You may encounter problems with timber installation during work:

- redevelopment and construction of new wooden walls;

- door frame installation;

- installation of hanging furniture;

- extension of the veranda;

- construction of a canopy over the front door;

- insulation of the house.

What tools are needed to attach a board to a brick wall?

The set of tools is determined by the type of fastening and functionality of the wooden elements. When attaching the timber you need:

- drill or hammer drill;

- drills and drills;

- hammer;

- roulette;

- pencil;

- dowels;

- corners;

- staples;

- nails;

- screws;

- screws, etc.

General recommendations

To choose the type of fastening, take into account what material the walls are made of, their thickness, and also what load they will withstand.

The hole in the wall must be made using a drill.

Using a drill, carefully drill a hole in the brick wall. While working, try not to expand it so that the brick does not crack. A dowel is inserted into the opening, which, when screwed, will curl into a knot and securely lock. This option is suitable for hollow brick. Next, a self-tapping screw will be screwed into the dowel. If the beam must withstand a large load, then it is better to use an anchor.

Methods of fastening to a brick wall

Soft method

This method is easy and quick to use, but unreliable - it is not suitable for heavy loads. But it is used for decoration and sheathing. This method can be used without the help of others, since it does not require construction skills. If you follow the instructions, the result will be satisfactory.

To perform fastening, you will need U-shaped metal brackets. They are fixed to the brick at a distance of 40 cm. At a level of half a meter from the floor, a 60 cm indent is made between them. The more fastenings, the more firmly the board holds. This will avoid deformation of the cladding. Under mechanical stress, the timber becomes loose and the structure is damaged. Therefore, be careful when working.

Hard method

To fix the board more firmly, wooden plugs are used.

This method is durable, reliable and will allow the structure to last for a long time. A hole is made in the brick into which a wooden plug soaked in glue is driven. A nail is driven through the beam into the cork. This method allows you to securely fasten the sheathing and prevent its deformation. It is designed for light load.

Other methods

Attaching timber to a brick wall is possible in other ways. To attach hanging furniture, the board is applied horizontally to the wall and secured using self-tapping screws, nails, and screws in the prepared openings. To ensure that the lockers can withstand the load, there are many attachment points. For partitions, the same rules are used, but they are fixed vertically. The timber should be secured with anchors for structures with heavy loads. This method is suitable for the door frame and roof canopies above the door.

The installation of timber for an extension occurs during the process of placing the end of the beam into the masonry. To do this, make a corresponding opening in the wall. But this is possible with a thick wall of one and a half bricks. If this is not the case, then the design will be end-to-end, which is unacceptable. In this case, you will need to use a support beam. It is attached to anchors, maintaining a distance of 30 cm. After which the beam is attached to the tree using metal corners and self-tapping screws.

What to choose - screws or nails

A nail is a long steel rod with a pointed tip. When driven into wood, it wedges its fibers, which, trying to return to their original position, compress the rod from all sides. This pressure holds it in the material.

The screw rod is equipped with a thread - a spiral-shaped protrusion, which, when screwed into wood, cuts grooves in its thickness. This fastener is held in wood not only by lateral compressive forces, but also by the resistance of the walls of these grooves.

Let's compare the resistance of these hardware to vertical (tearing) and lateral (shearing and bending) loads.

Resistance to vertical loads

If we consider propping and threaded hardware from the point of view of pull-out loads, then the latter are clearly stronger. To pull a nail out of wood, it is necessary to overcome the elastic forces holding its rod. To pull out the screw, this is not enough; you also need to destroy the grooves that compress the thread.

For example, a nail 40 mm long driven into a pine beam is pulled out of it with a force of 32 kg, and a self-tapping screw with the same thickness and length of 22 mm screwed into it can only be removed by applying a force of 74 kg.

The second stage - preparation of the bar

The finished material must be prepared accordingly.

The work instructions look like this:

- STEP 1: the material should be placed for a couple of days in the room that will be finished. This will allow the bar to acclimatize so that its temperature and humidity are the same as in the room.

- STEP 2: the elements are treated with an antiseptic composition. This can be done using a regular brush, treating all surfaces in order. You can do it differently and make a trough from the boards, which is covered with film. An antiseptic is poured there, and the block is simply dipped; this option provides the highest quality protection.

If there is a lot of bar, then it is easier to make a trough so that you can quickly process it by dipping

- STEP 3: While the products are drying, you can prepare the walls. To do this, markings along the width of the racks are applied to the surface. The work is done using a pencil and a level so that the lines are straight. This will allow you to clearly see what the structure will look like and will simplify your work; you will not need to be distracted by monitoring the correct position of the elements;

When marking vertically, you can use a plumb line rather than a level

- STEP 4: Measurements are taken to determine the length of the bars. It is better to do this in several places, since the walls or ceiling may be uneven;

Do not forget to leave gaps of 5-10 mm so that the block does not rest and deform due to changes in temperature and humidity.

- STEP 5: cutting the block is done with a hacksaw or jigsaw. Here it is important to correctly mark the elements and cut them perpendicularly so that the ends are even. It is also advisable to treat the cut off areas with an antiseptic so that the bar is completely protected from moisture and pests.

How to attach a wooden beam to a wooden wall?

In this case, the perforated fastening method is common both in roofing and in the furniture industry. Perforated elements are secured with nails, self-tapping screws or self-tapping screws.

Perforated plates connect parts in one plane, for example, roof installation. There are also corners of different widths to strengthen and connect the structure. For auxiliary elements of light weight, mounting tape is suitable.

The most common method of fastening wooden structures is with nails. Liquid nails are often used in everyday life, furniture assembly and construction. Using nails will seem like a very easy way, but we must not forget the technique of hammering a nail. If you use a bolt with a nut at the end, you can easily hammer a nail into any hard-to-reach place. Calculate in advance how long a nail you will need. For a more durable connection of the boards, the nails are driven in at an angle to each other. Wood that is too dry will split faster with a nail. If the timber is too dense, hold the nail in the middle with pliers to prevent it from bending. For large nails, you can pre-drill a hole that will be narrower than itself. Make a small drilling for the cap.