Manufacturing

The construction of a section of stairs in the form of a horizontal platform is mandatory for a system consisting of two or more flights.

Depending on the type of building, operating conditions and design load, components of lifting structures are made of light and heavy concrete. Reinforcement is carried out using welded frames and meshes. The steel class of working reinforcement is adopted based on the required design rigidity of stair landings. Series 1.152.1-8 clearly regulates the diameter of the rod and mesh used. Substitution of steel grades from which the metal parts of the product are made is prohibited by regulatory documents.

GOST for flights of stairs and landings - design options

Reinforced concrete flights of stairs are installed during the construction of a building, facilitating the delivery of building materials to the upper floors. A staircase is an important structural part of a building, connecting its components with a common power circuit.

The standard provides for the assembly of reinforced concrete stairs from the following components:

- an inclined march connecting horizontal platforms between floors;

- interfloor platform connected by reinforcement to the flight span.

The structures of reinforced concrete spans, consisting of individual elements, are classified according to certain criteria:

- span configurations;

- method of construction;

- design features of the march.

Any building that has more than one floor must be equipped with stairs

Reinforced concrete stairs differ in shape. The following execution options are possible:

- straight. They are assembled in spacious rooms from rectilinear concrete elements. They attract attention with their original decorative design, as well as pomp. Rectilinear structures combine horizontal floor areas, allowing rational use of free space;

- radius. Thanks to the curved configuration of a reinforced concrete staircase, space can be saved in a limited area. The need to manufacture special formwork, as well as the complexity of installation, limit the use of non-standard curved structures;

- prefabricated The composite version includes two separate flights, installed perpendicularly or in the shape of the letter P. The composite design is the optimal solution for movement in a limited area. The design of the staircase allows you to assemble a span without using separate platforms.

According to the installation method, the following options are possible:

- made. Consists of independent reinforced concrete spans and intermediate platforms installed using lifting devices;

- monolithic. Concreting of the flight is carried out simultaneously with the interfloor platforms using common formwork, forming a solid reinforced concrete structure.

Despite the variety of staircase designs in modern construction, it is customary to adhere to established standards

GOST for flights of stairs and landings provides for the possibility of using different types of flights:

- flat. They are marked with the LM index. They represent an inclined span without platforms and transitional (frieze) steps that facilitate docking;

- ribbed They are similar to flat ones, differing in the presence of stiffening ribs in the lower plane. They are designated by the abbreviation LMF;

- reinforced with ribs and manufactured together with the upper and lower half-platforms. Marked with the designation LMP;

- ribbed, made with one half-plate located in the upper part of the product. Designated similarly to the previous option.

Reinforced concrete stairs also differ in the magnitude of the perceived load. They can be manufactured in various designs, which provides the ability to move both clockwise and in the opposite direction.

Classification and serial sizes

The main types and sizes of landings, their configuration and controlled characteristics are defined in GOST 9818-85 and Series 1.152.1-8.

In addition to the design and dimensions of landings, the Series also determines their type and purpose. According to the method of arranging reinforced concrete products, there are:

- closed (when walls surround steps and intermediate platforms on three sides);

- open (when the staircase elements are not protected by wall panels).

Depending on whether the staircase is main or auxiliary, the slabs for it will also have structural differences. For auxiliary stairs, slabs of a smaller standard size are used; their operation is allowed from the outside of the building.According to GOST, reinforced concrete products can be:

- flat for a flat flight without frieze steps (LP),

- ribbed for the same type of products (2LP),

- ribbed for ribbed marches with frieze steps (LPF),

- ribbed half-court (LPP).

Depending on the brand, products are produced with lengths from 1.44 to 2.98 m and widths from 0.99 to 2.2 m. The maximum weight of the product is three tons.The standard provides for the production of rectangular platforms, but the production of structures that differ from the standard ones is allowed. They can have a round or curved shape, additional branches. In such cases, design documentation is subject to special approval.

INSTALLATION OF STAIRWAYS

You can get acquainted with the prices for components for stairs if you download it to your computer screen in PDF format or download it in EXCEL format.Visit

Our site will help you decide on the choice of wooden staircase design for your home.

A visit to our website will help you decide on the type of wood cladding for your home, outside and inside.

CONTENTS: CHAPTER 1. Choosing the type and design of a wooden staircase CHAPTER 2. Calculation of the number and size of steps CHAPTER 3. Useful width of a flight of stairs, length of steps, bowstring and stringer CHAPTER 4. Installation of stairs on bowstrings CHAPTER 5. Installation of stairs on stringers CHAPTER 6. Installation of a rotary sector from winder steps CHAPTER 7. Installation of duck step stairs CHAPTER 8. Installation of landings CHAPTER 9. Installation of stair railing - balustrade

Landings are installed at the end or at the beginning of a flight of stairs. If the landing is located between two flights of stairs or between two interfloor ceilings, then they speak of an intermediate landing. It is also called a recreation area. The intermediate landing, as well as the ceiling, can be made of reinforced concrete or wooden structures (Fig. 1a - 1d).

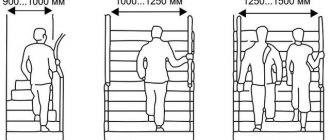

The connection of bowstrings, stringers and racks to the landing corresponds to the connection to the ceiling (Fig. 5 and Fig. 6). The purpose of the landing is to make walking up the stairs easier. They are also used to decorate stairs and change the direction of a flight of stairs. According to DIN 18065, the intermediate landing must be located between a maximum of 18 steps. The location of intermediate landings greatly influences the shape and location of strings and handrails. Here the requirement must be met that the vertically measured height of the bowstrings and handrails at the turning point must be the same (Fig. 7). If this is not the case, then the vertical development of the free bowstring and the handrail has at least one kink. Graphically checking the location of the handrails and bowstrings provides information on whether the transition has been completed correctly, or whether the position of the posts needs to be lengthened. As a rule, for transitions, the sum of the dimensions x and y is equal to the width of the tread in plan a. Let's determine the dimensions of the landings. The minimum width of the intermediate landing should be equal to the width of the adjacent flight of stairs, the same applies to the useful width of the flight of stairs (Fig. 8). The minimum useful width of a flight of stairs is: • 0.80 m - for stairs leading to common areas in residential buildings with no more than two apartments, as well as two-story apartments with an internal staircase; for basement stairs that do not lead to common areas. • 1.00 m - for stairs required by building regulations. • 0.50 m - for stairs to the attic that do not lead to common areas. The main dimensions of the landing are its width and depth (Fig. 8). To determine the minimum depth of a landing, use the following rule (Fig. 9): the width of the tread in plan is added to the step length (from 59 to 65 cm). Landing depth = step length + 1 • plan tread width Landing depth = step length + 1 • plan tread width If landing dimensions are to be increased from the values given here, the increase must be an integer multiple of the calculated minimum landing depth. If the landing has a round or curved shape, then the useful width of the flight of stairs should not be underestimated (Fig. 10). All elements of wooden stairs are constantly available at the Karpovsky construction market, pavilion 14/7, opening hours: Monday-Friday 9-00 to 16-00, Saturday 9-00 to 14-00, Sunday – closed. You can find the full range and prices for all staircase elements in the PRICE LIST. In addition, you can always contact us for help. Our specialists will help you correctly design a staircase with an intermediate landing, make the necessary calculations and, based on them, select the necessary staircase elements or order the assembly of stairs, in compliance with all the rules and requirements set out above. You can also order all components by phone: 8 (831) 415-55-87; 8-902-305-1662 or email [email protected] and we will deliver components throughout the city and region with payment on the spot upon delivery.

You can call the contact numbers listed on our website and we will answer any of your questions. —————————————————————————————————————————————————— ——————— If you are interested in the question of how to make a wooden staircase to the second floor? ATTENTION!!! Visit the section of our website if you want to buy only components and install the wooden staircase yourself.

Come to us or write by e-mail, indicating the dimensions of the room and we will calculate the stairs. You will be provided with an estimate for the material for the wooden staircase and the cost of assembling the staircase. —————————————————————————————————————————————————— ——————— From us you can purchase all the elements of a wooden staircase: and others, and also order the assembly of stairs, in compliance with all rules and requirements.

We offer the widest range of lumber from the Vologda region and profile planed kiln-dried products from Arkhangelsk:

Installation and finishing work

In multi-apartment and public buildings, the installation of the staircase landing is carried out on supporting elements - landing beams. The slabs are lifted to the installation site in a horizontal position and laid on a cement pad. The brand and size of the layer of mortar to be laid are indicated in the project.

Depending on the width of the marches and the method of their installation, when using the same slabs, structures of various shapes and sizes can be obtained.

The basic size of the slab is selected depending on the location of the marches. If they are connected perpendicularly, then the width of the product is selected 100 mm wider than the span. In the same way, the width of the slab is determined when ascending successively in steps. When connecting in parallel, the required dimensions are taken to be no less than twice the span width, plus a 10 cm gap between them.

After completing the installation of the staircase landing, it may be necessary to additionally decorate its surface by performing painting work or covering it with special finishing materials. Some reinforced concrete plants offer their customers products with a ready-made polished mosaic surface made of cement of different colors or crushed marble. The front side can be covered with ceramic tiles directly in the production workshop.

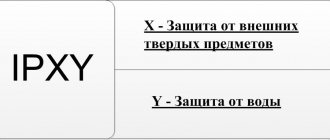

Marking

Finished products are marked in accordance with GOST 23009. First, the type is indicated, then the rounded overall dimensions in dm. If the reinforced concrete products are made of lightweight concrete, then the letter “l” is written down; if they are made of heavy concrete, then the value of the design live load in kPa, rounded to a whole number, is entered. Next comes information about the presence of additional structural elements, the method of finishing the front surface, additional conditions for installation and operation.

Example of marking 2LP25.15-4-K:

Markings should be looked for on the edge that will be mounted to the wall.

Step sizes

The average step size is 170 mm (tolerances are from 140 to 200 mm).

The safety of the stairs is characterized by the summation of the height of the step and its horizontal width. The optimal figure is 460 mm. The second norm is the difference between the height of the step and the width of the adjacent tread. This value according to standards is 120 mm.

When calculating the number of steps in a flight, first study the total height of the stairs. Important parameters are the width step and the slope angle. According to GOST dated March 14, 1985, the optimal marching structure is considered to be a structure with 15 steps.

Kawabanga! How to make a concrete staircase with your own hands

Specifications

According to GOST 13015.0, the landing must meet the standardized requirements for strength, frost resistance and water resistance of concrete. Its surface must be resistant to abrasion, the reinforcing parts must be protected from contact with air. In released products, the top surface is subject to processing in accordance with the placed order.

In the case of tiling, the difference in height should be no more than 1 mm. The size and location of channels and technical openings must correspond to the design drawings.

Transportation and storage

The conditions for transportation and storage of reinforced concrete products are regulated by GOST 13015.4. Moving and storing are done in stacks using spacers between the rows. The height of the stack during storage is no more than 2.5 m.

The ZhBI-4 plant offers its customers delivery of all products, including oversized ones. The plant has its own fleet of special equipment and all permits giving the right to transport heavy and oversized cargo in Moscow and the Moscow Region.

| < Previous | Return to list of articles | Next > |