The construction of buildings of any purpose from timber involves fastening the timber to the foundation. This procedure is complex and labor-intensive, and also requires the employee to have certain qualifications and experience. The reliability and durability of the entire structure depends on how well the first crown was secured. That is why installing timber on the foundation is an extremely important stage in the construction of buildings. In this article we will look at options for installing wooden beams on various types of bases.

The first stage of this process is the arrangement of a really high-quality foundation for the construction of a building, on which it is necessary to apply two layers of roofing felt sheets, and fill the surface with a cement mixture. Only now should you begin installing wooden elements on the base of the building under construction. The installation of timber should only begin when the foundation is equipped and has stood for more than a week. As already mentioned, installing timber on a foundation is a rather complicated process, and to facilitate it, the first row is used, which is called the bottom frame. To increase the strength of the structure, the harness must be made of wide material.

Before starting all work, you should stock up in advance with all the necessary tools and consumables. Here is their list:

- antiseptic composition;

- building level;

- anchor bolts;

- cement composition;

- sand;

- roofing felt;

- anchor studs.

Return to content

Technology for attaching timber to the base

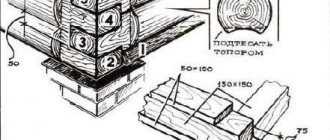

There are several methods for installing timber beams these days, but anchoring the timber to the foundation with anchor bolts remains the most common and reliable method. In this case, the wooden elements are laid on a grillage, which was previously covered with roofing felt sheets. They cannot be left open for a long time, since roofing material has a rather fragile structure, which can be damaged even by a slight mechanical impact. The timber must be laid strictly horizontally, so it should be regularly checked with a building level. If irregularities of more than one centimeter occur, they must be corrected with cement mortar; all other defects are quite acceptable. The lower beams are attached to each other by means of recesses in the corners of the base. It is preferable to use a paw or half-tree sample.

The beam is installed on the base of the future building using nuts and anchor pins, which should be installed in advance at the base of the building. Experts recommend installing wide washers for locknuts - this way you can significantly increase the contact area of the material with the fastener, thereby increasing the strength of the entire structure. If you plan to build fairly short walls, then you can use three fasteners per beam. Using a building level, all diagonals and corners of the base should be regularly checked.

When the fastening of the strapping beam to the foundation is completed, you should begin installing the main supporting structure.

It is important to know! Working with wet material is prohibited. You should wait until the timber dries before starting work.

Before starting work on installing racks and crowns, you should inspect the foundation and find out how horizontal its surface is. If the results are satisfactory, then you can begin impregnating the timber. For this purpose, special antiseptic compounds are used, which can be purchased at construction or hardware stores. The antiseptic packaging indicates the impregnation method, as well as the time required for the material to dry.

After the preparatory work, installation can begin. The installation of the beam on the base of the building occurs in parallel with the cutting of anchor bolts into special holes that are drilled in the material. The diameter of these holes must exceed the diameter of the fasteners by at least two millimeters. After the timber is installed on the base of the building being erected, the installation of vertical elements, which will subsequently become the frame, should begin.

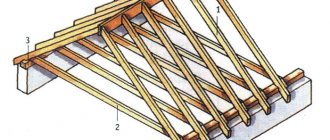

To prevent possible deformation of the material, it should be dried thoroughly. Diagonal strengthening of the supporting structure will significantly increase its strength and also increase its service life. For this purpose, special braces are used.

Building a house out of wood is quite expensive, but with the help of some tricks you can significantly reduce the cost. One such trick is to reuse waste materials. For example, the material that was used for the initial fixation of the supporting structure can be dismantled and cut into fragments that can serve as permanent jibs. Temporary spacers can easily be made from wooden parts of the formwork. If the reuse of wood products is planned before construction begins and included in the estimate, you can save significant money.

It is important to know! The material should be stored in a room with low humidity, and even minor contamination of the wood should not be allowed. You should not burn lumber waste that has been treated with antiseptic compounds, since such smoke is harmful to human health.

Return to content

Beam fastening schemes

Before attaching the beam to the foundation, it is better to understand the diagrams of this operation. According to building codes, the construction of buildings made of wooden beams allows two options for fastening this material:

Rigid fixation. This method involves strong contact between the timber and the grillage. In this case, the static nature of the first crown is guaranteed by a strong mechanical effect, which is created using various fasteners.

Overhead fixation. In this case, the wooden element is mounted without direct contact with the grillage. The static nature of the first crown in this case is ensured by the mass of the remaining building materials that are installed above it.

As practice shows, and confirmed by experts in this field, rigid fixation was and is the most reliable fastening option. Only this option can guarantee complete staticity of the lower crown and a reliable connection of the timber to the base of the building. But rigid fixation is quite difficult to achieve, so the most common type of fastening is overhead fixation. Now you know how to properly lay timber on a foundation, all that remains is to learn about the nuances of installation on various types of foundations.

Return to content

Methods for tying pile foundations with timber, corrugated pipe and angle

Types of tying pile foundations

Pile foundations are popular in industrial and private construction when the slope at the construction site is quite large or there is a large depth of strong rocks in the area.

It is not advisable to dig deep trenches in such soils, since the soil may shift or the bottom of the trenches will be flooded with groundwater. In turn, pile structures are ideal, given their features, design characteristics and low cost in general.

What is the harness used for?

Scheme of grillage arrangement in a columnar-pile foundation

To ensure greater structural strength and uniform transfer of load from the building to the ground, a special foundation frame or grillage is often used.

The grillage is connected to the piles using a hinge joint, reinforcing mesh, rigid welding and wire. In private construction, tying with a grillage made of wooden beams, corrugated pipe or channel is practiced.

The harness is used:

- To ensure geometrically even and correct location of all piles.

- Prevent the foundation from shifting under the influence of lateral, tangential and vertical ground displacements

- Ensure uniform distribution of loads from the mass of the future building through the piles to the ground.

When designing pile-grillage foundations, the number of piles must be taken into account. The more piles are used, the smaller the cross-section of the piping reinforcement will be. In addition, you can also use a regular wide board or small-diameter corrugated pipe; you need to connect all the links with corners.

Types and types of harnesses

The use of corrugated pipes for tying foundation piles of buildings

Pile-grillage foundations are highly durable; they almost completely neutralize vertical and horizontal soil movements.

They are used for the construction of houses on mobile and unstable soils prone to heaving.

Piles are also actively taken into account not only when designing a new house, but are also used during the renovation of an existing one, since they are strong enough and can withstand the load of buildings of several floors.

It is important to take into account the human factor, as well as the presence of hard rock in the soil. During the installation of piles, a small slope angle is inevitably formed due to the displacement of the core, so after installation of the structures they need to be leveled and strengthened

Methods for strengthening piles used in private construction:

- Tying with corrugated pipe, additional connection to the top of the pile with angles, welding or flexible wire.

- The use of metal channels with different installation directions.

- Use of wooden beams.

It is not necessary to do the tying at all if the location of the top point of the pile is no more than 60 cm from the ground level. But if it is higher, then it is impossible to do without strapping, since the load-bearing structures will shift even under the influence of wind or rain, and over time the building itself may become skewed.

Necessary materials for tying a pile foundation:

- wooden beam, you can use thick boards;

- metal channel, I-beam and connecting angle;

- flexible wire, rod or reinforcement with a cross-section of up to 8 mm.

You will need a welding machine and building levels.

Channel or corrugated pipe piping

Channel and corrugated pipe for tying foundation piles

A channel is a rigid metal beam of great thickness, has its own stiffening ribs, to which reinforcement or the top of the pile are attached by welding.

A profiled pipe is cheaper, it weighs less, but it is no different in strength; the connection principle is similar to a channel. The optimal connection method is to lay two beams on top of each other or overlap. Peculiarities:

- It is unacceptable to use separate beams on different piles; it must be a monolithic structure.

- If the foundation is large enough, then a crane will have to be used to install and fix the channel, so this strapping method is used in the construction of warehouse and industrial buildings.

- To ensure greater strength, it is recommended to use not only welding, but also bolted connections; the joints should be coated with anti-corrosion paints and checked with ultrasound.

- Channels are heavy load-bearing structures, so such grillages are not used in private construction.

Fastening timber to a strip or slab foundation

High-quality installation of wooden beams to the tiled base of the building is impossible without a number of works. At the initial stage, you should install a wooden element with special holes in the grillage. Installation occurs using locknuts that are screwed onto the anchors. This design is used during the construction of buildings from various types of timber.

Installation of wooden elements on the base of the building occurs as follows:

After pouring the foundation of the building, anchor bolts should be installed in the still uncured concrete. The bases of fasteners can be conical or curved. Bolts must be installed every 50 centimeters, so about three fasteners should be mounted on one beam.

Now you need to wait for the base of the house under construction to dry and start preparing the timber to be installed. These works at this stage include exclusively drilling holes for anchor studs, which are located on already installed bolts.

After these steps, you need to arm yourself with a building level and check the horizontalness of the structure. All detected defects must be eliminated immediately, for example, if you find a hill, you should cut it off with a knife, if a depression has formed, then it must be filled with solution.

After arranging the most even base, it is necessary to lay roofing felt sheets on it, which perform waterproofing functions.

As mentioned above, the layer of roofing felt cannot be left open for a long time, therefore, immediately after its installation, it is necessary to install beams that were cut into fragments of the required size in advance.

The corner joints of the beams are connected to the outlets, but you can do without them. To achieve the most durable connection, you must use corners made of metal. These metal products should be installed on self-tapping screws.

After this, a wide washer should be installed on each anchor stud on the bolts installed at the base of the building, and then the contact should be secured with locknuts. To prevent the occurrence of unevenness, the nuts must be tightened not one by one, but in parallel, and each time make two or three turns.

Now you know not only how to lay the first crown of timber on the foundation, but also how to create the rest of the supporting structure. This method is quite simple and if you have the necessary tools and some experience in construction work, you can do it yourself. As a result, you will receive a strong and durable building foundation, which is the key to a successfully built house.

Return to content

Attaching to a pile foundation

If the design documentation for the construction of a building from any type of wooden beam provides for the presence of an exclusively pile foundation, then the work on installing the beam will be slightly different. The first step is to mount special U-shaped heads on piles that are installed in the ground. Their side surfaces must be perforated, and the perforation must be suitable for fasteners.

Next, you need to install the wooden beam into the groove of the U-shaped bracket, and then fix it using fasteners. There is another option for creating this connection. It involves the use of a greater degree of perforation of parts, which in this case are drilled through. This method is much more difficult than the previous one, and the effect of both methods is the same, so the first option is more common.

Now let's talk about how to attach the timber frame to the foundation. This operation must begin with a selection of wooden parts for arranging the grillage. Beams with a square cross section are excellent for these purposes. The next operation will be securing the wooden beam to the pile. To carry out this operation, you should install a certain number of brackets on which to install the wooden beam. The brackets should not just be laid, but firmly welded to the piles. These metal products will subsequently serve as beacons for places where other heads need to be installed.

After this, a layer of waterproofing material, which in this case is represented by roofing felt, should be laid. In addition to protection from moisture, this layer is assigned the function of a buffer zone between the wooden and metal elements of the supporting structure.

Now the grillage beams should be installed in the brackets so that they are joined on tenons exclusively at the corner contacts. This procedure can be carried out using two methods - in the paw or in the bowl. The beams must be secured using special fasteners.

In principle, the bars can be installed without fixation. In this case, the beams must be mounted on T-shaped pile heads. The grillage is attached to the base of the building using metal corners. This scheme for attaching the beam to the base guarantees the most intimate contact of the crown with the foundation, which significantly increases the strength of the entire structure and its service life.

Return to content

Conditions for wood

The choice of material for constructing a durable crown of the house is based on the requirements of GOST 2695-83. Most often, the binding is made of oak or larch.

It is necessary to carefully select wood for long service life

Pay attention to the following:

- Linear dimensions 200 × 200 mm, no curvature;

- Humidity less than 20%. It is advisable to take wood from winter felling (December-March). Dry for at least 1 month in a covered area with natural ventilation in accordance with the rules for laying lumber;

- No wood defects exceed the amount allowed by GOST, including signs of rot (cyanosis), fungi, bugs;

- No mechanical damage or processing defects.

Lumber is assessed according to the worst edge of the face. A thorough inspection for flaws is required on each side of the workpiece.

After all the cuts, tongues, and cuts have been completed, the finished part is subjected to antiseptic impregnation on all sides. It is popular to use used machine oil for this purpose. The quality of the original log affects the result obtained during its processing, the further fastening of the timber to the foundation, the durability and reliability of the resulting structure.