The need to build on problematic soils dictates our own approaches and solutions.

One of them is a pile foundation, which provides support on deep, dense layers of soil.

Weak, waterlogged or loose surface layers do not participate in the operation of the support system, being, in fact, only an intermediate link between the upper above-ground structural elements and dense soils.

Individual piles, being vertical elements, take on a certain part of the load from the weight of the house, evenly distributed along all the trunks.

The grillage or strapping belt is responsible for taking the weight of the building and transferring it to the pile system, which should be discussed in more detail.

Pile foundation tying

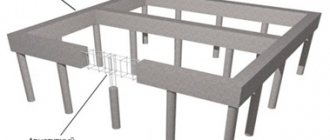

The pile system is a complex of vertical shafts immersed in the ground.

For further construction, a horizontal element is required that connects the supports to each other and serves as a reference line for the walls of the house.

This element is called a trim or grillage. It performs the most important function - it unites a group of individual trunks into a complex, making the pile field a single support system.

After immersion in the ground, the outer parts of the piles are cut, controlling their height to obtain an even horizontal plane at all reference points. Then special caps are installed on the upper parts - heads, equipped with horizontal platforms and shelves for mounting the harness .

The grillage usually follows the plan of the first floor of the house, i.e. load-bearing wall configuration.

However, for greater uniformity of load distribution and pile stability, additional transverse or diagonal beams are installed, increasing the rigidity of the bundle of individual supports and providing additional reinforcement to the load-bearing lines.

As a result, a design is achieved in which there are no separate supports; all of them are included in the integrated complex of the pile field.

In what cases is a channel recommended for tying a pile foundation?

The pile foundation, after construction, forms free-standing pillars with caps at the top. In the absence of a solid supporting part, it is almost impossible to build walls, so it is necessary to make a strapping. The main materials chosen are: profiled pipe, logs, timber. An alternative is to use a channel, which will create reliable support in such cases:

• during the construction of a log house, frame house;

• when the design documentation provides for laying walls of brick, blocks or concrete;

Types of strapping

The piping belt for a pile foundation can be implemented in different design options. They have their own capabilities and are designed to work with different loads and conditions.

There are the following types:

Wooden

Use a beam with a cross section of 200:200 mm, or a pack of edged boards 50:200 . The beams are installed around the perimeter of the house (under the external load-bearing walls), along the lines of the internal load-bearing walls, and also connect the remaining supports in order to equalize the loads and tie all the trunks to the common system.

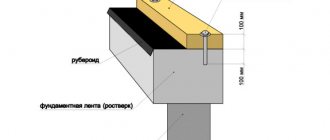

Corner joints are made into the wood floor, fastening to the ends is done through a double layer of roofing material for waterproofing.

The advantages of this solution are:

- Ease of processing, availability of material.

- The wood has sufficient strength and relatively low weight, which does not load the foundation.

- Installation is possible in the field, without the use of construction equipment or even without power tools.

The disadvantages of wooden types of strapping can be considered:

- Features of wood, tendency to warp or crack, need for high-quality waterproofing, etc.

- Fire hazard of wood.

- Possibility of material damage by insects or rodents.

Despite the obvious disadvantages of wood, a timber grillage is a common and popular option.

Metal grillage

Metal binding requires the use of welding.

From an installation point of view, it has noticeable advantages:

- High connection speed.

- Durability, resistance to all possible loads.

- A wide selection of types of rolled metal, allowing you to obtain various strapping options.

Along with advantages, metal strapping has disadvantages:

- The metal's tendency to corrode.

- The need for periodic maintenance of the structure (painting with waterproof polymer materials).

- Welded joints require the participation of a professional welder who is able to correctly select the operating mode and amperage. Otherwise, the seams will be brittle and brittle, which will create a significant danger to the building.

The main argument in favor of creating a metal frame is the high maintainability and speed of assembly of the grillage.

The cost of rolled metal and welding work is noticeably higher than that of wooden beams.

However, there are about the same number of supporters of this type of binding as there are fans of wooden parts.

The strength and stability of the metal are highly valued by users and increase the competitiveness of the material.

IMPORTANT!

To increase the strength of the metal frame, it is recommended to use additional bolted connections.

Concrete

Concrete lining is almost a full-fledged analogue of a pile-strip foundation.

The fundamental difference is the distribution of loads - on pile-strip foundations, both elements share the loads equally, and the concrete grillage of a pile foundation only transfers the load to the supports, without performing load-bearing functions as such.

At the same time, being only an intermediate element, concrete piping allows you to get the maximum effect.

It has high strength, durability, load resistance.

In addition, the concrete grillage is able to compensate for changes in loads or load-bearing capacities of individual supports, redistributing or partially assuming new working conditions.

The advantages of this design are:

- Ensuring maximum load-bearing capacity of the system.

- Independence from climatic or weather conditions.

- Relatively low need for periodic maintenance.

- Durability, reliability of the material.

The disadvantages of concrete elements are:

- The complexity of creation, the need to perform various successive stages of work.

- Large volumes of materials (concrete, reinforcement, wood for formwork, waterproofing materials, etc.).

- It takes a long period of time for the lining to harden (28 days from the moment of pouring), during which further construction is impossible.

The construction of concrete piping is usually chosen during the construction of large and massive buildings, where it is especially important to ensure the strength and reliability of the belt despite the high consumption of materials and labor costs.

NOTE!

For some types of piles, a combined version of the piping is often used, in which the grillage itself performs the main load-bearing functions, and the shafts are additionally connected by metal jumpers. This type of dressing is used, in particular, for screw piles . It strengthens the system and reduces the possibility of loosening or loss of traction.

Load calculation

When installing a pile foundation on screw supports, you have to work with the base for a light load. This scheme is well suited for small sheds, garages and bathhouses made from timber. The weak support will be more than compensated by the significant speed of construction and very low costs. The foundation on screw piles is constructed from supports installed vertically and piping horizontally. There are usually four supports for the entire system, although there may be more.

The piping in this case is represented by a grillage. It is created from a material suitable for creating a beam. It can be either concrete, wood, or metal. Wood is used as the base of the beam, a corner is made from metal, and blocks are made from concrete. The lashing of screw piles connects the beams to each other and to the grillage. The success of the process directly depends on careful compliance with all requirements of the installation and installation instructions.

The pile heads must be on the same horizontal line, which is controlled when the supports are immersed in the ground. The width of the beam should be one and a half times greater than the diameter of the piles. Another mandatory requirement is that the axis in the center of the supports must go only through the center of the beam. Screw pile tying connects supports and beams with a threaded connection, either welded or clamped.

Differences between the grillage and the lower frame of the foundation

The horizontal frame, which connects the support pillars to each other, scans the plan of the first floor of the house and is at the same time a supporting platform for the walls of the house, is called a grillage. It performs two functions at once - it makes the pile field a single support system and creates a platform for the construction of external and internal walls.

Additional diagonal and transverse beams, called the bottom frame, serve to evenly distribute the load and ensure stability of the supports.

This building element is used in the following situations:

- when the foundation is built on a complex rugged terrain, where the piles have different heights above ground level;

- when the structure is raised above the ground by more than 1 meter;

- for massive structures;

- for structures on moving soils.

The introduction of the lower frame increases the rigidity of the bundle of individual piles and at the same time increases the strength of the grillage.

Application of channel and I-beam

On lightly loaded structures, you can build a grillage from a channel. Such structures include, for example, bathhouses and sheds. A grillage made of piles and metal is tied together by welding. The base and structural elements are attached to a circular seam. The assembly procedure involves installing the channel on the pile heads. The element can be strengthened in such a way that the side edges will “look” down. The channel tying of screw piles is also carried out in the opposite direction, in which case the edges are directed upward.

When the channel is positioned along such a system, the resistance to loads on the transverse parts of the structure is much better. The result is formwork, which must be filled with mortar, this is how the wall masonry for the reinforcing belt is formed. To ensure high strength strapping, an I-beam of equal dimensions is used instead of a channel. When channels and beams are joined at the corners, then welding is used. After tying the supports, the grillage is coated with an anti-corrosion agent.

Wooden

A beam with a cross-section of 200:200 mm is used, or a pack of edged boards 50:200. The beams are installed around the perimeter of the house (under the external load-bearing walls), along the lines of the internal load-bearing walls, and also connect the remaining supports in order to equalize the loads and tie all the trunks to the common system .

Corner joints are made into the wood floor, fastening to the ends is done through a double layer of roofing material for waterproofing.

The advantages of this solution are:

- Ease of processing, availability of material.

- The wood has sufficient strength and relatively low weight, which does not load the foundation.

- Installation is possible in the field, without the use of construction equipment or even without power tools.

The disadvantages of wooden types of strapping can be considered:

- Features of wood, tendency to warp or crack, need for high-quality waterproofing, etc.

- Fire hazard of wood.

- Possibility of material damage by insects or rodents.

Despite the obvious disadvantages of wood, a timber grillage is a common and popular option.

Timber strapping technology

Most cases of using timber frames relate to the construction of frame houses on bored or screw piles.

Procedure:

- Cutting beams to length 200x200. Since a half-timber connection is usually used, the length of each span is measured in full, without taking into account the thickness of the adjacent beams.

- Laying the perimeter, connecting at the corners. A double layer of roofing material is laid on each head. The connections are sealed with jute strands .

- The timber is fixed to the heads using “wood grouse” - special wood screws with hexagonal heads.

- After laying the external beams, they begin to install the internal spans located under the load-bearing walls. Above the corresponding piles, recesses are made to the width of the beam (200 mm) and to half the depth (100 mm) . Suitably prepared connecting elements of the internal spans are placed in these recesses.

- All parallel spans are connected with additional beams or boards installed on the edge. Self-tapping screws and galvanized corners with stiffeners are used for connections.

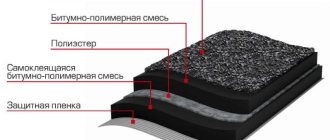

- The surface of all wooden parts is coated with an antiseptic and fire retardant composition . After drying, apply a layer of waterproofing (hot bitumen or bitumen mastic).

Method of bundling with a profiled pipe

A profiled pipe has a structure similar to a channel, but in terms of strength it is much inferior to it.

This is due to the less durable metal used to make the profile pipe, thinner walls and other features of the material . To achieve maximum strength, corner joints are made overlapping or overlaying.

As an option, the ends are trimmed at 45°, welded, followed by strengthening the joint with an oblique angle for bolted joints.

Procedure:

- Trimming piles, installing caps.

- Laying beams along the outer perimeter, connecting corners.

- Laying internal beams, welding with external elements.

- Tying the remaining supports to obtain maximum rigidity.

- Applying a layer of protective anti-corrosion coating.

IMPORTANT!

If possible, all connections are reinforced with metal gussets installed on bolted connections.

Technology of foundation construction on driven reinforced concrete piles with channel tying

The tying of the pile foundation with a channel is carried out immediately after driving the reinforced concrete piles. Acting in some way as a retainer, tying the piles with a channel will prevent violations of the specified foundation parameters under the influence of residual stress in the piles.

Peculiarities of work on channel tying foundations on reinforced concrete piles

- The channel, as a rule, is mounted on piles (heads), which assumes the proportionality of the geometric parameters of the channel and the pile. The piping is carried out along the outer perimeter, and to give additional strength to the structure and ensure its reliability - inside, including the installation of beams connecting two other channels along a perpendicular line and (or) two piles (their heads) diagonally.

- If this is provided for by the project, the channel is installed in such a way as to form a formwork for filling with concrete and creating a reinforcing belt for the subsequent installation of walls.

- As a compromise option, which allows you to preserve the upper “formwork” and the high strength of the grillage, an I-beam of the same size is used instead of a channel.

- The corner joints of channels or beams are connected by butt welding. Particular attention should be paid to fasteners. We do not recommend using only a weld for connection; it is advisable to combine it with bolted connections or rivets.

The sequence of channel tying a pile foundation

- The level of the upper part of the piles is measured - all ends of the supports must be at the same level. This is done first of all to ensure that the foundation is horizontal. Piles that are located above the required level must either be immersed deeper or cut off. If the supports are located below the required level, then a gasket should be placed on the head.

- The points of the external corners of the structure on the piles are marked. To do this, the point is defined as the first external corner. Then the remaining corners are outlined in exactly the same way.

- The accuracy of the angular dimensions of the structure is checked with a square.

- The first corner of the grillage is made from a channel.

- The entire channel lining structure of the supports is laid out sequentially from the prepared elements. When all the elements are laid, it is necessary to once again check the straightness of the corners and the horizontality of the entire resulting structure.

- Fastening channels. It is provided by welding or bolted (rivet) connections. Whatever the requirements for the foundation, a more reliable result is obtained by combining different fastening options. All foundation elements are fixed with a circular type seam. The assembly process involves installing the channel on the pile heads, which ensures high structural strength and the channel has high resistance to lateral loads or side faces down. The inverted channel forms a natural formwork that can be poured with concrete, creating a reinforcing belt for the masonry wall.

- Anti-corrosion treatment of the structure. Due to the fact that a layer of air forms between the soil and the platform itself, dampness appears, especially in the autumn-winter period, resulting in corrosive damage to the metal surface. To avoid this, after finishing channel tying the supports, the grillage elements are primed with anti-corrosion compounds.

Application of foundations on driven railway piles with channel piping

- Brick houses

- Wooden houses

- Frame country houses

- Garages

- Baths

- Gazebos

- Outbuildings

The use of a channel for tying the foundation is recommended during construction in lightly loaded structures or when installing a pile foundation in unstable soils. Many resort to channel tying to give the structure an additional margin of safety.

Channel bandage method

The difference between the channel piping technology and the method of installing a profiled pipe is the absence of standard ends.

The channel is installed with the wide side up, forming a horizontal platform along all the beams.

Otherwise, the procedure is similar to the technique for installing a profile pipe.

The usual channel sizes are m for piles with a diameter of up to 108 mm (a 160 mm channel is used for them).

Welded joints are additionally secured with bolted joints using gussets.

Welding must be carried out by a professional qualified specialist who has permission to work with critical structures . Waterproofing of the trim is carried out using traditional coating materials or protective polymer coatings.

When is a harness needed?

Metal strapping (aka grillage) is used when laying a pile or pile-screw foundation. It allows you to connect scattered vertical piles into a single strong structure that evenly distributes the weight of the building over all points of support.

Additional advantages of the grillage:

- smaller excavation works,

- low cost of foundation,

- Possibility of installation in winter,

- high stability on soft soils,

- possibility of construction with elevation differences on the site.

Tying a pile foundation with a channel is usually carried out during the construction of relatively light buildings: outbuildings or residential buildings made of brick, blocks, wooden beams or using frame technology.

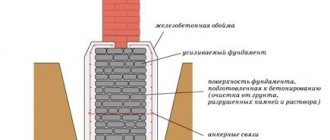

Using reinforced concrete

The creation of reinforced concrete piping is carried out in stages.

Procedure:

- Formwork assembly. Horizontal panels (bottom) are laid on the surface of the heads, the side walls are attached to them and are firmly connected at the top by crossbars . The internal dimensions must correspond to the parameters of the grillage.

- Laying waterproofing. The bottom and inner walls of the formwork are tightly covered with a film or layer of roofing felt. The joints of the material are overlapped by 10 cm and the joint is sealed with tape . The canvas must completely cover the entire surface of the bottom and walls of the formwork and fit tightly to the surface, keeping pace with it.

- Assembly of the reinforcing belt. Reinforcement with a diameter of 10 mm and smooth rods of 6 mm for vertical elements are used. The arm belt is knitted using soft wire, after which it is installed inside the formwork in the desired position . It is necessary to ensure that the horizontal rods are buried 2-5 cm inside the concrete.

- Pouring concrete. It is performed in one step, without long breaks (more than a day). Concrete should be poured from several points so as not to wait for the material to spread throughout the formwork . After pouring, the surface is covered with polyethylene or burlap and left for 28 days to gain structural strength.

- The formwork is removed 10 days after pouring.

- After the end of the exposure time, waterproof the surface and proceed to further work..

NOTE!

To pour concrete lining, it is necessary to use dense grades of concrete from M200 and higher.

Using a board

Tying with a 50x200 board is done when high-quality timber is unavailable.

The technology is somewhat more labor-intensive, since each beam has to be assembled separately, but there are also advantages:

- No warping or screw turning.

- Possibility of more precise corner joints.

- Each board can be pre-treated with an antiseptic and fire retardant, which can significantly increase the resistance of the beams to biological manifestations or fire.

The work consists of making a kind of prefabricated timber from a pack of boards.

The boards are cut to length, trimmed in the right places for corner joints and collected in a tight package.

For fixation, pins are used, which are passed through through holes and pulled tightly together .

The formed beams are assembled using a technology similar to the method of installing timber frames.

The beams must be positioned so that the boards are installed on edge and not horizontally.