There is an opinion that concrete is a material that can withstand any conditions, including weather, and can serve for many years without undergoing any changes. However, in reality this is far from the case. Of course, concrete is one of the most durable and durable materials. However, in order for a concrete foundation to last as long as possible, it must be protected, primarily from moisture, since it has a detrimental effect.

If you do not provide waterproofing for the foundation, after some time the base will simply collapse, which will lead to changes and destruction of the entire building. In addition, groundwater can cause great damage to the foundation of a house. Waterproofing is an important point when arranging the foundation; you should never forget about it, and you can even carry out concrete insulation work with your own hands. You can also find videos on the Internet on how to do similar work.

Waterproofing using lubricants

Do-it-yourself waterproofing of a strip foundation using coating is one of the easiest ways to protect the foundation from moisture. The method of this type of waterproofing works on the principle of applying paint. You just need to purchase the material, and then use a brush to cover the entire surface of the foundation with coating. To ensure waterproofing in this case, liquid glass, various bitumen mastics and much more can be used.

Using coating for waterproofing strip foundations has its advantages:

- Low cost of substances, and of the work itself to ensure protection.

- Good elasticity of the substance, which is ensured due to its consistency.

- Absence of any joints or seams.

- High degree of hydrophobicity after concrete coating.

- Ease of waterproofing work. Coating concrete with coating does not require the use of any complex tools or equipment, nor does it require any special skills.

- High degree of bonding to the foundation surface.

In addition to the listed qualities, the coating also has some disadvantages. Firstly, it is fragility. The shelf life of such a substance is on average about six years. After this time, the mastic or other substance becomes inelastic and brittle, and, accordingly, unable to provide adequate protection. As a result, the homeowner will have to carry out repairs and re-waterproofing work. You should pay attention to this when choosing a waterproofing method. If cracks appear on the mastic or liquid glass after a period of time, it is necessary to take measures to carry out repeated work as quickly as possible, since moisture can penetrate through the cracks to the concrete and provoke the process of its destruction.

If we take into account the fact that coating options are characterized by their low cost, waterproofing can be done every 7-8 years without spending a lot of money. However, if this option does not suit you, you can choose substances with the addition of polymers, rubber or latex. Such connections last much longer and are more resistant to external influences.

Waterproofing the foundation base. What types of waterproofing are used to protect the foundation?

In order to prevent the negative impact of moisture on the foundation, the following types of waterproofing and other construction and installation works are used:

- Giving construction materials additional water-repellent properties.

- Creation of waterproof coatings on the vertical walls of the foundation, from its base to the top edge of the base.

- Reliable waterproofing of horizontal interlevel seams, preventing capillary upward penetration of moisture.

- Reliable protection of the waterproofing itself from external mechanical influences.

- Measures to insulate the foundation and basement, reducing the negative impact of negative temperatures.

- Installation of a drainage system around the house.

- Creation of a reliable system for draining rain and melt water - drainage and storm sewerage.

- Ensuring reliable ventilation of basements and basements.

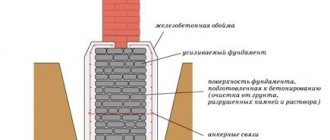

The proposed figure shows, as an example, a possible general scheme for waterproofing the foundation of a building:

The diagrams are marked with numbers:

Approximate foundation waterproofing scheme

1 – the base of the foundation, which usually rests on a compacted sand and gravel bed. Between it and the vertical wall of the foundation (2) there must be a cut-off horizontal waterproofing (4), which overlaps with the insulating layer located in the basement floor (4) between the base and the screed.

The outer vertical wall has a coating waterproofing coating (5), additionally protected by a waterproof membrane (7) and covered with a layer of geotextile (8), which protects against abrasive and other mechanical effects.

The upper edge of the plinth (foundation wall) is also necessarily covered with waterproofing roll material (6), on top of which further construction of the walls and ceilings of the building will be carried out.

To remove moisture, a drainage system is provided - pipes (9) laid around the perimeter at the level of the base of the foundation in a gravel cage. For more reliable protection against water from atmospheric precipitation entering deep into the soil, it is advisable to install a clay castle around the house (10).

In areas with a harsh climate, severe freezing of the upper layers of the soil, or in the case where residential or utility premises are planned to be located in the basement or basement, the waterproofing system of the foundation and basement is complemented by a system for their insulation:

The diagram in general terms repeats the one posted above, so the main numbering of parts and assemblies is preserved. In addition shown:

Scheme of foundation waterproofing with additional insulation

1.1 – sand and gravel cushion under the base of the foundation. This layer can also be made of lean concrete with coarse-grained filling.

12 – insulating panels made of extruded polystyrene foam, installed externally on top of rolled waterproofing along the entire height of the foundation and basement walls.

13 – plaster layer of the basement finishing. Nowadays, special base thermal panels are often used instead - they provide both insulation and reliable protection from direct exposure to water.

14 – wall of the building being erected. The figure clearly shows that it begins to be laid from the layer of horizontal cut-off waterproofing of the foundation.

The choice of a specific type of waterproofing, and therefore the materials used for it, largely depends on the specific purpose of the room located in the basement. The existing classification (according to BS 8102 standards adopted in Europe) divides them into four classes:

- The first, lowest class is utility or technical premises that are not equipped with electrical networks. They tolerate wet spots or even small leaks. The wall thickness must be at least 150 mm.

- The second class also includes technical or utility rooms, but already equipped with ventilation, in which only wet fumes are allowed, without the formation of damp spots, with a wall thickness of at least 200 mm. It is already permitted to install electrical appliances of standard mains voltage here.

- The third class is the most common, and most of all of interest to individual developers. It includes all residential buildings, offices, retail outlets, and social facilities. The thickness of the walls should not be less than 250 mm; a natural or forced ventilation system is required. No penetration of moisture is allowed.

- As a rule, you don’t have to deal with the fourth class of premises when building your own home - these are objects with a specially created microclimate - archival storage facilities, libraries, laboratories and others, where special requirements are imposed on a constant, clearly established level of humidity.

Technology of coating concrete with coating

Waterproofing a strip foundation with your own hands is not difficult at all.

- It is first necessary to thoroughly clean the concrete strips from dirt, dust and various foreign objects.

- Then you need to apply a special deep penetration primer. This is necessary for better adhesion of the coating to the surface of the foundation.

- After the primer has dried well, you can begin applying the waterproofing agent. This must be done using a special paint brush. The coating should be applied in such a way that there are no gaps or empty areas left on the surface. Additionally, you can watch a video on how to properly waterproof a strip foundation.

Waterproofing using roll materials

Inexpensive waterproofing of strip foundations can be done using rolled materials. The most striking and frequently used representative of this group is roofing felt. Rolls of aquazol and isoplast are also sometimes used for such purposes.

Roll materials are generally quite widely used in the construction of houses and other structures. Moreover, they are used not only to protect the foundation, but also for roofing work, building a swimming pool, making road surfaces and much more. This material can not only protect against external influences of water and moisture, for example, under adverse weather conditions, but also against underwater groundwater with strong pressure.

Roll materials from which waterproofing is made are divided into several types:

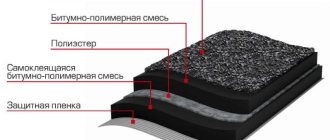

- Pasting. Such materials are attached to the surface of the base using special adhesives, for example, bitumen mastic, or using a special adhesive layer provided. The second option is more convenient and does not require much time to complete the work.

- Floating This type of material is convenient and interesting in that the pre-prepared layer from the roll is heated with a burner and then applied to the surface of the foundation. Under the influence of high temperatures, the material becomes sticky and adheres well to the base.

Roll materials also have some advantages:

- Easy to use and install.

- Durability.

- The ability to repel moisture.

- High strength materials.

- Reliable protection from external influences.

Roll materials have virtually no disadvantages, and therefore are used for a variety of purposes during construction.

Carrying out the necessary work

Specialists use several types of building insulation, each of which has its own characteristics and nuances.

Specialists use several types of building insulation, each of which has its own characteristics and nuances. Waterproofing can be:

- horizontal;

- injection.

Horizontal waterproofing. At the initial stage of the work, the basement of the house is isolated from the foundation itself. This process is carried out using rolled material, which must be laid out on top of the base. To carry out the work, it is recommended to use bitumen mastics, which are based on polymers. Mastic is combined with sheet polymer-bitumen material. Lay it overlapping and press it with a joint roller; the roller is first impregnated with mastic. Horizontal waterproofing provides a powerful layer of protection between the foundation and the brickwork.

Injection is based on the formation of a membrane that repels moisture from the foundation

Injection is based on the formation of a membrane that repels moisture from the foundation. This waterproofing between the foundation and the plinth is carried out using an injection of hydrophobic gel. Once the gel gets into the base, it hardens and closes the pores in the wall and soil. Most often, this method is used to eliminate errors and mistakes in construction.

Before applying the injection, examine the surface from the outside and inside. Next, small holes are made and polymer tubes with taps installed at the ends are inserted into them. The taps are connected to the system and everything is filled with gel under pressure. At the end of the entire process, the tubes are removed and the entire area is covered with a layer of moisture-resistant plaster. It will not be possible to carry out such work on your own, because... This will require the use of specialized equipment.

If it is not possible to create conditions to protect the building from moisture from the outside, it is necessary to ensure such measures from the inside. The same materials are used for the work as for horizontal insulation.

When protecting a structure, special attention is paid to corners and joints. Experts recommend additionally gluing them with reinforced insulating tape.

Carrying out measures to insulate bricks is mandatory, even if your site is located at a low groundwater level.

Coating technology with roll materials

To waterproof a strip foundation with rolled materials, you need to follow a simple sequence of actions that anyone can do:

- Prepare the base surface, level it, clean it from dirt and dust, remove excess inclusions and foreign particles.

- Apply bitumen mastic using a paint brush. In cases where the rolls are with self-adhesive or weld-on material, this step is skipped.

- Roofing felt or any other rolled material is applied to a clean and level surface, previously prepared.

- When fixing the material to the surface, it is important to overlap the layers at the joints. The overlap width should be at least 15 centimeters. In order for the roofing material to be securely fastened in this place, it must be soldered using a gas burner.

The process of applying the material to the surface does not take much time. The installation procedure for roofing felt or other rolled material can be viewed in more detail in the video.

Types of waterproofing works

Waterproofing the foundation with coating mastic before laying bricks

Measures to protect the foundation from moisture are divided into types:

- Coating waterproofing. Such protection is carried out with organic binders (bitumen, mastics and emulsions based on them with special additives) and polymer compounds. They can be applied either manually, with a roller or brush, or with a special gun using compressed air. Coating materials are very thick; before use, they should be diluted with solvents or heated to a liquid state, according to the manufacturer's recommendations. Such compounds are usually delivered to construction sites in buckets or barrels.

- Pasted insulation. As a rule, these are materials based on polymer fabrics or paper, impregnated with compounds containing organic binders. For ease of transportation and storage, they are produced in the form of rolls. Before application, the roll is unwound, the waterproofing is cut, after which it is applied to the concrete structure. During work, in order for such material to stick to the surface, it is heated with a gas burner so that the binder on the mounting side becomes liquid, after which the material is applied and leveled with a roller or trowel, removing dents and removing excess air from under the material. The adhesive insulation is more reliable and durable compared to the coating type, since it is not erased during seasonal ground movement, thanks to the use of a fabric frame, which makes the entire insulation a single rigid element.

- Liquid glass processing. For such protection, a special composition is used, which includes water-soluble substances based on quartz sand. When applied, this composition penetrates deeply into the pores of concrete, and after hardening it forms a durable protective layer on which additional insulation can be applied. It is not recommended to use such compositions separately, since they dissolve when exposed to moisture.

If you add liquid glass to concrete when preparing it, then the mixture, after hardening, will better resist moisture, since the additive will slow down its penetration deeper. However, this will reduce the strength characteristics of the concrete structure, for which it will have to be reinforced with reinforcement. This option is well suited for lightweight structures such as a bathhouse or shed.

Waterproofing using spray material

Waterproofing with sprayed materials is considered the most modern technology. Its main advantage is that it meets all the necessary requirements and clearly performs all tasks. In addition, such material can be used not only to provide foundation protection for the first time, but also to repair old insulation. Today, builders also use sprayed waterproofing materials for roofing work.

The main advantages of spraying include:

- Long service life.

- Ease of application of the material.

- Absence of any seams or joints.

- Fast drying and hardening.

- It has no toxic properties and does not cause any harm to health.

- Resistant to ultraviolet rays.

- Elastic.

The only disadvantages of sprayed materials include the relatively high cost of the work, as well as the need to use special equipment to carry out the coating.

The technology for applying the material involves preparatory work, and then spraying the substance using a special device. Geotexy is also applied for fixation. A video of how the spraying procedure is performed can also be seen online.

Features of base waterproofing

When applying waterproofing material, you need to remember some features. Firstly, do not forget that the soil contains moisture, as well as many other substances that lead to destruction. Therefore, it is important to provide protection from the lands located next to the foundation. Materials, especially coating materials, must be applied in different directions, horizontally and vertically.

If you are still wondering whether waterproofing is needed or whether protective work needs to be done, you should think about the fact that due to the destruction of the foundation, the building will gradually begin to tilt, and, therefore, walls and other parts of the structure will begin to collapse. Repairs in this case will be quite expensive, so it is better to prevent such difficulties from occurring.