Proper arrangement of the blind area and plinth allows you to reduce the negative impact on the foundation of the house, and therefore extend its service life. To do this, it is necessary to use high-quality materials and strictly follow the installation process. Not only the finishing is important, but also the waterproofing of the base, which can be done both during the construction of the building and during its repair.

Protecting the base from moisture

Why is a water barrier between the foundation and the brickwork of the basement necessary?

Waterproofing the base is a mandatory procedure that allows you to reduce the effect of moisture on building materials, and therefore prevent their premature wear.

The contact of the ground floor with the foundation and the walls of the house leads to the fact that all parts of the structure may collapse.

The base should be protected more carefully than other surfaces, since it is affected not only by precipitation, but also by groundwater.

Freezing and destruction of walls

Protecting the base at the border with the foundation helps prevent cracking of the brick, which occurs as a result of moisture accumulation.

Destruction and cracking of walls

When freezing, the volume of moisture increases, which has a negative effect on the surface of not only the base, but also the entire facade. The waterproofing layer prevents moisture from entering the pores of the brick and protects against premature deterioration.

Efflorescence on the surface

Waterproofing a brick plinth also helps prevent the accumulation of salts that are present in groundwater.

Formation of efflorescence

The deposits also change their volume, which leads to the appearance of cracks. In addition, efflorescence on the surface significantly impairs the attractiveness of the façade.

Increased humidity inside the building

Sealing the junction of the plinth and foundation prevents moisture from entering the internal surfaces of the building. If you do not use waterproofing materials, the smell of dampness may spread in the room, which negatively affects internal comfort.

The appearance of fungus and mold

External protection of the foundation from moisture is a preventive measure against the occurrence of fungus and mold.

The appearance of mold and mildew

These phenomena not only worsen the appearance of the room, but also negatively affect the health of the residents, since pathogenic spores can penetrate the respiratory tract and cause problems.

Why is it necessary to waterproof the basement?

Private housing construction is diverse, and decisions are made based on the capabilities of the owner. However, there are standards that are recommended to be followed in any case. The threat that arises when moisture enters load-bearing elements cannot be underestimated.

The structure of most building materials is porous and liquid will easily fill empty cavities. The capillary propagation effect moves moisture inside the structure in all directions, even upward. The element that has absorbed water becomes softer and begins to collapse under the influence of the mass of the house and natural vibrations that a person does not feel.

When sub-zero temperatures occur, ice forms in the body of the material. The expansion force is such that it can easily destroy both brick and concrete. If the basement is not waterproofed and insulated, then within a few years the supporting structure will crumble to such an extent that the house will begin to pose a serious threat to its inhabitants.

Destruction of the base in the absence of waterproofing

Materials used for waterproofing work

Waterproofing the basement of a house from the outside can be done using various materials. They differ in their composition and also have different methods of application. Compliance with the work technology allows you to reliably protect the basement part of the building.

Deep penetration mixtures and primers

Basement waterproofing is often carried out using deep penetration compounds.

These can be either liquid solutions or mixtures, with the help of which you can not only ensure the presence of a water barrier, but also repair minor surface defects. Such mixtures and primers are used as a waterproofing material, usually in combination with other options. In addition, the technology for their application has its own nuances: careful surface preparation, cleaning, and treatment with degreasing compounds are required. On the other hand, such basement waterproofing is very practical and economical, since it is considered one of the most accurate, not requiring additional external finishing work. Modern deep penetration compositions are made on the basis of polymers or mastics, which makes it possible to penetrate quite deeply - up to 25 cm - and create good protection. But to ensure high-quality waterproofing, it is worth choosing the right composition.

Polymer compositions

A hydrobarrier for the base can be created using polymer-based materials.

They include several components, among which there are special additives and plasticizers that simplify the process of applying the material, as well as providing waterproofing properties. At the same time, experts recommend combining such waterproofing with a reliable finish, since the mixtures provide protection only from moisture, while they themselves need protection from other phenomena.

Roll materials

This option is one of the most common, since the materials are quite affordable.

Waterproofing the base with rolled sheets should be carried out in several layers, the number of which depends on the degree of moisture in the area. In some cases, 4 layers or more may be required to reliably protect the base from groundwater and precipitation. To improve protection, it is necessary to consider the drainage system. In addition, rolled materials are subject to mechanical stress, which requires a reliable and high-quality finish. This waterproofing is quite durable. One of the most common options for rolled waterproofing materials is roofing felt. The most common manufacturer is TECHNONICOL. Also popular is “Izospan A base”, which has an affordable price and guarantees reliable protection. The process of laying such material is very simple and does not require additional skills. In addition, “Izospan A base” not only protects the surface from moisture, but also from wind. It has a high level of vapor permeability, which allows vapors to escape outside, creating a comfortable indoor microclimate.

Coating materials

Mastics based on polymers, cement or bitumen have been known for a long time.

They are able to reliably protect the base, but unlike Izospan A base, they are not as durable and will last about 5 years. This is especially true for bitumen compounds. But mixtures made using cement and polymers are more durable, as they tolerate low temperatures well without losing their quality characteristics. There are also more modern waterproofing materials, for example injection ones, which are inserted with a special tool into the base and create the necessary protection. But, if no special skills are required to install Izospan A Socle, then for such compositions you need to have professional training and specialized equipment.

Choosing a waterproofing method depending on the design of the base

Each element of the house carries a functional, semantic and architectural load. In fact, the base is part of the foundation. In some types of buildings the base is monolithic and the division is conditional. It is generally accepted that the base is the part of the house located between the upper boundary of the soil and the floor level, although technically this element can be a single structure with the foundation, but unlike the latter, decorative finishing is required.

The functions of the base are:

- the basis of the load-bearing part of the house. Walls, floor slabs or joists rest on the plinth;

- protection against moisture penetration;

- is part of the basement structure;

- increases the energy efficiency of the house, as it reliably protects the building from cold soil, with which direct contact is excluded;

- how the visible part of the facade plays an architectural and aesthetic role.

The building design notes the design features of the lower part of the building, since it is the basis of the structure and further operation depends on the shape, material and installation technology.

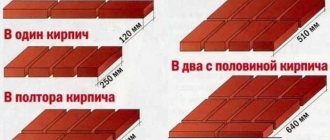

Based on its position relative to the wall of the house, the base is usually divided into three types:

- Sunken. The front plane of the base is shifted inward and is located under the main wall of the house. Technologically, it is the most optimal method in terms of protecting the building from moisture. The waterproofing of the foundation base is covered by the supporting structures of the house and is less exposed to external forces than in other types;

- Speaker. The facade of a house with this type of plinth gives the appearance of the facade solidity and visual reliability. Having chosen this option, you should focus on installing waterproofing of the base from the outside, since it is open to direct exposure to solar radiation, rain, hail and snow;

- In the same plane as the wall. The option differs little from the previous type in terms of functional characteristics. Serious measures are required to ensure reliable protection of the building.

Depending on the tasks of creating the exterior of the house, a constructive solution is selected. But in any type, maximum waterproofing of the base from the outside must be ensured. If insulation is provided, then an outer layer of moisture protection is also placed on top of it.

Insulation is not always provided on the inside. They do it as needed, for example, when the basement or ground floor is used as an office space or workshop, which is not desirable. Moisture penetration from the soil is not the only reason. The basement floor is waterproofed from the inside when a sauna or swimming pool is installed in the room.

Types of base

It is recommended to use non-hygroscopic materials as insulation, such as polystyrene foam boards. Mineral wool is not the best option, but with proper protection this method is acceptable. The disadvantage of absorbent substances is their possible wetting and freezing during cold weather.

This will be a significant load for the construction of the foundation and plinth, since mineral wool under the decorative cladding can retain moisture for a long time.

Might be interesting

Waterproofing

Foundation waterproofing: optimal choice of technology

Waterproofing

Clean water is the key to health, waterproofing concrete…

Waterproofing

Instructions for waterproofing a swimming pool

Waterproofing

Selection of materials, methods of waterproofing work...

When equipping a basement for specific purposes, it is necessary to have accurate geodetic data on seasonal fluctuations in groundwater levels. Consultation with neighbors and information from regional bodies of the State Geology Department will help to correctly determine the technology for waterproofing a building.

Projects of modern houses provide owners with the maximum level of comfort. An insulated garage, home theater or billiard room are becoming a familiar attribute of everyday life. It is not advisable to equip premises of this type in the main area of the housing. Therefore, they are often moved to the basement or semi-basement space.

If you approach this problem wisely, then high-quality waterproofing and insulation of the basement floor will increase the usable area of housing, which is not inferior in comfort to the upper level.

There are many high-quality materials on the market today to achieve the required degree of protection. The variety of products in this category allows you to create a space with precise characteristics.

Insulation of the base with expanded polystyrene sheets, under which the waterproofing layer is visible

The maximum degree of protection, where effective thermal insulation is ensured, will allow the room to be used as a living space. A cold cellar is perfect for storing food. The area with humidity and temperature control is suitable for wine connoisseurs.

Waterproofing methods

Waterproofing a brick plinth can be carried out in two planes. It is important to consider that for better protection, it is necessary to carry out work in two directions.

Horizontal waterproofing

This option involves laying the material directly between the foundation and the outer part of the base.

Horizontally

The optimal choice in this case would be rolled roofing felt or roofing felt. The first one is more popular. The material made on the basis of bitumen copes well with its functions.

Vertical waterproofing

Treatment of the surface of the base from the outside is vertical waterproofing. There is a larger selection of waterproofing materials here.

Vertical

These can be mastics, varnishes, roll versions, as well as synthetic resins, etc.

Waterproofing technology

The process of waterproofing work depends on the type of material chosen. To obtain maximum effect, it is recommended to approach waterproofing comprehensively. It is required to strictly follow the technology in order for the result to be satisfactory.

Required Tools

Before starting work, you must prepare all the necessary equipment. For waterproofing, you will need to carry out a variety of work, so you will need different tools:

- To prepare the surface, you need a jackhammer, hammer drill, fan heater or other more specialized equipment for cleaning and drying the base.

- To apply mastics or penetrating compounds, use a brush or spatula.

- Gas burner, disc knife for cutting rolled waterproofing materials.

- Personal protective equipment to prevent contact of aggressive substances with the skin and mucous membranes.

Tools and accessories

If you have everything you need, you can start doing waterproofing yourself.

Sealing cracks and cavities

To create a reliable hydrobarrier, you will need to carefully treat the surface, eliminating all defects and leveling the base, sealing all cracks and cavities.

First of all, you need to widen all the cracks and clean them.

Next, you need to treat the surface with a primer, after which it dries, all defects are sealed with cement mortar. Once the mixture has dried, you can proceed to the main work.

Insulation between plinth and foundation

Horizontal waterproofing of the base and foundation is carried out at the stage of construction of the structure. To do this, you need to use rolled materials. For greater efficiency, you can pre-treat the fabric with water-repellent compounds.

Laying of roll materials

Installation can be done using two methods:

- Cold. The canvases are overlapped to prevent moisture from seeping through the joints.

- Hot. With this method, the sheets are laid exactly at the joint and, as a result of heating, a strong connection is formed.

If horizontal waterproofing is carried out at the construction stage, then a vertical water barrier can be created on a completed house.

Waterproofing with bitumen

The use of bitumen is considered an effective and economical option.

The waterproofing process is very simple:

- the surface is prepared: cleaning and leveling are carried out;

- a bitumen solution of the required consistency is diluted;

- the surface is treated with a roller or brush;

- reapply, possibly in several layers.

Correct application guarantees reliable protection of the base from moisture.

Application of liquid rubber

The use of liquid rubber allows you to create a durable and seamless waterproofing layer. The material must be applied to a well-cleaned surface. To improve adhesion, the surface should be pre-primed with a deep penetration compound.

Application of liquid rubber

For application, you can use a roller or spatula, since the mixture is quite plastic and it is important to distribute it evenly over the surface.

Installation of roll materials

Rolled materials, such as roofing felt, roofing felt or membranes, for example “Izospan A base” , require additional protection from mechanical stress, so you should carefully take care of additional finishing. As with other materials, the surface must be carefully prepared: cleaned, leveled, and primed. Before laying the canvases you need to level them. To do this, the material is left unrolled for a day. Before installation, it is recommended to apply mastic to the surface.

Laying is done from bottom to top. The base of the canvas is heated for strong adhesion to the surface. Next, using a roller, you need to level the sheet, expelling air bubbles, as when gluing wallpaper.

All canvases are laid with an overlap, which should be at least 10 cm.

If you plan to install a second waterproofing layer or more, then each next one is installed after the previous one has completely hardened.

Carrying out waterproofing work

According to modern requirements, it is advisable to perform double horizontal insulation. The first layer is laid between the foundation itself and the plinth at a height of 20 cm from the blind area, and the second layer is laid on top, in front of the walls made of blocks or bricks in a place not reaching 10 cm from the floors of the first floor.

First, the surface of the foundation is leveled using cement mortars and covered with a primer. You should choose a deeply penetrating type of solution. Then the waterproofing material is laid in 2 layers.

The strips are laid flush with the brickwork. Smooth edges are laid along the outer perimeter of the walls. The material is overlapped to prevent the joints from getting wet. It is better to fix the roofing material with hot bitumen. You can cope with such work yourself. Laying roofing felt will require the efforts of two people.

All joints must be thoroughly coated with bitumen several times, otherwise reliable protection against moisture ingress will not be created.

Experts advise additionally applying liquid rubber in 1-2 layers 2-5 mm thick to create an additional waterproofing layer. Thanks to its special elasticity, even cracks in the foundation and its movements will not lead to moisture penetration. Existing cracks should be slightly widened and given a rectangular shape to ensure penetration of the solution into them.

Polymer coating materials are easy to apply. No additional surface preparation is required. The disadvantage is the high cost of the material.

Ways to eliminate possible errors

One of the common mistakes that novice builders make is neglecting horizontal waterproofing. This will soon affect the quality of the basement masonry. This problem can only be solved with the help of injectable formulations, which are expensive and require the use of specialized equipment. Therefore, waterproofing should be taken care of even at the stage of building a house.

There is a second option to solve the problem - partial dismantling. But this is a rather labor-intensive and lengthy process. To do this you will need:

- remove the part of the brickwork closest to the foundation;

- then the rolled material is laid on the surface of the foundation;

- the masonry is returned to its place;

- All seams are carefully sealed.

Work on the next section can be carried out only after 20 days, when the masonry mortar has thoroughly hardened.

To avoid problems, it is necessary to select only high-quality waterproofing materials and strictly follow the installation or application technology.