The integrity and reliability of the capital structure subsequently built on it depends on the quality of foundation construction. In cases where soil characteristics do not allow choosing a conventional type of foundation, you can use a pile foundation for a brick house. Before you begin its construction, you need to know all the features, types, advantages and disadvantages of this design.

Necessity of application

The main reason for choosing a pile foundation is weak soil. These include: loess-like soil, which loses its stability at high humidity, plant soil with a large amount of peat, quicksand and loam, highly saturated with water.

In these cases, it is necessary to transfer the entire load from the brick house to denser soil located at depth.

The organization of a pile foundation is also often chosen to reduce the volume of earthworks and the costs of removing earth after digging a trench, backfilling and subsequent pouring of concrete.

Advantages and disadvantages

A pile foundation for a brick house has many advantages:

- Chemical stability and inertness to aggressive acidic soils.

- Increased resistance to transverse and longitudinal loads.

- Versatility - can be used for swampy and coastal soils with a significant depth of ground freezing.

- Reduced foundation construction time and minimal amount of “wet” work.

- Long service life and increased safety margin.

Disadvantages include:

- The possibility of violating the integrity of neighboring structures, especially if powerful hammers are used during construction. This technique creates strong ground vibrations.

- The use of large-sized special equipment is required, which requires significant space for maneuvers.

- A geological report is required. During the installation of a pile foundation, displacement of the supports may occur in winter due to heaving of the earth.

- Accurate calculations are required to construct the foundation.

Foundation on screw piles for a brick house

The pile foundation for a brick house is a continuous pile field

and can be installed on complex and moving soils (with the exception of rocks) subject to frost heaving.

Screw piles, screwed below the soil freezing level, are concreted, so they can withstand very heavy loads and last for many years. Then the channel is tied

.

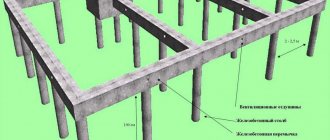

Pile foundation with grillage

for a brick house is especially popular in low-rise construction. More often a grillage with metal is used, less often with concrete, but brick houses can be placed on a foundation with such piping without fear. The harness is divided into three types: suspended, above-ground and buried. For heavy buildings, the latter option is suitable.

Features of installing a pile foundation for a brick house

To install a pile-screw foundation for a brick house, you first need to create a pile field - determine how many piles will be needed, what diameter, with what step they need to be installed, and to what depth.

Types of piles for a brick house

The piles take on the entire load from the building and transfer it to the ground. These are long rods made from different materials and installed in the ground. Pile supports are classified according to:

- interaction with soil;

- method of immersion;

- material.

Types of piles:

- Bored supports. The well is filled with cement mixture simultaneously with its drilling. When the recess is filled, a reinforcement cage is installed into it. The peculiarity of this type of piles is the minimum production time.

- Driven piles are the most widely used type of foundation. The rods are driven into the ground using pneumatic hammers. First, calculations are made of the depth of immersion of the piles, the impact power and the duration of the work. They are then set perpendicular to the ground level and deepened by striking the rods.

- Bored supports are installed by drilling a well in the required area, further immersing the reinforcement and pouring cement into the structure. Typically cylindrical in shape.

- Submersible piles using the screw-in method are characterized by the type of tip and certain design features for use on different types of soil.

- Pressable - technology created for immersing rods near buildings in use. This method eliminates the vibration effect on their base. Installation occurs by pressing the piles into the ground using special equipment.

- Vibro-loaded - use the property of the soil to change its structure during vibration action. Mounted by creating vibrations on the ground. So it changes the structure, and the rods gradually sink. Requires special equipment.

Stages of work execution

Before you build a brick house on a pile foundation, you need to create a project. In this case, it is necessary to calculate the bearing capacity of the piles and additional loads on the base.

Attention: Load-bearing characteristics are determined “by the soil”, since the load-bearing characteristics of cement as a building material exceed these soil properties. For example, 1 cm2 of M100 cement can withstand a load of up to 100 kg/cm2, while 1 cm2 of clay soil can withstand no more than 7 kg/cm2.

To determine the load-carrying indicators, geodetic studies at the construction site are required. During their implementation, geodetic wells are drilled and soil is taken from them for subsequent analysis in the laboratory.

To organize a pile foundation with your own hands for brick houses, it is recommended to construct pillars with a diameter of at least 35 cm; smaller supports are only permissible for the construction of non-critical structures and massive fences.

To find out the number of piles in the foundation, you need to calculate the mass of the future building. This is done by multiplying the total area of the structure by the standard weight of the building materials used.

The following additional loads are added to the calculated mass of the house:

- Snow load on roofing material (taking into account the region of construction of the building).

- Payload during operation is 100 kg per 1 m2 of building floors (basement, floors between floors).

The result obtained is multiplied by an additional strength factor of 1.2. Then the resulting figure is divided by the load-bearing capacity of one support. This is how the required number of piles is determined.

Support arrangement diagram:

- The piles are buried below the freezing point of the ground in a specific construction region.

- Mandatory installation of supports in areas where walls are connected, both external and internal.

- The step between piles is at least 1 m and no more than 3 m.

Preparation for construction

Before constructing the foundation, it is necessary to purchase the necessary materials for construction - boards for formwork and grillage, reinforcement and cement.

You will also additionally need:

- To install piles - a shovel, a concrete mixer, containers for delivering concrete, a drill, a wheelbarrow for transporting soil, tape, roofing felt,

- For marking - rope, wooden stakes, tape measure, pencil, level, screws.

- For the grillage - cement in the required volume, electric drill, wire, self-tapping screws, a hacksaw, waterproofing material for protection after completion of construction.

- For the manufacture of reinforcing frames: reinforcement rods (corrugated, with a cross-section of 11-14 mm, and smooth, with a cross-section of 9-11 mm), a grinder, a welding machine.

Initially, you need to prepare the site for construction - remove stones, debris, stumps from the surface that interfere with the work. If the area is hilly, it needs to be leveled.

Features of base marking

To mark the foundation, you need to assemble stripping boards from boards and timber. Structurally, they consist of 2 horizontal belts. One is required to mark the zero level of the supports, the other is required to determine the upper limit of the grillage.

First, the main lines of the future foundation (the perimeter of the walls of the house) are marked - taking into account the landmark (fencing or the boundary of the construction site), the distance is calculated and the first wall is stripped, a rope is stretched between the panels (attached to the beam with a self-tapping screw).

The adjacent wall is marked perpendicular to the resulting shield at a right angle. The angle can be checked using the Egyptian triangle (on one rope, 3 m are retreated, on the second - 4 m, the distances are marked with tape and the length of the diagonal is measured - if everything is correct, the length should be 5 m).

Then other walls are marked in the same way. At a distance of the width of the grillage, a second rope is attached, which defines the inner perimeter of the walls. The location of the supports is marked taking into account the created project - wear guards are installed and a plumb line is attached at the intersection of the rope, a piece of reinforcement is driven under this point, it determines the location of the future support.

Foundation construction

When the base is marked, the rope is removed and only the stakes are left on the pile construction areas. The stages of constructing supports occur in the following sequence:

- A drill is used to make holes for future supports. It is advisable to make all the wells at once, so that subsequently the piles can be filled with cement mortar in one pass.

- A cylinder equal to the thickness of the pile is made from roofing felt and fixed to it with tape. In this case, the cylinder plays the role of formwork, that is, its height must be equal to the length of the support (if required, go beyond the level of the well). Once the formwork is made, it is installed into the cavity.

- Next, reinforcement bars are installed in the amount of 5-10 pieces. (taking into account the diameter of the support). The length of the reinforcing frame must be half a meter higher than the support column; this distance is required to connect with the grillage reinforcement.

- A concrete composition is poured into the drilled wells (concrete for a pile-brick foundation with a grillage is chosen at least grade M200-300). You can mix the solution yourself using a concrete mixer or order a ready-made concrete composition in the required volume.

- When the cement mixture is poured, it is bayoneted with reinforcement bars. This is required to remove accumulated air from the composition.

After pouring the concrete, you need to wait at least a month to carry out further work. During this time, the support pillars gain the required strength.

Requirements for the arrangement of a brick plinth on screw piles

A pile foundation is the best option for a two-story brick house, the construction of which should be carried out in a region with problematic soil. Dynamic loads on the base, even without insulation of the base structure after the installation of screw elements, will not have an impact on the structure. The depth of the foundation for a one-story house also depends on the characteristics of the soil, so it is necessary to make recesses for supports, guided by established standards.

The foundation of a house on stilts resembles a monolithic foundation in its properties. It can prevent the impact of groundwater on the structure. Neither tape nor slab can compete with screw piles in terms of reliability. These elements, installed during soil drilling, are made of steel, which is corrosion resistant. The structure is prefabricated, as it can be completed within 1-2 days.

A pile foundation with a grillage has its own negative characteristics. Even if the width of the foundation on screw piles is acceptable, the thermal insulation of the house may be at a low level. As a result, the loss of thermal energy will be noticeable. To prevent this from happening, it is necessary to observe all the nuances of the technology for installing a two-story brick house with a base on stilts. It is necessary to insulate the base at the stage of building a house.

An obligatory stage of foundation insulation is the installation of a false base and a blind area - a fence that protects the free space under the house from wind and precipitation. To insulate the foundation of a brick two-story house on stilts, you will need to prepare the following types of thermal insulation materials:

- extruded polystyrene foam (penoplex);

- regular foam.

These materials can be used to insulate different types of foundations. Thermal insulators have a long service life, are durable and reliable. Before insulation, it is necessary to waterproof the brick foundation if the house is planned to be built with a basement.

A layer of waterproofing should be used to cover the upper part of the grillage, where the walls of a two-story brick house, its lower and side parts should be placed. It is also necessary to waterproof the pile heads adjacent to the grillage.