Technical significance of restrictions

First of all, you need to understand why it is necessary to maintain a protective layer when installing the formwork and assembling the reinforcing frame. Until now, iron reinforcement, which is prone to corrosion, is more often used to strengthen monolithic structures. That is, the rods need to be covered with a concrete mass from the influence of environmental conditions that provoke the appearance of rust.

Upon closer inspection, the corroded metal increases in size. Because of this, the steel rods no longer cope with their load-bearing function and the load on the concrete shell from the inside increases. As a result, the monolith is completely destroyed and its design characteristics are lost.

Example of damage to a monolithic structure Source mpkm.org

A protective layer of concrete for reinforcement helps solve the following problems:

- improving the heat resistance of structures made of reinforced concrete products;

- strengthening the position of the reinforcing frame in the body of the monolith;

- insulation of metal from temperature and humidity changes, mechanical and chemical influences;

- uniform distribution of mechanical load on reinforced concrete products;

- ensuring the possibility of using anchor-type fasteners without the risk of damage and exposure of reinforcing rods.

In total, the protective layer of concrete is the shell of the reinforcing frame, which, in addition to its strengthening role, performs a load-bearing function. Improved fixation of metal rods provides stability to structures. A reliable barrier made of a mineral composite prevents the formation of destructive rust, which ultimately has a positive effect on the durability of buildings.

Restoring the protective layer of concrete for reinforcement

Gradually, defects provoked by negative influences develop on concrete monoliths. Because of this, small chips and small cracks appear in the base, constantly expanding. After this, the protective layer ceases to perform its original functions. There are several factors that cause its destruction:

- loads are greater than the pre-calculated limit values;

- unsuccessful use of special equipment during construction;

- violations in the technology of foundation construction, addition of an additional floor;

- soil movement and increased moisture;

- poor waterproofing of the monolith.

The main reason for the destruction of the integrity of the protective layer of concrete for foundation reinforcement is a deviation from the technology, a change in design parameters. To guarantee the restoration of this coating if it is damaged, it is necessary to perform certain actions:

- strengthen the constructed structure;

- attach additional posts across the foundation;

- carefully repair any chips or cracks that appear;

- restore as much of the damaged surface as possible.

To restore the protective coating layer, high-quality cement mortars are used using formwork, as well as additional reinforcement with steel anchors.

Algorithm of actions

Figure 2. Thickness of the protective layer of concrete

Such procedures are performed in the following ways:

- Repairing damage. The surface is first thoroughly cleaned, then a cement mixture is applied to it. To enhance resistance to aggressive influences, frost-resistant additives are added to the solution. This method prevents the appearance of cracks during the setting of the mixture.

- Concreting. Damaged areas of the layer and parts of exposed reinforcement are completely removed, and a new metal mesh is installed. The surface is covered with the appropriate grade of concrete. This option is suitable for restoring slabs or other horizontal surfaces.

- Pasting. The pre-cleaned surface is coated with a polymer material that has the required thermal insulation characteristics. It is glued to the concrete, after which the monolith becomes ideally protected from moisture. The technique is used for the restoration of concrete columns and other vertical structures.

- Shotcrete. Concrete is supplied to the monolith under pressure. The technique allows you to quickly reconstruct large areas and ideally repair any cracks in them. The disadvantage is the overconsumption of the solution, the difficulty of applying a layer clearly defined in thickness.

When repairing, it is advisable to increase the thickness of the protective layer by at least 5 mm. This ensures its ability to withstand loads. Particular care must be taken in preparing the mixture using high-strength cement to ensure its adhesion to the site of destruction.

The protective layer is extremely important for maintaining the technical characteristics of the reinforcement. It extends the operational period of reliable retention of structures by the foundation. As soon as minimal damage appears, it is necessary to restore it immediately so as not to trigger the problem. Otherwise, a full repair of the monolith will cost more and take more time.

Factors affecting shell size

Having understood what a protective layer of concrete is and why it is needed, you can begin to determine its thickness.

Thickness of the protective layer of concrete over a metal frame Source odstroy.ru

See also: Catalog of companies that specialize in finishing materials and related work

Let's consider what the parameter depends on and what deviations from the optimal values lead to. At the design stage, specialists are guided by current recommendations from SP 63.13330 from 2012 and SNiP 52-01 from 2003. The documents define the basic data on which the required parameter depends:

- technical characteristics and cross-section of reinforcing bars;

- actual location of steel rods: longitudinal or transverse;

- functional significance of the reinforcing frame: working or constructive;

- specified state of the reinforcement: normal or prestressed;

- type of concrete reinforced concrete product;

- design load on the element under consideration;

- physical parameters of a monolithic sample;

- operating conditions relative to the environment.

When pouring concrete yourself, the optimal thickness of the protective layer of concrete for reinforcement is often violated. Saving on the mineral component helps reduce the durability of the barrier.

Consequences of saving on cement mortar Source stroyding.ru

Thickness of the protective layer of concrete

For each type of reinforced concrete structures, a different thickness of protection is sufficient. This parameter is regulated by regulatory documents, in particular SNIP 52-101-2003 (Concrete and reinforced concrete structures without prestressing reinforcement). The standards are described in the section Reinforced concrete structures. There are four main types of protection:

- The first (smallest) option is 20 mm thick. It is used in enclosed spaces where the humidity level does not exceed normal values.

- The next option is slightly thicker - 25 mm. It is used under similar conditions, but in the absence of additional protective measures.

- The 30 mm thick option is used outdoors, unless other protective measures are provided.

- The latter option has a minimum thickness of 40 mm and can be used in soils and foundations subject to concrete preparation.

An additional 5th option is used for those structures that are in direct contact with the ground. In this case, the recommended protection thickness is 70-75 mm. But some sources mention a smaller thickness.

There are also special specifications for specific reinforced concrete products, for example, columns, beams, slabs, blocks. The situation is similar with the requirements for different types of concrete, for example, light, heavy, cellular, etc.

A few words about the recovery process

The protective layer of reinforcement in concrete is often destroyed for one reason or another. This phenomenon must be stopped in a timely manner and repair work carried out. First, rust, peeling, dirt and dust are removed. Next, the reinforcement is coated with an anti-corrosion compound, and the working area of the monolith is treated with a primer. Concrete concrete is restored using cement plaster, concrete mortar, alternative polymer-based materials or the shotcrete method (supplying the mixture under pressure). In any case, the strength of the selected composition must be equal to that of the structure being repaired.

Restoring the protective layer of concrete

The protective layer of concrete is a layer of concrete mixture, the thickness of which is equal to the distance from the surface to the beginning of the reinforcing parts. The main purpose of the protective concrete layer is to protect the reinforcement from the adverse effects of the external environment - high humidity, heating, corrosion, etc. In addition, the protective layer is necessary to secure the reinforcement in the concrete and ensure the joint work of iron and concrete.

During the operation of buildings or structures, building structures are exposed to severe atmospheric influences, the main of which are periodic wetting of the concrete surface and temperature fluctuations, which lead to the gradual destruction of the protective concrete layer. Various kinds of cracks and peelings appear in it, the reinforcement is exposed and its subsequent corrosion occurs. All this indicates the need to restore the protective concrete layer.

In the modern construction industry, there are a number of methods used to restore and strengthen the protective concrete layer. Let's take a closer look at them.

1. Plastering the building structure with a dense cement-sand mortar followed by application of a crack-resistant paint and varnish coating;

2. Coating the surface with cement or polymer concrete having a strength not lower than the structure being restored.

3. Application of special polymer adhesive materials to the surface.

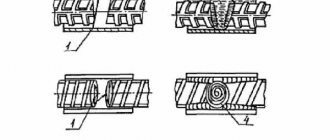

4. Gunning of concrete surfaces.

The first three methods allow you to effectively get rid of damage to the protective layer, however, they do not directly improve the performance characteristics of the structure being repaired. In addition, these methods do not provide sufficient adhesion of new concrete or cement mortar to old concrete, and the protective layer obtained after restoration does not have acceptable strength, water resistance and corrosion resistance. The use of special adhesive compositions is complicated by the high cost of work and poor compatibility of the repair layer material with the material of the structure being repaired in terms of deformation properties.

Shotcrete can be used on surfaces with any irregularities located in any plane. The main advantage of shotcrete is the high adhesion strength of the repair layer to the surface of the structure being repaired. The concrete layer obtained after shotcrete has increased density, mechanical strength, water resistance and frost resistance. In addition, the physical and mechanical properties of the repaired concrete surface are significantly improved - bending strength increases by 40%, compressive strength by 15% and elasticity of concrete by 5 percent or more. Important advantages of shotcrete are high productivity (and, as a result, speed) and low cost of construction work.

There are two methods of shotcrete – “wet” shotcrete and “dry” shotcrete.

When using “wet” shotcrete, a mixture of cement, water and special additives is prepared in advance, and only then is supplied through a transport hose to the surface to be repaired. “Wet” shotcrete has the following advantages - uniform concrete composition, the ability to carry out work in tight spaces, minimal rebound, etc. This shotcrete method is used for repairing large surfaces (with an area of 2 thousand sq.m. or more).

With “dry” shotcrete, shotcrete and water are mixed only at the exit from the nozzle of the shotcrete installation. The use of the “dry” shotcrete method does not require preparation of the base of the surface to be repaired, allows you to apply a thick layer of shotcrete in one pass and makes it possible to carry out repair work intermittently (unlike “wet” shotcrete, in which the prepared mixture must be used continuously).

Thus, shotcreting of concrete surfaces is the fastest and most effective way to restore the protective layer of concrete. This method has been used in construction for many years. The fundamental principles of the company's work are high speed and quality of work, the use of advanced technologies and materials. Highly qualified specialists and extensive experience allow SDT LLC to guarantee the quality of work on restoring the protective layer of concrete using the gunite method. Here at this link you can learn in more detail about how shotcreting of concrete surfaces is carried out, prices and deadlines for completing the work.

Briefly about the main thing

Over time, exposed reinforcement begins to corrode and collapse, which negatively affects the general condition of the monolith.

To extend the service life of reinforced concrete products, it is important to form a protective layer of concrete of the required thickness.

To determine the distance from the metal frame to the surface of a monolithic product, there are regulatory documents.

The parameters depend on the diameter of the fittings, its condition and location, the dimensions of the products, their purpose and operating conditions.

If the concrete shell has collapsed, it can be restored using cement or polymer compounds with similar strength.

Ratings 0

Under what conditions is the protective layer of concrete destroyed?

- use of low-quality concrete mortar for the manufacture of reinforced concrete structures;

- discrepancy between the grade and class of concrete and the scope of application of the reinforced concrete product;

- difficult operating conditions of the facility (sea water, prolonged rainfall, sudden temperature changes, strong winds, high air humidity, exposure to aggressive liquids and oils, high seismic activity, etc.);

- long service life of a building or structure without timely restoration of the protective layer of concrete;

- incorrectly calculated thickness of the concrete protective layer.