Home |Reinforcement |Is it possible to weld reinforcement for the foundation?

Date: January 13, 2019

Comments: 4

When starting the construction of a house, we hope that it will be a reliable protection for the family hearth. In order for expectations to be met, you need to make an effort in your work, competently approach the solution of many issues, one of which is whether it is possible to weld reinforcement for the foundation.

There is still no consensus on what is better – welding or knitting a frame for the foundation. If for high-rise buildings, the foundation of which carries enormous loads, welded reinforcement is the only correct solution, then when constructing one-story buildings, expert opinions differ. Let's figure out what advantages and disadvantages are inherent in welding and knitting.

Strengthening the foundation - what is it for?

A well-designed and high-quality foundation is a guarantee of the durability of the structure. A strong, indestructible base will prevent shrinkage, which causes cracks and subsequent destruction of the structure. Therefore, strengthening the foundation is a serious issue that cannot be treated superficially. Increasing the strength of the foundation is achieved by reinforcing the structure with metal mesh or rods of a certain diameter.

Should the reinforcement for the foundation be welded or knitted - this is the main question that many people think about

For low-rise buildings, a strip foundation is most often installed. You can save money and fill the foundation with regular concrete without additional reinforcement. Most likely, after some time, cracks and deformations will appear in the foundation. To prevent undesirable consequences, carry out reinforcement work with a steel frame that:

- Increases strength.

- Evenly distributes the load.

- Compensates for soil reactions during freezing.

- Will increase the service life of the structure.

Reinforcement in concrete will protect the foundation from cracking and destruction.

Methods for connecting reinforcing elements

There are various methods to increase the strength characteristics of the foundation. Private developers use any available material (waste metal, broken glass, etc.). For country houses this is an acceptable option. But to build a reliable house, even a one-story one, use proven technologies for strengthening with metal mesh or rods. If your choice is a mesh, then you only need to cut it correctly and install it properly in the prepared trenches. The use of metal elements implies the creation of a single structure from them, the so-called frame.

It is worth knitting reinforcement in cases where you need to get a good foundation on difficult soil

There are two ways to achieve this:

- tie using flexible wire for connection;

- apply welding to fix the structural elements.

Both options have strengths and weaknesses. Let's conduct a comparative analysis of each of them.

Knitting or welding of reinforcement - what to choose?

Of course, many people use reinforcement welding in the construction of foundations. However, this is impractical and incorrect in some cases.

Firstly, if a large building is being built, then welding turns out to be a more expensive undertaking than tying reinforcement. If we take into account the required number of welders, then a considerable amount of money will be spent on paying for their labor.

In addition, we must not forget about the human factor. Today, finding a good welder is really a problem, since few people want to devote their lives to this profession. Welders don’t earn that much, but their work is hazardous and requires free milk.

Well, it won't stray from the topic. Therefore, let's move on to the next disadvantages. On moving soils, welding reinforcement for the foundation is completely prohibited. This is due to the fact that, as mentioned above, the welded reinforcement frame will have great rigidity.

And if soil subsidence suddenly occurs, the reinforcement will simply burst at the welding points, while on the wire, the frame will pull a little, but it will remain intact. In addition, we must not forget that not all fittings are suitable for welding.

READ Do-it-yourself foundation drainage for a private house

Only special steel is used for welding, which is designated by the letter “C”. Thus, if we summarize, it becomes clear why exactly it is impossible to weld reinforcement for the foundation.

This is due, first of all, to a large number of restrictions that are absent when tying reinforcement. Feel free to add your comments and share your own experiences. It is, as they say, priceless.

SNiP 52-01-2003

"8.2.3. Welded reinforcement products (mesh, frames) should be manufactured using resistance spot welding or other methods that ensure the required strength of the welded joint and do not allow a decrease in the strength of the reinforcement elements being connected (GOST 14098, GOST 10922).”

“In addition to the requirements for tensile strength, the reinforcement is subject to requirements for additional indicators determined according to the relevant standards: weldability, endurance, ductility, resistance to corrosion cracking, relaxation resistance, cold resistance, resistance at high temperatures, elongation at break, etc.

Non-metallic reinforcement (including fiber) is also subject to requirements for alkali resistance and adhesion to concrete.”

Flaws

A direct disadvantage is the rigidity of the structure. That is why this does not make it possible to build foundations in this way on all types of soil. On moving soils in the support belt, excessive stress may appear, leading to cracks and uneven load distribution with adverse consequences for the entire building. Inaccurate pouring of the concrete mass can lead to rupture and distortion of the welded structure.

Possible shortcomings are caused by violations of technology during operations, parameters of welding equipment and the human factor represented by the performer (manufacturer) of the work. All this, even with a carefully calculated project, requires vigilant control and step-by-step checks of the implementation of all operations.

Methods for connecting reinforcing elements

There are various methods to increase the strength characteristics of the foundation. Private developers use any available material (waste metal, broken glass, etc.). For country houses this is an acceptable option. But to build a reliable house, even a one-story one, use proven technologies for strengthening with metal mesh or rods. If your choice is a mesh, then you only need to cut it correctly and install it properly in the prepared trenches. The use of metal elements implies the creation of a single structure from them, the so-called frame.

It is worth knitting reinforcement in cases where you need to get a good foundation on difficult soil

- tie using flexible wire for connection;

- apply welding to fix the structural elements.

Both options have strengths and weaknesses. Let's conduct a comparative analysis of each of them.

Basic techniques for tying reinforcement

You can knit reinforcing bars in different ways. But basically the reinforcement is knitted in accordance with the following principles:

- To perform the work, wire cutters must have blunt ends (so that the wire does not break during the bending process);

- You can connect the rods by pulling them one to the other;

- The easiest way to connect reinforcement cages is with the help of special racks;

- if a special hook is used to knit rods, the number of turns must be at least three;

- if it is inconvenient to knit the reinforcement, use a sectional connection.

Experienced specialists prefer to knit rather than weld foundation reinforcement for the following reasons:

- the strength of the reinforcement is maintained at the original level;

- the structure of the metal is preserved;

- the strength properties of metals are preserved;

- The stiffness parameters of the material are saved.

Today, in the relevant sector of the market, you can purchase special guns that are used to knit reinforcing bars.

In some cases, reinforcement bars are knitted using reinforcing couplings. But in the modern domestic market it is not used very often, although foreign builders use couplings quite actively.

Quality checking

To preliminarily determine what kind of seam will turn out, two small sections of rods are welded. The cooled joint is inspected for the presence of cracks, the depth of penetration of the body, and the quality of the resulting slag. If at least one of the parameters is in doubt, then it is necessary to change the current settings in the welding machine or replace the electrodes:

- The electrode sticks - increase the current;

- It does not stick, but immediately burns the surface - reduce the current;

- It is difficult to catch the arc without burning the rod - take an electrode of a smaller diameter;

- The electrode is burning, the slag is foaming - this means it is of poor quality, replace it.

Advantages and disadvantages of welding reinforcement

There is no consensus on whether it is possible to weld foundation reinforcing bars together. Some experts are sure that this cannot be done, while others hold the opposite point of view. However, the welding method for fastening segments of reinforcing wire together is used in practice quite often.

Many builders prefer to weld foundation reinforcement simply because it is quite simple and quick. But during the welding process, the metal of the reinforcement becomes very hot, as a result of which it loses such characteristics as rigidity and strength. Accordingly, if the frame is boiled, it will be less reliable.

Welded reinforcement products can be divided into the following categories:

- welded frames;

- welded mesh;

- welded rods.

Reinforcing welded frames are made from longitudinal and transverse rods, the connection of which is carried out by welding at the intersection points.

Speaking about the advantages of welding foundation reinforcement, the following points should be noted:

- low cost of consumables;

- insignificant time costs;

- the possibility of obtaining a structure of high strength if welded correctly.

When you decide to weld foundation reinforcement, do not forget to first prepare all the surfaces to be treated for work. Upon completion of work, you should ensure that the product cools down on its own, without outside intervention.

Welding reinforcement can significantly simplify the process of laying the foundation as a whole. The strength of the welded frame, even if a small error is made, will significantly decrease.

You can weld the foundation frame only if you are confident in the skill level of the worker who will be entrusted with welding work.

Welding methods

The most common method of electric arc with continuously adjustable current strength (inverter). The assembly can be performed using the following methods:

- Stykov;

- Overlap;

- Tavrov;

- Krestov.

It is better not to use butt joints and tee joints (the end rests on the reinforcement at an angle of 90°) due to low bending strength. These docking methods are used only if there are no other options. The lengths of the rods are welded overlapping, and the crossbars are overlapped. According to the American standard, cross intersections are not cooked. Watch the video on how to reinforce the foundation .

Sources:

https://pobetony.ru/armirovanie/pochemu-nelzya-svarivat-armaturu-dlya-fundamenta/ https://mmasvarka.ru/pochemu-nelzya-svarivat-armaturu-dlya-fundamenta.html https://po4emuchka.ru /pochemu-nelzya/pochemu-nelzya-svarivat-armaturu-dlya-fundamenta.html

Reinforcement knitting technology

There are several ways to knit foundation reinforcement with special wire. This work is carried out directly on site. You can use the services of specialized workshops where the work will be completed efficiently and within the agreed time frame. There is a small downside to this service. You will have to find transport to transport large structures. In small settlements this is difficult and expensive. Therefore, we advise you to independently master the process of knitting frame elements:

- Decide on the number of connection points.

- Cut the appropriate number of pieces of steel wire 20 cm long. The diameter corresponds to 1.2-1.4 mm.

- Fold the cut piece in half.

- Bring the resulting loop to the junction of the elements.

- Use a crochet hook. You can make it yourself or purchase it in a store. Insert the working part into the loop.

- Grab the loose ends and pull them through the hole. The junction of the rods must be covered with wire.

- Tighten with maximum force and, by turning the hook several times, ensure a tight connection of the frame structure parts.

The reinforcement is knitted using a special wire that connects the rods at the corners of the structure

Knitting using a crochet hook is one of the cheapest, but most labor-intensive methods of connecting reinforcing elements. No expensive construction tools are used here; the work is carried out by one or two workers. If you want to speed up and make your work easier, you can purchase:

- automatic tying gun. With its help, the connection speed will increase significantly, but handling it requires certain skills;

- a rotary power tool, such as a drill or screwdriver with a special attachment, which can be purchased in specialized stores.

The advantages of automated devices include increased productivity, the ability to connect structural elements in hard-to-reach places of the frame, and a significant reduction in physical costs.

Knitting reinforcement: advantages and disadvantages

Knitting reinforcement for the foundation is used somewhat more often than the welding method. Let's try to find out why this happens. You can knit the reinforcement using special wire. No other materials can be used.

Knitting a frame is inherently the simplest method of joining. In addition, it is necessary to knit such rods, the marking of which does not have the index “C”, meaning that this reinforcement is not suitable for welding.

Wire is most often knitted from annealed low-carbon steel. The wire used for this purpose can be of different diameters. If you use thinner rods, for reliability it is better to fold them several times. Too thick rods will not bend very well, and therefore it is not recommended to use them. You need to knit materials that are soft in bending.

If the reinforcing wire you are using bends poorly, and there is no other option for use, you can try holding the reinforcement over the fire for half an hour, and then let it cool. This procedure can help make the metal somewhat more pliable.

If you have at least a little experience in the construction industry, knitting reinforcement is quite simple. If the weld is a strong connection, the bonding gives the reinforcement a certain freedom. So settlement of the foundation will not be a problem.

You can knit reinforcement even if construction is carried out on difficult soils. Why is it better to tie? If the reinforcement is welded in this situation, the structure simply will not withstand the loads placed on it and will fall apart over time. If the reinforcement is knitted, nothing like this will happen, since all the connections will remain movable. In this situation, the only thing that can change is the location of the reinforcing bars in space, which does not in any way affect the occurrence of additional stresses in the foundation.

Organization of work

When starting work on creating a reinforced frame using the knitting method, purchase the necessary tools and materials in advance. By following simple recommendations, you will quickly master the connection technique and be able to perform the assigned tasks efficiently:

- Place the bottom row of horizontal structural elements at a short distance from the ground surface - 4/6 cm. Wooden or plastic pads are suitable to ensure the required gap. Their task is to prevent the frame from coming into contact with the soil.

- Install vertical elements at a fixed distance from each other.

Keep your step even. Ensure that the bars remain stationary using locking devices. Protect metal from contact with the ground using non-metallic cup holders. It is important to comply with this requirement to avoid corrosion of the reinforcement in the future. The knitting process itself is different in that it can be done either directly at the site of construction of the building or in a special workshop - Proceed to fixing the frame elements. Pay special attention to the reliability of connections. They must withstand the stage of pouring concrete mixture without moving.

- When constructing a reinforcing frame in several tiers, maintain equal distances between horizontal and vertical elements. Provide additional fastening to the corners of the structure - they tend to move during pouring. Make sure that the corner parts of the reinforcement are bent inward and do not protrude beyond the base.

- Observe the requirements laid down in the technical specifications for the selection of grades and assortments of materials.

- Carry out simple strength tests on the frame after completion of the work. Place a board on the top tier of the structure and walk along it - the frame should remain motionless under the influence of human weight.

- Immediately before pouring concrete, additionally fix the entire structure to prevent vertical deviations.

In what cases is welding used?

Welding can be used if the expert has analyzed the location of the building, the structure of the soil where the construction of a house or other structure is planned. If the soil is resistant to subsidence, then welding is used, since this is a fairly quick method of fastening the structure.

If, after testing and all related measurements, it turns out that the load on the ground is small and the profile will not tolerate serious deformations and changes, then they choose to install reinforced rods for the foundation frame using the welding method.

To avoid a decrease in the strength of the welded reinforcement and, as a result, the quality of the entire structure, it is necessary to correctly and carefully select the technology, tools and materials for welding surfaces, as well as follow the technology for such work. There is an important recommendation: before starting mass work, it is advisable to test the material and the tool used. This will help you evaluate the quality of work and pay attention to all the nuances.

Rebar welding technology

Although welding reinforcement for the foundation is more labor-intensive than knitting, it is impossible to completely abandon it. On large construction sites, when constructing multi-story buildings, it is impossible to do without welding. The foundations of such structures bear increased loads, and therefore the strength requirements are appropriate. To weld reinforcement for the foundation, use special brands of products - A400C or A500C. The diameter of the rods is within 3-5 centimeters. Resistance spot welding is used for the work. Considering the fact that when the metal overheats, changes in the structure occur, causing a weakening of the strength characteristics, it is desirable that the welding of reinforcement for the foundation takes place at specialized enterprises or is carried out on construction sites by qualified welders.

When welding, the strength of the reinforcement is reduced and the internal structure is damaged

The production of welded frames in industrial conditions is carried out in several stages:

- The technical control department checks the quality of materials that are planned to be used in the manufacture of the frame. Material that does not meet the requirements of standards and specifications is rejected;

- Round rolled steel made of St. 0 or St. 3, previously cleaned of rust and dirt, is straightened, marked, and cut to a given size. The elements are cleaned with an abrasive tool;

- the workpieces are connected into a flat structure. Spot welding of reinforcement is carried out with a workpiece diameter of up to 26 millimeters. When working with reinforcement of increased diameter, deformations of the structure occur due to strong heating during welding. To avoid distortion, the elements are lightly grabbed;

- Using special conductors, flat elements are installed vertically above each other at a calculated distance. Conductors are manufactured with a high degree of accuracy - deviations from the specified parameters do not exceed three millimeters;

- a preliminary bunch of elements is made;

- The compliance of the spatial design with the technical design is checked, the entire assembly as a whole is corrected, and the required length of welding seams is determined. To avoid deformation of elements from overheating, the sequence of welding joints is clearly defined;

- The spatial structure is finally welded.

Most often this method is used in places where the soil has a stable position, that is, it does not settle too much

When welding directly on a construction site, the procedure is similar. The only difference is the inconvenience of using arc welding. Therefore, when assembling a frame module on site, spot welding of reinforcement is used. It is mobile, and when equipped with special pliers, you can perform work even in a suspended state, with rotation to any angle.

Methods for connecting reinforcement

Since the reinforcement frame is assembled directly at the construction site, the simplest methods of connecting rods are used to quickly complete this part of the work. The most common and reliable method is considered to be knitting reinforcement using pre-annealed soft wire.

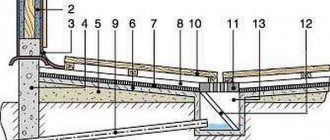

Methods of connecting reinforcement: 1 – knitting, 2 – welding, 3 – plastic clamps.

The technology for such a connection is extremely simple, but for many beginners in construction it is unacceptable due to the lack of appropriate skills. Therefore, some of them prefer to choose the second connection option, which will require stocking up on welding equipment. This approach once again forces us to address the main question of this article: is it permissible to weld reinforcement under the foundation and will this not lead to its weakening?

Knitting features

To decide on the choice of method for assembling a reinforcing structure, you should familiarize yourself with the knitting procedure in more detail. This method refers to universal methods for connecting rods, suitable for both steel and fiberglass reinforcement. The function of the fastening element in this assembly method is performed by annealed wire with a diameter of about 0.8-1.5 mm. The consumption of binding wire varies from 5 to 20 kg per ton of metal.

According to most reinforcers, the most convenient wire diameter for crocheting reinforcement is 1.2 mm.

Before starting work, you will need to prepare short pieces about 25-30 cm long and a special hook for tying reinforcement. The sequence of actions is as follows.

- First, the wire is folded in half.

- The resulting loop is then thrown around the prefabricated elements.

- Finally, it is grabbed with a hook and turned several times, forming a twist.

The entire procedure, if you have the skills, is completed in a matter of seconds, and you can learn this quite quickly. The video below shows an example of how the reinforcement is tied correctly and what speed a professional reinforcement worker can achieve.

The main advantage of knitting is the ability to work in the absence of power. The only requirement in this case is good illumination of the installation area. The advantages of the method include the low cost of wire blanks (electrodes and rental of a welding unit will cost much more). Therefore, professional builders often knit reinforcement rather than weld when assembling steel frames to reinforce strip foundations and other reinforced concrete structures.

Advantages and disadvantages of welding

Under certain conditions, welding the frame seems to be a more reliable option for solving the problem. But at the same time, its use, as a rule, is limited by climatic difficulties (heavy rain, for example) or the lack of electrical connection. On the other hand, unlike bonding, under normal conditions welding can be used everywhere (except for the situation with thin rods).

Cross-shaped connections of reinforcement using manual arc welding are permitted for rods with a diameter of 10 mm or more.

Many novice builders consider the main reason for the difficulty of using this method to be the high cost of equipment, which includes the following items:

- Welder.

- Several packages of electrodes of the desired type.

- A set of welder protection equipment (including glasses and overalls).

During work, it is important to strictly adhere to safety requirements. To eliminate the possibility of getting a burn, you will need to stock up on personal protective equipment (mask, mittens and special work equipment). Under certain conditions, the contractor will need to obtain a work permit to carry out high-risk work.

One of the main conditions for welding reinforcement by any method is that it is necessary to use reinforcement with the index “C” - weldable, for example A500C, A600C, etc.

There are no contraindications to the use of welding when assembling frames. In addition, in accordance with the instructions of regulatory documents, when working on foundation structures with oversized reinforcing bars, this method is the only acceptable one. Since frame structures made from reinforcement with a diameter of 32 mm and above are too massive, which is why twisted wires are not always able to withstand increased loads.

It is important that during the welding process of the reinforcement its diameter does not decrease and the ribs are not damaged. Otherwise, if it serves as the main reinforcement, it will need to be replaced.

Which connection method do you prefer?

Before you finally decide whether to knit or weld a reinforcement frame, weigh the pros and cons. Each connection method has positive and negative aspects. Recommendations from specialists will help you choose the optimal solution. When constructing multi-storey buildings with an increased load on the foundation, welding is clearly chosen. The diameter of the steel bar is selected to be at least 30 millimeters. Why should reinforcement with a larger cross-section be preferred? Answer: to minimize the risk of burnout, which will weaken the strength of the connection.

The disadvantages of the welding method, which limits the scope of application, include the occurrence of internal stresses, which increase the likelihood of cracking during casting. It is problematic to use in seismically unstable areas and on complex soils, where the shrinkage process takes a long time and can cause destruction.

But we must not forget about the advantages of welding:

Speed of work, allowing to significantly reduce construction time.

- Increased rigidity of the finished module.

- Obtaining a solid foundation that can withstand heavy loads.

For private buildings, it is better to use the knitting method, which:

- it is simple and accessible, even for those starting a construction career;

- eliminates the need to search for a welding machine and a high-class welder capable of performing work without defects;

- does not create additional stress at the joints;

- allows the use of cheaper reinforcement of reduced cross-section for reinforcement.

The disadvantages include slight rigidity, which is not particularly important when constructing low-rise buildings.

Welding or knitting?

What should you choose – tying or welding of reinforcement? Now we can draw conclusions which method of installing the frame should be preferred. In this case, you should rely on the data described above - weld the reinforcement or use knitting rods. Each method has its own specific advantages and disadvantages. Tying reinforcement bars takes quite a lot of time, but welding is a quick method, but requires certain knowledge and calculations in foundation construction. Tying reinforcement is used mainly in the construction of small buildings and houses. This method is recommended as the most effective in such cases. For the construction of large buildings and houses, you need to look at the welding option. Large diameter rods are used for this. If you use ordinary wire, a strong connection will not work, or rather, this is a rather difficult task. Welding in this option is the best and only choice.

READ Transverse reinforcement in compression reinforced concrete elements is installed

There are some special features for using welding as the main method for reinforcing the foundation frame. The disadvantages of this method sometimes prevent its use on some soils. You can immediately exclude this option for fastening reinforcement in swampy areas - here the soil is too unstable. In such construction, after the foundation is laid out, shrinkage occurs, which takes a long time. Such a welding joint will suffer deformation and destruction; it simply will not withstand the load of the building. Since the main goal of any builder is to obtain a strong and durable structure, it is necessary to pay attention to each stage of construction. And the method of fastening rods when reinforcing the foundation is no exception.