General requirements

Requirements for raw materials used to produce the mixture are specified by GOSTs. Their list includes indicators such as:

- percentage of dust particles (size less than 0.14 mm) – no more than 10% of the total weight;

- amount of dust and clay impurities – no more than 3%;

- content of large particles (0.5 cm or more in diameter) – 5% or less;

- fractions larger than 1 cm are not allowed at all;

- the material should not contain any organic impurities.

Only building materials that have undergone additional processing - washing with water and sifting using special machines - can meet these requirements.

Determination of the presence of impurities

Impurities that can be observed in sand

In addition to the size, it is necessary to take into account the presence of organic matter and impurities. The presence of organic components, such as vegetation residues, etc., is unacceptable. You can get rid of these contaminants using regular sifting.

It is more difficult to get rid of the presence of clay, which should be no more than 5%, if sand is used to construct the base. Otherwise, the solution will not meet the standards and will reduce its strength.

You can check sand for suitability using the “old-fashioned” method. You need to pour a little sand into a glass container, add a small amount of water, shake and leave for a while.

The next type of impurity is gravel. Its presence is acceptable if particles measuring 10–12 mm do not exceed 5% of the mass. If these particles are smaller, then their presence is acceptable, but not more than 10% of the total mass.

Varieties

This building material is classified according to the following criteria:

- origin – natural and artificial;

- place of production - river, quarry, sea;

- processing method - unprocessed, washed, seeded;

- bulk mass – solid and porous;

- mineral composition - dolomite, limestone, feldspathic, quartz, marble, perlite;

- particle size - small, medium or large.

Types of raw materials differ in strength, quality and other properties. Not all of them are suitable for screeding and making concrete blocks.

Sand fractions

Depending on the size of the grains of sand, the following types of fractions are distinguished:

- Very thin contains grains of sand up to 0.7 mm , but due to the low fraction it is unsuitable for foundations. The foundation based on it will be as fragile as possible.

- Fine contains sand grains ranging in size from 0.7 to 1 mm . This sand is not dense, so it is also not suitable for foundation mortar. Typically, fine sand is used to pour concrete.

- Very fine contains grains of sand up to one and a half mm , but is still not suitable for pouring a foundation, since the strength will still not be optimal.

- Fine contains grains of sand ranging in size from one and a half to 2 mm . And again, it is not suitable for pouring a foundation due to the high cost of cement for it.

- The middle one contains sand grains ranging in size from 2 to 2.5 mm and is ideal for pouring foundations due to its strength and high performance properties.

- Large contains grains of sand up to 3 mm and is intended for the production of high-quality and expensive grades of concrete. This sand is very expensive.

- Extra-fine sand contains sand grains up to 3.5 mm and is used to make sand cushions designed to increase the strength of the base and distribute the load evenly across all corners.

Pouring the foundation assumes that the edges of the medium sand you choose should be sharp. It is the sharp edges of the grains of sand that increase the performance properties of the solution and make it as durable as possible.

Return to content

Differences between quarry and river sand

When creating concrete, quarry or river sand is often used. There are several differences between them, namely:

- The quarry sand grain has a rough shape, while the river sand grain has a smooth shape. Because of this, their adhesion to crushed stone differs - the first type is distributed easily, while the second requires constant stirring.

- The building material extracted from reservoirs is uniform in size fractions.

- Quarry sand contains much more clay and dust.

- The price of river building materials is higher.

When choosing a product, you need to know the nature of the work for which you plan to use it. For plastering walls, creating masonry, building pillows for the foundation, the quarry type is suitable. Sand for semi-dry screed, pouring blocks and other structures, constructing foundations and elements on frames must be river or sea.

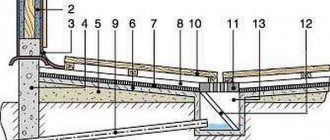

Calculation of sand for a pillow under a house

The amount of sand required to create a foundation cushion depends on the area of the base and the thickness of the cushion. We discussed this issue in more detail in an article on the topic: building a foundation on sandy soil.

You can determine the area of the base yourself, just know its parameters.

As for the thickness of the sand cushion, the following factors are taken into account:

- Location of groundwater.

- Soil freezing depth.

- Total load on the foundation.

Based on these factors, you can choose the optimal height of the sand cushion. However, the recommended parameters should be taken into account: the minimum height of the sand layer should be 10 cm, the maximum value can be 20 cm.

The final volume of sand to create a cushion is calculated by multiplying the area of the foundation base by the height of the sand layer.

Processing and preparation

Based on the type of processing during and after mining, building materials are divided into two types:

- Alluvial. It is processed and extracted in quarries using a device called a decanter. In it, the mass settles in water, after which the liquid is drained, washing away the remaining clay and dust. The result is a pure product.

- Seeded. It is processed with a mechanical sifter, as a result of which all unnecessary elements are removed from the building material. Rarely used due to the labor-intensive and expensive process.

Processing is carried out only on sand mass extracted from quarries.

Kinds

Depending on where the raw materials are mined, construction markets sell them in three varieties - quarry, washed river and sea. Each of them has its own characteristics, advantages and disadvantages that determine the scope of application. Therefore, you should know them and take them into account so as not to make a mistake when choosing an embankment for the foundation.

Career

The most in demand and most affordable (due to the high content of clay and other impurities in the composition) raw materials extracted in quarries by breaking rocks. Humidity is the main parameter of this type; a value of 1-5% is an indicator of the stability and reliability of such sand. Read about the difference between quarry and river sand.

The moisture content of the material can be determined easily and quickly by eye. If you can’t make a lump of it, then the value of this parameter is not enough. Such a foundation will simply crumble and will not be reliable.

According to processing methods, the following types of quarry sand are distinguished:

- Sandy soil is an unrefined, impurity-rich option. Suitable for landscape work (leveling areas, sprinkling paths and filling trenches).

- Washed sand – produced in quarries filled with water using hydromechanical tools; raw materials without impurities, and therefore of higher quality. It is used in road construction, for the production of tiles for paving sidewalks and paths, bricks, reinforced concrete products, and concrete.

- Seeded sand is a variety that has been technically and mechanically cleared of large debris. Typically used for mixing construction mixtures and compositions.

Raw materials extracted from quarries are in the highest demand; their price in specialized markets is usually 300-700 rubles/cubic meter.

River

The purest, most expensive product that is extracted from the bottom of freshwater reservoirs. It contains almost no impurities, and its shape is smooth and even thanks to natural polishing with water. This option is well suited for foundations, mixing solutions for interior decoration, and forming drainages.

It, like fireclay, has a lot of advantages: in addition to environmental safety, it also has excellent sound insulation, moisture resistance, durability (the raw materials are not subject to negative environmental influences), and compliance with technical requirements important in construction. However, due to its quality, the product has a high price - 700-1000 rubles per cubic meter. Read about the sizes of concrete wall blocks here.

Sand from the bottom of the river is divided into the following groups:

- Large - produced from rocks using crushing and grinding equipment, the fraction size is about 5 mm.

- Coarse-grained - extracted from dried river beds, has a natural shade. It finds its application in decorating interiors and landscapes, as well as in finishing (external and internal) premises.

- Washed river - medium in size, grayish-yellow in color.

The finer the sand, the easier it is to compact, and therefore the more susceptible to shrinkage. Therefore, a cushion made of fine-grained river sand is suitable only for light buildings. For capital construction you need an option with a medium fraction, and for multi-storey construction - with a large fraction.

Nautical

Raw materials extracted from the seabed and coastline are also suitable for creating a foundation. It is divided into fractions by size:

- Very thin (0.7 mm) – unsuitable for construction work; It is mainly used for filling playgrounds.

- Thin (0.7-1 mm) - also not suitable for foundations, but finds its application in the preparation of thin building mixtures.

- Fine (1-2 mm) - its use increases the consumption of the building mixture.

- Medium (2-2.5 mm) – used for mixing standard concrete mixtures.

- Large (up to 3 mm) - most in demand as a component for the production of high-quality concrete and cement.

- Very large (more than 3 mm) - suitable for forming a pillow under the foundation.

Sea sand is the most expensive variety, and for good reason. It has a high percentage of organic matter (shells, algae) and foreign debris, for example, fragments of bottle glass. To make it suitable for the construction industry, cleaning and rinsing procedures are mandatory. Find out what cement is made from at home here.

Which sand is better to choose for the foundation - which one is suitable?

Considering all of the above, it is best to form a pillow under the foundation of a house from river sand. A layer of such raw materials will create a solid foundation for the entire building and will not allow cracks to form. Of course, due to its excellent quality characteristics, very coarse sea sand is also suitable, but in this case you need to remember the high cost of this material.

If the construction budget is limited and river or sea sand is too expensive a solution, then washed quarry sand would be a good choice.

Another option for creating a cushion for the foundation is a sand-gravel mixture. Gravel in the composition of ASG will improve the characteristics of the composition, making it more stable and less susceptible to fluidity.

Which sand to choose for making concrete

The choice of raw materials for concrete depends on the required grade of material. For M50-M150 it is better to use medium-grain options, as they are cheaper. If you are building a foundation, wall or road (you should use M200-M300 concrete for them), you will need a higher quality sand composition with large particles and no impurities. When creating durable and super-strong concrete (M350 and above), only coarse-grained types of sand are suitable.

To determine which sand is best for construction, you need to consider the type of room. So, for work in industrial and public buildings, it is worth giving preference to high-quality river (or sea) varieties that have been sifted and carefully checked for the presence of any impurities. This is due to the fact that the structures in them are subject to heavy loads: shocks, vibrations, the weight of equipment and people.

Inexpensive quarry varieties of sand are chosen for finishing residential premises and apartments. The best option is washed building material with a medium grain size.

Types of quarry sand

Depending on the type of processing, quartz raw materials are classified as follows.

1. Sandy soil. This is an unrefined mixture with various impurities. As a rule, it is used to level summer cottages and fill trenches.

2. Washed sand. It is extracted from flooded deposits using hydromechanical equipment. The technology allows you to assemble the mixture without any impurities or unnecessary components. This material is used in the production of roads, paving slabs, concrete, bricks and reinforced concrete products.

3. Seeded sand. It is cleaned using a technical and mechanical method to remove large particles and stones. Typically, such raw materials are used to prepare a mass of plaster, masonry mortars and in the casting of stone products.

Harmful impurities

In addition to the dust and clay specified by GOST, harmful substances enter the building material, including:

- iron oxides – provoke the appearance of stains on blocks;

- mica – weakens the bond of concrete components, creating a risk of corrosion;

- sulfur and its derivatives – lead to the appearance of cracks;

- gypsum and pyrite - harden upon contact with water, destroying the structure from the inside.

Third-party elements can be identified by laboratory analysis.

Preparation of concrete

In this process, it is important to correctly calculate the proportions of cement, sand, crushed stone and water, taking into account their weight. The ratio should be 1:2.8:4.8. This standard is suitable for preparing M200 concrete, which is most often used for indoor work. A bucket is used as a unit of measurement.

The procedure for preparing building materials consists of the following steps:

- Pour a small amount of water into the concrete mixer.

- Add cement and mix the mixture thoroughly.

- Add sand. Stir for a long time until the mass becomes homogeneous, without lumps and separate fractions of components.

- Add crushed stone. Dilute with the remaining water and stir until the consistency of thick sour cream is obtained.

The mixture should be used immediately after preparation, since it “sets” in 12 hours and hardens in a week. It is better to carry out all work in the warm season at a temperature not lower than 0 °C.

Required amount of sand

Usually take one part cement to five parts sand. But this calculation is suitable if the solution is made only from these two components. The ratio of sand, crushed stone and cement for the foundation will be completely different. As a rule, they are taken in the following proportions: four parts sand, two parts crushed stone and one part cement.

As can be seen from the calculations, it is always necessary to take more sand than other components. The sheer amount of materials directly depends on the height of the pillow and the building itself. It is better to buy sand with a small reserve so that you do not have to buy more at the wrong time. The remains can be used to prepare solutions for finishing walls or laying them.

Liquid waterproofing

When making concrete mixtures, liquid waterproofing materials are added to the sand mass. It can be:

- coating mixtures;

- plaster;

- grout;

- fluids to eliminate leaks.

Additives enter microscopic cracks in the structure, where they react with minerals to form waterproof, durable crystals. They completely block the pores, preventing liquids from penetrating inside the blocks, increasing their durability and strength.

The main advantage of such insulation is durability. It lasts as long as the concrete structures themselves, and therefore does not require replacement or maintenance.

Characteristics

The parameters of sand and other components of the concrete mixture determine its quality, durability, ability to withstand loads and adverse external conditions. Therefore, you must pay attention to them when choosing ingredients.

Classification by factions

One of the most important characteristics of a building material is the sand fraction for screed (that is, the average size of its grains). According to GOST, according to this parameter, bulk material is divided

for 8 varieties:

- very thin – up to 0.7 mm;

- thin – 0.7-1 mm;

- very small – 1-1.5 mm;

- small – 1.5-2 mm;

- average – 2-2.5 mm;

- large – 2.5-3 mm;

- increased size – 3-3.5 mm;

- very large – 3.5-5 mm.

For construction work, it is advisable to choose a sand mixture that contains both medium and large particles. This will help reduce the consumption of valuable materials such as cement.

Particle size

Based on particle size, sand is divided into two classes. The first excludes all building materials with a fraction of less than 2 mm, that is, unsuitable for construction. In the second, impurities from particles of any size can be found. To create a concrete composition, only the first class is used, since small particles do not distribute stress well on the cement.

Place of extraction

The place of extraction of the material affects its mineral and grain composition, uniformity, presence and nature of impurities. This is one of the most important parameters when determining which sand is best for construction.

River

River sand is mined from river beds. It is almost devoid of clay and rocky inclusions. The sand grains are continuously washed with water, causing them to become smooth and uniform in size and shape. The grain size of this type of building material is low and the fraction size is small.

River material has an advantage over other types because it requires almost no additional processing after extraction, as it initially has good characteristics. But when it is removed from water bodies, their ecosystems are disrupted, which leads to undesirable consequences.

Career

This type of material is extracted directly from rock formations or in sand quarries. It always contains clay, stones and dust, and therefore requires additional processing before use. The particles in the material are heterogeneous in size and shape, angular and rough, which provides them with good adhesion. The advantages of quarry building materials include the ease of extraction and low price.

Nautical

Sea sand is an alternative to river sand with similar characteristics. Its disadvantage is the presence of small stones and fragments of shells in the composition. The advantages include the absence of impurities and relatively low cost.

Gully or mountain

Mountain or gully species are extracted from deposits of material in the ground. They are distinguished by a large number of impurities, mainly clay. It reduces the final quality and strength of the concrete solution, therefore the use of gully sand in screeding and creating blocks is limited.

River sediment is a versatile material

A universal type of quartzite raw material is mined from the bottom of freshwater rivers. The composition is considered a natural, pure product, designed for multi-purpose use in accordance with GOST - 8736-93. It rarely contains impurities and other organic compounds. Thanks to natural polishing, the river rock fractions have an ideal shape. Experts note the fact that it is better to use it for building foundations. The fine-grained product is relevant for interior and exterior decoration, for brickwork and wall plaster, as well as for creating a drainage system.

Breed gradation

Raw materials extracted from the river bottom are characterized by heterogeneity. When choosing the right size of pebbles for the base, it is worth understanding the factional diversity. There are the following types of river bulk material:

- Washed – represents grains of sand of medium size, gray or yellow. They contain silicon and iron oxides.

- Coarse-grained - mined in the beds of dry rivers. It has an unobtrusive neutral color. It is used for decoration and finishing of premises.

- Large – pebbles reach sizes up to 5 mm. It is obtained using specialized crushing and grinding equipment by splitting rock.

River bulk material comes in several fractions. Sizes range from 0.7 mm to 3.5 mm. The cushion, equipped with a mound of small grains of sand, is intended only for lightweight buildings. The fine-grained filling is strongly compacted and shrinks.

Positive characteristics of river sand

For residential capital buildings, it is better to use medium and large-sized chips - 2-3 mm, and for multi-storey buildings, only the coarse-grained type is used. River sedimentary rock has a number of positive qualities:

- meets aesthetic and technical requirements;

- has increased moisture resistance;

- is not exposed to aggressive environments and does not rot;

- characterized by excellent sound insulation qualities;

- environmentally friendly and safe.

It is popular not only on construction sites. Bulk rock is used for arranging playgrounds, for the manufacture of concrete products, landscaping, in decorating rooms and in landscaping work.