December 9, 2021 Stroyexpert Home page » Foundation » Types and types

This is what a peat foundation looks like

It is impossible to surprise Russian builders with the presence of peat soil on the site, since most of the territory of Russia is covered with swamps. This factor greatly complicates the construction of any building structures. To avoid negative consequences, you need to know the characteristics of peat soil and choose the right foundation for the future structure.

Features of peatlands

Any type of soil has a number of distinctive properties, and peat is no exception.

- Firstly, over time, peat soil changes its properties.

- Secondly, at low air temperatures, peat heaving cannot be ruled out.

- Thirdly, when groundwater rises, peat soil increases in volume.

- Fourthly, changes in the size of peat occur due to the constant decomposition of organic matter in the soil.

- Fifthly, peat soil is considered an aggressive environment that has a negative effect on metal and concrete.

In addition, it is worth taking into account the composition of the soil on the site and the occurrence of peat at the construction site. Therefore, before choosing a foundation, you should contact specialists to conduct research or study the soil yourself.

Choosing a foundation

Depending on the occurrence of peat, the type of foundation for the building is chosen:

Types of foundations on peat

- Strip and monolithic foundations are installed when the peat bog is located to a depth of no more than 1.5 meters. The technology for constructing a monolithic foundation is complex, but can be done with your own hands. The monolithic base is reliable, can withstand heavy loads, does not shrink, and can be used for a long time.

- You can also build a columnar foundation with your own hands. The complexity of such a basis lies in carrying out detailed calculations. It is necessary to accurately determine the shape of the pillars, their size and number, and also select the location of the pedestals.

- A pile-screw foundation is erected when the thickness of the peat exceeds 3-5 meters. Such a foundation supports the structure, resting on a dense layer of soil. Such a foundation structure can be installed anywhere, regardless of the composition of the soil and the terrain.

Methods for arranging a foundation on peat

Depending on the depth of the peat, the foundation can be built in several ways:

Replacing peat with another soil

The use of the first method is economically advisable in the case when the peat lies to a depth of no more than 1.5 meters, and underneath there is a layer of clay or coarse sand. The work process proceeds in the following order:

- Remove peat until the soil is compact.

- Geotextiles are used.

- Cover the area with sand or crushed stone.

- The sand layer is thoroughly compacted.

- The foundation is built on a sandy base.

The area where peat is removed depends on the foundation chosen. To build a strip foundation, a trench is dug. A monolithic foundation requires a larger area, so a large pit is dug using an excavator. It is also worth considering the type of future structure. For example, for a house with a basement, the pit depth can be 2 meters.

Partial removal of peat

In the case when the peat lies at a great depth, but it is not possible to remove all the weak soil, partial removal of the peat layer can be carried out. In this case, a high strip foundation is created. The main condition for this method is the foundation to stand. Construction of a house on such a foundation is possible only after 2-3 years. During this time, the necessary shrinkage will occur, and the base will rise to the required depth.

Construction of a pile foundation

In the case when the study showed the occurrence of peat to a depth of more than 4 meters, digging a pit is not profitable in material terms. Pile structures come to the rescue, in which bored, driven reinforced concrete or steel screw piles can be used as supports. The use of screw piles is possible only after treatment with special anti-corrosion compounds.

Which foundation is better on peat soil?

Solving problems with foundation construction on peaty soil, unfortunately, is not a rare task for our compatriots. A significant part of the territory is either covered with swamps or has ever been swampy.

Finding peat on a site and then searching for solutions to build a house on it is a real headache.

In this article we will try to give recommendations on the construction of foundations on peat, we will describe some of the nuances of construction on such weak-bearing soil.

Let us immediately make a reservation that it is impossible to give specific recommendations for construction without conducting geological research. Before you start choosing the type of foundation for your house, you must either trust specialists in this field, or independently study the thickness of the soil under the future building site.

In the latter case, a pit is dug to a depth no less than the GPG and the soil layers are assessed. Another option is to drill several wells with a garden drill. It is good if the peat layer is small and its thickness does not exceed 1-1.5 m.

But if it was not possible to get to the bottom of more resistant soil, and the groundwater level is high, then you can even think about the feasibility of building a house on this site - foundations on subsidence soils are complex and labor-intensive to develop.

How to make a foundation on peat soils

Typically, peat layers form on previously waterlogged soils that have been drained. Peat soil is a real problem for the developer due to the specifics of such soil.

Slab foundation on peat soil

The foundation can be built on it using one of two technologies:

- First, completely replace the peat layer with a different soil and then build any foundation;

- Construct a pile-based building on the existing soil type.

Before deciding on the technology for constructing the foundation, it is necessary to determine the actual depth of the peat, that is, to examine the structure of the soil, and also think over a building design suitable for it.

Detailed guide to constructing a pile foundation

Advantages of a pile foundation

Soil studies at the construction site, showing a peat layer thickness of more than 3 meters, indicate the need to construct a pile foundation. In addition to high load-bearing capacity, a pile foundation has many other advantages:

- Reduction of construction time,

- Possibility of carrying out work at any time of the year,

- Durability,

- Strength and stability in soft soils.

Tools and materials for work

To install a pile foundation yourself, you need to prepare:

- Roulette,

- Wooden stakes for marking,

- Level,

- Hand drill,

- Shovel.

The materials must include:

- Reinforcement bars,

- Several rolls of roofing felt,

- Crushed stone,

- Sand,

- Cement.

To mix the solution, you will need a concrete mixer, which you can rent, or a wide container.

The main stages of constructing a pile foundation

The foundation is the main element of any structure, therefore, maximum attention should be paid to this stage. The construction of the pile foundation is carried out in the following order:

Preparation and pouring of the pile foundation

- To begin with, the site is marked, the locations of the piles are marked with stakes. Correct placement of piles on the site helps to obtain a foundation with excellent load-bearing characteristics.

- Then, in the places where the piles will be located, holes are dug up to 40 cm deep.

- Using a special attachment on a drill, the base of the base is expanded.

- After this, wells are drilled. Their depth depends on the freezing of the soil. It is important that the pile rests on solid soil.

- In finished wells, waterproofing is performed, which at the same time serves as formwork. For these purposes, an asbestos-cement pipe is lowered into the well or a pipe made of several layers of roofing material is twisted. It is recommended to secure the seams with masking tape.

- Next, it is necessary to reinforce the wells. A mesh is mounted from reinforcement rods with a diameter of 7 mm, performing transverse fastening every 50 cm. The reinforcement will evenly distribute the load on the piles that the soil layer will exert during freezing and thawing. The reinforcing mesh should reach the bottom and be 30 cm above the soil level.

- The wells need to be filled with concrete mortar. The most suitable option is considered to be ready-mixed concrete grade M400. It is particularly durable, which allows the material to be used for the construction of power plants and airfields. The price of M400 concrete is slightly higher than other brands, but this material is an ideal solution for building houses on peat soil. You can prepare a concrete solution with your own hands. To do this, it is necessary to prepare high-quality cement, river sand, crushed stone of different fractions and a ribbed surface. It is possible to obtain a high-quality concrete solution only if the proportions are observed. Sand, cement and crushed stone are taken in a ratio of 3:1:2. After thoroughly mixing the components, add water. The amount of water may vary, the main thing is that the finished solution has the consistency of thick sour cream.

- Concrete solution must be poured into the well continuously. In this case, every 50 cm it is necessary to compact the concrete using a special vibration installation. Continuous filling will prevent the formation of technical cracks, which largely affects the strength of both the base and the structure as a whole.

Piles for peat soils

The classic pile foundation made of reinforced concrete products, which are driven into the soil using a pile driver, is not always suitable for swampy areas with a predominance of peat in the soil. Such a foundation is installed only on a solid base. If the peat layer at the construction site is of insignificant thickness, and after it there are hard rocks, on such soils it is possible to make a foundation of reinforced concrete piles. In this case, the piles rest on a rigid base, which guarantees the stability, strength and durability of the building.

It’s another matter if the peat layer has a predominant thickness of more than 2 meters. In this case, it is possible to build two types of pile foundations, using:

- bored piles;

- screw piles.

Foundation on peat bogs: bored piles

The technology for constructing a foundation using bored piles is complex. First of all, this is due to the need to perform deep casing wells. In peat soils, digging deep wells is associated with large labor costs, as well as the cost of using expensive special equipment.

It is especially difficult to work in water-saturated peat soils when the groundwater level reaches a high level. When watching the video you will learn a lot of information about bored piles. It is necessary to lower a pipe into the well and install a reinforcement cage made of special reinforcement in it. The frame can be tied using tying wire or welding. Then the concrete mixture is poured into the prepared well through a special funnel.

It is very important to prepare the solution correctly; this will require cement grade M400 or higher. The solution is mixed from cement, sand and crushed stone in a ratio of 1:3:2, and it is necessary to use a small amount of water - the solution should be thick and plastic. Crushed stone must be used of the highest quality, acute-angled, of different fractions. Concreting of the pile is carried out quickly and without interruptions to prevent the formation of artificial cracks.

A grillage is erected on the finished bored piles, on which the walls of the building are actually mounted.

Foundation on peat bogs: screw piles

By using a peat foundation made from screw piles, the work can be made much easier. The piles are screwed into the ground by hand; no special equipment or expensive materials are required. The video details the pros and cons of screw piles.

There is one big disadvantage - screw piles made of metal in wet peat soil are very susceptible to corrosion, so protective measures are necessary to treat the supports before screwing in with special compounds.

Constructing a foundation of screw piles in marshy areas has some advantages:

- The building is located above ground level, so the cost of waterproofing can be avoided.

- The technology of installing a house on screw piles allows you to mount a building on any site, even with the most uneven soil.

- Ventilation of the lower crowns of the house prevents rotting processes.

- Piles have a low cost, which significantly reduces the cost of construction.

Grillage installation

On soft soil, the piles do not have lateral support, so it is necessary to fasten the piles together. To do this, a binding layer is installed - a grillage. There are two options for constructing a grillage.

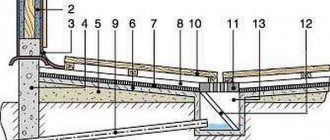

Recessed grillage

Type of recessed grillage

To install this structure, a shallow trench is dug around the perimeter of the house and under the load-bearing walls. A sand cushion is built at the bottom, which is thoroughly moistened and compacted. Crushed stone is poured over the sand to the top level of the piles. The bottom and sides of the trench are covered with roofing felt and formwork is installed. A reinforced frame is constructed inside the formwork, and the reinforcement of the piles is fastened to the frame. The prepared trench is filled with M300 concrete and left to dry for a month. During this time, the concrete will strengthen, and the base can be used for further construction.

Pile-type foundation on peat soil

The construction of a pile foundation begins with marking the site. Pegs are used to mark places where wells for piles will be drilled in the future. The distances between piles are usually 2-2.5 meters, which allows you to have a foundation with high load-bearing capacity.

In the marking areas, depressions of 30-40 centimeters are made. This is done in order to remove the top plant layer with grass and roots to facilitate the work of the drill. You can drill wells with a gas drill, an electric drill, you can also hire a drilling rig, or you can drill it manually.

The drilling depth should be such that the piles pass through the peat layer and rest on a dense layer of soil.

Next, the piles are waterproofed. Most often, roofing felt is used for this. Ruberoid is rolled into a pipe of several layers with a diameter equal to the diameter of the well. The seams are taped. The resulting structure is lowered into the well. In addition to waterproofing, it will also play the role of formwork, preventing concrete from leaking into the ground.

To strengthen the piles and give them flexibility, in case of horizontal soil displacements, the piles are reinforced. Reinforcement is made with reinforcement with a diameter of 6-8 millimeters. 4 rods are connected to each other by crossbars in the form of squares with a distance of 20 centimeters, a frame is made. The connection is made using annealed wire knitting. The frame is lowered to the entire depth of the well, leaving 20-30 centimeters above the surface for connection to the grillage.

To prepare concrete for pouring piles, cement of a grade not lower than M400 is used. Sand can only be used from river sand. Crushed stone is used in various fractions with a corrugated surface. Proportions: one part cement, three parts sand and two parts crushed stone. The solution should not be too liquid and moderately thick.

After the concrete is ready, it is fed into the well in small parts. It should be 40-50 centimeters, after which compaction is necessary. Tamping can be done either manually or using vibrating machines. The process of concreting one pile must take place without stopping; the set and fresh concrete will form an artificial crack, and the pile will no longer be monolithic, which will significantly worsen its load-bearing capacity.

Grillage arrangement

After pouring all the piles, they must be connected into a single structure. For this purpose, a grillage is created. The grillage is made either shallowly recessed or not recessed.

The installation of a shallow grillage begins with the preparation of a trench running along the entire perimeter of the house, capturing all the pile caps.

In the dug trench, a so-called sand cushion is made: about fifteen centimeters of sand is poured onto the bottom of the trench and thoroughly compacted on top. They also fill about fifteen centimeters with crushed stone. The pile caps should be higher than the fill.

Next, waterproofing is carried out. Roofing material is laid on the crushed stone fill and the formwork is installed. The formwork must be properly secured to avoid being squeezed out by concrete. After which the grillage is reinforced. The grillage reinforcement frame must be connected to the pile caps.

After all stages are completed, the grillage is poured with concrete. For the grillage, it is allowed to use cement grade M300; all other proportions are taken the same as for pouring piles.

The installation of a non-buried grillage occurs in exactly the same way, with the exception of preparing the trench. It is poured directly onto the surface of the soil.