Advantages and disadvantages

This type of foundation is different in that it can be installed in areas with different types of soil. It is also used in cases where the soil layer is deep or it is not possible to use other types of structures.

Advantages of a bored foundation:

- There is no need to create a pit. There is also no need to level the soil on the site. That is why such a foundation is often chosen by owners of plots with large differences in height of the soil surface. If a strip foundation is created on such land, this requires significant effort to prepare the surface.

- Relatively low cost. The described type of foundation will cost about half as much as a monolithic foundation.

- High speed of base installation. The described type of foundation can be created within 12 hours. In this case, such a base needs to stand for about 8 days. It is worth noting that the strip foundation must settle for about a month.

- There is no need to find an additional place where the piles need to be placed, since they are created at the construction site.

- No additional waterproofing required.

This is why many people create a bored foundation with their own hands.

The disadvantages include:

- The service life of such a foundation is approximately 70-100 years. If a brick base is created, it can be used twice as long.

- With this type of foundation it is impossible to create a basement. That is why most often such a base is used during the construction of a summer house or bathhouse.

- Weak load-bearing capacity. Such a foundation is often created for one-story buildings.

- Inability to use a bored base on moving soil.

Basic principles of drilling technology and its advantages

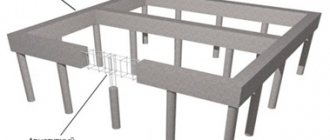

The construction of a bored foundation with a grillage is based on the following technological principles:

- the base of the foundation is point-fixed in a fixed earthen layer and has a static tubular or metal frame base;

- load-bearing loads are provided for uniform distribution;

- the number of points of required application of load stability is determined by calculation methods;

- key points have a unified structure due to monolithic reinforced piping or grillage.

This technology has a number of undeniable advantages.

- Possibility of constructing a foundation for construction on any surfaces and soils, except rocky ones, including:

- in areas with large differences in elevation;

- on soils subject to swelling and horizontal movement;

- in places with increased levels of exposure to seasonal water factors.

- High reliability and stability of the foundation due to the installation of its base below freezing of the soil.

- There is no need for large-scale excavation work, which allows construction to be carried out with minimal disruption to the surrounding landscape, and the need to remove soil is eliminated.

- It is possible to carry out foundation work directly near existing buildings without additional mechanical negative impact on them, as well as without damaging previously installed underground communications.

- The time required to carry out foundation work is minimal and it is possible to carry it out year-round.

- The ability to use this technology for buildings and structures made of any materials, any height and purpose due to the uniform distribution of the design load.

- Low construction costs and ease of work, the best option for arranging the foundation of a building with your own hands.

Foundation installation technology

Installation of the described type of foundation involves drilling wells into which concrete mixture is poured. Drilling can be done with hand tools or heavy machinery.

Often the drilling process is carried out using a hand drill. The strength of the piles increases due to the installation of a reinforcement cage. The cross-section of the metal rods should be approximately 10-12 mm.

Professionals advise connecting reinforcement frame elements in a horizontal plane. Dressing should occur in 1 meter increments using smooth reinforcement with a cross section of 6-8 mm.

When creating a grillage, the metal elements must protrude above the piles. This increases the rigidity of the structure. The reinforcement cage helps protect the gap during soil heaving.

Construction of a bored foundation with a grillage with your own hands

To construct a building, it is necessary to carry out a series of site studies and calculation operations in order to obtain:

Geological conclusion on the composition of the soils available on the site. Determination of the maximum depth of soil freezing, necessary for calculating the length of pipes, due to the fact that they must be laid 20 - 30 cm below this level to prevent them from being pushed out during winter frosts. Estimated weight of the house taking into account additional snow load.

The work on the site necessary for the construction of a foundation on bored piles with a grillage is divided into several stages:

- Site marking carried out to finalize the number and location of piles. As a rule, asbestos-cement or steel pipes are used, 2 meters long and 150 - 250 mm in diameter. The calculated load weight per pile is about 1600 kg. To build a typical average-sized house, 30 to 50 piles are used.

The process of constructing a foundation using piles is based on drilling wells. In stable soils, you can do without pipes, and as waterproofing you can use a double layer of roofing material, which is lowered into prepared drilled holes. The surface of metal pipes must be treated with a special anti-corrosion coating, and when lowered, protect them with a layer of waterproofing. Typically, two layers of roofing material are used for this. It is necessary to lower the prepared reinforcement into the well, making sure that it does not touch the ground and does not reach it a few centimeters. This is important to protect the metal from moisture and prevent corrosion. The upper edge of the structure should protrude above the piles to ensure further connection with the grillage reinforcement. The next stage is concreting the piles. To do this, concrete is poured into the pipes in parts and then compacted using a special drill that creates vibration. If the site has loose soils, then before concreting, a mixture of sand and gravel in equal proportions should be poured into the well. For more detailed instructions on making piles, read the article Do-it-yourself bored piles. And here we invite you to watch a short video that shows the process of assembling and pouring the pile structure step by step: Columnar foundation - easy! The protruding parts of the piles must be cut off in one plane and connected to each other using a grillage, which will combine them into a single structure and make it possible to evenly distribute the entire load between the piles and along the perimeter.

Foundation with grillage

The grillage is a structure that connects the upper parts of the supports. Wood can be used to create a grillage. It is often created using reinforced concrete.

In order for the foundation to withstand the loads acting on it well, it is necessary to correctly reinforce the grillage. To do this, a structure is created from metal rods in two rows, which are connected by vertical rods.

Wooden elements approximately 35 mm thick are laid under the bottom layer of reinforcement. To ensure that the frame does not move during concrete pouring, it must be securely fastened. The width of the grillage is about 30-40 cm. It is important to take into account that the thickness of the walls should be less.

Types of grillage and its implementation

A bored foundation with a grillage for a brick house is in most cases made in the form of a strip or slab. If a slab grillage will completely unite the heads of each individual pile, then a strip grillage will unite only those piles that are in close proximity to each other, and at the same time located directly under the walls of the building.

Modern specialists, in order to equip a bored foundation with a grillage, use a wide variety of materials, including wood, steel, as well as monolithic and prefabricated reinforced concrete, but the use of metal is highly not recommended, for the reason that it will have to be consumed in large quantities.

In order to equip a metal grillage, you will also need to use a specialized crane, as well as apply an anti-corrosion coating. That is why modern experts call the construction of a monolithic grillage made of reinforced concrete the most technologically advantageous and practical option.

Bored foundation is the most common

In addition to the fact that piles, in principle, are a relatively inexpensive material that provides significant strengthening of the foundation, they are also distinguished by their extremely high load-bearing capacity. In the vast majority of cases, a high-quality pile can withstand loads of about 1600 kg, and to maximize the strengthening of the foundation of a house, it will be enough to use approximately 30 to 50 piles.

Bored piles with a grillage are located below the soil freezing level, and it is worth noting the fact that after installation they will necessarily need to be enclosed in a jacket, that is, covered with two layers of roofing material. Using such a jacket will allow you to significantly reduce the pressure on the piles at low temperatures, when they begin to be pushed out, and will also provide good waterproofing.

How to build a foundation with a grillage

In fact, if the work is carried out with skill and skill, then you are guaranteed to receive high-quality work, regardless of what time of year it is carried out. It is erected approximately as follows:

- formwork is installed on top of the piles;

- the frame is mounted directly inside the formwork;

- The grillage is carefully filled with concrete. It is worth noting that in this case exactly the same technology is used as in the case of strip foundations;

- The height of the grillage is ideally approximately 30 cm, while the width of the structure should be an order of magnitude greater than the thickness of the walls of the building, that is, at least 40 cm.

In this case, it is important to note the fact that to build a foundation on bored piles it will not be necessary to carry out any large amount of excavation work, as well as devote a large amount of time and finances. If you definitely decide on this method of construction, then in the end you will get an extremely reliable and high-quality foundation that will fully meet modern requirements.

Load calculation

First you need to calculate how many piles are needed to ensure that the structure is securely fastened. To do this, you only need to know the load-bearing capacity of one pile and the weight of the future structure.

The strength of piles depends on the brand of concrete used to create them. The brand number indicates the load that the pile can withstand per centimeter of its weight. If a pile with a cross section of 20x20 cm is cast from M100 concrete, it can withstand a load of up to 40 tons.

Knowing the load that will act on the foundation, you can accurately calculate the required number of piles. To calculate the load on the foundation, you need to add up the weight of the materials that will be used during the construction of the house. You also need to add the weight of furniture in the house and appliances. Both the load from people and seasonal loads are taken into account.

The use of bored piles in private construction

The technology for creating piles is simple and can be used even without professional heavy equipment. There are many different types of drills that can be used by hand. Using hand-held devices, you can create wells up to several meters deep.

The diameter of the created piles can be either 15 or 40 cm. TISE drilling technology involves the creation of wells up to 20 cm with an expansion of the base. With this method of creating a well, the support area of future piles increases, which prevents heaving from pushing them out of the ground.

There are many types of hole drills that can facilitate the process of creating wells.

Types of equipment used

Drilling wells under a bored foundation can be done using different types of devices:

- gasoline drill;

- heavy equipment;

- bobcat.

Using a gasoline drill is the best option if you are creating a standard structure. Such devices are relatively inexpensive, so they can be purchased by anyone who is planning to build their own home.

You can also use specialized equipment. The use of specialized machines will allow drilling on the site in just one day. There are machines that can create several wells from one place due to the presence of a long boom. But it is worth remembering that after creating a well, it is necessary to carry out work on pouring piles as soon as possible. This is due to the fact that when precipitation falls, the walls of the holes will quickly collapse.

Calculation of the installation location of piles

During the development of the project, it is necessary to calculate not only the number of supports, but also their locations. They are installed in rows along the markings of the walls of the house and at the intersections of walls. Calculation of the distance between piles should be carried out depending on the weight of the structure. The greater the weight of the structure, the smaller the distance should be between the supports.

The minimum allowable distance is 3 pile diameters. This is due to the fact that with a more frequent arrangement, the supports can withstand less load.

With a pile diameter of 40 cm, the distance will be 120 cm. When creating piles, it is necessary to check whether the heads are at the same level.

Making a grillage

The grillage is the upper part of the foundation, combining the pile heads and distributing the load on them. It is needed as a supporting structure for the components of the house and can be made of wood, metal or, most often, concrete with a reinforcing frame.

To determine how to make a grillage, depending on the type of soil, you should consider:

- Hanging grillage, often used for swelling soils, has the appearance of being suspended above the ground with a gap of about 10 mm or more; see its production in the video below: Recessed grillage - used for the construction of brick, monolithic, wooden houses with a wall thickness of about 30 cm.

Monolithic grillage - is a rigid structure characterized by increased strength and reliability; a foundation on bored piles with a monolithic grillage is suitable for building a house with your own hands; it provides a combination of an affordable, simple method with improved quality of construction.

To make a grillage, it is necessary to dig trenches at the location of the future foundation and install formwork in them. The entire perimeter of the grillage should be reinforced by tying the edges of the reinforcement left in the piles (see How to properly tie reinforcement for a foundation). Subsequent pouring of concrete is carried out in the same way as the production of a foundation strip.

We recommend a video on the stages of work

PILE FOUNDATION WITH GRAPHIA AND PLATE ON GROUND.

For the correct installation of the grillage, it is recommended that the height dimensions be at least 30 cm, and the width dimensions should be approximately 10 cm wider than the thickness of the walls. When choosing the type of foundation when building a house, you should remember that the existing type using bored piles will help reduce costs, facilitate work, significantly reduce the time required to complete individual operations, and, therefore, speed up the construction of the entire house. At the same time, the conditions for reliability, strength and durability of the structure will be met.