Pile foundation with monolithic grillage

The main components of this type of foundation are piles or piles with a grillage. Grillage - consists of beams or slabs that can connect piles above the ground.

This type of foundation is used in cases where construction takes place on soft soil:

- the final calculation of the width of a conventional strip foundation is more than 1.6 m

- the structure is erected in strict accordance with frame technology

- soils have a fairly high freezing depth.

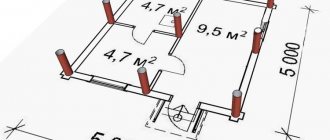

Rice . Reinforced concrete piles with a monolithic grillage

Pile foundation price

When building cottages and ancillary buildings, a strip foundation is most often installed - it is easy to manufacture and reliable, and, in addition, is one of the most inexpensive ways to arrange the foundation of a building. However, on special types of soil (floating, moving, with close water occurrence), it is necessary to additionally strengthen the building structure. Piles come to the rescue. When piles and strip foundations are combined, a pile-strip foundation is obtained.

A pile-strip foundation is a single structure consisting of piles and a strip frame. Piles immersed in the ground are connected to

strip foundation reinforcement, the structure is filled with concrete.

When arranging the foundation, you can use the following types of piles:

bored (ready-made piles are installed in the holes or they are made on site from reinforced concrete);

driven (driven into the ground using special equipment);

screw (screwed into the ground similar to a screw).

Types of pile foundations by material of manufacture

- Wooden (perhaps the most rarely used piles in construction due to their inefficiency)

- Metal (screw - quickly installed and have a relatively low cost)

- Concrete

- Reinforced concrete piles (relatively low cost with the highest degree of quality and reliability)

In addition, piles have different types of sections :

- Square

- Rectangular

- Round

- Square, with a round cavity

A pile foundation can have a grillage, which is made in the form of a foundation beam. Its main purpose is to consistently connect adjacent piles to each other. Also, such a foundation can be made in the form of a slab. The first option is installed exclusively under load-bearing walls, and the second should cover the entire area under the building.

The pile foundation grillage can be prefabricated or monolithic. The monolithic type is produced by pouring concrete into pre-prepared formwork, and the prefabricated type uses ready-made reinforced concrete products. Read more about the pros and cons of a pile-grillage foundation.

STAGES AND TIMELINES OF CONSTRUCTION OF A TURNKEY PILE-GRILLAGE FOUNDATION

The installation of a pile-grillage foundation takes 10-15 days. Construction is carried out according to design documentation. Specialists conduct soil studies, calculate the load and other parameters that determine the depth of the piles, the reinforcement scheme, and the width of the grillage. Each stage of construction and installation work is controlled by a foreman.

MARKING THE AREA FOR THE FOUNDATION AND DRILLING HOLES

MARKING THE AREA FOR THE FOUNDATION AND DRILLING HOLES

Marking the area for a pile-grillage foundation is carried out according to the architectural design of the house.

The location of underground communications in the area of the construction site is being clarified so as not to damage them. The top layer of soil along the perimeter of the grillage is removed, and a drainage cushion is installed. Drilling holes for piles is carried out using a small-sized drilling rig or manually - it all depends on the access conditions. The diameter of the wells is 20 - 40 cm, depth is from 1.3 to 2 meters. The number of piles, their parameters, and location are calculated by engineers, depending on the area of the building and the construction material. We carry out site preparation and drilling of holes without subcontracting. We have our own professional tools and equipment. The complex of work at this stage takes 1-2 days, depending on the area of the house. If necessary, we will help you obtain a building permit.

ENGINEER CONSULTATION

CONSTRUCTION OF BORED PILES

CONSTRUCTION OF BORED PILES

The technology for constructing bored piles involves their creation directly at the construction site.

Installation work begins with the formation of a sand cushion at the bottom of each pillar. If the soil is saturated with water or has a loose texture, then formwork is installed - casing pipes. Then a frame of reinforcement is mounted into the holes. We use steel reinforcement with a diameter of 14 and 16 mm. The length of the rods should be such that they extend beyond the well by 30 - 60 cm, for subsequent connection with the reinforced frame of the grillage. Concrete is poured simultaneously with the grillage to create a single monolithic structure or separately if it is a high grillage located above the ground. We erect bored piles in 1-2 days. Construction is carried out in accordance with SNiP 2.02.03-85 “Pile foundations”. We purchase slag-based concrete mortar of a grade no lower than M350 from trusted manufacturers in Moscow and Moscow Region. We do not allow layer-by-layer filling of wells using the “seized” solution.

ENGINEER CONSULTATION

KITING REINFORCEMENT FRAMEWORKS Grillage and INSTALLING FORMWORK

KITING REINFORCEMENT FRAMEWORKS Grillage and INSTALLING FORMWORK

To form the grillage, removable formwork is installed.

It is important to use professional shields and install spacers correctly so that the structure does not deform under concrete pressure. Using formwork with a continuous, flat surface will help reduce the cost of leveling the foundation during finishing. Concrete has low bending and tensile strength. These loads are taken on by the reinforced frame, creating a solid, reliable foundation for the future home. Reinforcement is made from steel and fiberglass reinforcement of class A3. A minimum of 4 rods are used in longitudinal belts. For the strength of the structure, it is not allowed to overlap the corners of the frame from rods. L and U-shaped curved rods are used. We manufacture reinforced frames strictly according to the design diagram and in accordance with GOST 14098-91 “Welded connections of reinforcement and embedded products of reinforced concrete structures.” To construct the grillage we use professional panel formwork. It forms a smooth concrete surface and leaves minimal gaps at the joints.

ENGINEER CONSULTATION

RECEPTION AND VIBRATION OF CONCRETE

RECEPTION AND VIBRATION OF CONCRETE

The concrete mixture is delivered to the site by concrete mixer truck.

Before accepting the solution, markings of the zero level are applied on the formwork. Then the work comes down to pouring concrete and distributing it along the grillage trenches. To prevent the strength of the pile-grillage foundation from decreasing, the concreting process cannot be interrupted for a long time. Each layer of concrete is compacted using deep vibrators. This reduces porosity, shrinkage time, increases water resistance and strength of the foundation. After the concrete is completely distributed over the trenches, the surface is smoothed. We follow technologies for working with concrete mixture (SNiP 3.03.01-87), which eliminates delamination of concrete. Filling is carried out continuously within 1 day. To compact the solution, we use up to 4 deep vibrators simultaneously.

ENGINEER CONSULTATION

MAINTENANCE OF CONCRETE AND REMOVING FORMWORK

MAINTENANCE OF CONCRETE AND REMOVING FORMWORK

Freshly laid concrete for a pile-grillage foundation needs to create conditions conducive to hydration of the solution and strength gain.

To prevent moisture evaporation and protect against precipitation, the structure is covered with plastic film. In hot weather, to maintain optimal humidity and prevent the appearance of hairline cracks, the concrete is regularly moistened. The formwork is removed after 5 - 8 days. But construction work can be continued no earlier than 28 days, when the concrete has completely hardened. Depending on the ground conditions, the pile casings are also removed or left as additional protection for the pillars. To protect the fresh pile-grillage foundation, we cover it with a thick plastic film. We provide daily maintenance of concrete. The formwork is removed after the concrete reaches 70% of its brand strength. We carry out dismantling carefully, without damaging the structure.

ENGINEER CONSULTATION

Types of monolithic grillage

Grillages are distinguished according to the ratio of the height of the device to the level of the ground surface:

- Tall or hanging - placed above ground level (10-15 cm, but in individual cases these figures may be higher). This type can be used on all types of soil under a building that are light in weight. The only drawback is that there is a mandatory need to insulate the empty space that is formed between the ground and the grillage.

- A ground or intermediate grillage is constructed in such a way that its base should be located at ground level. If this type is used, there will be no void between the soil. The main feature of this grillage is that it can only be used on soft soils.

- The buried grillage differs from previous options in that its lower part is immersed in the ground, thereby its level is located below the surface of the earth. This type is a regular strip foundation, but at the base of which there are piles. This option is quite expensive and is used only during the construction of heavy objects.

Rice .

Pile foundation with high and low grillage

installation of a pile foundation

Concrete piles are made directly at the foundation construction . This process can be carried out in various ways: filling a hole in the ground with concrete; driving an inventory pipe with the lower end closed (in most cases) followed by filling. To pour a concrete pile, a hole 10-40 cm in diameter is drilled. Next, the well is strengthened with casing and concrete is poured in layers, followed by compaction. Afterwards, the casing pipe is lifted to a level below the surface of the laid concrete. When constructing a pile foundation using this method, vibration is widely used, which promotes better shrinkage of concrete and facilitates the unhindered lifting of the pipe. To connect with the grillage, reinforcement is released from the piles to the level of the height of the future foundation.

Pile foundation with a monolithic grillage - do-it-yourself construction technology

- Number of wells

The number of required foundation formwork is obtained as a result of mathematical calculations. To do this, you should take the total weight of the structure being built, and you should not forget about the operational loads. The calculation of the characteristics of the internal rods is based on the pressure exerted by several elements: floor, partitions, roof structure, etc.

- Drill work

After receiving all the data, you can proceed to the process of drilling wells. If the plans did not include the use of modern technology, then you need to remember that a hand drill is capable of making a well, the diameter of which will not exceed 30 cm, and the depth will not exceed 5 m.

Rice . Drilling a well with a hand drill

- Ruberoid pipes

After the wells are ready, roofing felt pipes need to be made. Their length should exceed the depth of the resulting wells by 20-30 cm. The upper part is made of several layers in order to tighten them together with wire. Thus, the resulting result is formwork and waterproofing.

Rice . Ruberoid pipes

- Foundation reinforcement and formwork

Rice . Scheme of reinforcement of a monolithic grillage

If a small amount of water was found at the bottom of the well, then you should not pump it out immediately.

The technology of constructing a pile foundation allows this fact to occur. But in cases where the liquid exceeds the depth threshold by a quarter, it should be pumped out before pouring concrete.

Rice . Formwork for piles

Policy regarding the processing of personal data

1. General Provisions

This personal data processing policy has been drawn up in accordance with the requirements of the Federal Law of July 27, 2006. No. 152-FZ “On Personal Data” and determines the procedure for processing personal data and measures to ensure the security of personal data.

1. The operator sets as its most important goal and condition for the implementation of its activities the observance of the rights and freedoms of man and citizen when processing his personal data, including the protection of the rights to privacy, personal and family secrets. 2. This Operator’s policy regarding the processing of personal data (hereinafter referred to as the Policy) applies to all information that the Operator can obtain about website visitors

2. Basic concepts used in the Policy

1. Automated processing of personal data – processing of personal data using computer technology; 2. Blocking of personal data – temporary cessation of processing of personal data (except for cases where processing is necessary to clarify personal data); 3. Website – a collection of graphic and information materials, as well as computer programs and databases that ensure their availability on the Internet; 4. Information system of personal data - a set of personal data contained in databases, and information technologies and technical means that ensure their processing; 5. Depersonalization of personal data - actions as a result of which it is impossible to determine without the use of additional information the ownership of personal data to a specific User or other subject of personal data; 6. Processing of personal data - any action (operation) or set of actions (operations) performed using automation tools or without the use of such means with personal data, including collection, recording, systematization, accumulation, storage, clarification (updating, changing), extraction, use, transfer (distribution, provision, access), depersonalization, blocking, deletion, destruction of personal data; 7. Operator - a state body, municipal body, legal or natural person, independently or jointly with other persons organizing and (or) carrying out the processing of personal data, as well as determining the purposes of processing personal data, the composition of personal data to be processed, actions (operations) transactions performed with personal data; 8. Personal data – any information relating directly or indirectly to a specific or identified User of the website; 9. User – any visitor to the website; 10. Providing personal data – actions aimed at disclosing personal data to a certain person or a certain circle of persons; 11. Distribution of personal data - any actions aimed at disclosing personal data to an indefinite number of persons (transfer of personal data) or familiarizing with personal data to an unlimited number of persons, including the publication of personal data in the media, posting in information and telecommunication networks or providing access to personal data in any other way; 12. Cross-border transfer of personal data – transfer of personal data to the territory of a foreign state to an authority of a foreign state, a foreign individual or a foreign legal entity; 13. Destruction of personal data - any actions as a result of which personal data are destroyed irrevocably with the impossibility of further restoration of the content of personal data in the personal data information system and (or) as a result of which the material media of personal data are destroyed.

The need to install a roofing felt pipe

A little higher, the mandatory presence of a roofing felt pipe was indicated. Non-experts in this matter may wonder why it is needed at all?

- Firstly, the setting of the manufactured concrete mixture to the limit of the desired strength level depends on the cement fluid. Without the use of a pipe, it is absorbed into the soil and thereby disrupts the technology.

- Secondly, during periods of low temperatures without a roofing material product, heaving has a much stronger effect on the surfaces of the components of the pile foundation.

As for the cost , there is no fixed cost. For example, the foundation of a house whose dimensions are 6x6 will cost approximately $1,200.

Attention! It is prohibited to cross the grillage with a pipeline! The deviation after completion of the concreting process should not exceed a threshold of 5 cm.

Cast-in-place piles for monolithic pile foundations

The main distinguishing feature of this type of piles is that they can be made independently at the construction site. This process occurs by placing material in already prepared holes. In this case, reinforcement is carried out if necessary. This option allows you to save on transportation, and it is also possible to carry out the construction of the facility next to other buildings. The most important disadvantage of this type is the lack of quality control. Any oversight in production may cause deformation of the object in the future.

Rice . Cast-in piles for monolithic grillage

Reinforcement of a monolithic slab on piles

Reinforcement of the support and monolith of the foundation

The peculiarity of the reinforcement of the monolithic foundation is that it is necessary to connect the reinforcement frame of the load-bearing supports and the grillage into a single structure. For reinforcement, it is necessary to create two independent reinforcement belts, one installed at the top, the other at the bottom. At least two longitudinal reinforcements must be used in each section. Spiral rods with a diameter of up to 14 mm are used for reinforcement, and smooth rods with a diameter of up to 9 mm are used for vertical rods.

Transverse reinforcement has nothing to do with loads; it knits the entire structure into a single frame. The reinforcement frame is completely immersed in concrete solution; during installation, it is important to always leave the upper ends of the rods - they are then connected to the reinforcement of the load-bearing supports.

Before pouring a monolithic slab, a flexible connection is made at the points of contact between the formwork and the internal frame of the slab . If steel load-bearing supports are used, then the heads are welded to the lower reinforcing chord. At the same time, the lower edge of the belt must be buried in concrete to a thickness of up to 5 cm in order to protect the metal from corrosion. The frame for the slab is considered completed, the distance between the belts is up to 10 cm, and between the vertical rods - up to 50 cm.

Piles also need to be additionally reinforced, especially if they are reinforced concrete or steel structures. Wooden and steel supports are not reinforced; they are connected to each other by reinforcement or wire rod. To securely connect the grillage and supports, the heads are welded with wire rod or rods to the bottom layer of the slab reinforcement. The width of the grillage should be slightly larger than the external dimensions of the sections to better strengthen the structures.

Bored piles

Bored piles are installed using a similar system as the previous option. If it is necessary to strengthen an existing foundation, then the technology of injection piles should be used. They are poured under a certain pressure into small-width holes, approximately 10-13 cm, with single reinforcement. After this action is completed, the foundation is pressed with water.

Rice . Creating a bored pile

Driven piles

This option consists of ready-made pipes. It is worth noting that their installation in the ground occurs only with the help of special equipment. Such piles are divided into three types:

- Trapezoidal

- Prismatic

- Cylindrical

Rice . Iron tubular piles

The latter option includes in its structure a bordering ring at the junction, the main purpose of which is to build up additional links. According to statistical data, it is known that cylindrical driven piles are the cheapest and have a fairly high load-bearing capacity.

Screw piles

Screw piles are intended for structures with fairly high horizontal loads. The tip of such a pile is an element made of steel or reinforced concrete. Screw piles securely fix the foundation and do not allow it to deform. In cases of strong horizontal loads, screwing in piles at an angle is allowed.

Rice . Screw foundation with monolithic grillage