The accuracy class of a measuring instrument is a generalized characteristic determined by the limits of permissible basic and additional errors, as well as other properties affecting accuracy, the values of which are established in the standards for certain types of measuring instruments. The accuracy class of measuring instruments characterizes their properties in terms of accuracy, but is not a direct indicator of the accuracy of measurements performed using these instruments.

In order to estimate in advance the error that a given measuring instrument will introduce into the result, normalized error values are used. They mean the maximum errors for a given type of measuring instrument.

The errors of individual measuring instruments of this type may be different, have systematic and random components that differ from each other, but in general the error of a given measuring device should not exceed the standardized value. The limits of the main error and influence coefficients are entered in the passport of each measuring device.

The main methods for normalizing permissible errors and designating accuracy classes of measuring instruments are established by GOST.

On the scale of the measuring device, the value of the accuracy class of the measuring device is marked in the form of a number indicating the normalized value of the error. Expressed as a percentage, it can have values of 6; 4; 2.5; 1.5; 1.0; 0.5; 0.2; 0.1; 0.05; 0.02; 0.01; 0.005; 0.002; 0.001, etc.

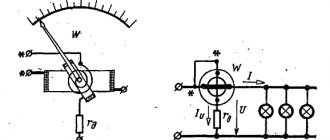

If the accuracy class value indicated on the scale is circled, for example 1.5, this means that the sensitivity error δ s = 1.5%. This is how the errors of scale converters (voltage dividers, measuring shunts, measuring current and voltage transformers, etc.) are normalized.

This means that for a given measuring device the sensitivity error δ s= dx/x is a constant value for any value of x. The relative error limit δ (x) is constant and for any value of x is simply equal to the value of δ s, and the absolute error of the measurement result is defined as dx = δ sx

For such measuring instruments, the boundaries of the operating range within which such an assessment is valid are always indicated.

If on the scale of a measuring device the accuracy class number is not underlined, for example 0.5, this means that the device is normalized by the reduced zero error δ o = 0.5%. For such devices, for any values of x, the absolute zero error limit is dx = d o = const, and δ o = d o / xn.

With a uniform or power scale of a measuring device and a zero mark at the edge of the scale or outside it, the upper limit of the measurement range is taken as xn. If the zero mark is in the middle of the scale, then xn is equal to the length of the measurement range, for example, for a milliammeter with a scale from -3 to +3 mA, xn = 3 - (-3) = 6 A.

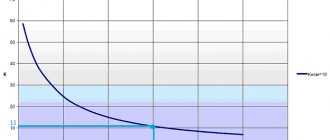

However, it would be a gross mistake to assume that an ammeter of accuracy class 0.5 provides an error of ±0.5% in the measurement results over the entire measurement range. The value of the error δ o increases in inverse proportion to x, that is, the relative error δ (x) is equal to the accuracy class of the measuring device only at the last mark of the scale (at x = xk). At x = 0.1xk it is 10 times greater than the accuracy class. As x approaches zero, δ (x) tends to infinity, that is, it is unacceptable to take measurements with such devices in the initial part of the scale.

On measuring instruments with a sharply uneven scale (for example, on ohmmeters), the accuracy class is indicated in fractions of the scale length and is designated as 1.5 with the “angle” sign below the numbers.

If the designation of the accuracy class on the scale of the measuring device is given in the form of a fraction (for example, 0.02/0.01), this indicates that the reduced error at the end of the measurement range is δ prk = ±0.02%, and at the zero of the range δ prk = -0.01%. Such measuring instruments include high-precision digital voltmeters, DC potentiometers and other high-precision instruments. In this case

δ (x) = δ k + δ n (xk/x - 1),

where xk is the upper limit of measurement (the final value of the instrument scale), x is the measured value.

Source

What is the accuracy class of a measuring instrument?

Taking into account all the standardized metrological characteristics of measuring instruments is a complex and labor-intensive procedure, carried out only for very high-precision measurements, characteristic of metrological practice. In everyday life and in production, such precision is not rational. Therefore, for measuring instruments used in everyday practice, it is customary to divide them into accuracy classes.

The accuracy class of measuring instruments is a generalized characteristic of a given type of measuring instrument, usually reflecting the level of their accuracy, expressed by the limits of permissible main and additional errors, as well as other characteristics affecting the accuracy.

For example, the accuracy class of gauge blocks characterizes the proximity of their size to the nominal, the permissible deviation from plane-parallelism, as well as grindability and stability; The accuracy class of voltmeters characterizes the limits of permissible basic error and permissible changes in readings caused by an external magnetic field and deviation from normal values of temperature, alternating current frequency and some other quantities.

Accuracy class

During laboratory measurements, it is necessary to know the accuracy of the measuring instruments, which in turn have certain characteristics and differ in design. Each of the measuring instruments (MI) has certain inaccuracies, which are divided into basic and additional. Situations often arise when it is not possible or simply not required to make a detailed calculation. Each measuring instrument is assigned a certain accuracy class, knowing which, you can find out its range of deviations.

Normalized error values will help you find out the errors of the measuring instrument in a timely manner. This definition should be understood as the limiting indicators for a measuring instrument. They can be different in size and depend on different conditions, but they should not be neglected in any case, because this can lead to a serious mistake in the future. The normalized values should be less than what the device shows. The limits of permissible error values and the necessary coefficients are entered in the passport of each dimensional measuring device. You can find out detailed standardization values for any device using the corresponding GOST.

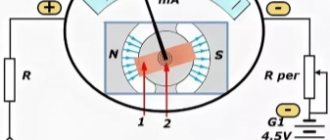

Electrostatic instrumentation

These devices operate on the principle of interaction of charged electrodes, which are separated by a dielectric. Structurally, they look almost like a flat capacitor. At the same time, when the moving part moves, the capacity of the system also changes.

The most famous of them are devices with linear and surface mechanisms. They have a slightly different operating principle. For devices with a surface mechanism, the capacitance changes due to fluctuations in the active area of the electrodes

Otherwise, the distance between them is important

The advantages of such devices include low power consumption, GOST accuracy class, fairly wide frequency range, etc.

The disadvantages are the low sensitivity of the device, the need for shielding and breakdown between the electrodes.

Accuracy class of the measuring device

A generalized characteristic, which is determined by the limits of errors (both basic and additional), as well as other properties that influence accurate measurements and whose indicators are standardized, is called the accuracy class of the measuring apparatus. The accuracy class of measuring instruments provides information about a possible error, but at the same time it is not an indicator of the accuracy of a given SI.

A measuring instrument is a device that has standardized metrological characteristics and allows measurements of certain quantities. According to their purpose, they are exemplary and working. The first ones are used to control the second or exemplary ones, who have a lower qualification rank. Workers are used in various industries. These include measuring:

- devices;

- converters;

- installations;

- systems;

- accessories;

- measures.

Each measuring instrument has a scale on which the accuracy classes of these measuring instruments are indicated. They are indicated in the form of numbers and indicate the percentage of error. For those who do not know how to determine the accuracy class, you should know that they have been standardized for a long time and there is a certain series of values. For example, the device may have one of the following numbers: 6; 4; 2.5; 1.5; 1.0; 0.5; 0.2; 0.1; 0.05; 0.02; 0.01; 0.005; 0.002; 0.001. If this number is in a circle, then this is the sensitivity error. It is usually indicated for scale converters, such as:

- voltage dividers;

- current and voltage transformers;

- shunts.

Accuracy class designation

The limit of the operating range of this device, within which the value of the accuracy class will be correct, must be indicated.

Those measuring devices that have numbers next to the scale: 0.05; 0.1; 0.2; 0.5, are referred to as precision. Their scope of application is precise and particularly precise measurements in laboratory conditions. Devices marked 1.0; 1.5; 2.5 or 4.0 are called technical and, based on the name, are used in technical devices, machines, and installations.

It is possible that there will be no markings on the scale of such a device. In such a situation, the error given is considered to be more than 4%.

If the value of the device’s accuracy class is not underlined below with a straight line, this indicates that such a device is normalized by the reduced zero error.

Deadweight piston pressure gauge, accuracy class 0.05

If a scale displays positive and negative values and the zero mark is in the middle of such a scale, then you should not think that the error will be constant throughout the entire range. It will change depending on the value that the device measures.

If the measuring unit has a scale on which the divisions are displayed unevenly, then the accuracy class for such a device is indicated as a fraction of the scale length.

There are options for measuring devices with scale values in the form of fractions. The numerator of such a fraction will indicate the value at the end of the scale, and the number in the denominator at zero.

A Question of Choice

To install an electric meter in a private house or apartment, models that have a class of at least 2 are suitable.

In addition, when going to the store to buy an electric meter, you should know exactly the following characteristics:

- Phase of the electrical network. If the electrical network connected to the meter is single-phase, then the device must also be for a single-phase network. A three-phase electric meter can also be installed to track electricity usage, but such devices tend to be more expensive. When the meter is installed to measure three-phase current, the corresponding inscription must be indicated on it. Single-phase devices are not used to calculate three-phase current.

- The load under which this device will be operated. Depending on the maximum load that will be connected to the electricity metering device, a model is selected, on the body of which this indicator is indicated. For a standard load used in a private home, electric meter models designed for a maximum current of 60 A are used. If you plan to connect powerful electric heating boilers, then an electric meter is selected with an indicator of at least 100 A.

- If the electricity supplier can sell electricity at 2 tariffs, then the tariff of the meter is also taken into account when purchasing. Two-tariff devices allow you to save significantly on electricity bills. When using electricity at night, such a meter will record consumption separately. If the electricity supplier allows such payment, then installing a multi-tariff meter will allow you to use electricity more efficiently.

- Mounting method. Allows you to install the device in an existing box, or in place of a device that was previously installed.

Rationing

Accuracy classes of measuring instruments tell us information about the accuracy of such instruments, but at the same time it does not show the accuracy of the measurement performed using this measuring device. In order to identify in advance the error in the instrument readings, which it will indicate during measurement, people normalize the errors. To do this, they use already known normalized values.

Rationing is carried out according to:

Formulas for calculating absolute error according to GOST 8.401

Each device from a specific group of devices for measuring dimensions has a certain value of inaccuracies. It may differ slightly from the established standardized indicator, but not exceed the general indicators. Each such unit has a passport in which the minimum and maximum error values are recorded, as well as coefficients that have an impact in certain situations.

Types of marking

The accuracy classes of absolutely all measuring instruments are subject to marking on the scale of these same instruments in the form of a number. Arabic numerals are used to indicate the percentage of normalized error. The designation of the accuracy class in a circle, for example the number 1.0, indicates that the error in the device’s needle readings will be equal to 1%.

If the designation uses a tick in addition to the number, this means that the scale length is used as a normalizing value.

Latin letters for designation are used if it is determined by the limits of absolute error.

There are devices on the scales of which there is no information about the accuracy class. In such cases, the absolute should be equated to one half of the smallest division.

Limits

As mentioned earlier, the measuring device, thanks to standardization, already contains random and systematic errors. But it is worth remembering that they depend on the measurement method, conditions and other factors. In order for the value of the quantity to be measured to be 99% accurate, the measuring instrument must have minimal inaccuracy. The relative one should be about a third or a quarter less than the measurement error.

Basic method for determining error

When setting the accuracy class, first of all, the limits of the permissible main error are subject to standardization, and the limits of the permissible additional error are a multiple of the main one. Their limits are expressed in absolute, relative and reduced form.

The reduced error of a measuring instrument is relative, expressed as the ratio of the maximum permissible absolute error to the standard indicator. Absolute can be expressed as a number or binomial.

If the SI accuracy class is determined through absolute, then it is denoted by Roman numerals or Latin letters. The closer the letter is to the beginning of the alphabet, the smaller the permissible absolute error of such a device.

Accuracy class 2.5

Thanks to the relative error, you can assign an accuracy class in two ways. In the first case, the scale will show an Arabic numeral in a circle, in the second case, a fraction, the numerator and denominator of which indicate the range of inaccuracies.

The main error can only occur under ideal laboratory conditions. In life, you have to multiply data by a number of special coefficients.

Additional occurs as a result of changes in quantities that in some way affect the measurements (for example, temperature or humidity). Exceeding the established limits can be identified by adding up all the additional errors.

Random errors have unpredictable values due to the fact that the factors influencing them are constantly changing over time. To take them into account, they use the theory of probability from higher mathematics and keep records of previously occurring cases.

Example of error calculation

The statistical value of a measuring instrument is taken into account when measuring a constant or a quantity that is rarely subject to change.

Dynamic is taken into account when measuring quantities that often change their values over a short period of time.

Types of electricity meters

Induction

Induction is a device familiar to almost everyone. Their characteristic feature is a constantly rotating wheel behind transparent glass. It spins at different speeds and depends on the electricity consumption. The higher it is, the faster the wheel spins.

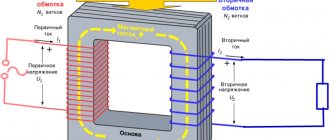

The readings can be seen on special reels with the numbers depicted. Its operating principle is as follows. The design has 2 coils. One of them is a voltage coil. It limits alternating current and also serves as a kind of barrier to various types of interference.

Its other function is to create a magnetic flux, which is equivalent to the voltage passing through it. The second coil is called the current coil. It also produces a magnetic flux, but only it is proportional to the strength of the current.

Both magnetic fluxes eventually penetrate through a special aluminum disk. Since they have a parabolic trajectory, they pass through the above-mentioned obstacle 2 times. Due to this, forces arise that cause the aluminum disk to spin.

As a result, the axis on which it is located acts on those same drums with numbers through a gear-screw drive. Thus, the readings depend on the rotation speed of the aluminum disk, and this, in turn, depends on the magnetic fluxes that are created by the coils.

As a result, the higher the voltage in the electrical network, the larger the numbers on the reels will be. Such meters are quite widespread even in the age of high technology.

Their advantages include:

- High reliability.

- Durability.

- Absolute independence from random voltage surges.

- Low price.

However, they have several disadvantages:

- Low accuracy class.

- The actual absence of any protection against electricity theft.

- High electricity consumption by the meter itself.

- Inevitable increase in error at low loads.

- Large overall dimensions.

Electronic

Electronic ones are more profitable these days and are used somewhat more often. They are superior to induction ones in terms of accuracy and make it possible to take into account such an indicator as multi-tariff.

This type of meter operates by converting an analog signal that comes from an electric current sensor. The device turns it into a digital code, which is numerically equal to the energy consumed. Then the received code is decrypted in the microcontroller and after that the readings can be seen on the digital screen.

An electric type meter has a much larger number of advantages than its induction counterpart, these include:

- High class of accuracy.

- Multiple tariffs.

- Measuring the consumption of all types of electricity.

- Storing all readings.

- Ease of information availability.

- When attempting to steal, unauthorized access is recorded.

- Possibility to take readings from the device remotely.

- Small overall dimensions.

A few disadvantages include:

- High sensitivity of the device to voltage changes.

- Relatively high cost

- Difficult to maintain and repair.

Related Posts

- How to use a multimeter correctly

- Calculation of resistor resistance for LEDs: online calculator

- How to check grounding

- Correct choice of current transformer according to GOST

- Current and voltage transformers

- How to check basic battery parameters with a multimeter

- Surge protection: overview of available options and effective devices (90 photos)

- Electric meter verification: verification period and verification interval

- Uninterruptible power supplies for heating boilers of any type

- How to measure the resistance of a phase-zero loop?

- Three-phase voltage relay

- Technical characteristics and connection diagram of Neva electricity meters

- Check the electric meter: simple methods for checking electricity meters (115 photos)

- All the nuances of measuring voltage with a multimeter

- Quality of electrical energy at the enterprise

- How to choose a surge protector with a surge protector

- Calculation of the resistance of parallel connection of resistors

- Voltage regulator

- Sewage metering unit: features, measuring instruments

- How a hair hygrometer works

- Adjustable voltage stabilizer

- Technical characteristics of meters CE 101

- Methods for testing board parts with a multimeter

- How to measure current with a multimeter?

- Calculation of a resistor for an LED: how to choose a current-limiting element

Read with this

- How to use a multimeter correctly

- Calculation of resistor resistance for LEDs: online calculator

- How to check grounding

- Correct choice of current transformer according to GOST

- Current and voltage transformers

- How to check basic battery parameters with a multimeter

- Surge protection: overview of available options and effective devices (90 photos)

- Electric meter verification: verification period and verification interval

- Uninterruptible power supplies for heating boilers of any type

- How to measure the resistance of a phase-zero loop?