Classification of protective equipment

Electrical protective equipment refers to instruments, devices, fixtures and devices that serve to protect personnel from electric shock, exposure to an electromagnetic field, and electric arc burns..

They are divided into basic and additional.

The main ones are those protective equipment whose insulation reliably withstands the operating voltage of electrical installations. With their help, you can touch live parts that are energized.

The main protective means are:

- in installations 1000 V and below

- current and insulating clamps, dielectric gloves, tools with insulated handles, voltage indicators; - in installations above 1000 V

- insulating rods (operational and measuring), insulating and current clamps, voltage indicators, insulating devices and devices for repair work, insulating ladders, platforms, rods, panel markers, insulating links of a telescopic tower.

Basic protective equipment is made from materials with stable dielectric characteristics (bakelite, porcelain, ebonite, getinax, special plastics, laminated plastics, etc.).

Additional are those protective equipment that, at a given voltage, cannot by themselves ensure safety from electric shock. They can only be used in conjunction with basic protective equipment and also serve to protect against touch voltage and step voltage, and against burns from the arc and its combustion products.

Additional protective equipment are:

- in installations up to 1000 V

- dielectric overshoes, dielectric mats, insulating stands; - in installations above 1000 V

- dielectric gloves and dielectric boots. In areas with increased danger, in addition, insulating supports and dielectric mats.

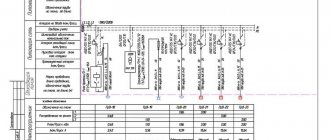

Basic and additional protective equipment in operation (except for insulating stands, dielectric mats and grounding rods) are periodically subjected to electrical tests. The value of the test voltage, the permissible value of leakage current through the product under test, the time and timing of tests and inspections are regulated by the “Rules for the use and testing of protective equipment used in electrical installations.”

Insulating rods - used for work near or on live parts of any voltage. They consist of 3 main parts ( Fig. 1a

): working

1,

insulating

2

and gripping handle

3.

Depending on the purpose, the working part of the rod has a different design.

For example, in rods for measuring voltage on individual insulators in a garland, the working part is made in the form of a removable head, a bakelite tube 4,

closed with caps 5, in which replaceable probes

6 are attached,

connected to the measuring device

7.

When taking measurements, the head can be tilted at an angle of up to 45 ° using a hinged-spring connection

8.

In the operating rods, the working part is made in the form of a steel tip 1

with finger

2

(

Fig. 1b)

for gripping the disconnector poles or in the form of a clamp.

There is a ring 3

with thread for mounting a voltage indicator.

The insulating part of rods for any purpose can consist of several links 2,

connected by couplings

10

(

Fig. 1a

).

The number and length of links depend on the operating voltage. Handle grip 3

is separated from the insulating part by a restrictive ring

11.

9

is placed on the handle indicating the date of the next test, operating voltage, rod number and the name of the laboratory that performed the test.

Insulating pliers ( Fig. 2

) - used for work in electrical installations with voltages of 35 kV and less.

With their help, fuse inserts are changed, insulating caps are removed or put on the blades of single-pole disconnectors, etc. Clamps also consist of 3 parts: a working part - jaws 1,

an insulating part

2

and a grip handle

3.

Current clamps, for example type C -91 ( Fig. 3

), are used to measure alternating current up to 500 A in single conductors without breaking the circuit at voltages up to 600 V. The working part of the current clamp consists of a detachable magnetic core

1,

on which a secondary winding is located inside the housing

2

.

An ammeter 4 is connected to this winding ,

the measurement limits of which are changed by switch

3.

Thus, the current clamp is a current transformer, the primary winding of which is conductor

5,

covered by a detachable magnetic conductor.

The connector is made by pressing lever 6.

The device can also be used to measure voltages of 0-300 and 0-600 V. For this, it is equipped with 2 conductors

7

with tips, which are inserted into special sockets on the device body.

For measurements in installations with voltages up to 10 kV, clamps with an ammeter installed on the working part are used. They can make measurements when the possibility of electrical breakdown between phases or to the ground is excluded (due to the reduction of insulation distances by the working part of the clamps during measurement). On cables with voltages above 1000 V, measurements are permitted only if the cable cores are insulated and the distance between them is more than 250 mm. Measurements are made wearing dielectric gloves, holding the pliers suspended and not bending over the ammeter.

Voltage indicators.

To check the presence or absence of voltage on live parts of electrical installations with voltages up to 110 kV, voltage indicators are used.

Voltage indicators above 1000 V use the glow of a neon lamp to detect voltage while a capacitive current flows through it. The pointer is a portable device consisting of 3 parts: working, insulating 5

and gripping handle

6

(

Fig. 4

).

The working part consists of a bakelite tube 1,

in which a neon lamp

2 is mounted,

connected to a metal probe

3

and a capacitor

4.

Stamp

7

indicates the operating voltage of the indicator and the date of its next test.

Before checking the absence of voltage, check the serviceability of the indicator by bringing its probe closer to the current-carrying part, which is obviously energized, and making sure that the lamp is lit. Then touch the probe to all 3 phases on the switches and disconnectors on both sides of the disconnected part of the installation and make sure that the lamp does not light. Under no circumstances should you conclude that there is no voltage based on the readings of warning lamps and voltmeters, since they are only auxiliary means of control.

When checking the absence of voltage on lines with voltages up to 20 kV, when measurements are taken from wooden supports or ladders, the capacitive current is insufficient for the lamp to glow. In this case, it is allowed to ground the indicator with a special conductor at the connector of the insulating part 8.

Checking the serviceability of the indicator and the absence of voltage is carried out while wearing dielectric gloves.

In electrical installations with voltages up to 500 V, indicators called current detectors of the TI-2 type are used ( Fig. 5

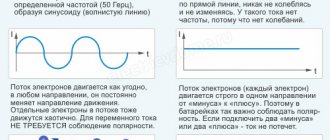

) (UNN-90, MIN-1), operating on the principle of

active current

3 2.

The lamp, resistance and probes

1,

which touch current-carrying parts, are mounted in handles made of insulating material. The use of test lamps to detect voltage is prohibited.

Tools with insulated handles as the main means of protection are used only in installations with voltages up to 1000 V. Tool handles must have a smooth, crack-free and burr-free insulating coating made of moisture-resistant, non-fragile insulating material at least 10 cm long. It must fit tightly to metal parts, completely insulating from the metal hand of a worker. After manufacture or repair, the tool is tested with a voltage of 2.5 kV for 1 minute. On ( Fig. 6a

) a set of plumbing and installation tools is shown, which is used as the main protective equipment at voltages up to 1000 V.

Insulating stands are used in cases where grounding or zeroing is difficult to perform or safety requirements are increased. Insulating stand ( Fig. 6b

) is a wooden flooring supported on porcelain support insulators. The height of insulators from the floor to the bottom surface of the flooring is at least 5 cm for installations of all voltages.

Dielectric cut protective equipment.

To isolate a person from the ground and from live parts, products made of dielectric rubber are used: gloves, overshoes and rugs (

Fig. 6c).

Unlike ordinary rubber dielectric shoes, they are not varnished. Rubber is easily subject to mechanical damage, especially under the influence of moisture, light, high temperature, oils, gasoline, and acids. Protective equipment is made of rubber and should therefore be stored in closed cabinets or drawers.

Temporary fencing - used during repair work to protect personnel from accidentally approaching live parts that are energized and located near the place of work.

Temporary fences are wooden panels (screens), insulating linings, caps, fences, cages

.

in (

Fig. 7

): an insulating cover for a circuit breaker made of textolite (

Fig. 7a),

a rubber cap placed on the blades of disconnectors (

Fig. 7b),

a hanging screen for fencing insulators and wires (

Fig. 7c).

Portable grounding connections are used in the absence of stationary grounding blades to protect against erroneous supply of voltage to parts of electrical installations that are disconnected for operation and against the appearance of induced voltage on them. Portable grounding type ShZP consists of ( Fig. 8

) from wires 2 for connecting short-current-carrying parts of all 3 phases of an electrical installation, wires

6

for connecting them to a grounding device, clamps 1

or

for

Grounding is applied using a permanent or removable grounding rod, which is an insulating part 3

with a grip handle, which is limited by ring

4.

It is allowed to use single-phase portable grounding connections on power lines. The wires are made of flexible copper conductors, their cross-section is selected according to thermal stability during a short circuit, but not less than 25 mm 2 in electrical installations with voltages above 1000 V and not less than 16 mm 2 in installations 1000 V and below.

Before applying grounding, its serviceability is checked by inspection. Grounding is applied in the following sequence. Check the pointer

voltage, which will be used to check the absence of voltage on the grounded part of the electrical installation. Connect the ground wire to the ground electrode. Check that there is no voltage. Immediately after checking with the grounding rod, the grounding clamp is applied to the live part and secured. Remove the grounding in the reverse order. All operations are performed with dielectric gloves.

It is not permitted to use random conductors for grounding or to connect grounding wires by twisting.

On current-carrying parts, the places where grounding is applied are marked with 2 black stripes, the gap between which is cleaned to a shine. Special wing-type screw terminals are usually mounted on the grounding bus to connect the grounding.

Basic protection

For a more accessible perception of information, it is necessary to take a closer look at the means of protection in electrical installations up to and above 1 kV and the scope of their application. So, the set includes basic and additional means of protection in electrical installations.

Let's take a closer look at what each of them is intended for.

Insulating rods

The designs of insulating rods are different and allow you to install protective portable grounding, perform operations with switching devices, install insulation pads, change fuses, carry out measurements and release victims in case of electric shock.

When using the boom, make sure it is designed for the job. It is prohibited to perform work with the bar for which it is not intended.

Insulating pliers

This type of protective equipment successfully allows you to replace fuses and remove insulating linings, fencing panels, etc. When performing work to replace fuses whose voltage class is more than 1000 V, in addition to insulating clamps, you should also use dielectric gloves, masks or goggles. You can replace fuses in electrical installations up to 1000 V using pliers or dielectric gloves using glasses or masks.

Clamp meter

Everything should be clear here; these clamps are needed for measuring electric current. There can be both narrow-profile ones, which allow you to measure only the amount of electric current, and universal (modern) ones, with the help of which you can also measure the voltage and resistance of the circuit. The first category includes instruments above 1 kV.

This type of clamp effectively measures the network load, the power of devices, allows you to check electrical energy meters and determines the network parameters. In electrical installations above 1 kV, such a tool is designed for voltages up to 10 kV inclusive.

Voltage indicators

Voltage indicators are used to check the absence or presence of voltage on live parts of equipment.

If you need to check whether there is voltage on live parts, a preliminary check of the functionality of the voltage indicator itself is necessary. This test is carried out on live parts of distribution-type devices that are under operating voltage. You can check the functionality of voltage indicators over 1000 V using special devices that are designed to test indicators.

Dielectric gloves

In electrical installations of different voltage classes, dielectric gloves can be used as a primary or additional means of protection. In electrical installations with voltages below 1000 Volts, dielectric gloves are the main means of protection; in electrical installations above 1000 Volts, they are an additional means.

Dielectric gloves are used by employees exclusively when they are dry. If the air humidity in the room exceeds the norm, the gloves should be completely dry at room temperature before use.

Before using these products, you should carry out an external inspection of them, check the date of the next tests and the absence of punctures. In order to detect punctures, you should twist the gloves from the edges towards the fingers. The glove is inflated, and then pressure is used to identify potential punctures for air to escape.

Tools with insulated handles

This category includes all hand tools equipped with insulating handles (various pliers, screwdrivers, wrenches, etc.) used as the main means for electrical protection if electrical work is performed in electrical installations up to 1000 V that do not require voltage relief. This tool is a plumbing tool and is used for connecting and repairing electrical installations whose voltage is up to 380 Volts.

In electrical installations over 1000 V, a tool with an insulating handle is not completely safe during work.

If an electrician performs work on equipment up to 1000 Volts without removing the voltage, one tool equipped with insulating handles will not be enough. The employee should be isolated from the ground or floor using dielectric carpets, insulation stands or dielectric shoes. Protective equipment (goggles, masks) are selected depending on the nature of the work.

The above protective equipment in electrical installations are basic and provide electrical protection when performing work in electrical installations up to and above 1000 V. Next we should talk about what the list of additional protective equipment represents.

Rules for using protective equipment

Insulating protective equipment should be used in electrical installations with a voltage no higher than that for which they are designed and which is indicated on the stamp. Protective agents should be used in dry weather; It is not permitted to use them outdoors during rain, snow, fog, or frost. There are special protective equipment for this. Not allowed for use as unsuitable protective equipment, the test period of which specified in the stamp has expired .

Before use, protective equipment is cleaned of dust, inspected, and checked for external damage.

To store protective equipment in switchgears, a special place is allocated, which is equipped with hooks for hanging rods, portable grounding, warning posters, cabinets or drawers for placing gloves, boots, mats, safety glasses, gas masks and a voltage indicator. During transportation, protective equipment is protected from moisture, contamination and mechanical damage; they are kept separate from the rest of the instrument.

For the provision of electrical installations with protective equipment, their accounting, proper storage and frequency of inspections and tests, removal and replacement of unsuitable equipment, the heads of workshops, services, substations, electrical network areas, and the chief engineer for the enterprise as a whole are responsible. The personnel servicing the electrical installation is responsible for the availability, proper storage, use and suitability of protective equipment. Unusable and faulty protective equipment is immediately removed from the electrical installation, and senior administrative and technical personnel are notified about this.

Content:

To ensure the electrical safety of persons authorized to work with switchgear, protective equipment is provided in electrical installations up to 1000 V and above. Their main function is reliable protection against electric shock, so all products must strictly comply with GOST standards. All of them are classified as electrical protective equipment, protection against electric fields, and personal protective equipment. Each group should be considered in more detail.

Classification and purpose of electrical protective equipment

Electrical protective products include those used against direct electric shock. They provide reliable electrical safety when working with various electrical installations and switchgear.

All types of electrical protective equipment are divided into two groups: basic and additional.

- The main means of protection in electrical installations include a list of insulating electrical protective equipment that has insulation capable of withstanding the operating voltage of the network for a long time. They allow you to safely perform work on live parts that are energized.

- Additional ones also include insulating electrical protection means. However, unlike the main ones, they do not directly protect against electric shock, but only complement them, thereby increasing the degree of protection of working people. In addition, additional means protect personnel from stressful contact.

- In accordance with the voltage class, all types of electrical protective equipment are divided into those used at voltages up to 1000 volts and over 1000 volts.

Electrical protection for voltages over 1000 volts

Protective equipment in electrical installations used when working with voltages greater than 1000 volts include various types of insulating rods and clamps, high voltage indicators, as well as various types of devices used in testing and electrical measurements in switchgears.

Various devices and special protective equipment used in electrical installations with voltages exceeding 110 kilovolts are classified separately. This list does not include rods used to level and transfer potential.

Electrical protection for voltages up to 1000 volts

The main means of protection in electrical installations up to 1000V include insulating clamps and rods, electrical clamps, low voltage indicators, dielectric gloves, as well as various types of manual insulating tools.

Additional protective equipment

The classification of additional electrical protective equipment is carried out in the same way. When working with voltages above 1000 volts, personnel must use dielectric gloves, boots, etc. If necessary, insulating supports, caps and linings, as well as rods for leveling and transferring potential are used.

When working at height, personnel must use insulated stepladders and ladders made of fiberglass and other dielectric materials. Additional electrical protection means for voltages up to 1000 volts are represented by the same products as for voltages above 1000 V.

What protection means are used in electrical installations

When performing work in electrical installations, regardless of which area or department they belong to, maintenance personnel must use various protective equipment to prevent electric shock. Any electrical protective agent is divided into two types: basic and additional. What is their difference?

The main means of protection in electrical installations withstand voltage for long working hours and are used during work when the equipment does not need to be disconnected from the network. That is, a worker, using the main means of protection, can safely work on equipment whose live parts are energized.

Additional protective equipment in electrical installations cannot provide 100% protection for personnel from electric shock; it is used in conjunction with basic equipment.

I present a screenshot of what the literal definition sounds like and what a “primary and additional” protective agent is according to the rules.

We should talk in more detail about the essence of electrical protection means in electrical installations with voltages up to and above 1000 Volts and the requirements for them.

Protection against electric fields

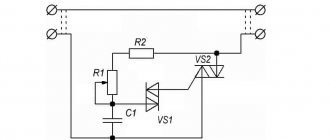

In second place in importance are protective equipment against the effects of high-intensity electric fields. First of all, all personnel working in hazardous areas must use individual shielding kits. Their use is mandatory during work in open switchgears at ground potential and at the potential of overhead power lines.

Workers must use a variety of portable and removable shielding devices, as well as. At high-risk facilities, information posters are posted, as well as prohibiting, warning, prescriptive and safety signs.